Crystal plasticity finite element modeling simulation method

A technology of crystal plasticity and simulation method, applied in the direction of design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of complex procedures and many steps, and achieve the effect of realizing process flow and reducing manual operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

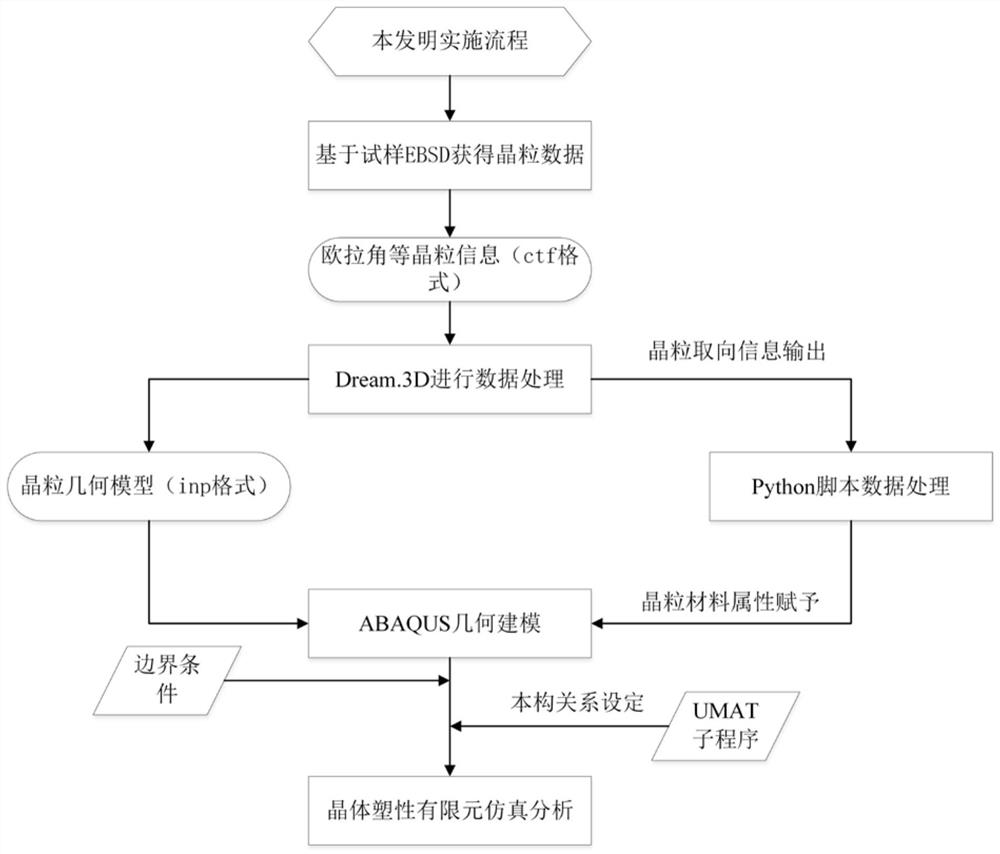

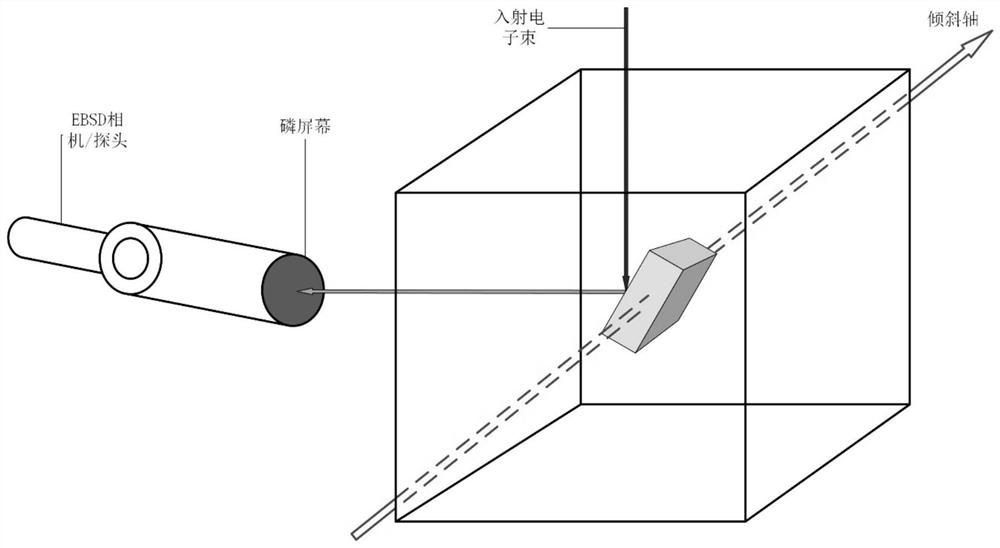

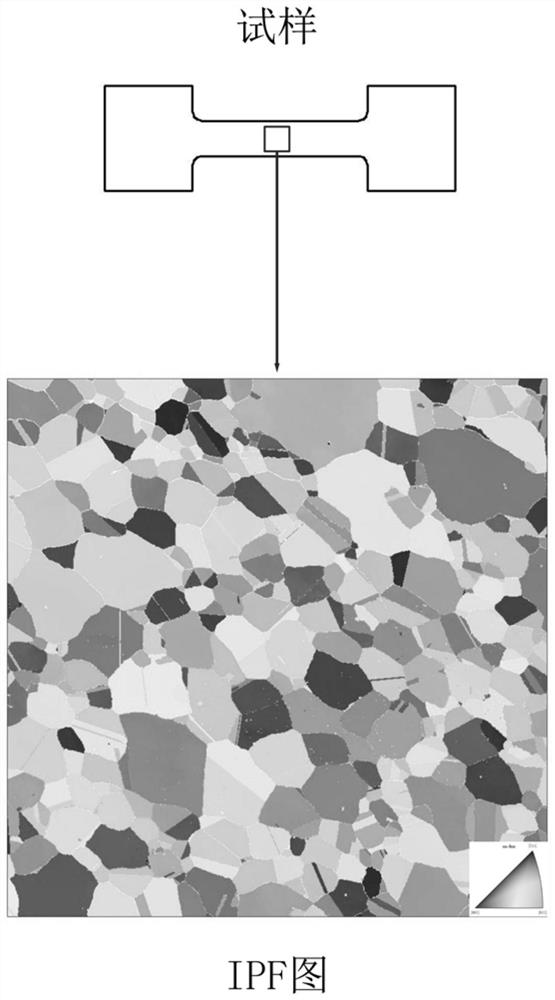

[0023] Such as figure 1 As shown, a kind of crystal plasticity finite element modeling and simulation method of the present invention obtains grain information based on EBSD analysis; the (ctf format) file containing grain information such as Euler angles generated by EBSD analysis is imported in the open source software Dream.3D , realize the automatic reconstruction of the grain structure, and output the input file containing only the geometric information of the ABAQUS finite element analysis software model nodes, units, etc., as well as the geometric orientation data of each grain; Grain average geometric orientation information; use Python script to combine grain average geometric orientation information with the input file representing the geometric model to generate a complete input file with geometric model information and material property info...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com