Virtual experiment method and device for anisotropic mechanical behavior of metal material

A metal material, anisotropic technology, applied in the direction of instruments, geometric CAD, design optimization/simulation, etc., can solve the problems of long production cycle and high cost, and achieve the effect of shortening the production cycle and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

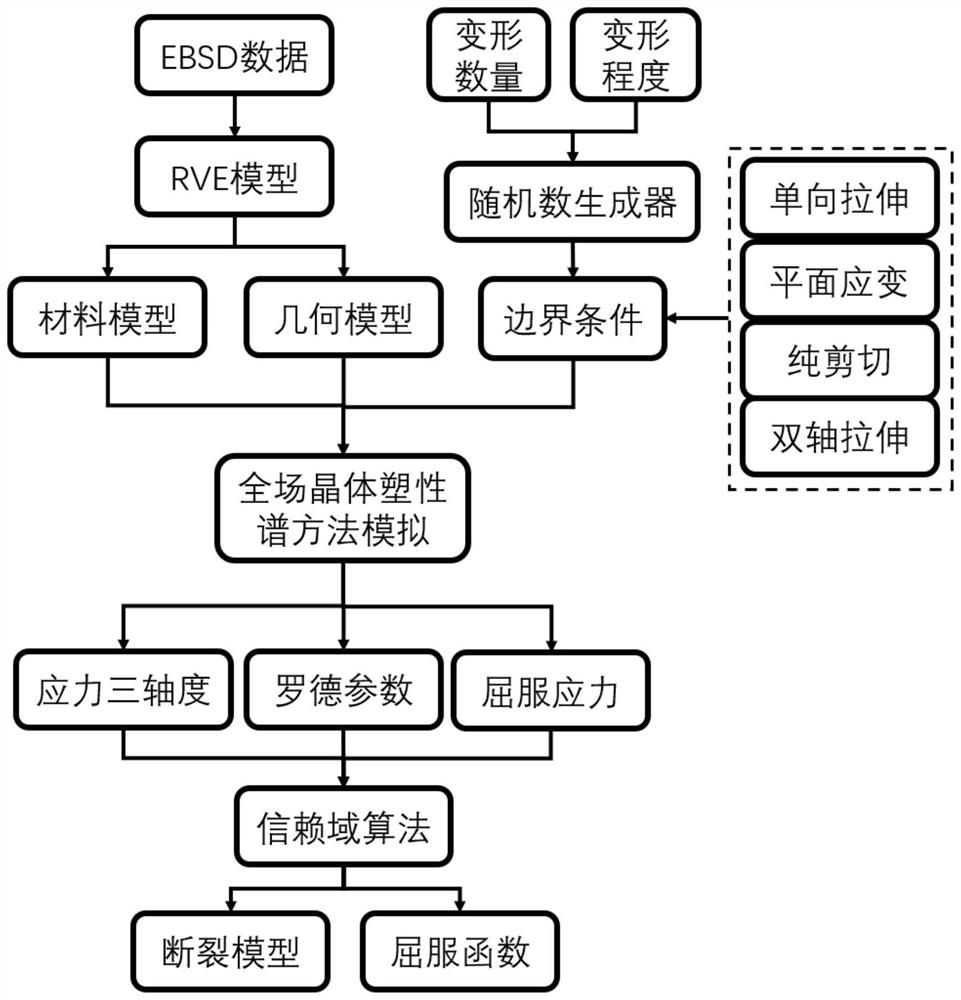

[0030] Such as figure 1 As shown, the present embodiment provides a virtual experiment method for the anisotropic mechanical behavior of metal materials, comprising the following steps:

[0031] Construct the microstructure representative volume element (RVE) model of the metal material to be tested according to the electron backscatter diffraction (EBSD) experimental results of the metal material to be tested;

[0032] Specify the number of arbitrary periodic boundary conditions and the microstructure to represent the degree of deformation of the voxel model under arbitrary periodic boundary conditions, and generate arbitrary periodic boundary conditions through a random number generator;

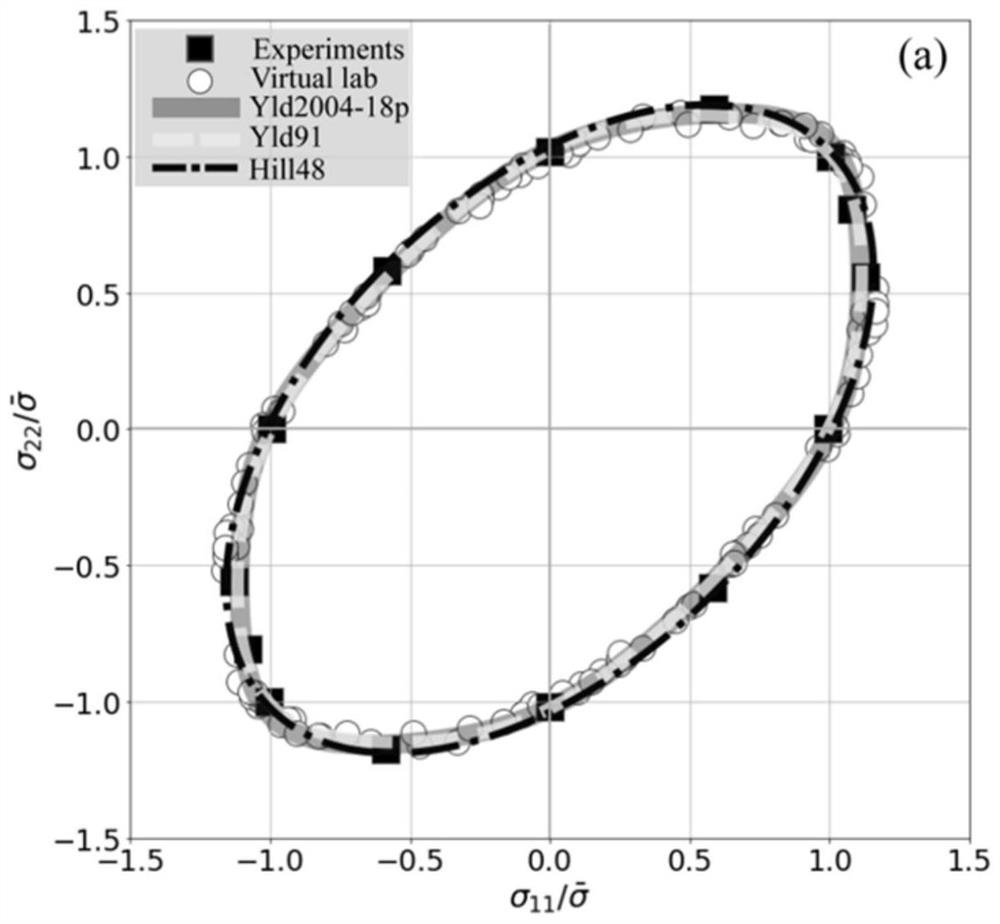

[0033] Perform full-field crystal plasticity simulation based on the microstructure representative voxel model and arbitrary periodic boundary conditions, extract the yield stress point of the microstructure representative voxel model with a specified deformation degree under periodic boun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com