Creep fatigue residual life evaluation method based on crystal plasticity theory

A technology of crystal plasticity and creep, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as the inability to describe the evolution law of the microstructure of materials and the inability to quantitatively describe the degree of material damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] According to the attached Figure 1-5 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and features of the present invention can be better understood.

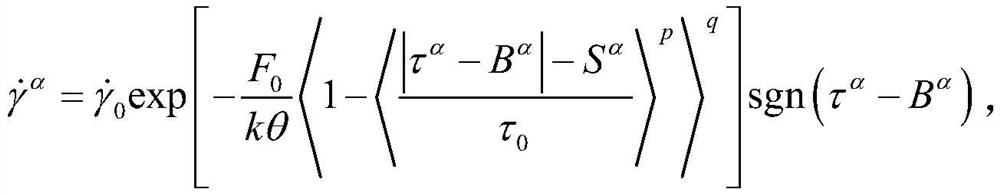

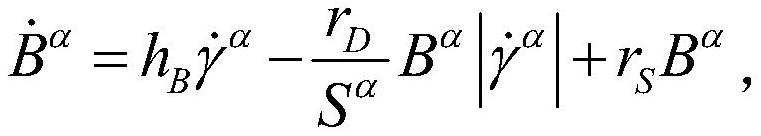

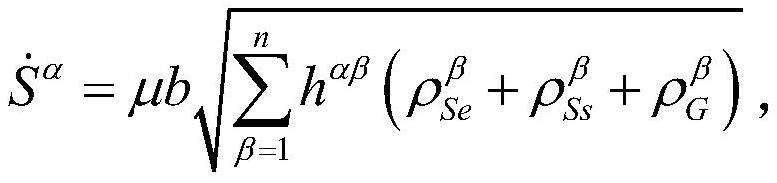

[0055] A finite element model of crystal plasticity based on dislocation density used in the present invention needs to be compiled with the help of the unit user-defined subroutine UEL provided by ABAQUS software, and finally the crystal with complex working conditions of creep fatigue is realized by calling the compiled UEL Plastic finite element simulation. see figure 1 , a method for evaluating the remaining life of creep fatigue based on crystal plasticity theory provided by the present invention comprises the following steps:

[0056] In step S1, the constitutive equation of crystal plasticity based on dislocation density is compiled through the unit user subroutine UEL of ABAQUS finite element software.

[0057] Wherein, step S1 specifically include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com