Patents

Literature

54 results about "Metamodeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A metamodel or surrogate model is a model of a model, and metamodeling is the process of generating such metamodels. Thus metamodeling or meta-modeling is the analysis, construction and development of the frames, rules, constraints, models and theories applicable and useful for modeling a predefined class of problems. As its name implies, this concept applies the notions of meta- and modeling in software engineering and systems engineering. Metamodels are of many types and have diverse applications.

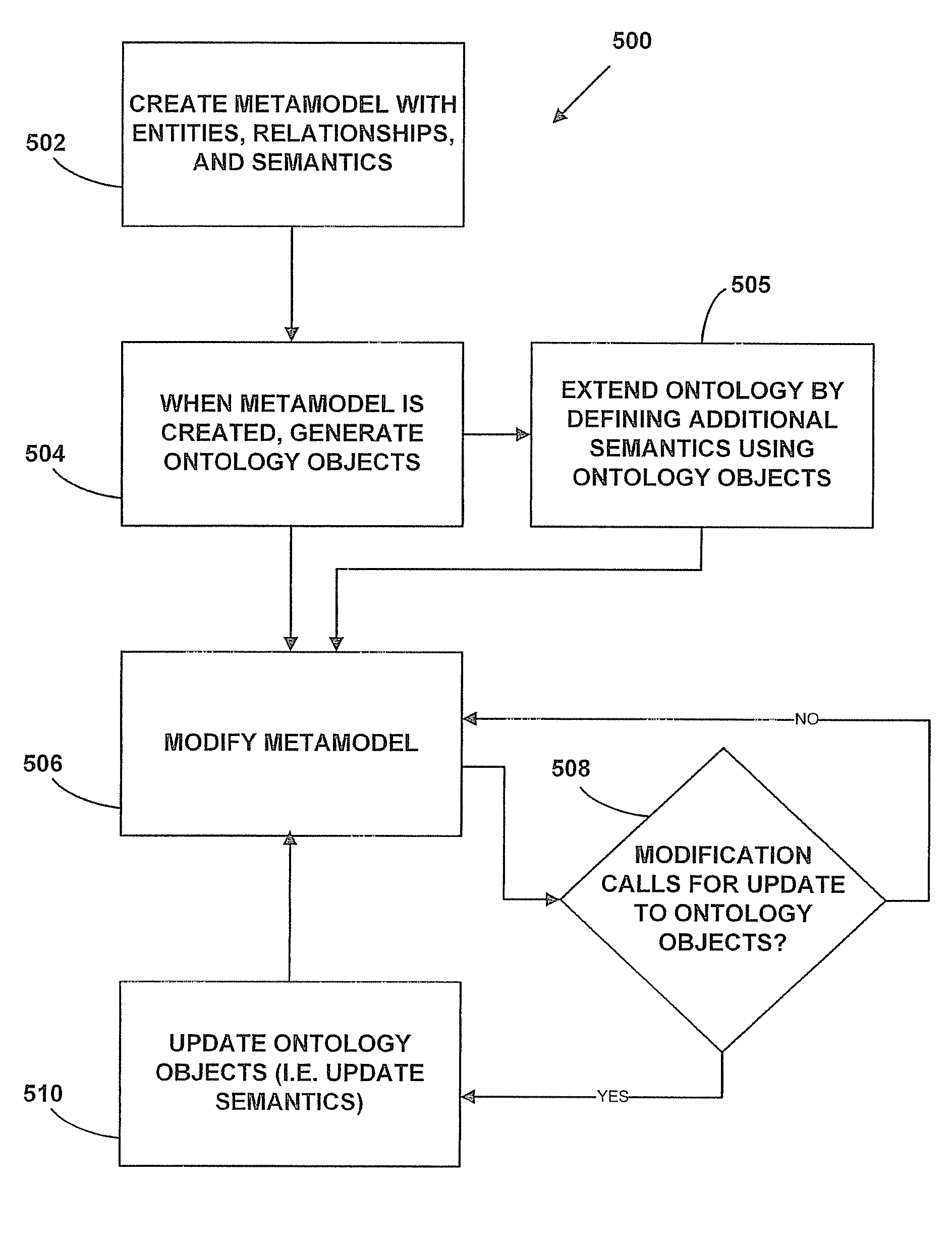

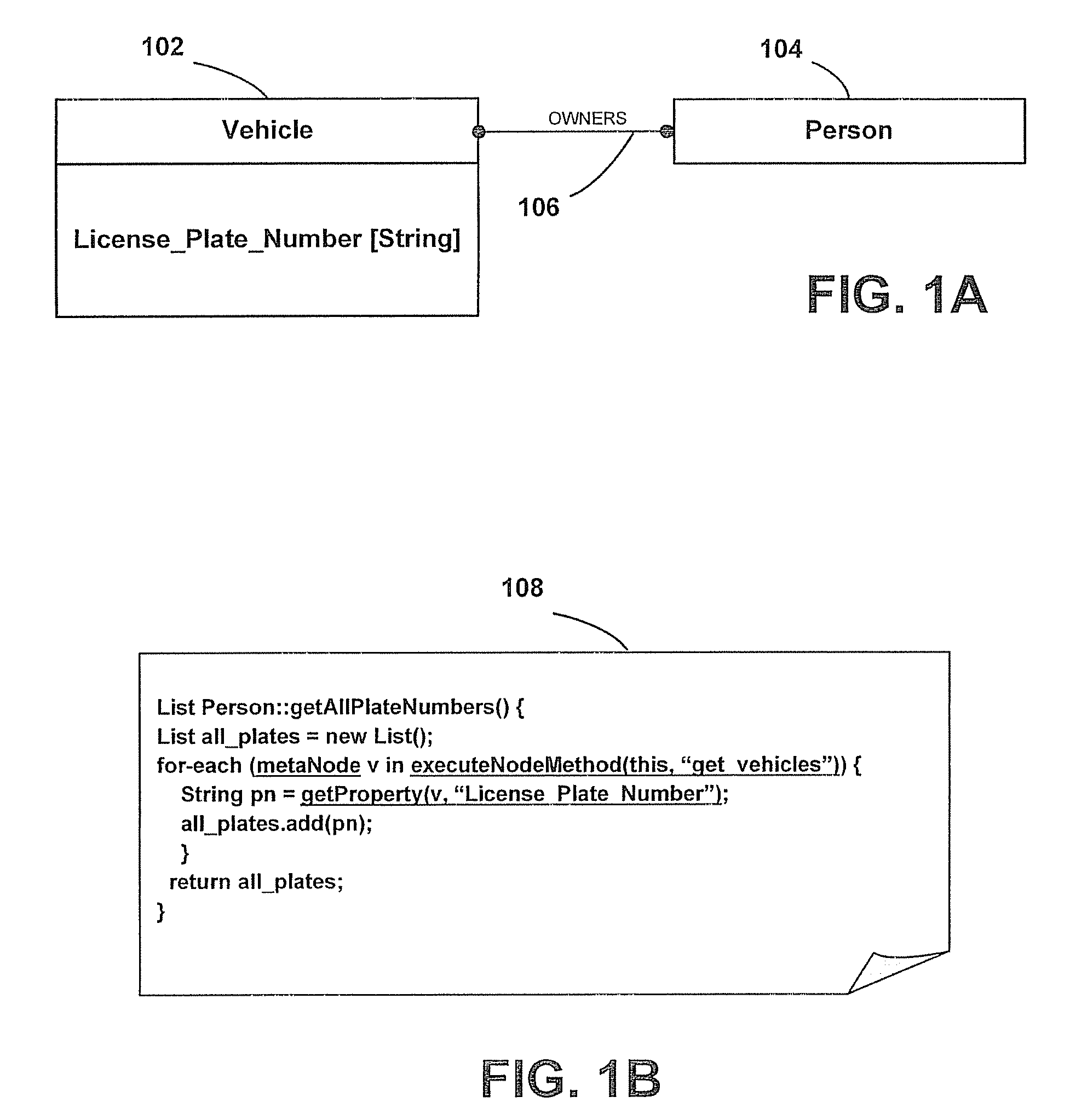

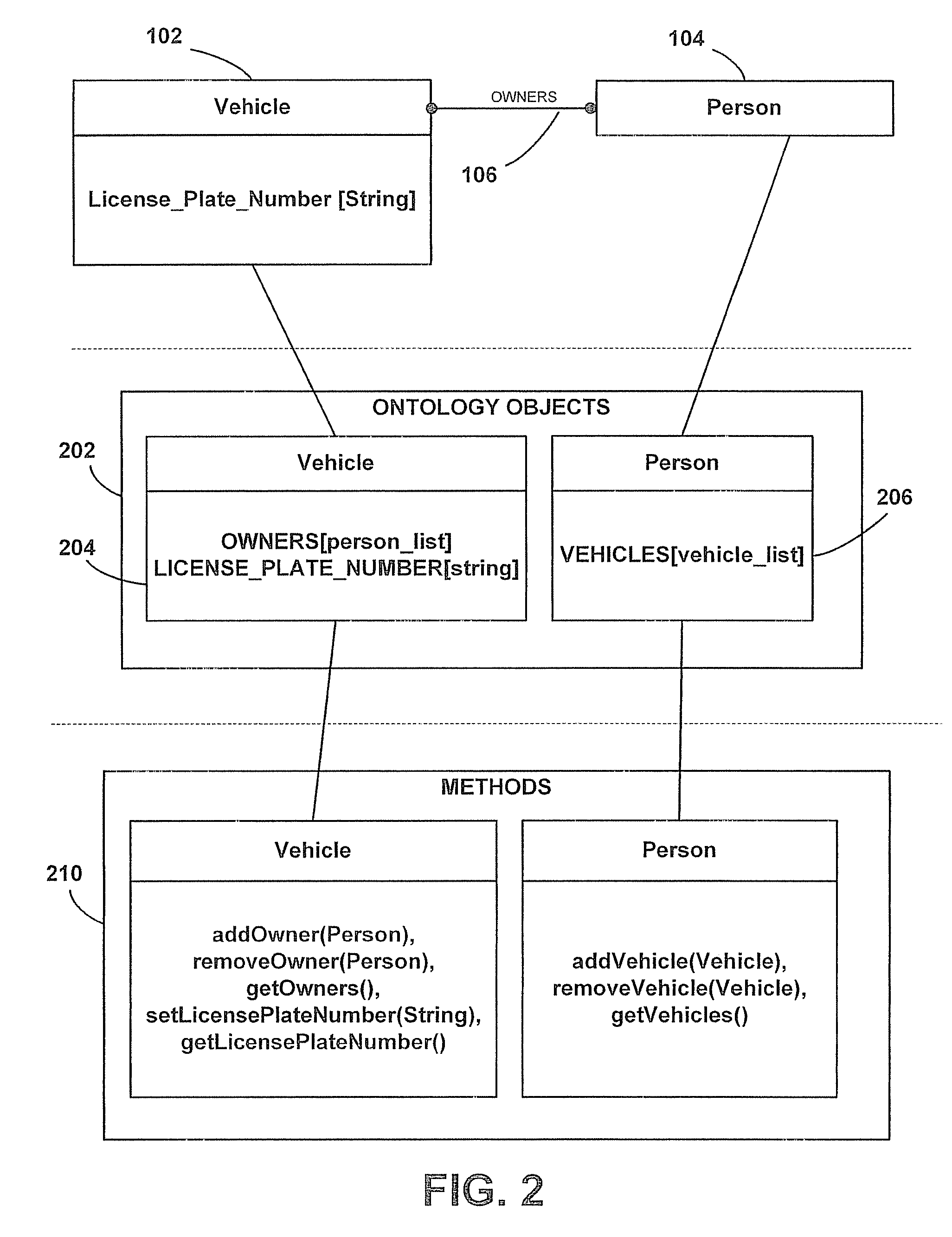

Method and System for Metamodeling Using Dynamic Ontology Objects

A system and method for providing ontology objects for use in a metamodeling environment is disclosed herein. The method comprises (a) providing a framework for creating a metamodel, wherein the metamodel comprises one or more entities, relationships, and semantics and the framework accepts input from a user to create the entities, relationships, and semantics, (b) generating ontology objects, wherein the ontology objects comprise source code for one or more classes, and wherein each class corresponds to one of the entities; and (c) compiling the source code. Further, the method may comprise detecting that a change has been made to the metamodel, updating the ontology objects to reflect the change to the metamodel, wherein updating the ontology objects comprises generating new source code for one or more classes; and compiling the new source code.

Owner:HONEYWELL INT INC

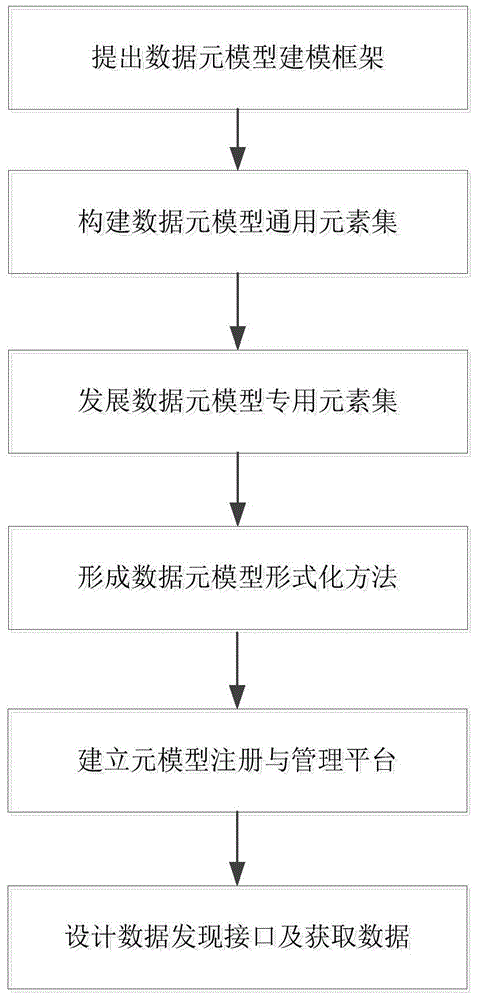

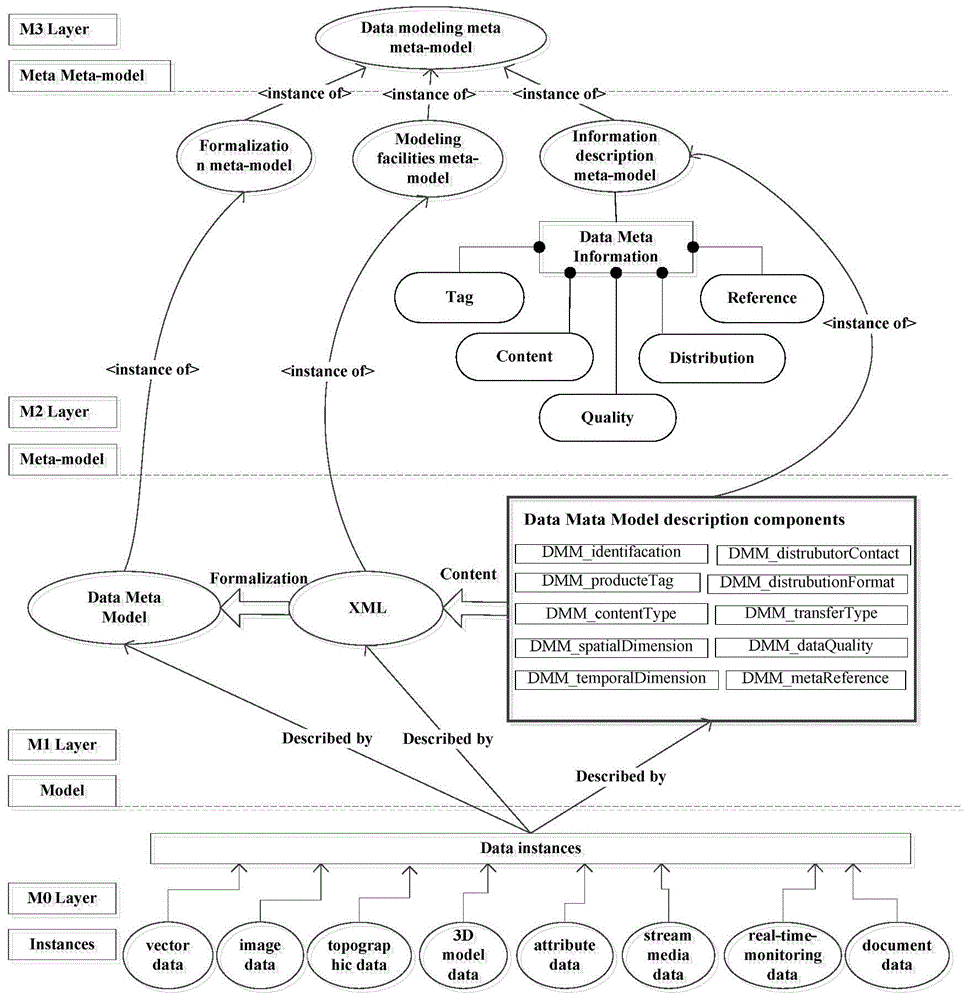

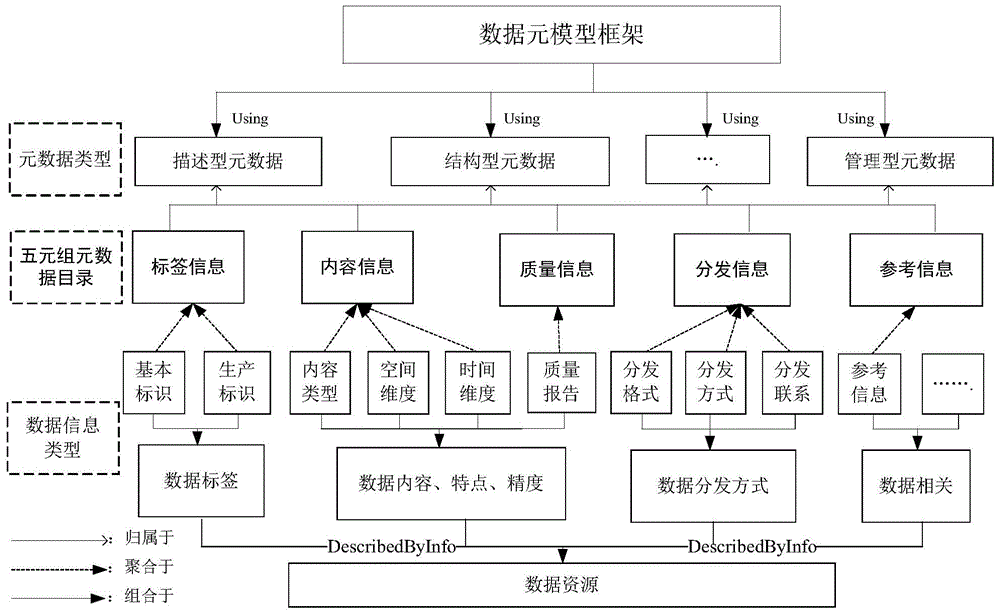

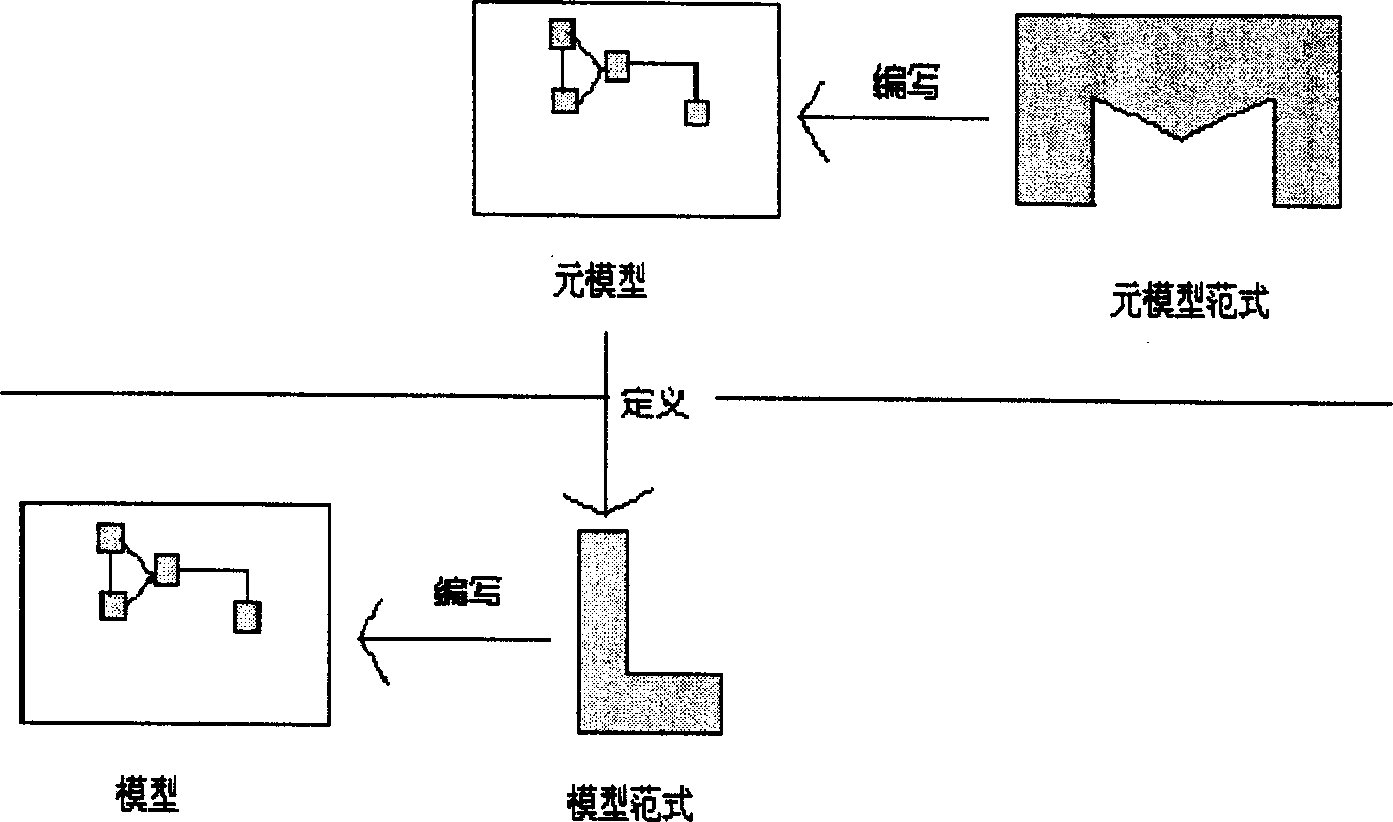

Smart city heterogeneous data sharing method based on meta model

ActiveCN104462244AAchieving a unified and comprehensive descriptionEasy to shareDatabase management systemsSpecial data processing applicationsIntelligent cityMetamodeling

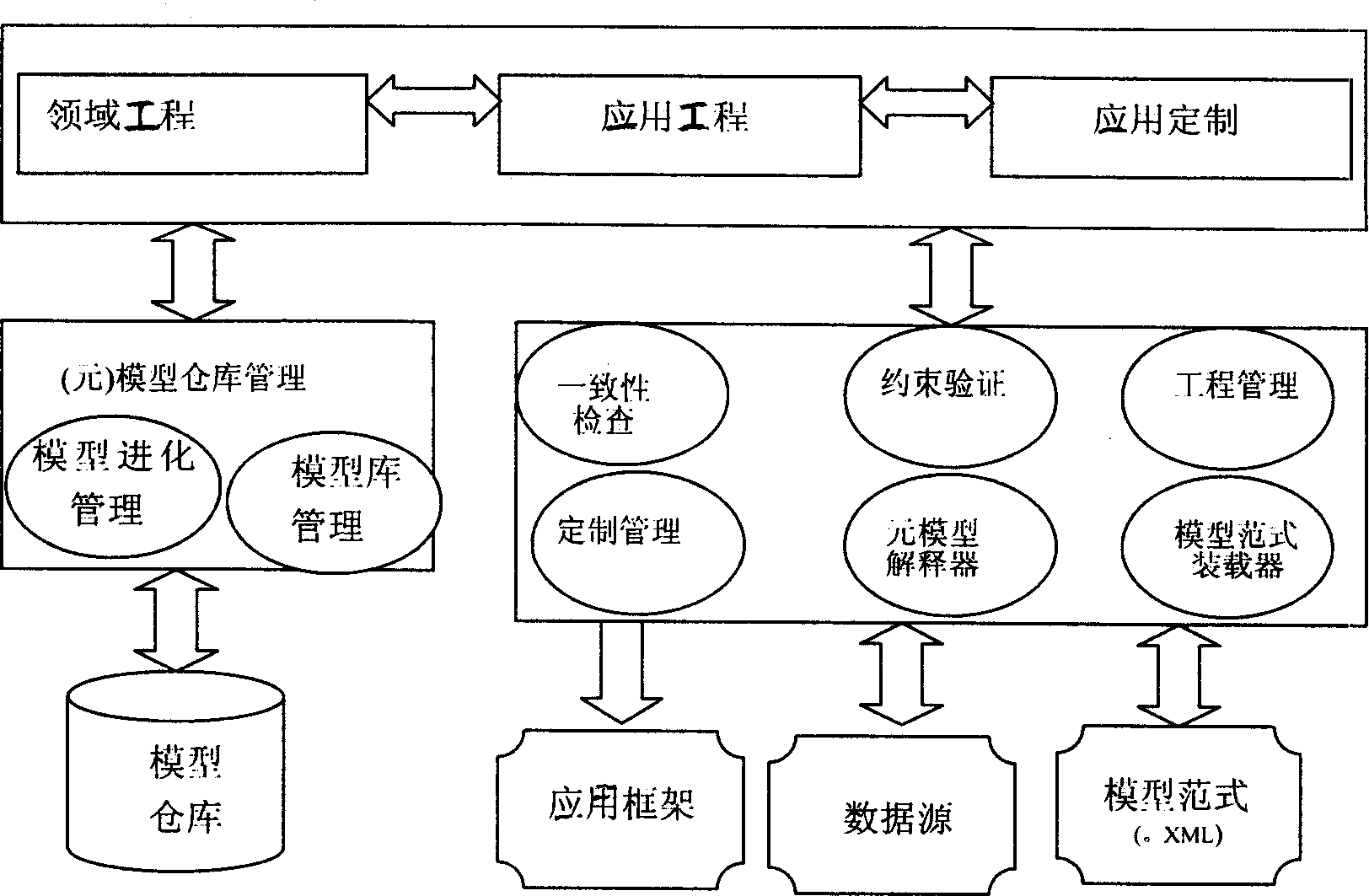

The invention discloses a smart city heterogeneous data sharing method based on a meta model. The smart city heterogeneous data sharing method based on the meta model comprises the first step of establishing a city data meta model modeling frame according to the MOF meta modeling theory, the second step of establishing a city data meta model universal element set according to city data characteristics and description requirements, the third step of developing a data meta model special element set according to city data basic classification and a special element set expansion mode, the fourth step of forming a meta model universal element set and special element set formalization method on the basis of XML template modeling, the fifth step of achieving network directory services and data services and establishing an open city data meta model registering and managing platform, and the sixth step of designing a city data fine granularity discovery interface and obtaining data according to practical application requirements of users. According to the smart city heterogeneous data sharing method based on the meta model, an open and standard city heterogeneous data sharing solution is provided for users, support is provided for city heterogeneous data online access, follow-up processing and collaborative application, and the method is efficient, practical and reliable during city heterogeneous data sharing.

Owner:WUHAN UNIV

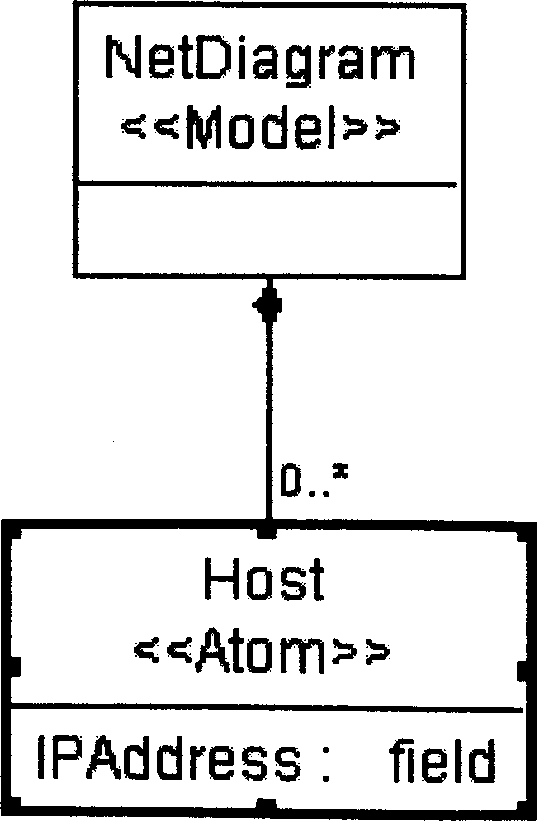

Tele communication region modeling tool based on unified modeling language and modeling method

InactiveCN1794170AImprove efficiencyImprove accuracyData switching networksSpecific program execution arrangementsMetamodelingSimulation

A modeling method of telecommunication field based on unified modeling language includes structuring two¿Cstage of modeling mechanism for elementary modeling and modeling based on structure of unified modeling language of four layer elementary data, using elementary modeling to establish field elementary model and modeling to establish a concrete application model, applying custom ¿C made function to relate a concrete component in model to a concrete equipment and using model to control and supervise equipment.

Owner:JILIN UNIV

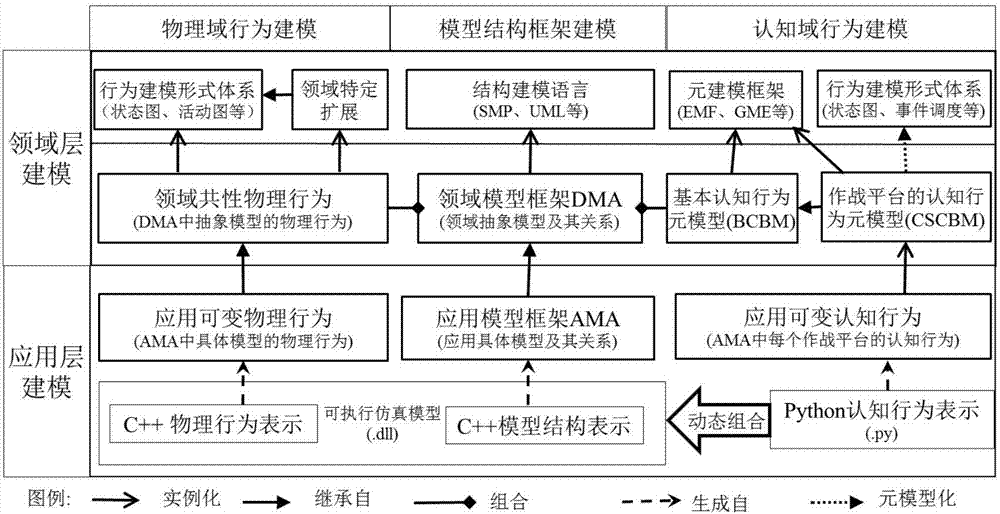

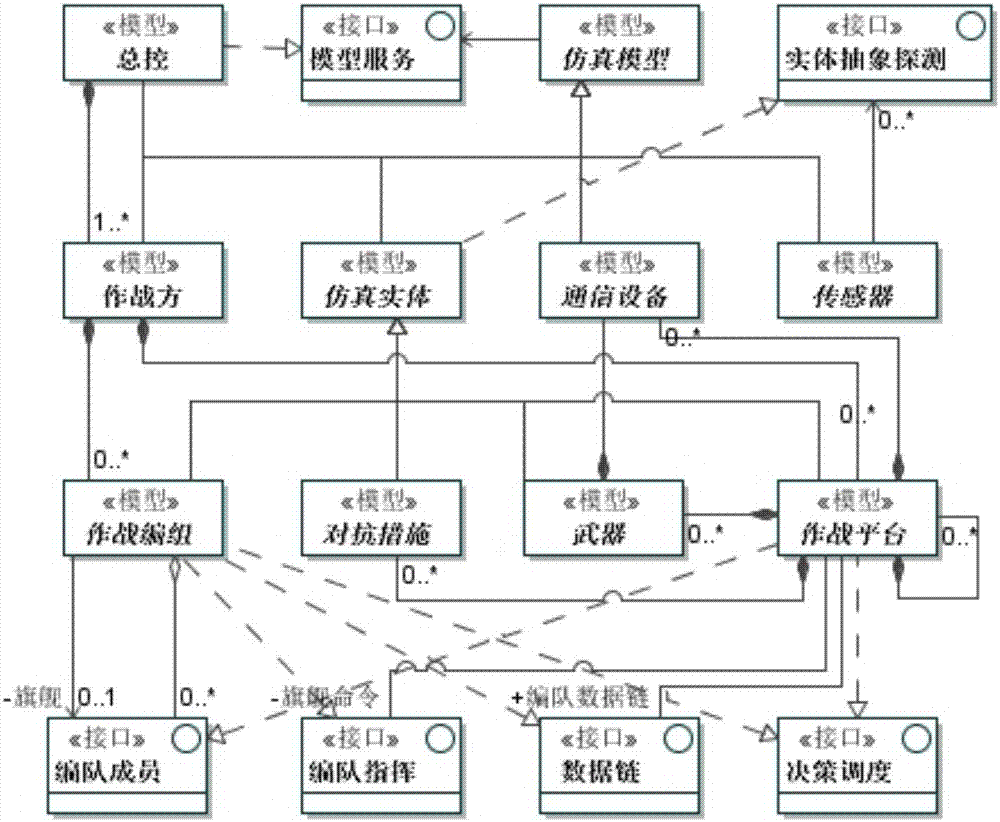

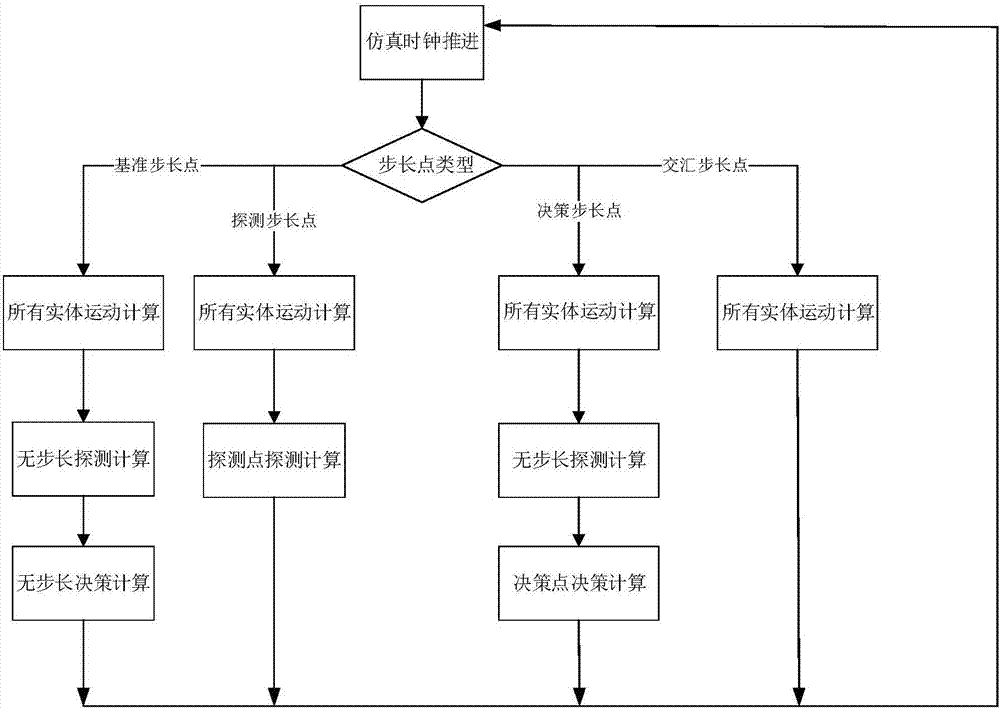

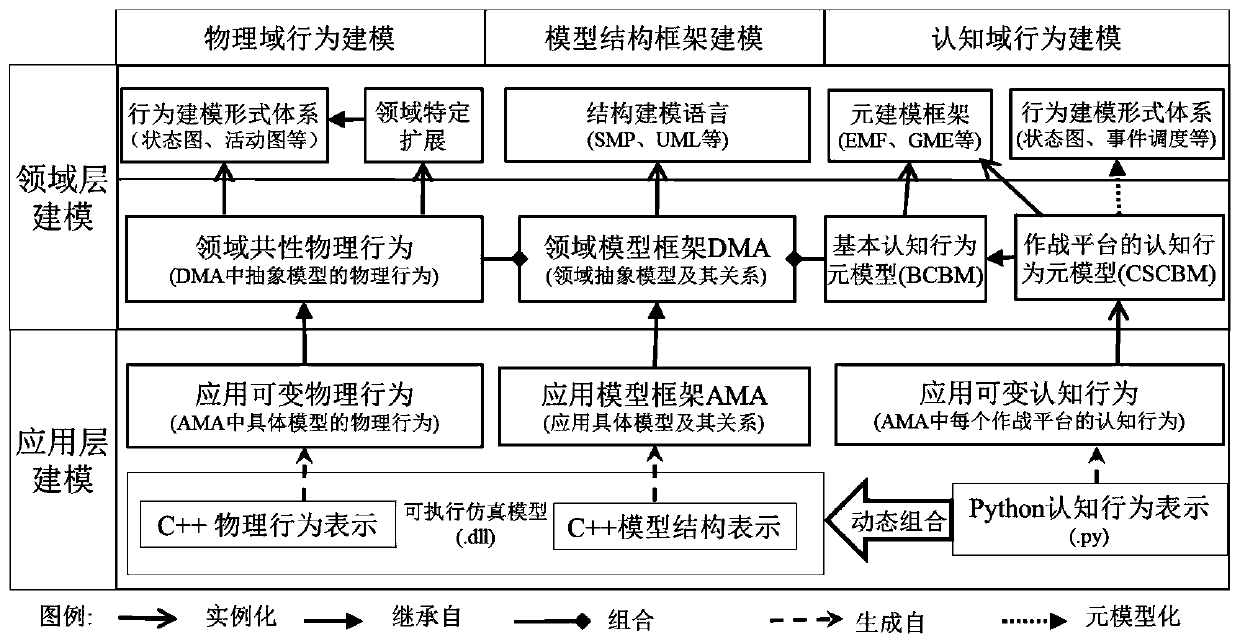

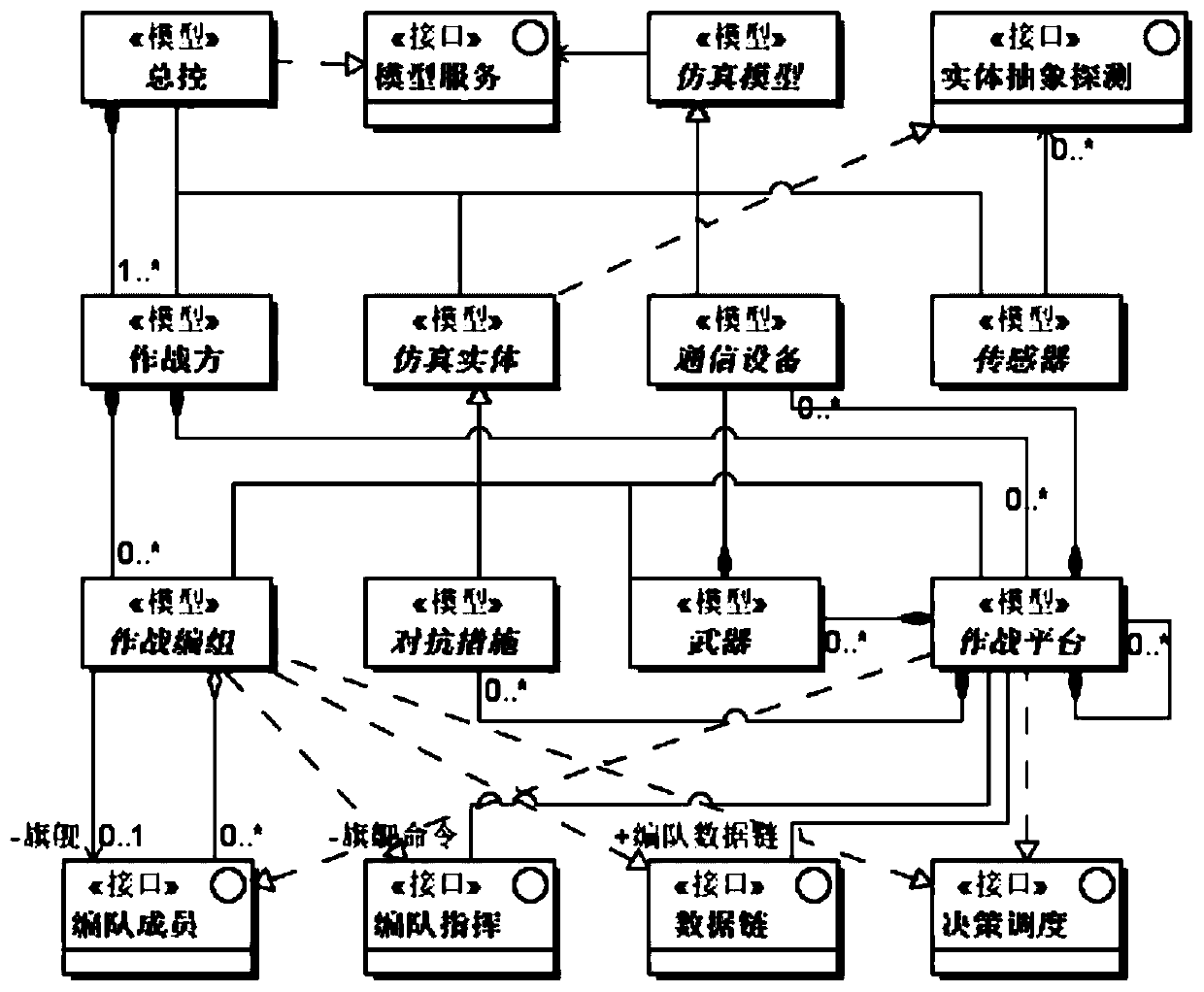

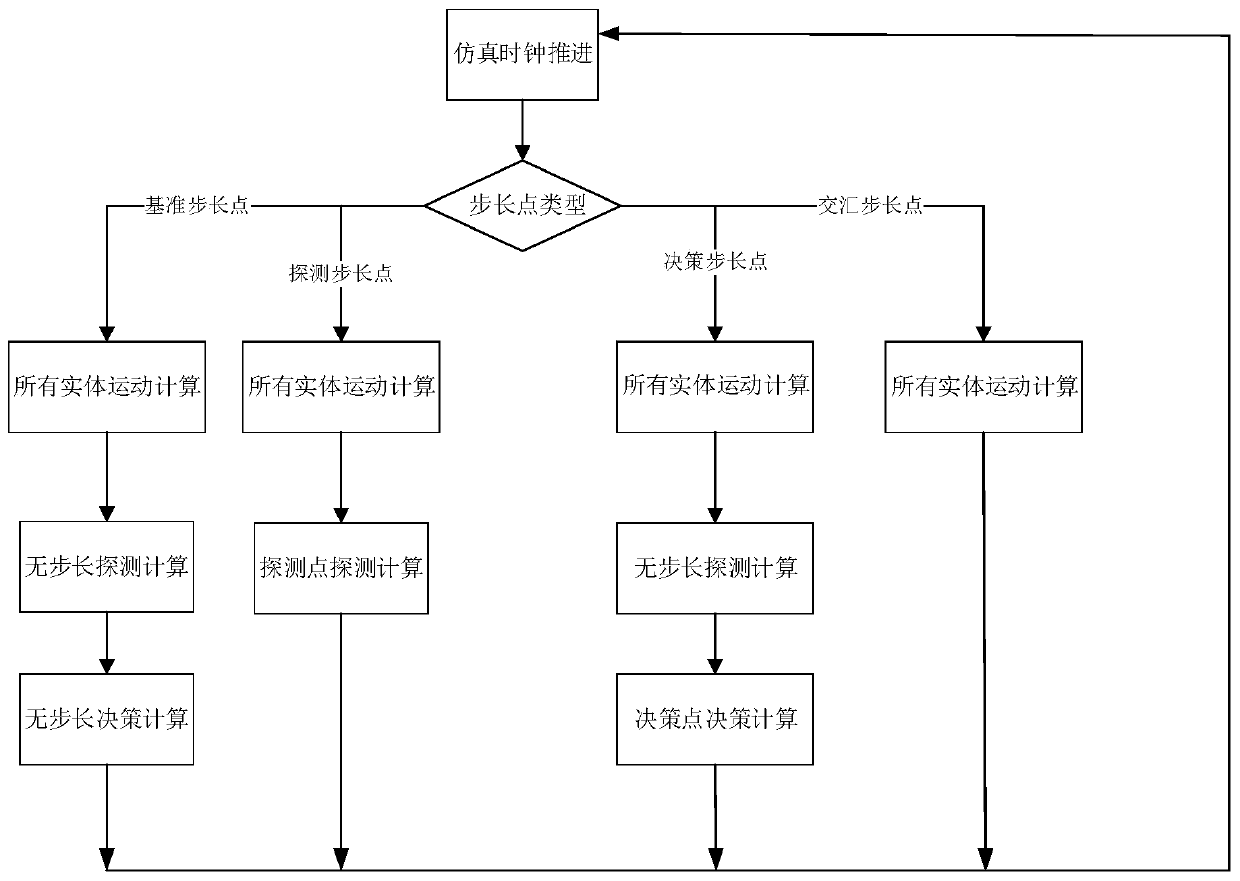

Novel combat effectiveness simulation modeling method

ActiveCN107967134ASupports semantic compositionEfficiently buildSoftware designVisual/graphical programmingMetamodelingProcess behavior

The invention discloses a novel combat effectiveness simulation modeling method, and the problems that a simulation model in combat effectiveness simulation is difficult to combine, reuse, expand andevolve, and a decision behavior model lacks flexibility and problem pertinence are solved. On the one hand, the method emphasizes clear distinction between two levels of knowledge including domain commonness non-variable knowledge and application variable knowledge of the combat effectiveness simulation, and describing the two levels of the knowledge separately; the domain commonness non-variableknowledge is applicable to the entire combat effectiveness field, accordingly a field abstract model is established; the application variable knowledge depends on specific combat effectiveness assessment questions, and an application-specific model which can be instantiated and deployed is established on the basis of the field abstract model. On the other hand, the method emphasizes the distinction between physical process behaviors of weapons and cognitive decision-making behaviors of combat commanders, the cognitive decision-making behaviors compared with the physical process behaviors havegreat difference in different applications according to missions and different choices of the commanders, and dynamic flexibility of the cognitive decision-making behaviors and pertinent expression ofquestions are realized by means of a script technology and a meta-modeling technology.

Owner:NAT UNIV OF DEFENSE TECH

Product unified model construction system based on semantic meta model and construction method thereof

InactiveCN106127395AReduce lossReduce errorsSemantic analysisResourcesMetamodelingInteraction interface

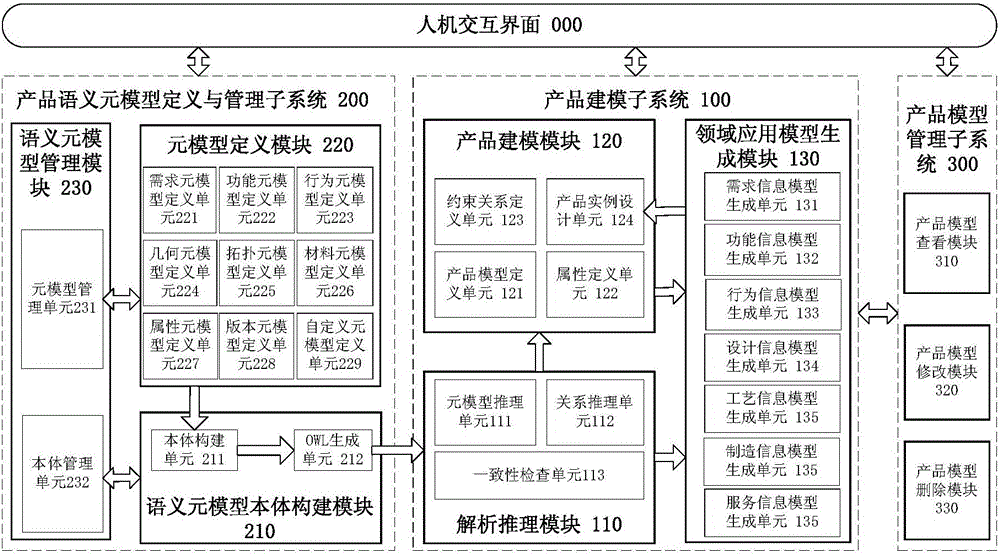

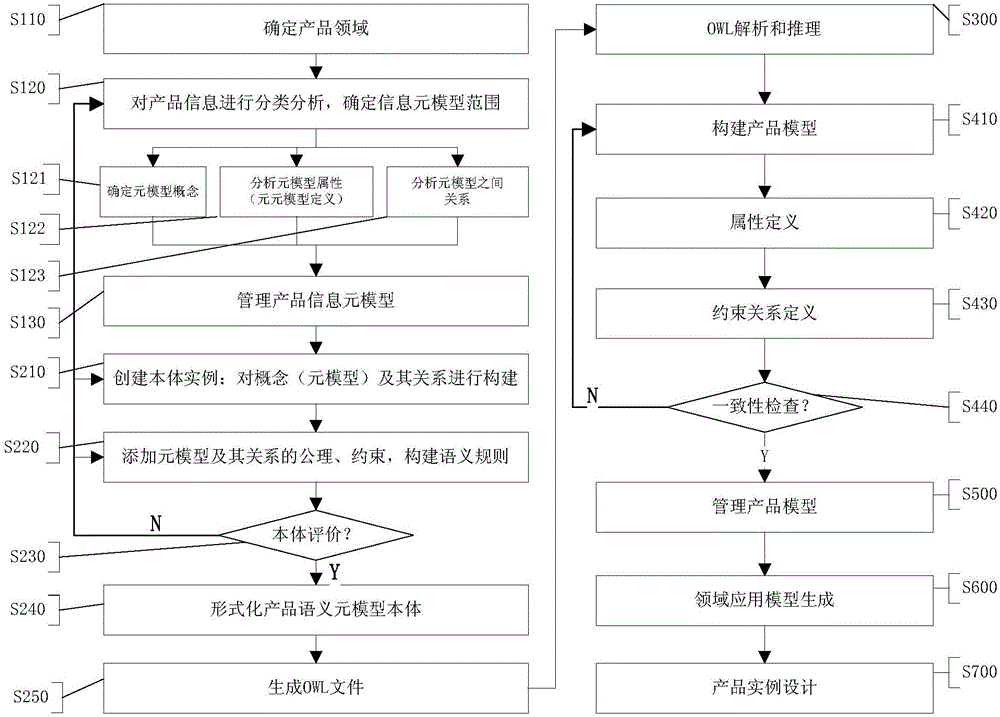

The invention relates to a product unified model construction system based on a semantic meta model and a construction method thereof, and belongs to the technical field of product modeling. The system comprises a human-computer interaction interface (000), a product modeling subsystem (100), a product semantic meta model definition and management subsystem (200) and a product model management subsystem (300). The human-computer interaction interface is connected with the product modeling subsystem, the product semantic meta model definition and management subsystem and the product model management subsystem. The product modeling subsystem is connected with the product semantic meta model definition and management subsystem and the product model management subsystem. Compared with the systems and the methods in the prior art, a multi-level product modeling framework is constructed through combination of the meta modeling mechanism and the ontology technology so that product geometric and non-geometric information semantic description can be realized, and product life cycle information integration, sharing and reusing can be realized; and design personnel can create normal product information models without being proficient in the ontology thought or the modeling language internal structure so that the design efficiency and quality can be enhanced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Semantic business model management

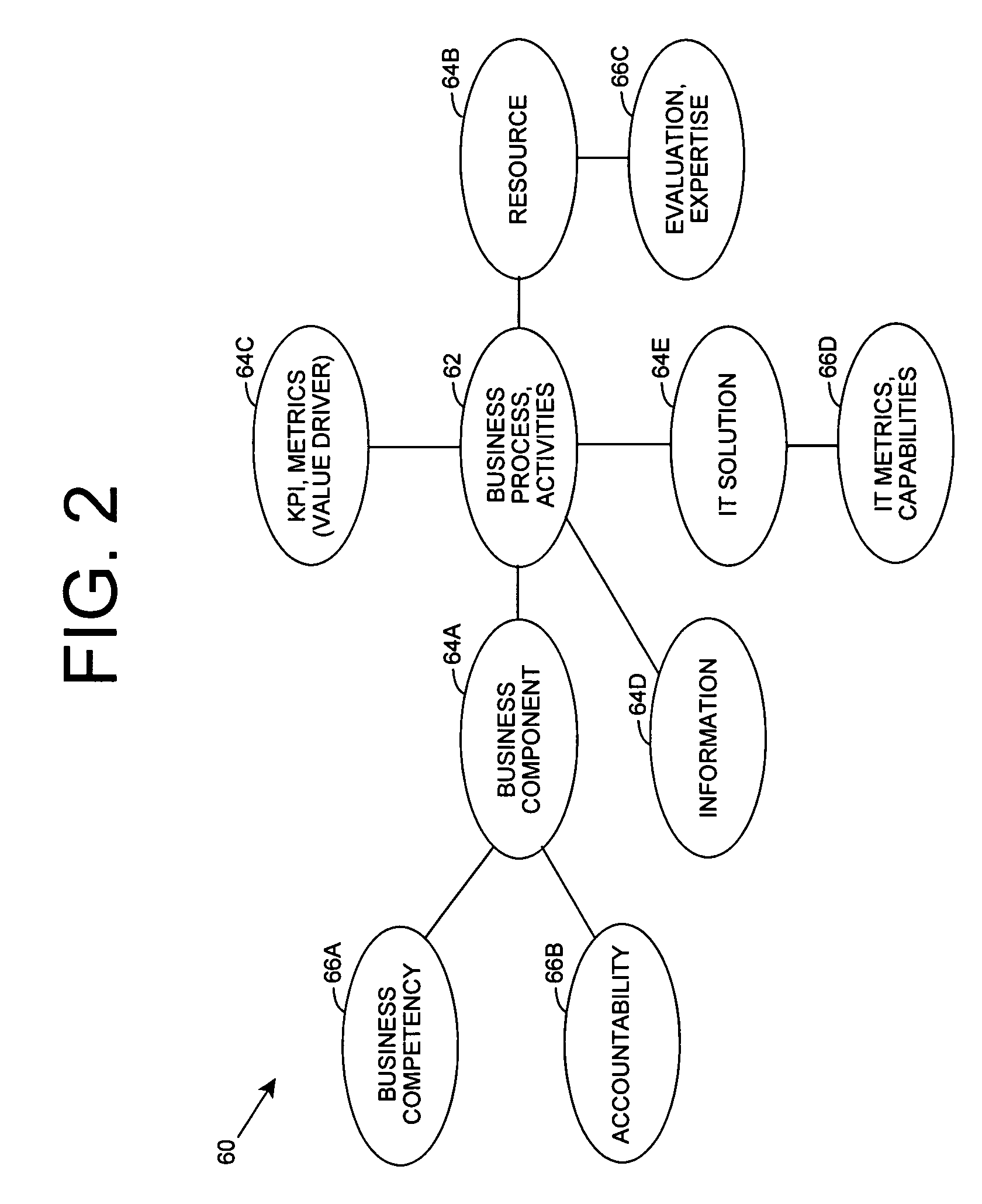

ActiveUS7761478B2Large scaleReduce the burden onDigital data processing detailsResourcesModel managementMetamodeling

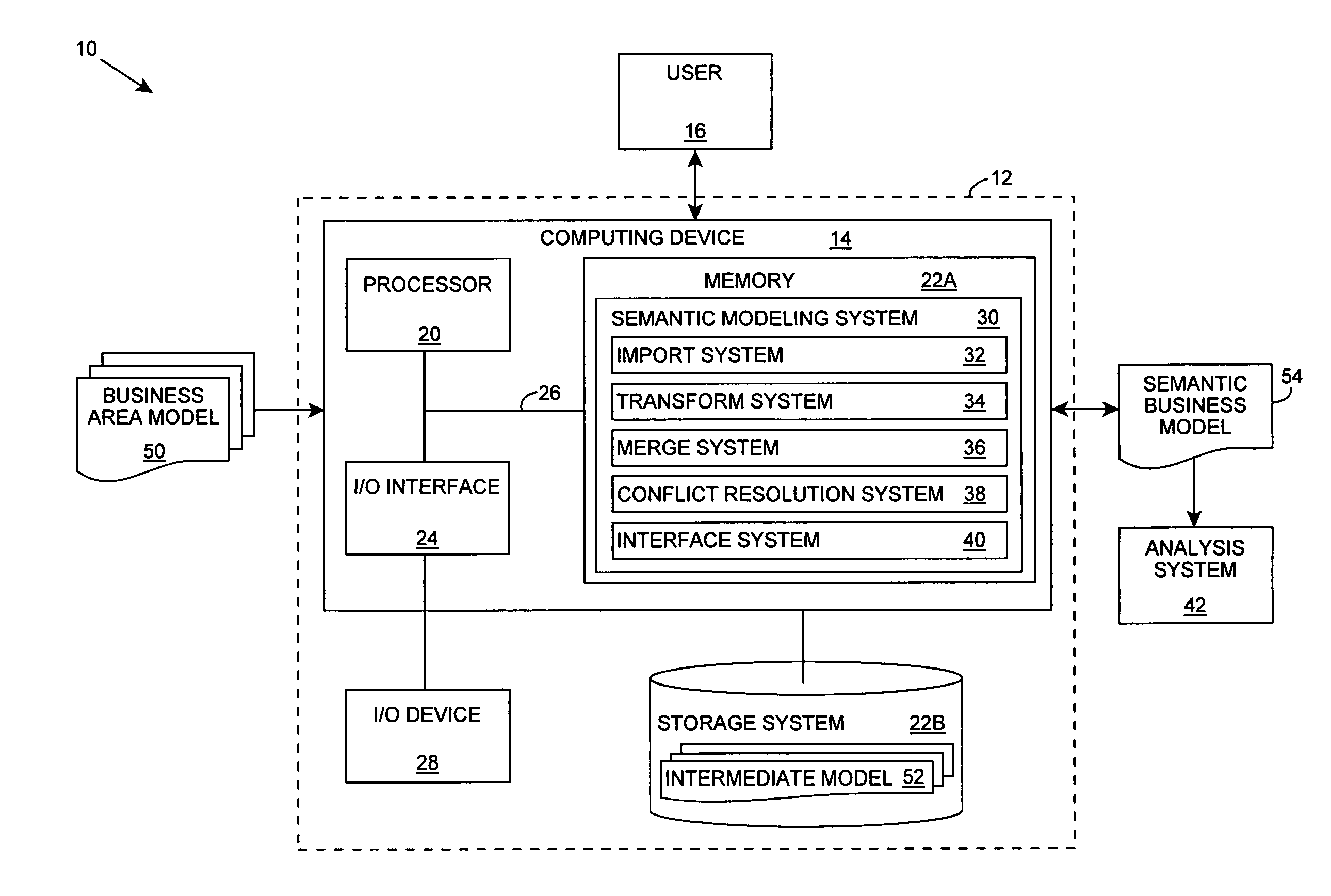

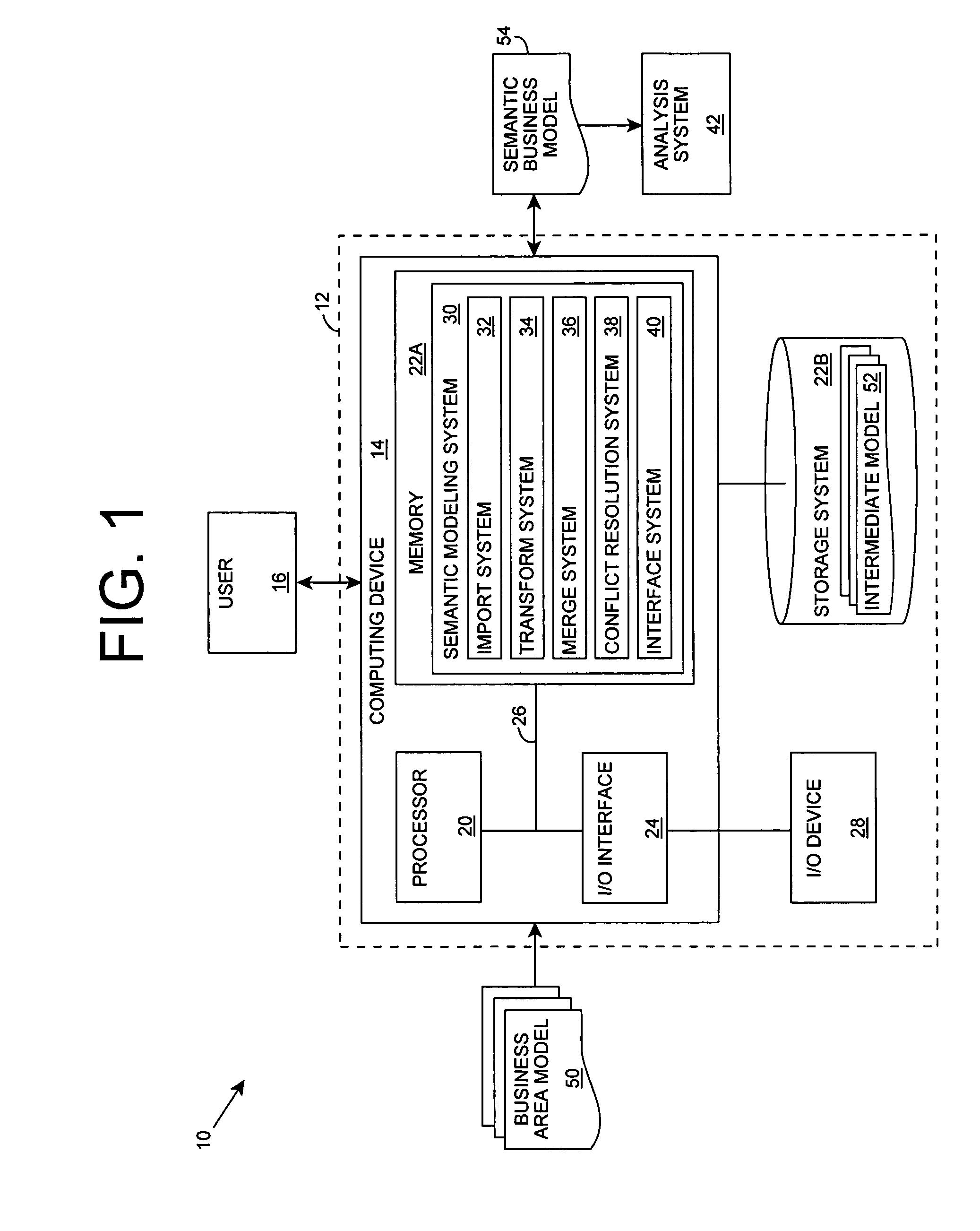

A computer-implemented solution for managing a semantic business model is provided. In particular, one or more business area models for a business entity are obtained and transformed into intermediate model(s). Each intermediate model is represented using a substantially similar meta-modeling language. Subsequently, the semantic business model is generated by merging the set of intermediate models. In this manner, the semantic business model can be generated in a manner that reduces the overall burden on a user. The semantic business model can be provided for display to the user and / or use in performing qualitative analysis on various aspects of the business entity.

Owner:KYNDRYL INC

Modeling method of asymmetric spur gear pair

ActiveCN104318017AEnables dynamic mesh analysisAvoid crossingPortable liftingSpecial data processing applicationsModel methodElement model

The invention relates to a modeling method of an asymmetric spur gear pair. The modeling method includes firstly calculating coordinates of equant key points on a gear profile by a gear profile of an asymmetric spur gear, creating gear profile key points by ANSYS software, generating a gear profile sample curve of the key points, setting up a single-gear end face, an integral-gear end face, a solid asymmetric spur gear model and an asymmetric spur gear transmission pair model, finally dividing finite element grids and setting dynamic constraints and load to obtain an asymmetric spur gear transmission pair finite element model. The integral modeling process realizes parameterization, and finite element modeling quality of a gear transmission system as well as analysis efficiency is greatly improved.

Owner:JIANGSU UNIV OF TECH

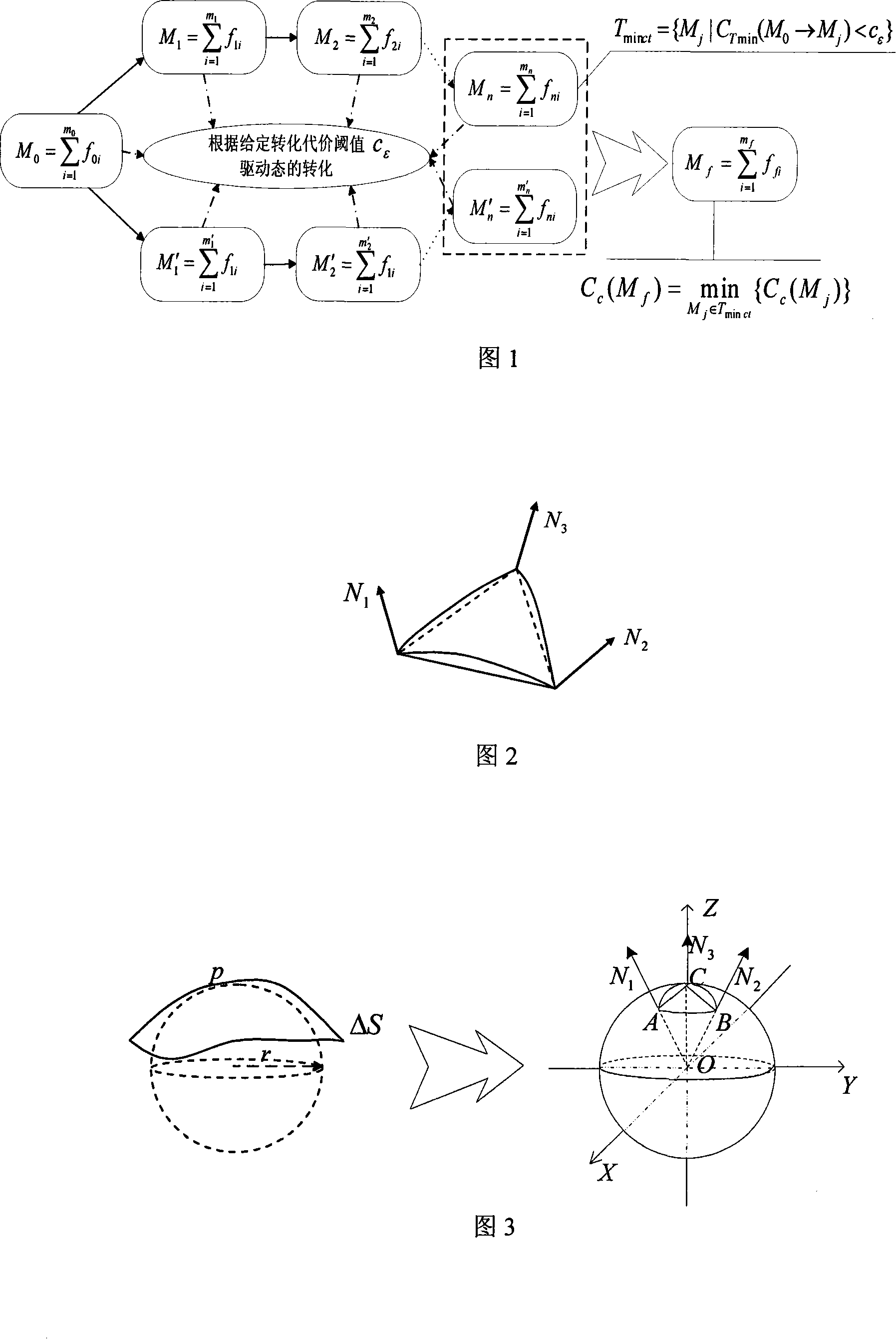

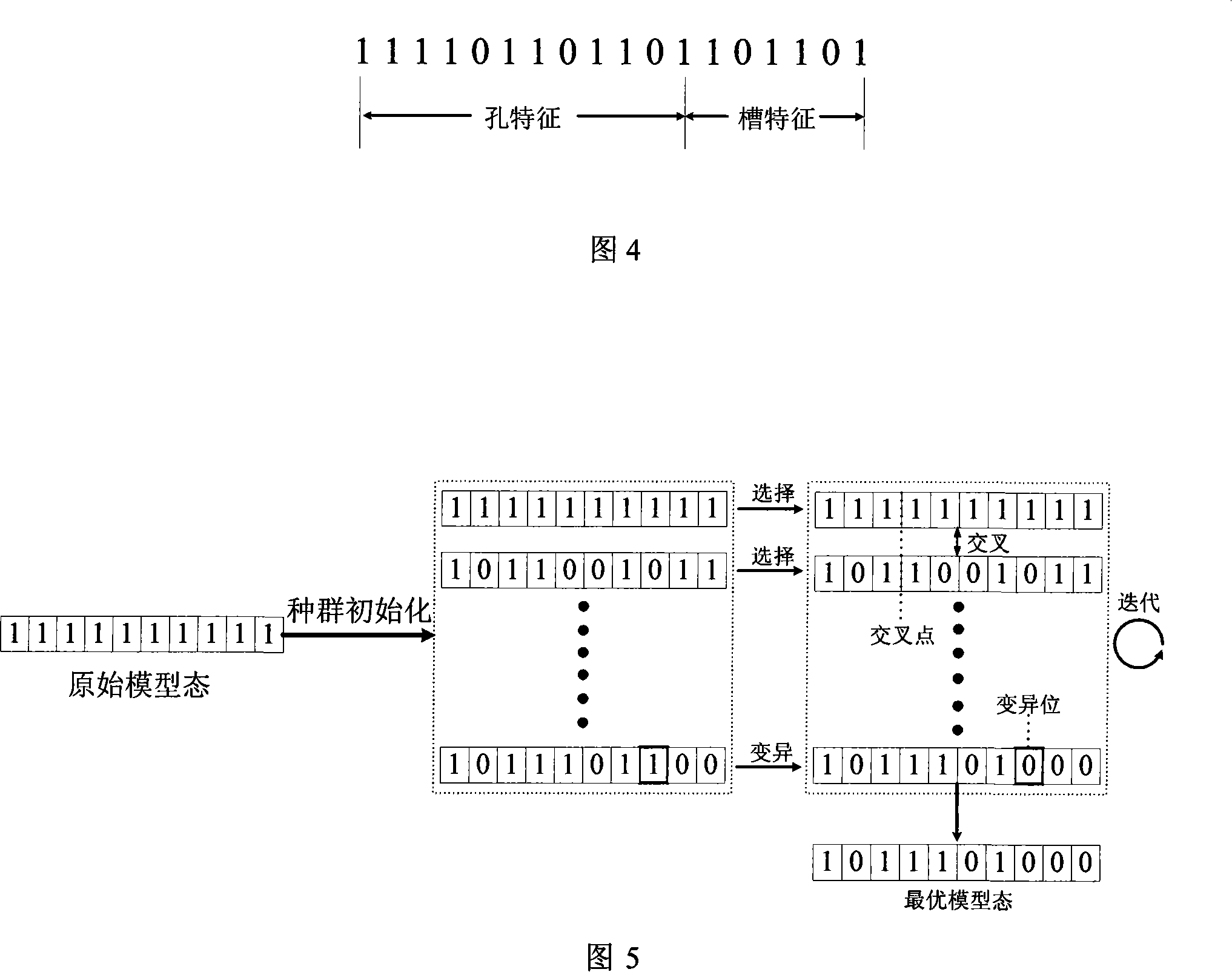

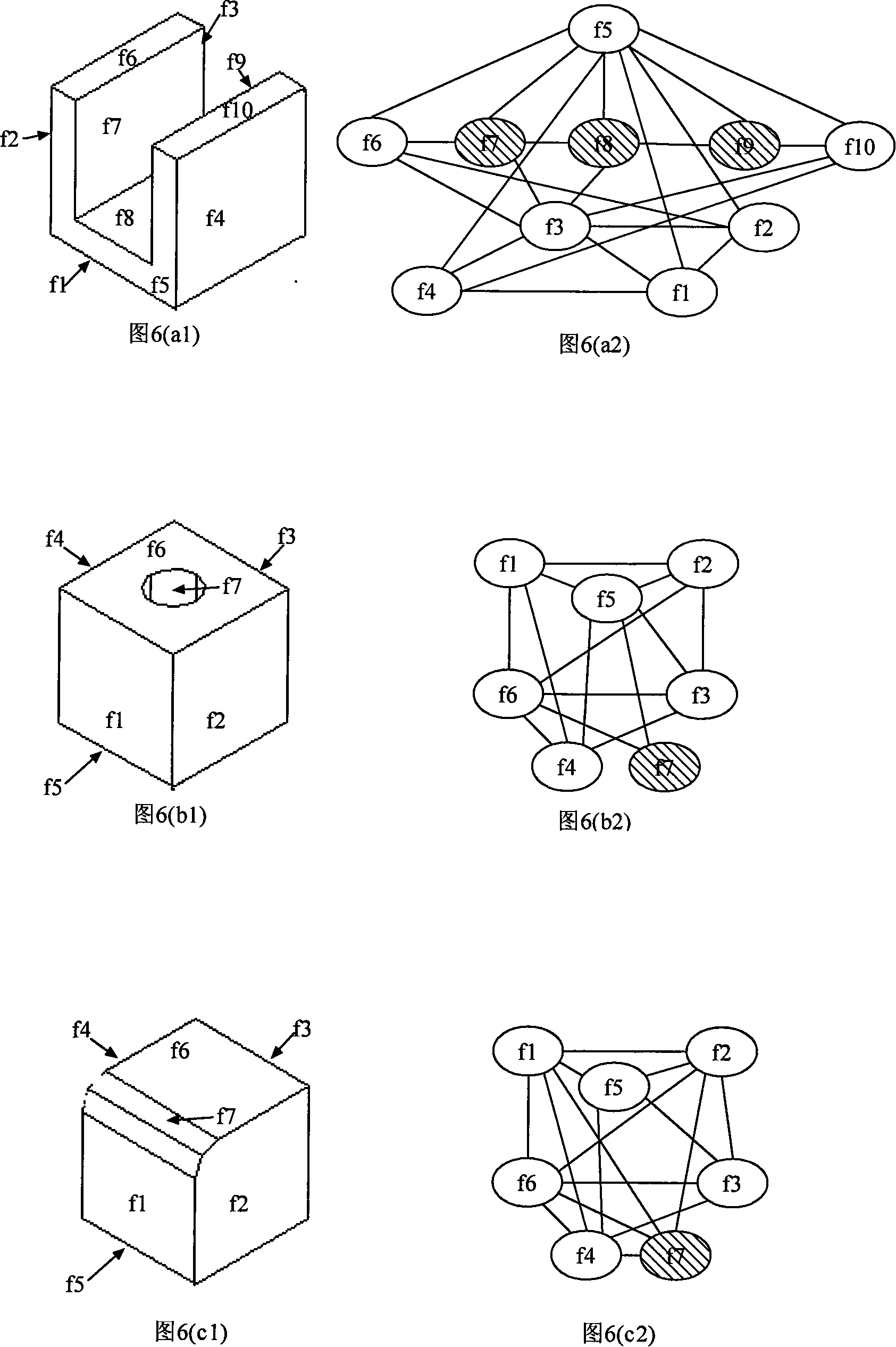

Model state creation method based on characteristic suppression in finite element modeling

The present invention provides a restraining model generating method based on the characteristics in finite element modeling, characterized in that the providing unreduced model by users; identifying reducible characteristics in the unreduced model; determining numbers of unreduced characteristics; acquiring sensitive value of the unreduced characteristics after being suppressed representing model lateral error by the sum of all suppressed characteristics sensitive values; evaluating unit amount of the model after being grid divided; selecting the model according to the lateral error of the model and the unit amounts Ne, acquiring simplified model code; a simplified model corresponding to the simplified model code generated by suppress characteristics method. The invention achieves that each characteristic changes in the model objectively evaluates the finite element result sensibility, establishes sensibility measurement system of results by choosing and changing of each element in the model, and gives an precise evaluating method of the model time consumption, generating model on the basis.

Owner:HEFEI UNIV OF TECH

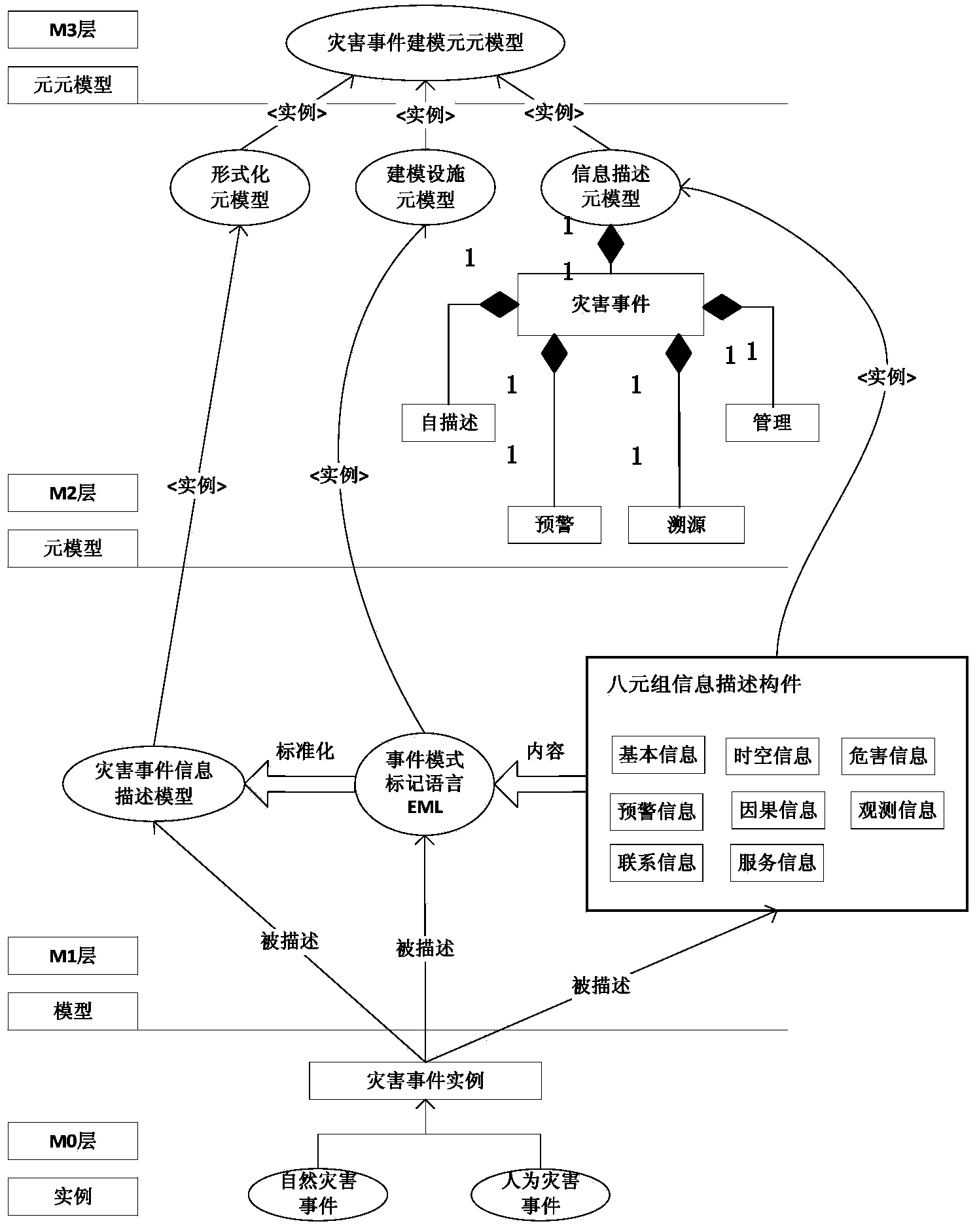

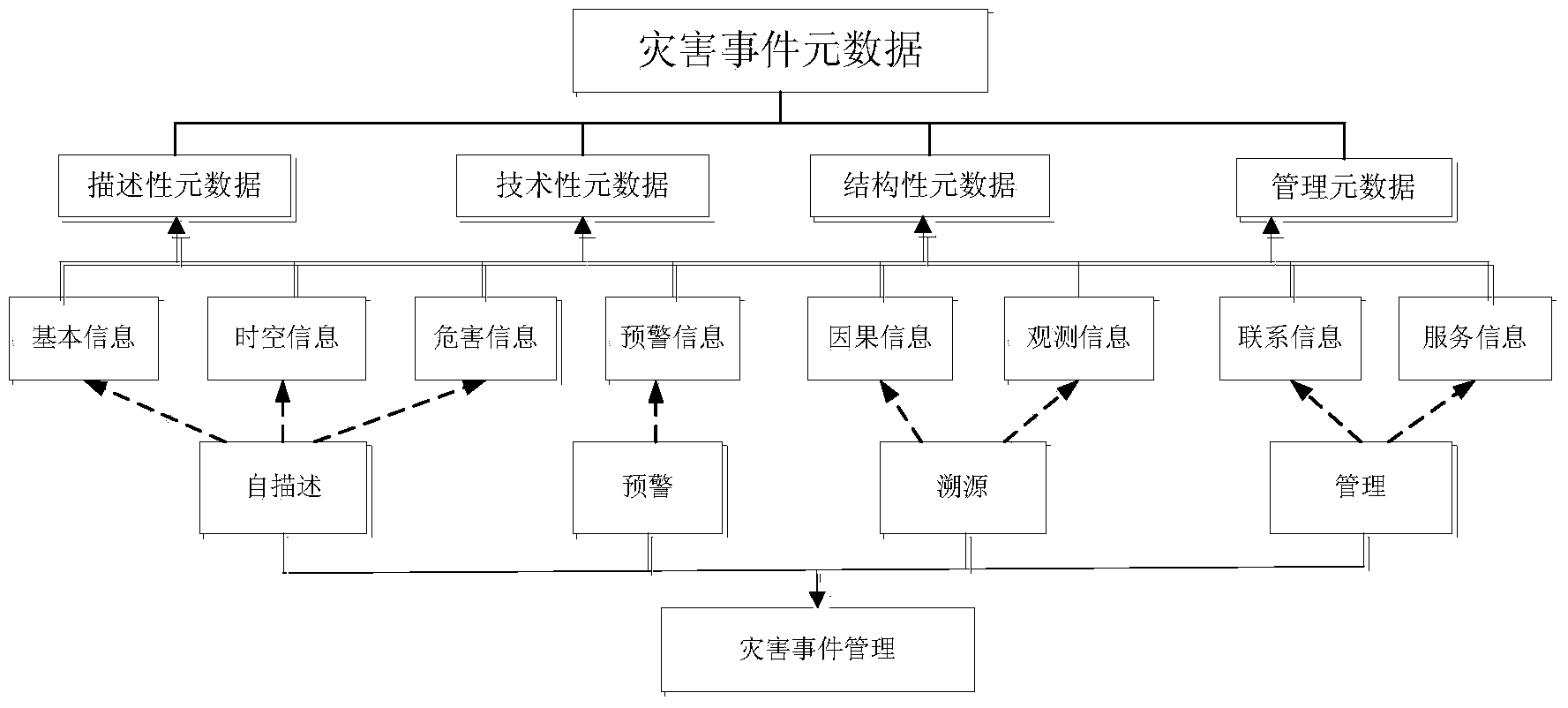

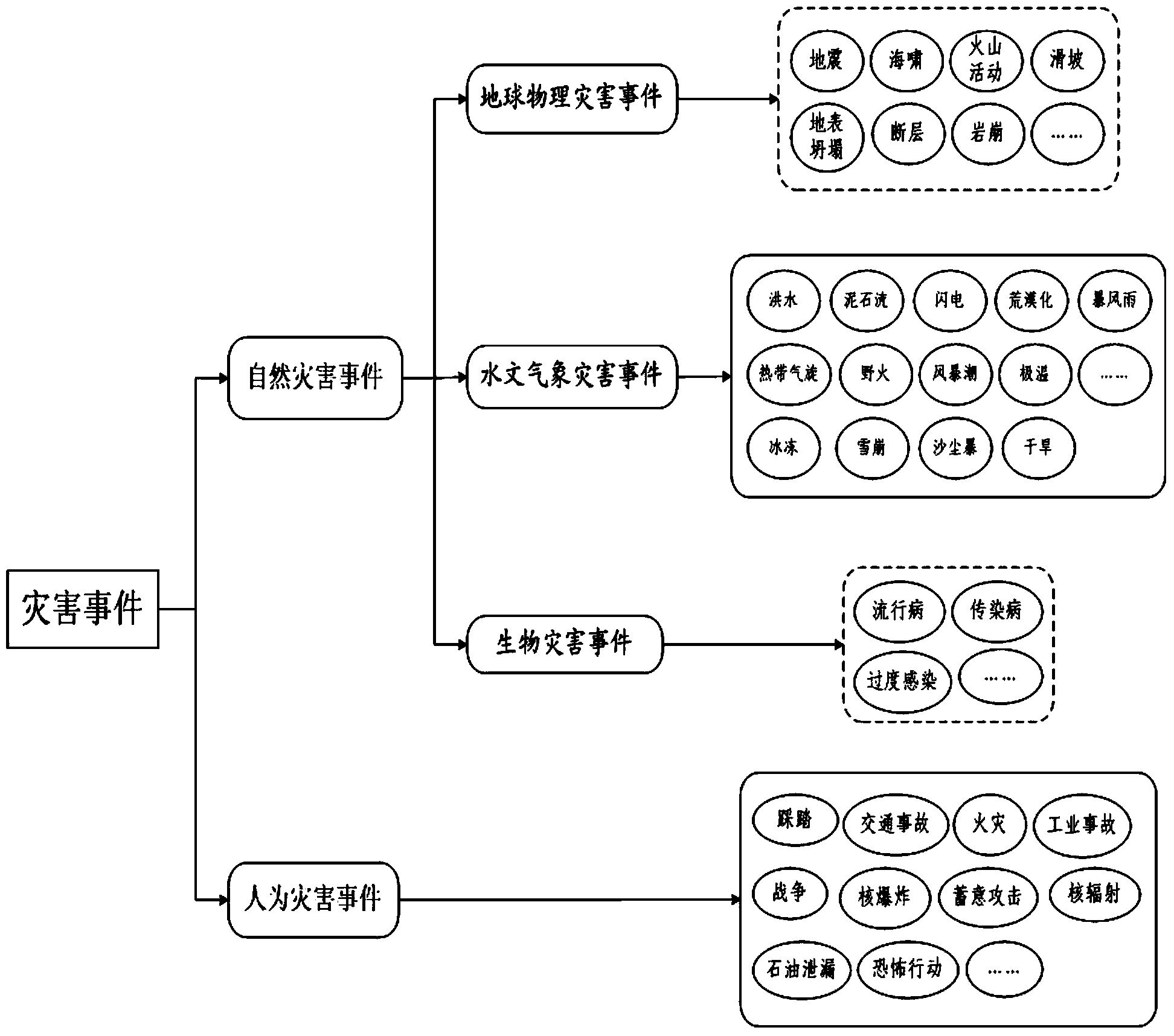

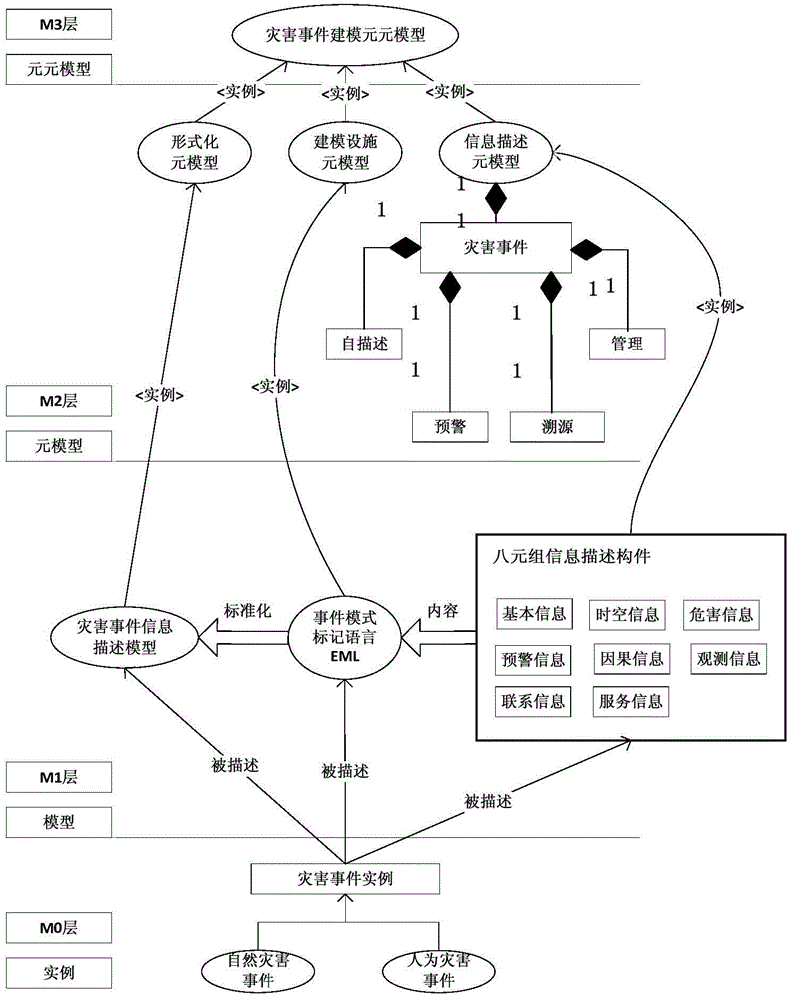

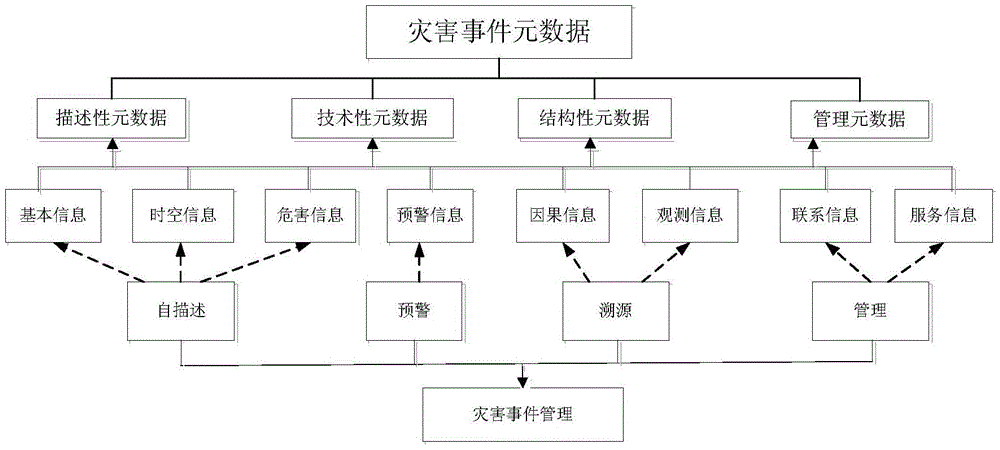

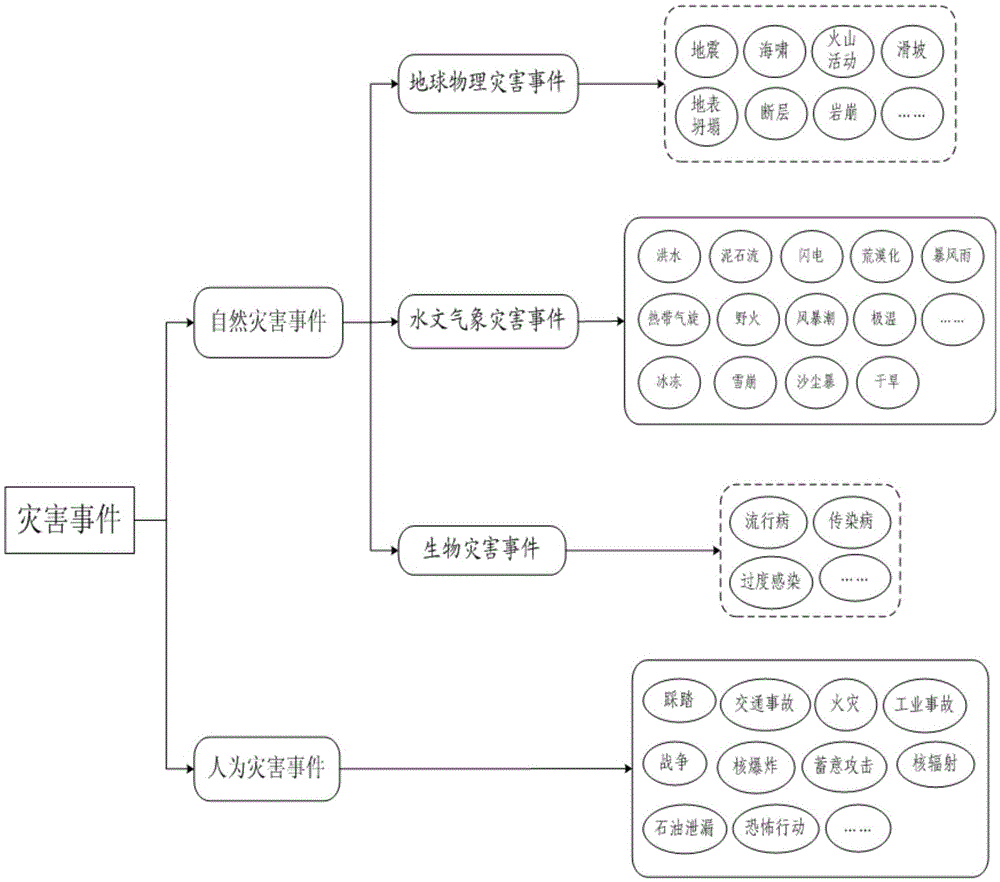

Common modeling method and system of heterogeneous disaster events

ActiveCN103440347ATo achieve a unified descriptionConducive to unified archivingSpecial data processing applicationsNODALData information

The invention relates to a common modeling method and system of heterogeneous disaster events. The method comprises the steps of building a disaster event meta-modeling frame, building a mode structure of a disaster event meta-model and building a heterogeneous disaster event information model. The method and the system have the advantages and positive effects that the problems that existing heterogeneous disaster events lack effective description means and information models are not uniform are solved; the disaster event meta-model is built; four metadata components and eight-tuple node information description models are developed and the mapping relations between the geography markup language, the sensor model language, the event pattern markup language, sensor network common data information models and an event meta-model are designed; compared with existing disaster event management modes, the disaster event meta-model in the method and system provided by the invention comprehensively describes related information of the heterogeneous disaster events, thus providing supports for unified management and accurate discovery of the disaster events and proving that the method is beneficial to modeling of the heterogeneous disaster events and is more practical and reliable in disaster even management.

Owner:WUHAN UNIV

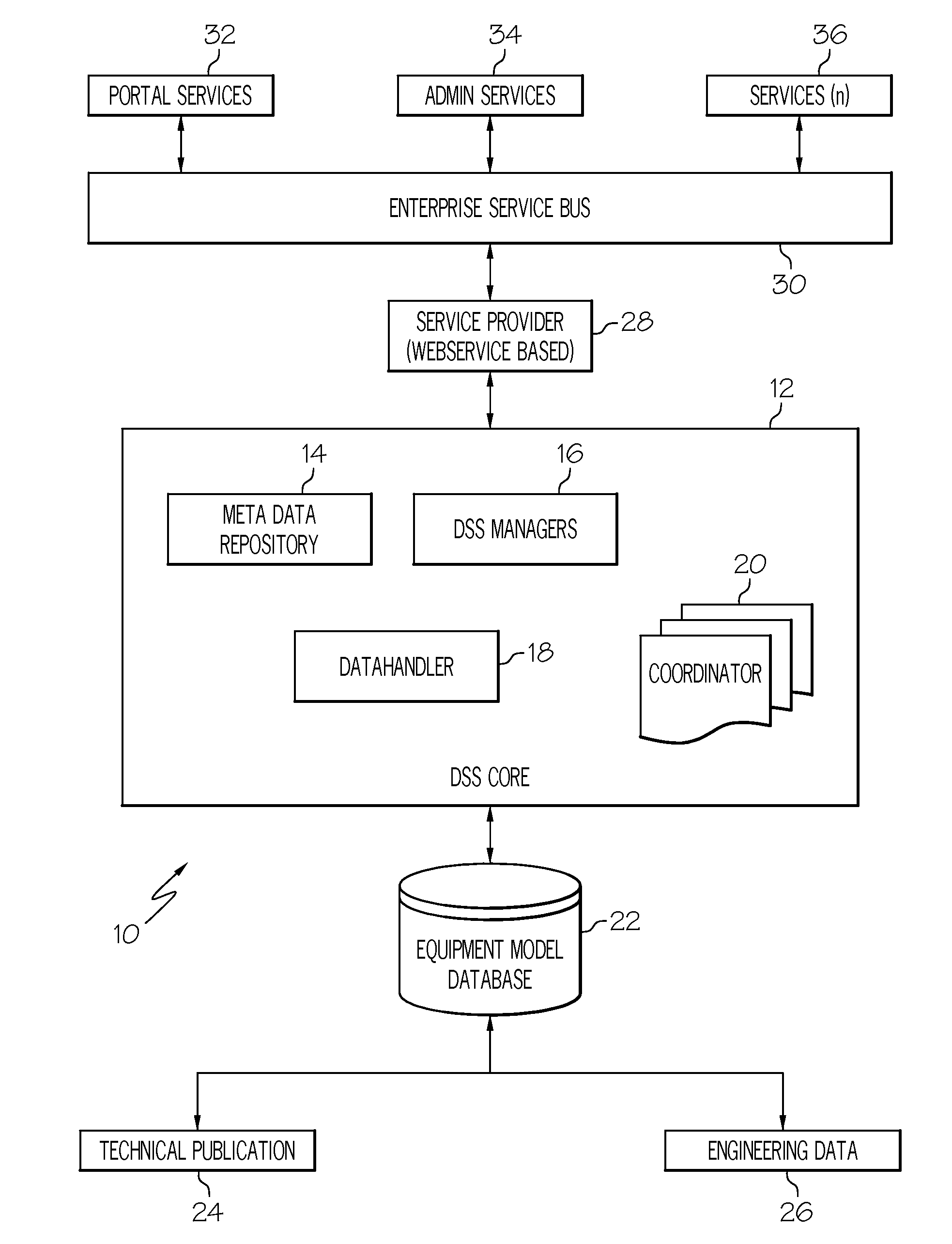

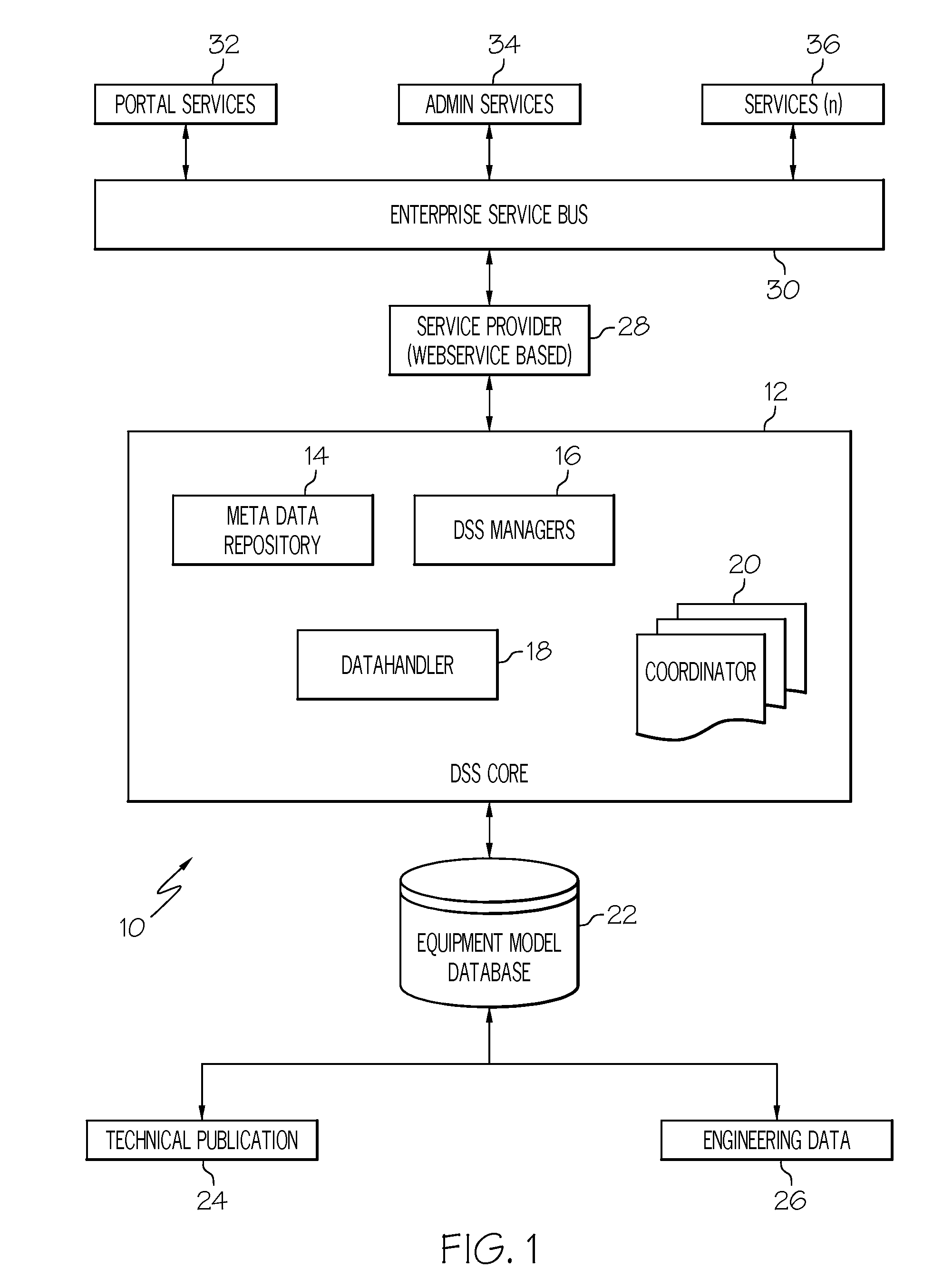

Meta modeling in decision support system

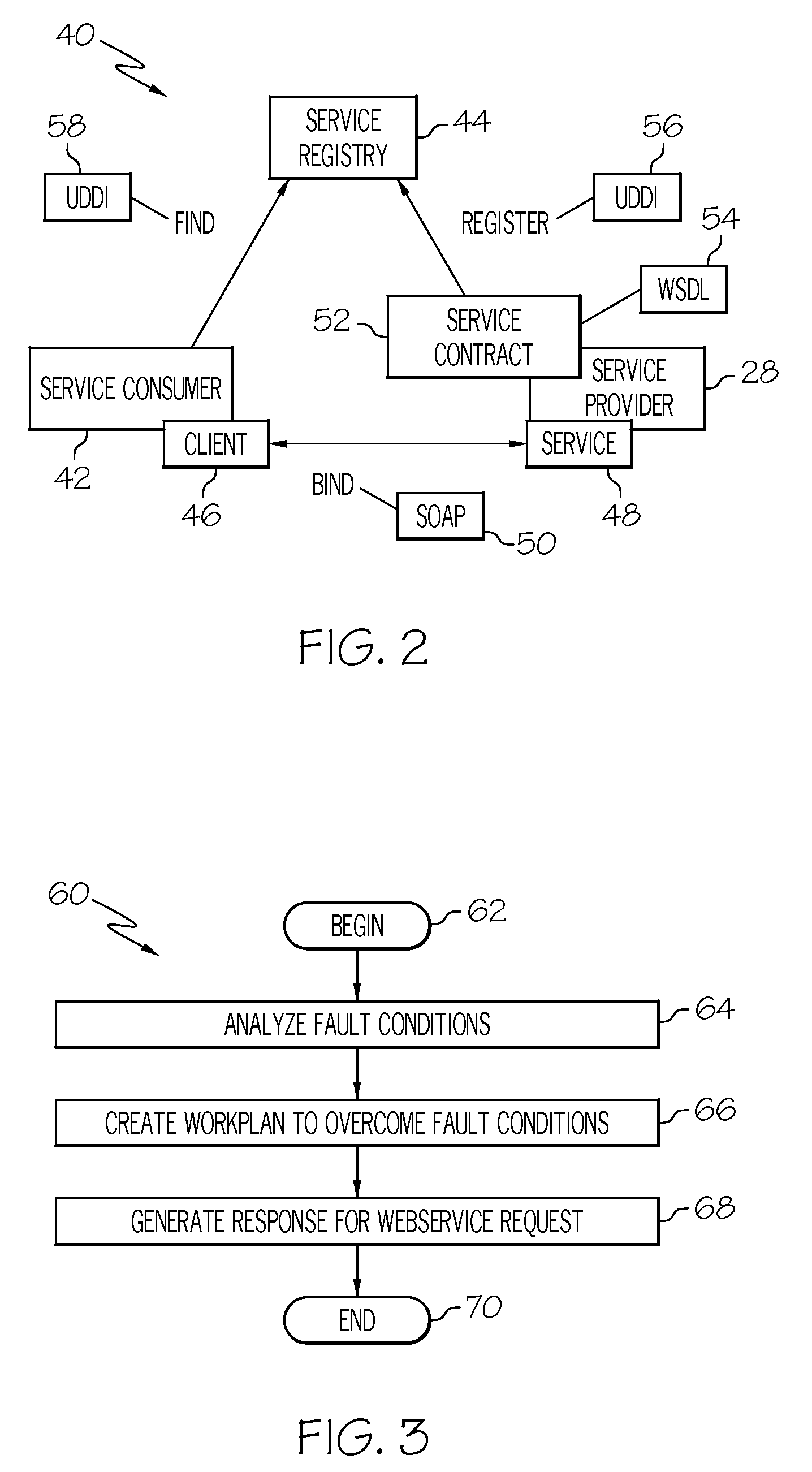

A method, system, and computer program product for providing troubleshooting data for reported fault conditions on equipment is provided. An engineering model is configured for the equipment. The engineering model includes at least one failure scenario and an associated symptom. The engineering model is stored in an equipment model database. A meta model representative of at least one relationship between the engineering model and a reported fault condition for the equipment is instantiated. A user input for the reported fault condition is stored in a decision support system (DSS) database. The DSS database forms a wrapper over the equipment model database based on the user input. The meta model is further instantiated using user input data from the DSS database. An optimal troubleshooting procedure for the equipment is determined based on the meta model as instantiated.

Owner:HONEYWELL INT INC

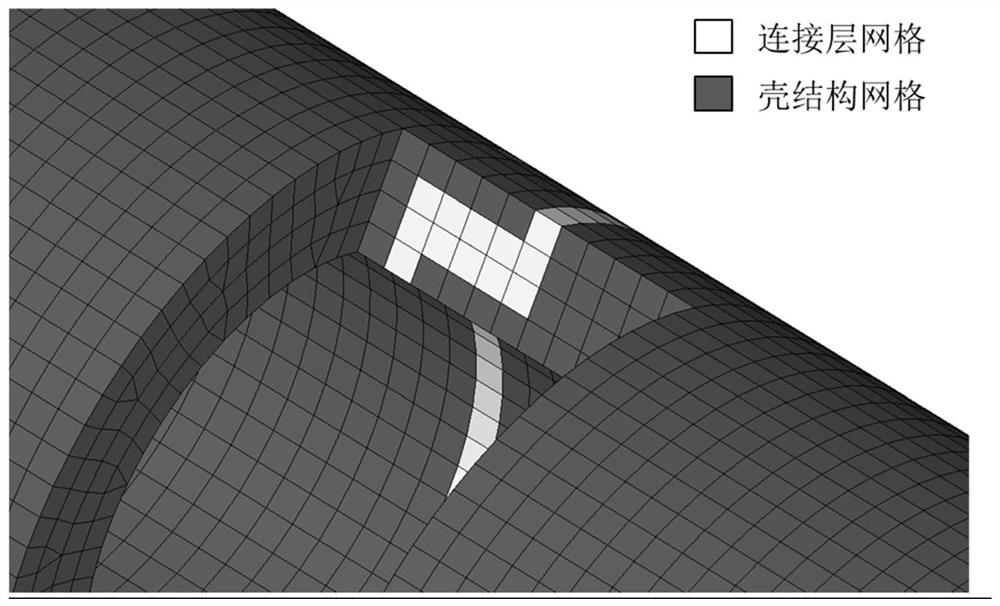

Method for rapidly generating plate-type satellite-structure node merging grids

InactiveCN105677965AEliminate gapsAvoid introducingGeometric CADDesign optimisation/simulationGeometric modelingElement modeling

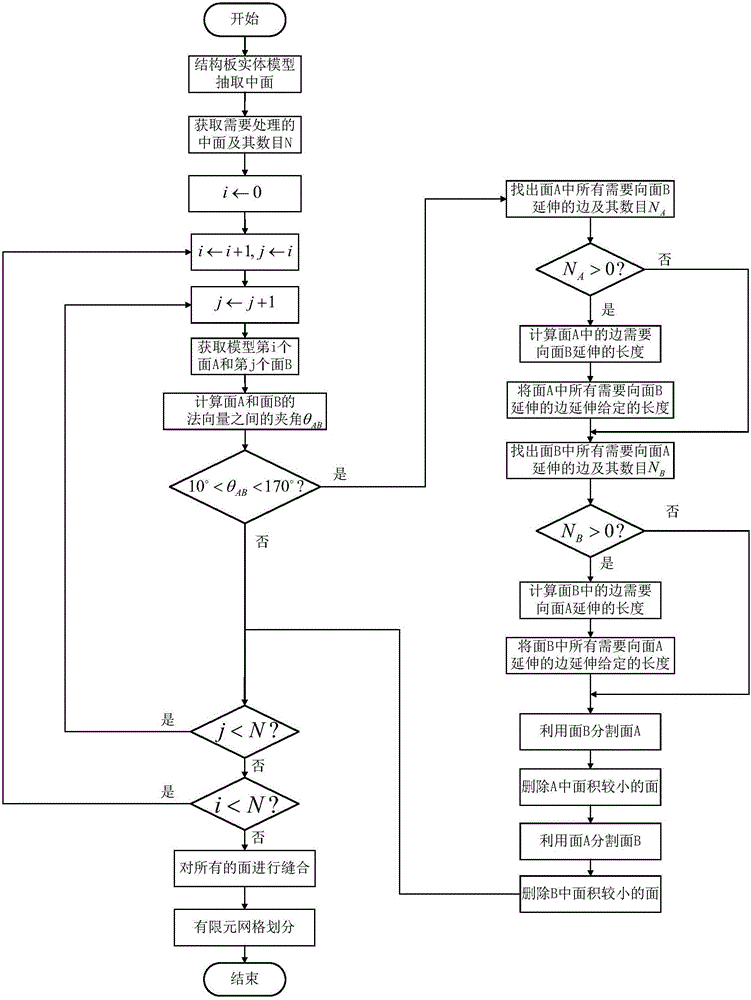

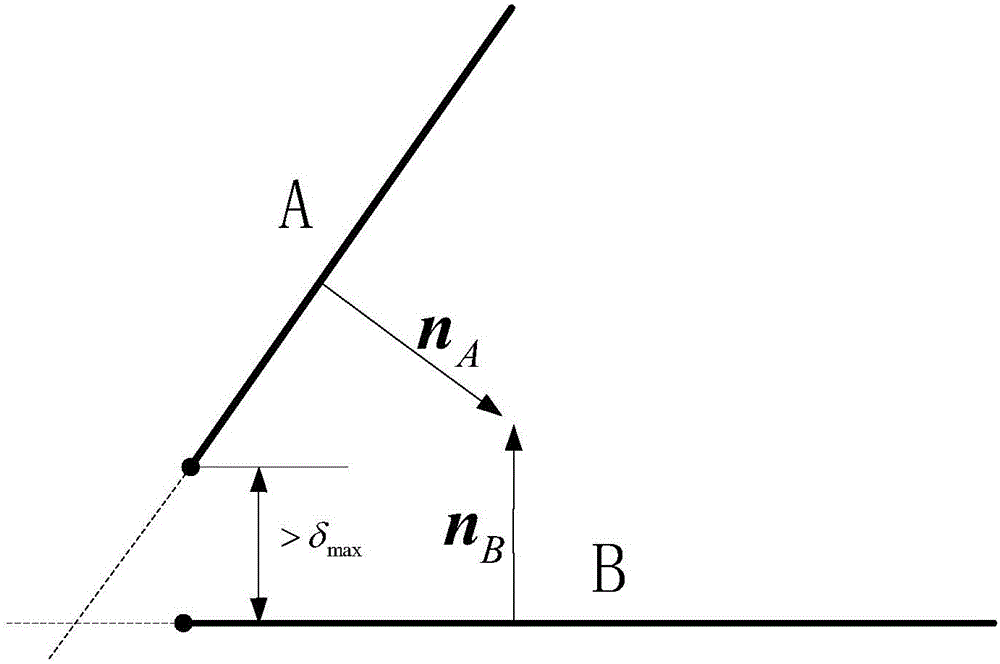

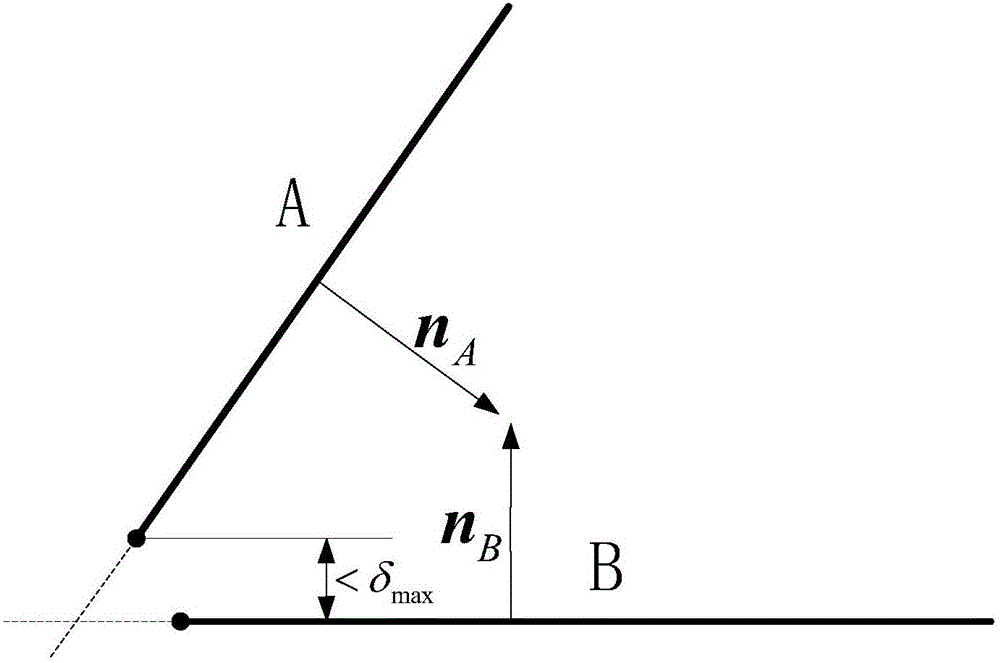

The invention discloses a method for rapidly generating plate-type satellite-structure node merging grids. The method includes the following steps that 1, middle surfaces of a satellite-structure geometric model introduced into finite element modeling software are extracted; 2, to-be-processed middle surface sets and the number N of elements of the middle surface sets are obtained; 3, related operation is carried out on all surface pairs (A, B); 4, all the surfaces are sutured; 5, the geometric model of the structure is divided into finite element grids. According to the method, the geometry obtained in the mode that the middle surfaces of the satellite-structure three-dimensional solid model are extracted can be automatically processed, gaps between the faces are eliminated, redundant parts are deleted, and the high-quality node-merging finite element grids can be divided through the finally-generated geometric model. A large amount of human-computer interaction operation is avoided, required time is short, universality is high, the application range is wide, and the quite-high practical engineering value is achieved.

Owner:BEIHANG UNIV

Finite element modeling method of thermal barrier coating of turbine blade with multiple cooling channels

ActiveCN103886164AThe calculation result is accurateHigh speedSpecial data processing applicationsElement modelMetamodeling

The invention relates to a finite element modeling method of a thermal barrier coating of a turbine blade with multiple cooling channels. The finite element modeling method includes the steps of firstly, modeling a whole turbine blade without the cooling channels, wherein the particular modeling process includes the steps of tenon modeling and blade body modeling; then building a geometric model of the turbine blade with the multiple cooling channels, wherein the modeling process includes the steps of modeling a blade body part with the multiple cooling channels, modeling a tenon part with the multiple cooling channels and connecting the two models. The finite element modeling method is completely carried out in finite element software ABAQUS, and the problem of mismatching, caused by incomplete compatibility of multiple pieces of software, between parts is solved; in addition, the true shape of a tenon and the practical condition that the turbine blade is provided with the multiple cooling channels are considered during building of the geometric model, the built finite element model of the thermal barrier coating of the turbine blade is close to the practical condition, and computing results of follow-up temperature field and stress field analysis are accurate.

Owner:XIANGTAN UNIV

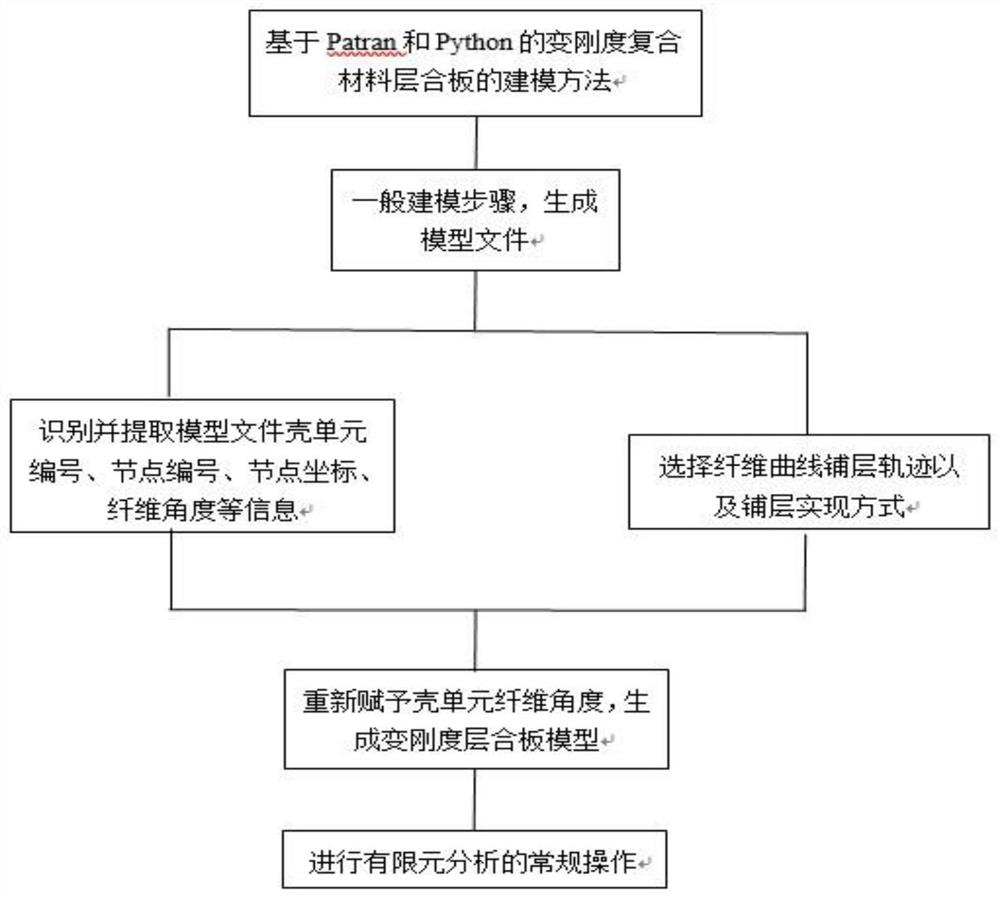

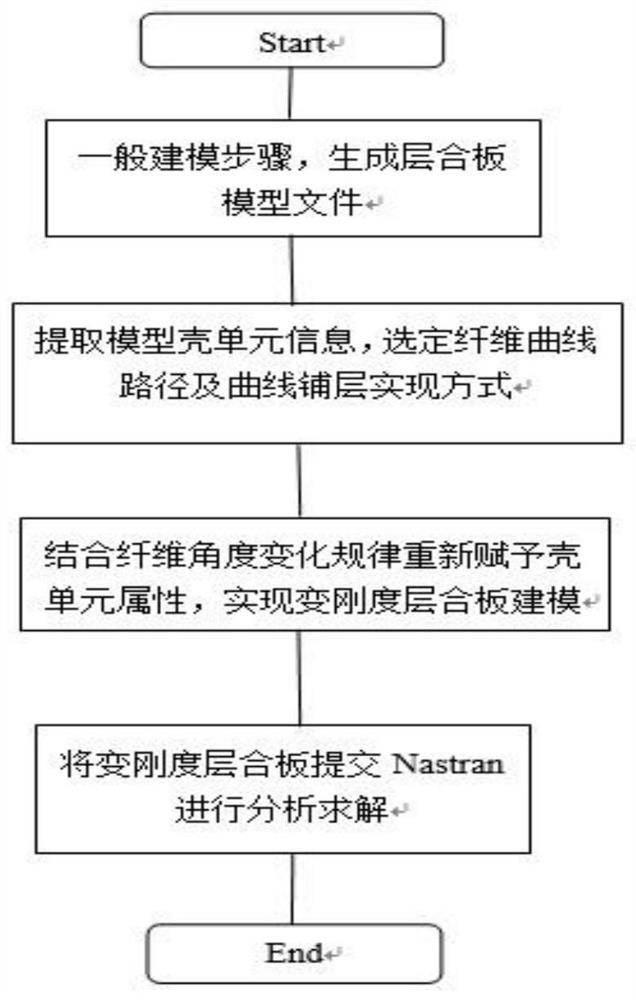

Finite element modeling method for variable stiffness composite laminate

InactiveCN111898295AFinite element modeling implementationRealize layingDesign optimisation/simulationSpecial data processing applicationsPython (programming language)Fiber

The invention discloses a finite element modeling method for a variable stiffness composite laminate. The method includes performing programming through Python and a PCL language; directly extractingthe fiber angle and node information of a laminated plate shell unit in a finite element model established by a Patran finite element through an operation file; calculating a central node coordinate of each shell unit, if the size of the shell unit is relatively small, approximately regarding the fiber angle of the point as the fiber angle of the unit, and finally re-endowing the fiber angle of each shell unit with the attribute of the shell unit according to a set curve track, thereby realizing fiber curve laying of the laminated plate. A variable stiffness laminate model is obtained by combining Patran and Python, then the model is submitted to Nastran to be solved and analyzed, and visualization processing is carried out through Patran import. According to the method, two programming languages of Python and PCL are combined, other platforms are not needed, and finite element modeling of the variable-rigidity laminated plate can be achieved through Patran.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

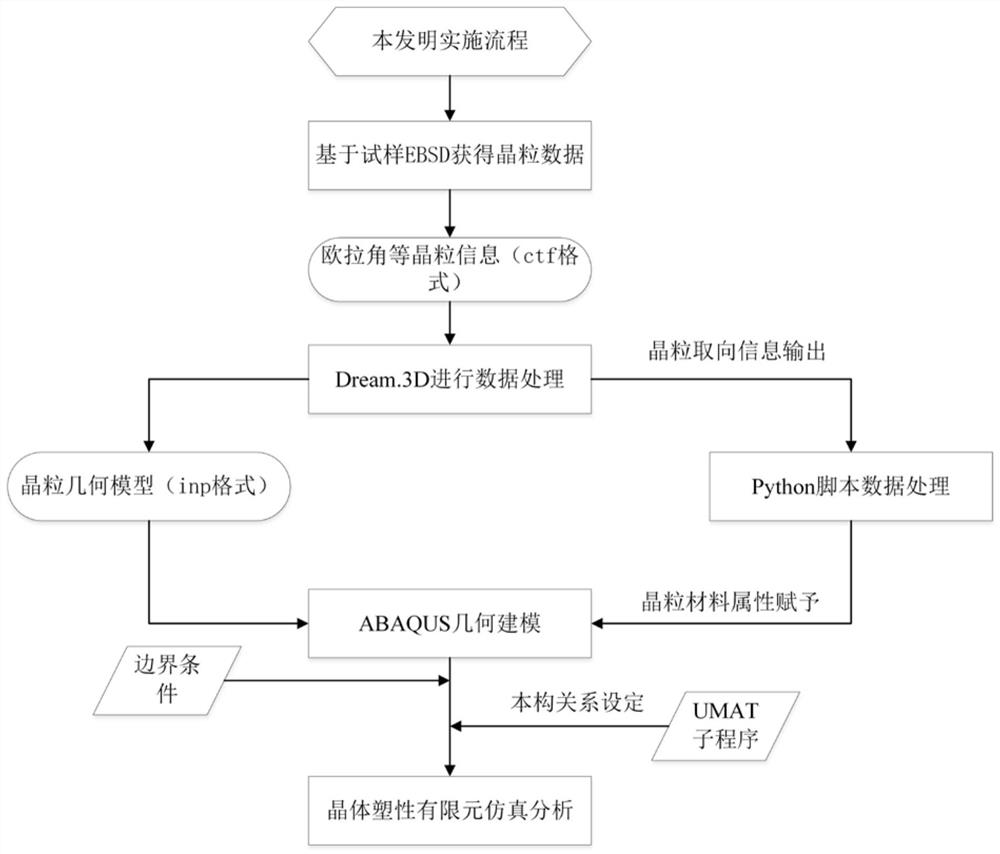

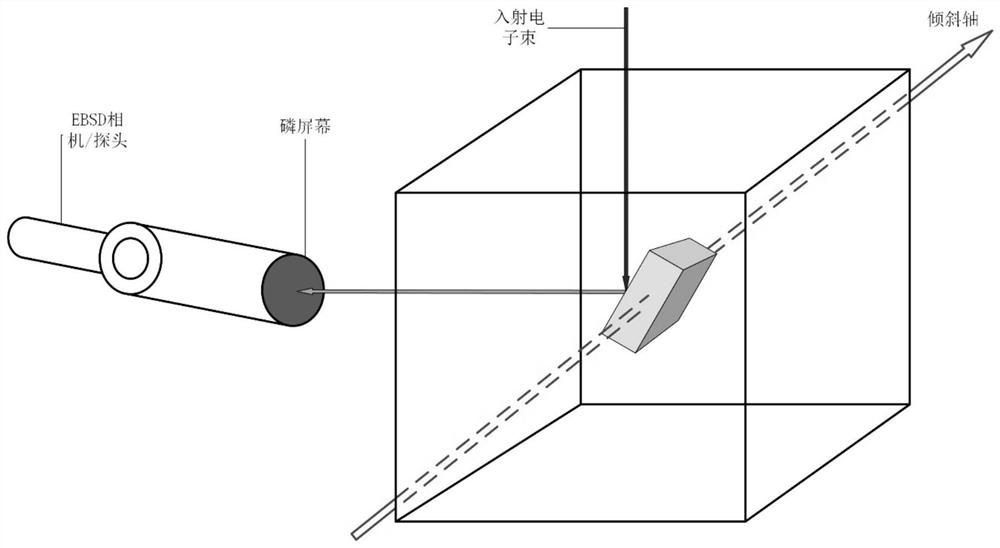

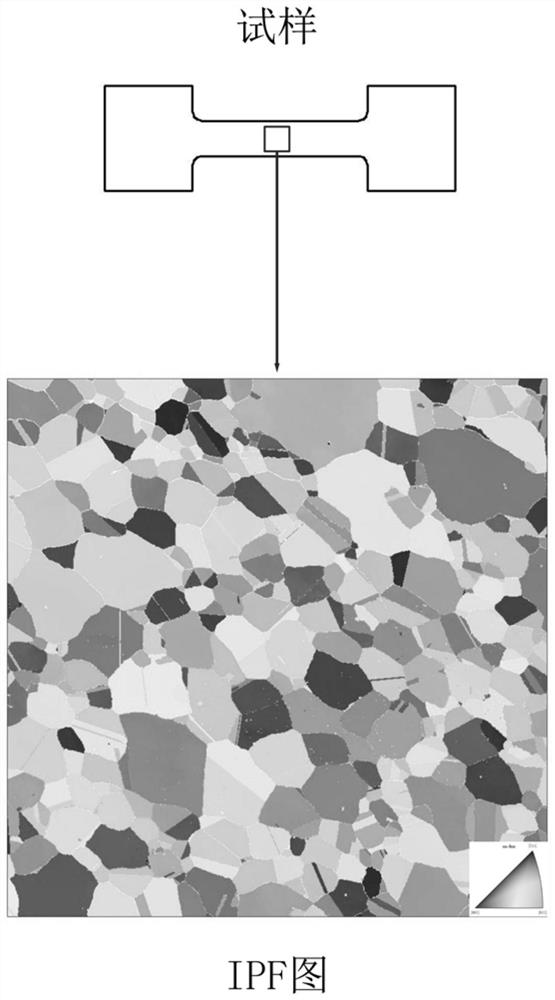

Crystal plasticity finite element modeling simulation method

PendingCN113987695AMechanical performance simulation prediction is convenientThe convenience of simulation predictionGeometric CADDesign optimisation/simulationComputational sciencePython language

The invention discloses a crystal plasticity finite element modeling simulation method. The method comprises the following steps of acquiring grain information based on EBSD analysis; importing a ctf format file generated by EBSD analysis into Drem.3D software to realize automatic reconstruction of a crystal grain structure, and outputting an input file and geometric orientation data of each crystal grain; processing the grain geometric orientation data through a Python language script to obtain average geometric orientation information of each grain; combining the grain average geometric orientation information with the input file by using a Python script to generate a complete input file with geometric model information and material attribute information; giving boundary conditions to the model in ABAQUS finite element analysis software, and setting a constitutive relation of the model by utilizing a UMAT subprogram, so that the whole crystal plasticity finite element analysis process is realized. The process of crystal plastic finite element modeling and simulation analysis is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

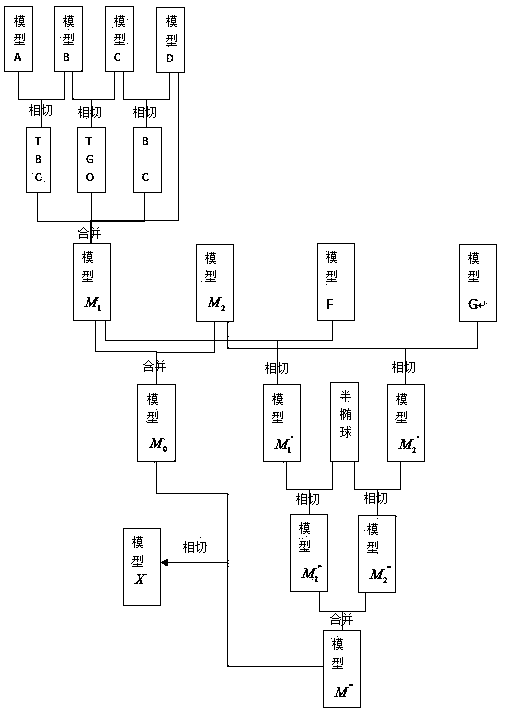

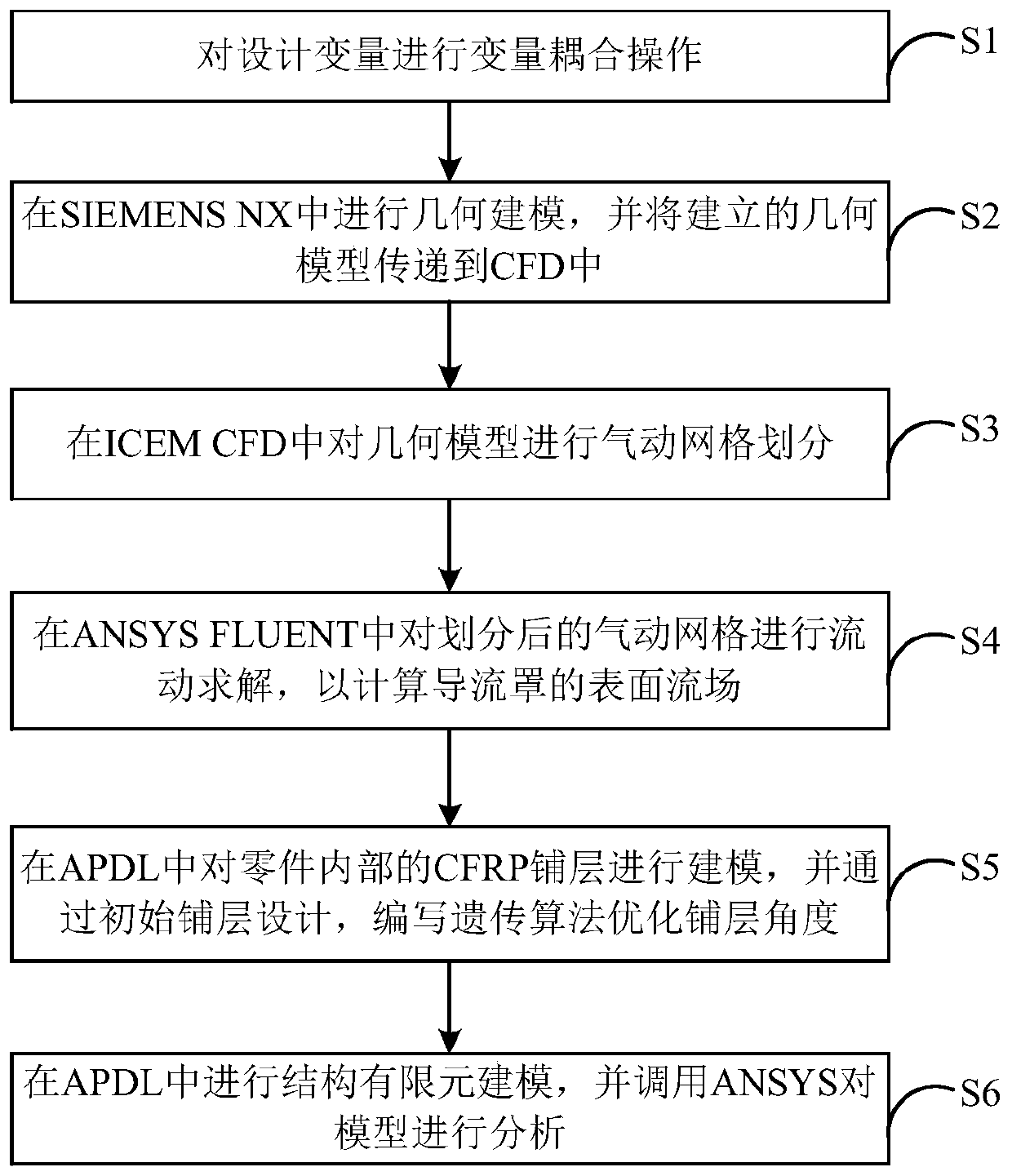

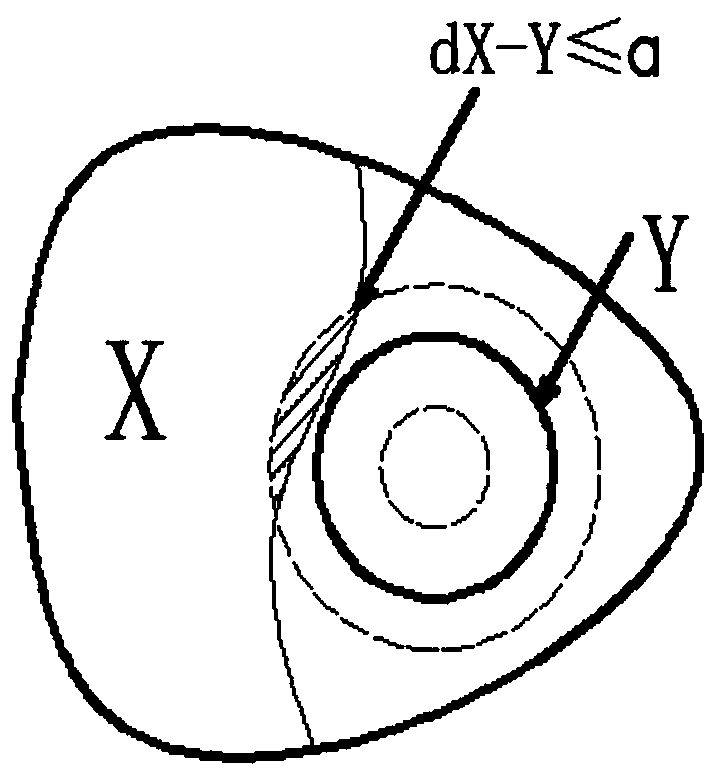

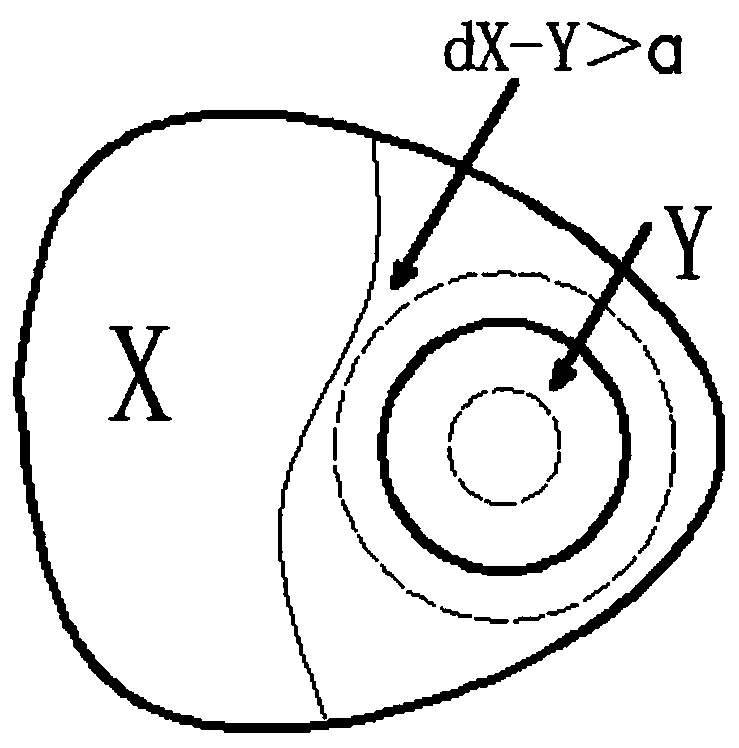

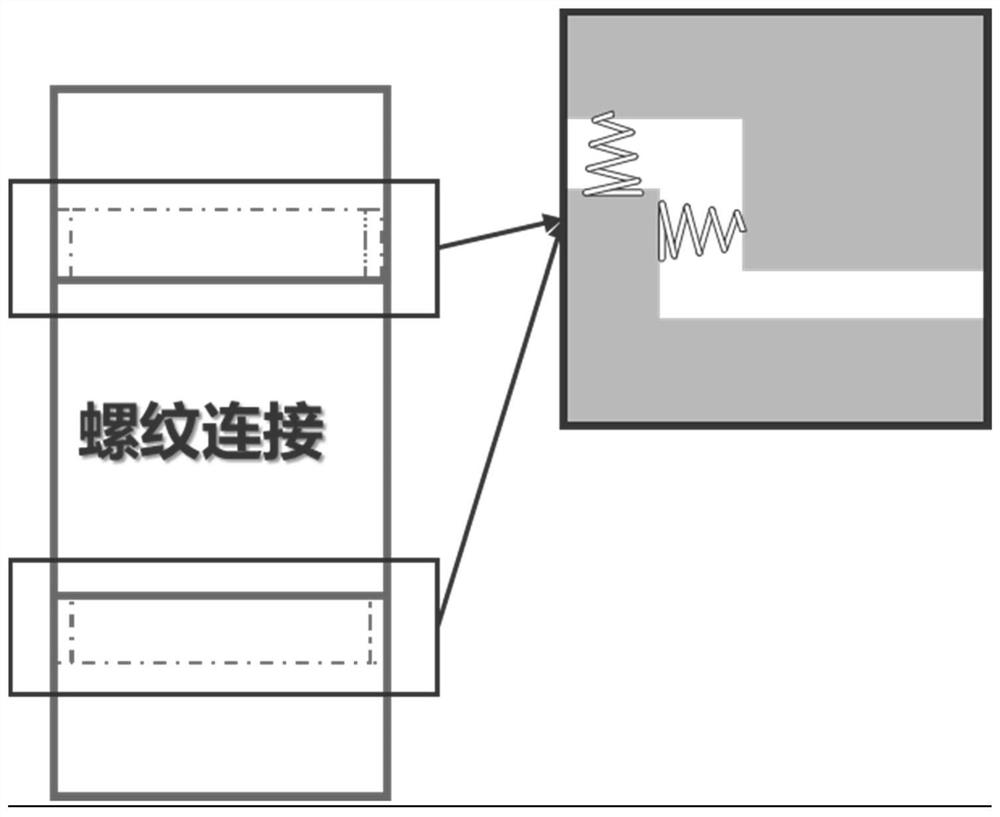

CFRP air guide sleeve integrated design method based on variable coupling and software integration

PendingCN111563339ADesign optimisation/simulationSpecial data processing applicationsMetamodelingGenetics algorithms

The invention provides a CFRP air guide sleeve integrated design method based on variable coupling and software integration. The CFRP air guide sleeve integrated design method comprises the steps thatvariable coupling operation is conducted on design variables; geometric modeling is carried out in the SIEMENS NX, and the established geometric model is transmitted to the CFD; aerodynamic mesh generation is carried out on the geometric model in ICEM CFD; flow solving is carried out on the divided aerodynamic grids in ANSYS FLUENT to calculate a surface flow field of the air guide sleeve; a CFRPlayer in the part in the APDL is modeled, and a genetic algorithm is compiled to optimize a layer angle through initial layer design; and structural finite element modeling is performed in the APDL,and ANSYS is called to analyze the model. According to the method, cooperation of multiple disciplines such as part macrostructure disciplinary optimization, microcosmic material layering disciplinaryoptimization and fluid dynamics can be considered at the same time, and the parts are integrally designed.

Owner:JIANGSU UNIV OF TECH

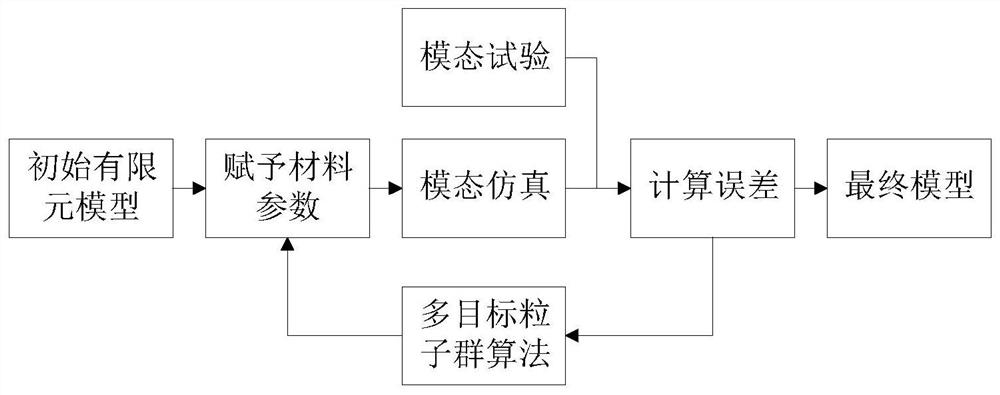

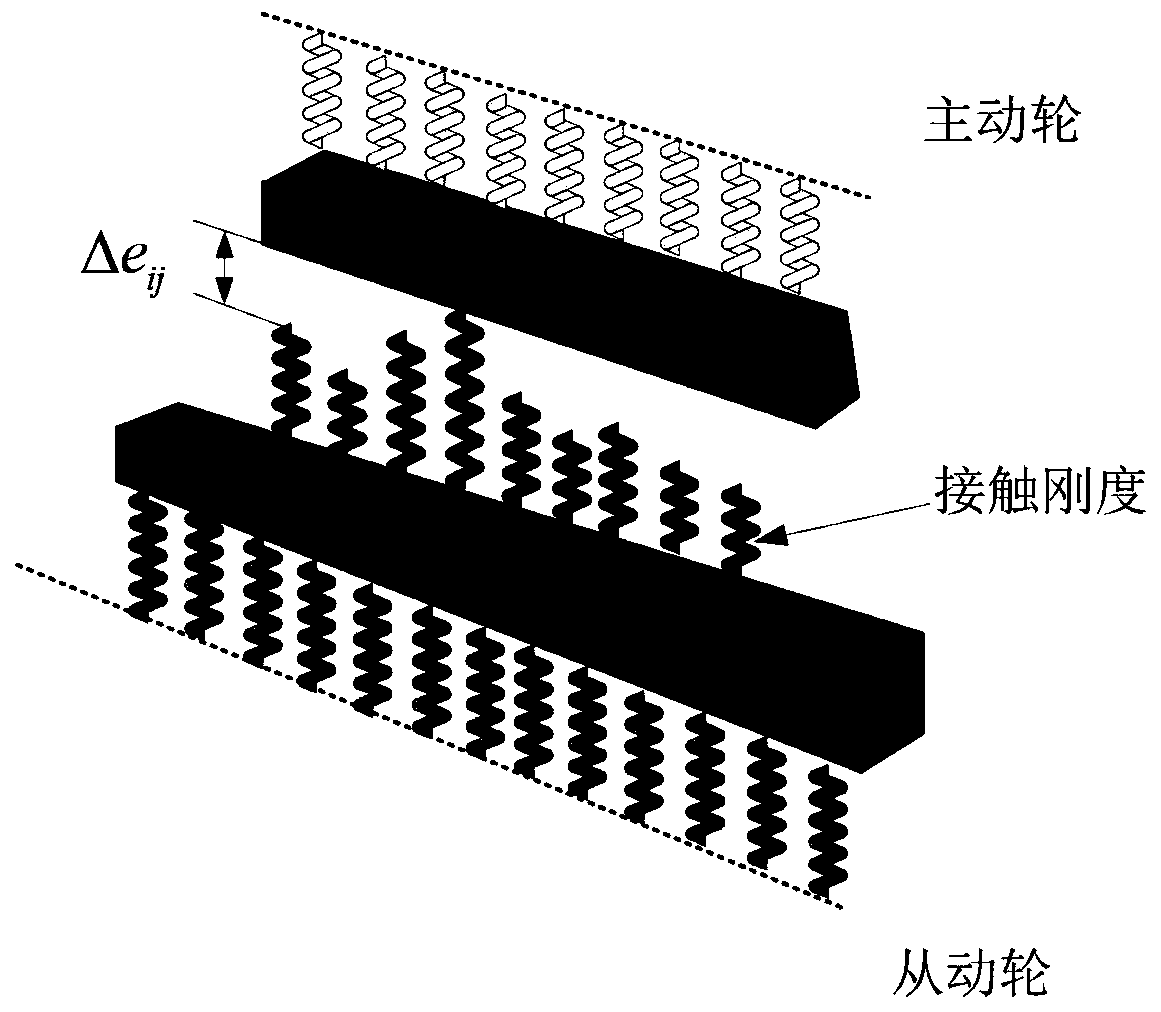

Finite element modeling and correcting method and system for structure with connection relationship

ActiveCN112685841ASimultaneous approximationOptimizing Modal ParametersGeometric CADInternal combustion piston enginesElement modelAlgorithm

The invention discloses a finite element modeling and correcting method and system for a structure with a connection relationship. The method comprises the following steps: establishing an initial finite element model of the structure with the connection relationship; carrying out a modal test on the structure with the connection relationship; performing simulation calculation on the finite element model to obtain a simulation result; comparing the simulation result with the test result to obtain a result error; using an optimization algorithm to transmit a result error, correcting the connection layer grid, and performing simulation calculation on the corrected finite element model to obtain a corrected simulation result; and iterating to a preset convergence condition to obtain a corrected final finite element model, and completing finite element modeling and correction. According to the method, equivalent modeling is carried out on a connection part in an engineering structure by adopting a connection layer grid, and grid parameters are corrected by adopting a multi-target particle swarm algorithm to obtain an accurate finite element model.

Owner:XI AN JIAOTONG UNIV

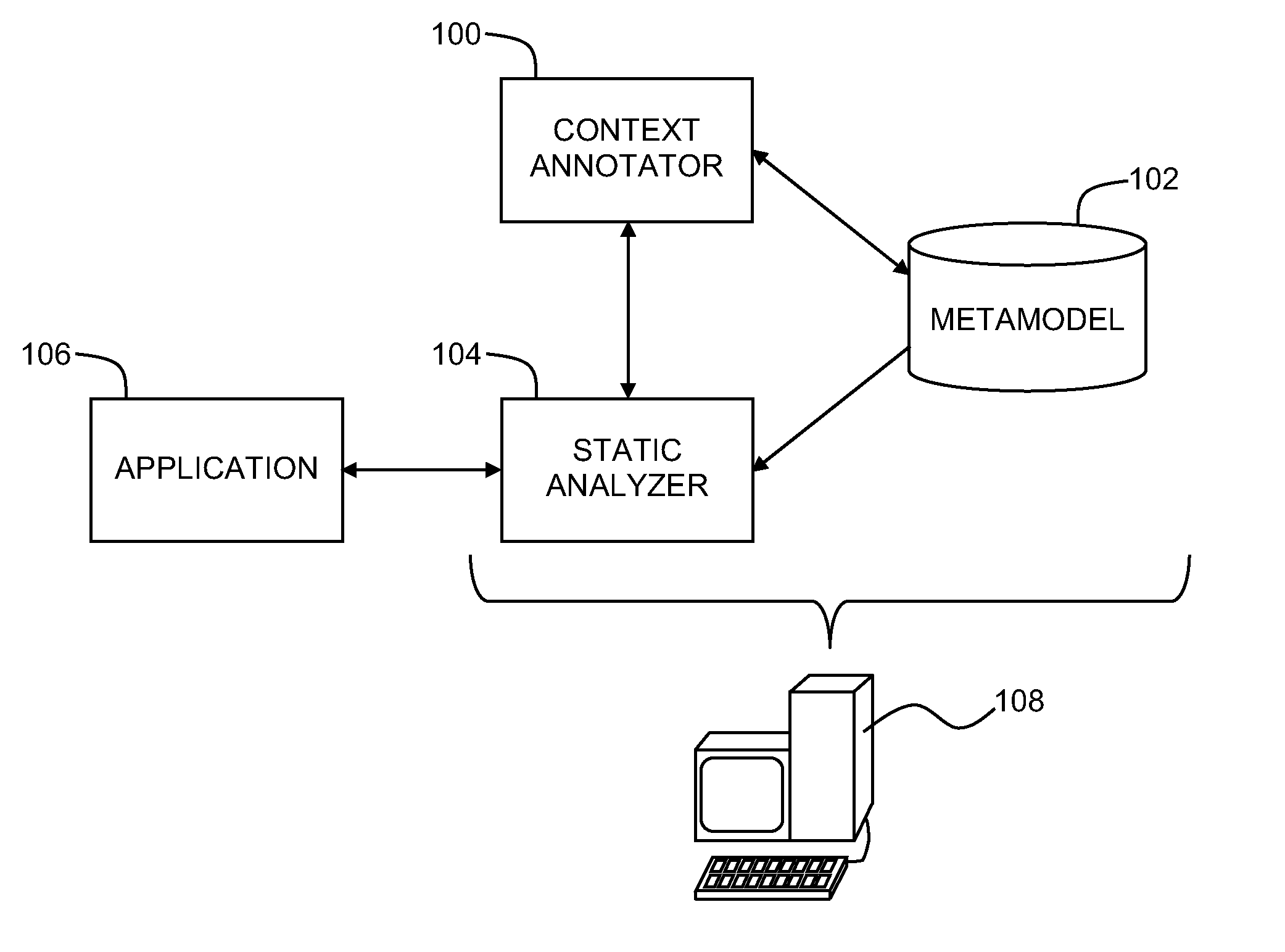

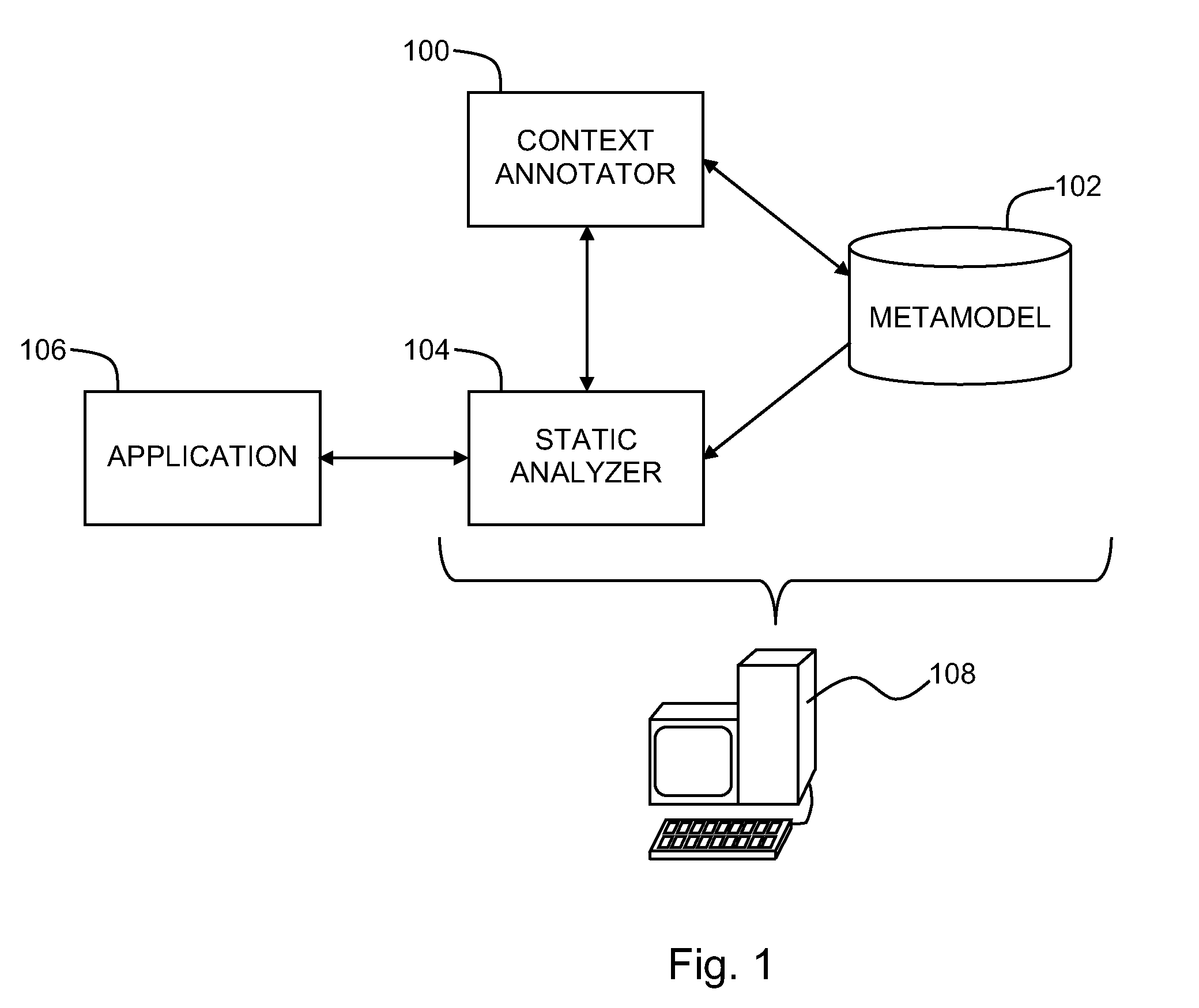

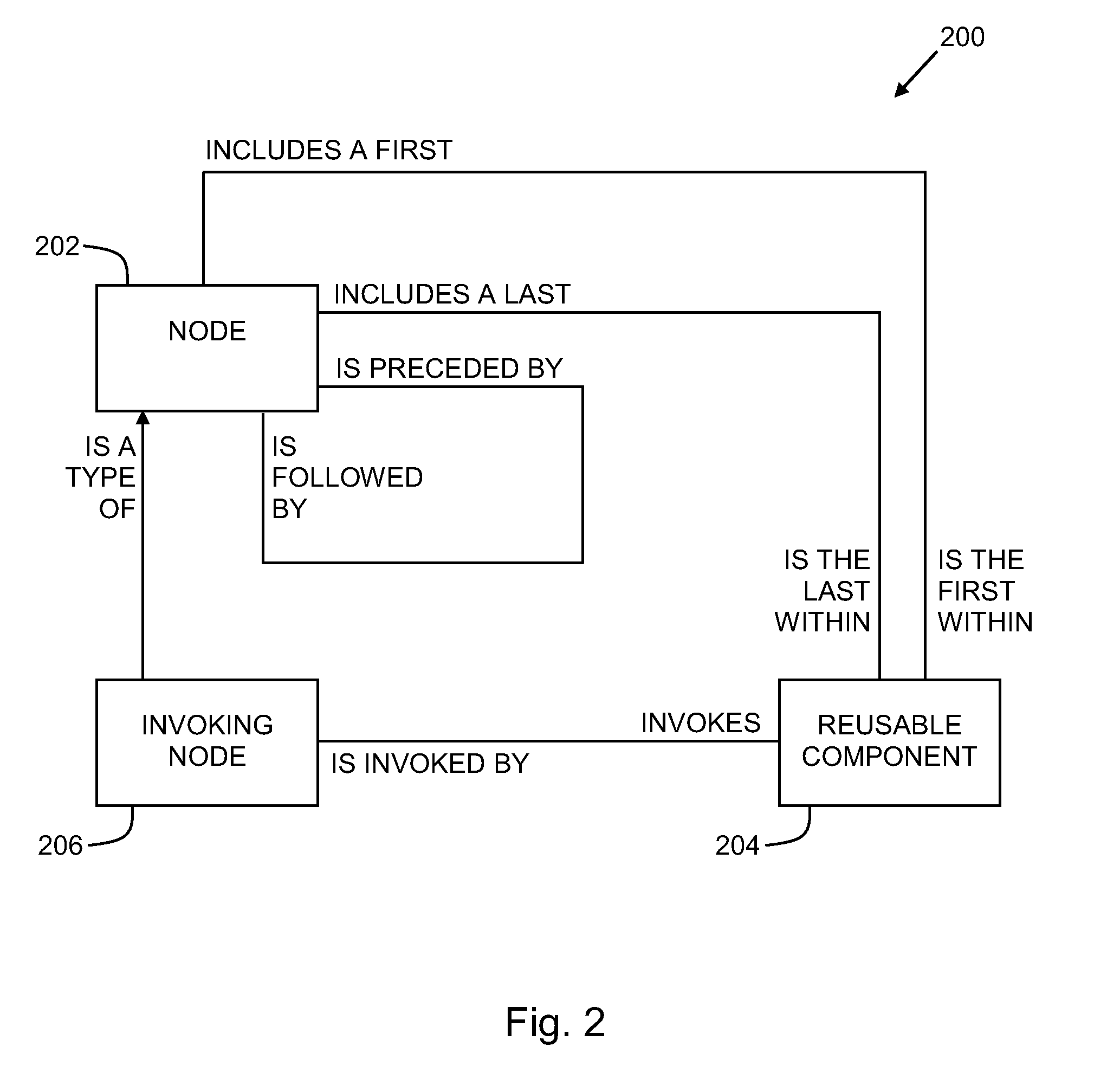

Metamodeling Contextual Navigation of Computer Software Applications

Using metamodels during context-sensitive analyses of reusable components of computer software applications, including identifying entry and exit paths into and from a reusable component within a metamodel of a computer application development environment, determining during a static analysis of a computer software application that navigation will proceeds along a path corresponding in the metamodel to such an entry or exit path, retaining, if an entry path, an identifier of an invoking node along the path within the computer software application, and, if an exit path, for each terminal node along each of a plurality of paths from the reusable component within the computer software application, comparing an identifier of an invoking node preceding the terminal node with the retained invoking node identifier, and determining, if the invoking node identifiers match, that the path among the plurality of paths is a correct path for a current context of the static analysis.

Owner:IBM CORP

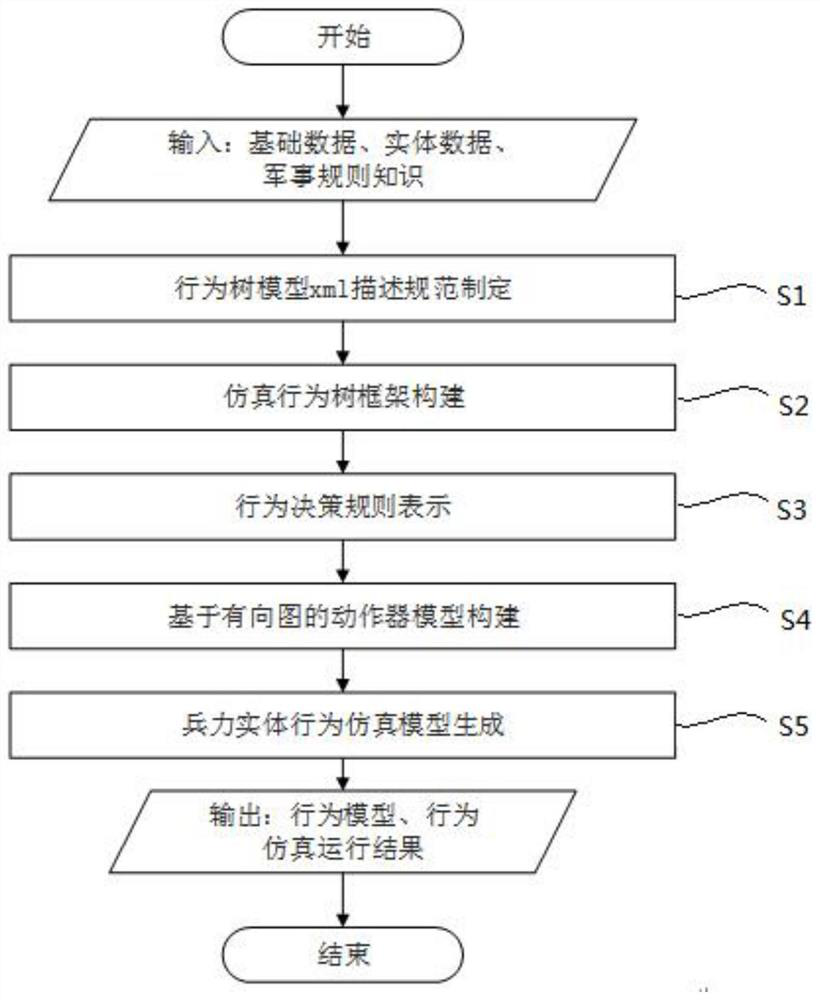

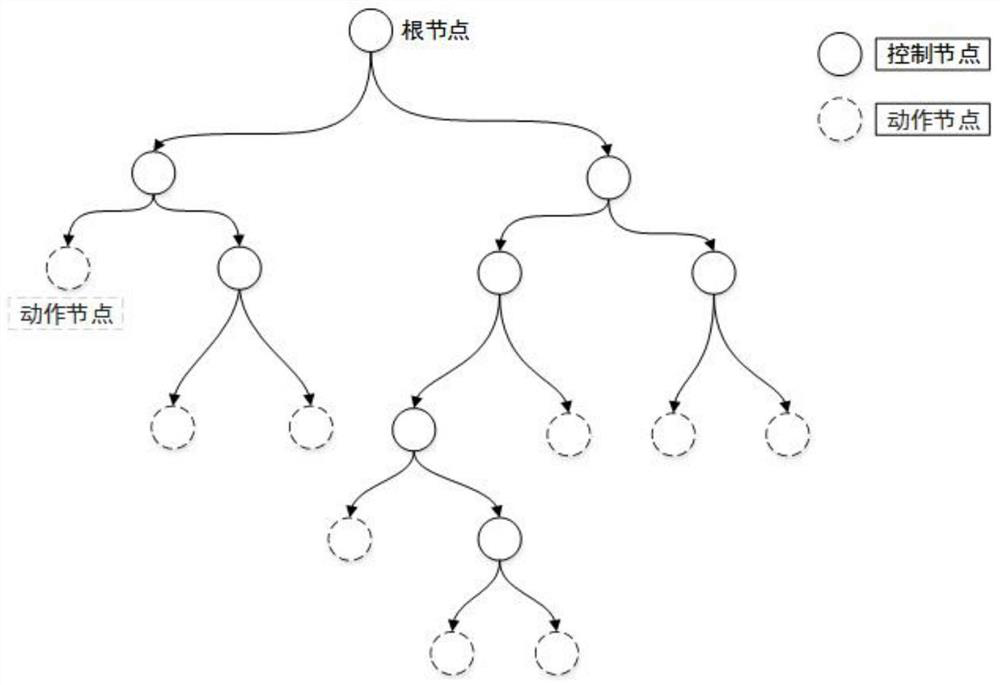

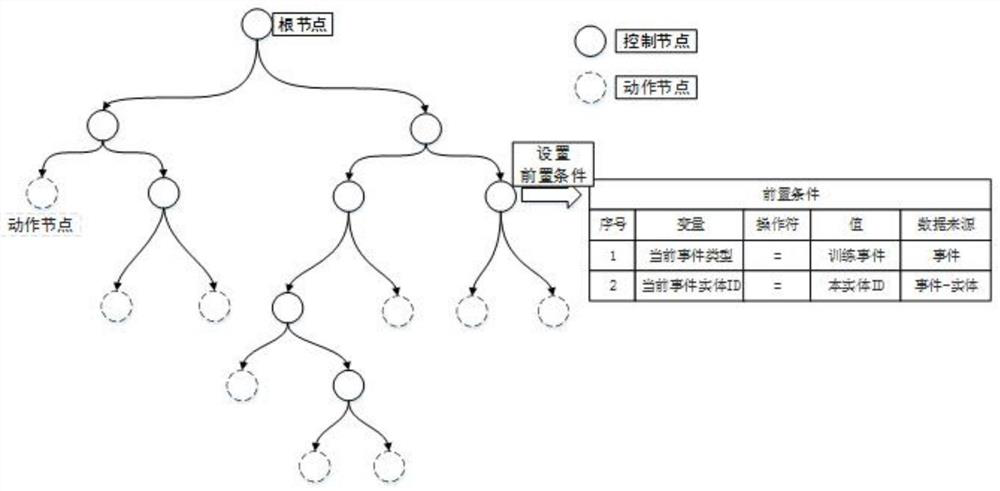

Weapon strength entity behavior simulation meta-modeling method and system based on improved behavior tree

ActiveCN114201885AFlexible configurationResolve Details Not VisibleData processing applicationsDesign optimisation/simulationMetamodelingTheoretical computer science

The invention discloses a military strength entity behavior simulation meta-modeling method based on an improved behavior tree, and the method comprises the steps: formulating a behavior tree model xml description specification, building a simulation behavior modeling tool, and outputting a behavior tree model xml file; improving the behavior tree, and constructing a simulation behavior tree framework; preconditions are set for the behavior tree nodes, and behavior decision rules are formed through the behavior tree nodes, the multi-way tree structure relation between the behavior tree nodes and the preconditions; constructing an actuator model; and on the basis of the simulation behavior tree framework, behavior decision rule representation and actuator model construction, generating a military strength entity behavior simulation model according to a process. According to the method, an effective solution is provided for military strength entity behavior meta-modeling and simulation from the aspects of model specifications, behavior trees and directed graph technologies, and the problems that bottom-layer technical details of behavior modeling of a simulation platform / engine are invisible, and model parameter configuration is not flexible are solved; the method can be widely applied to equipment support behavior simulation modeling, combat behavior simulation modeling and the like.

Owner:AEROSPACE INTERNET OF THINGS TECH CO LTD +1

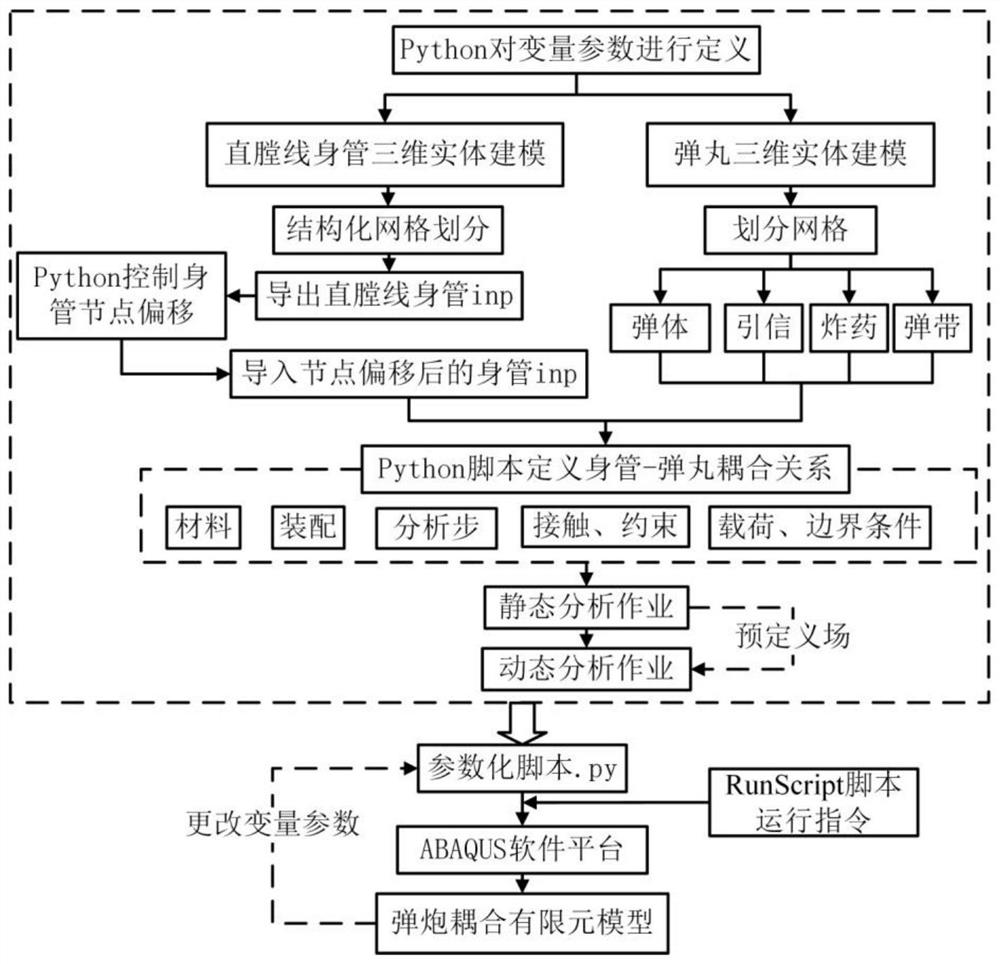

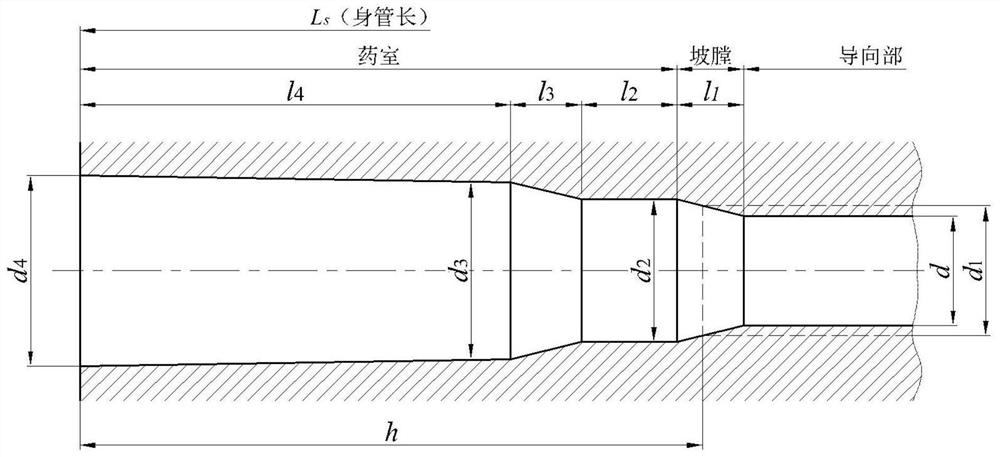

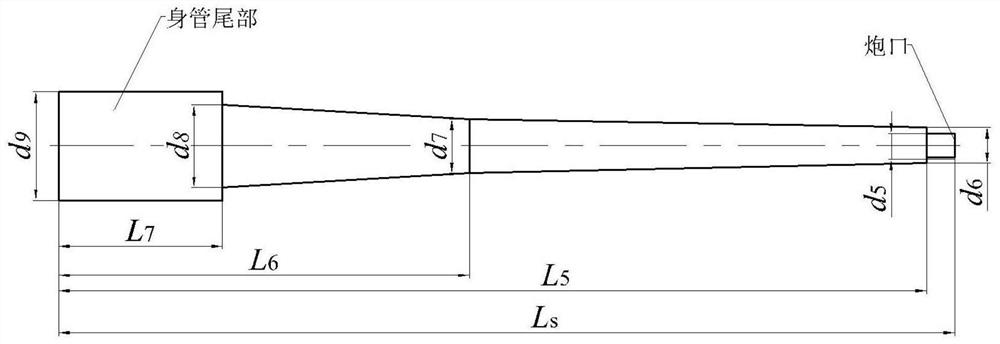

Missile-gun coupling finite element parametric modeling method

ActiveCN112784458AGenerate fastImprove modeling efficiencySustainable transportationDesign optimisation/simulationPython languageElement model

The invention provides a missile-gun coupling finite element parameterized modeling method, and relates to the technical field of mechanical structure parameterized modeling. A chamber barrel missile-gun coupling finite element modeling process is described through a Python language, and a missile-gun coupling finite element model is established by using a script, so that the establishment of the missile-gun coupling finite element model is more convenient and faster. The method mainly comprises: firstly, establishing a barrel and projectile two-dimensional sketch, realizing full constraint on the two-dimensional sketch and defining parameterized variables, automatically generating a three-dimensional model according to the two-dimensional sketch, shifting barrel nodes by adopting a Python language according to a winding angle change rule, and establishing a coupling relationship between the projectile and the barrel by adopting Python description. According to the method, automatic change of the missile-gun coupling finite element model and automatic update of the numerical model are realized by adopting a programming technology, so that the modeling speed of the missile-gun coupling finite element model is increased, the design period is shortened, and the working efficiency is greatly improved.

Owner:NANJING UNIV OF SCI & TECH

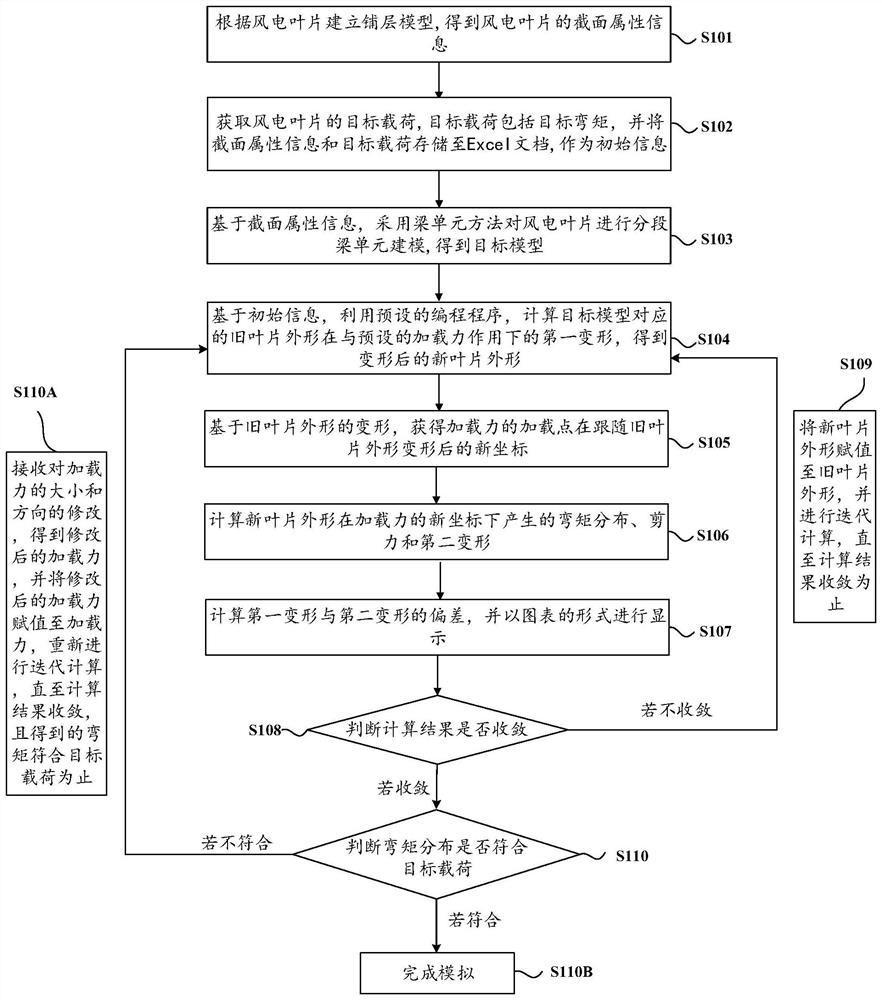

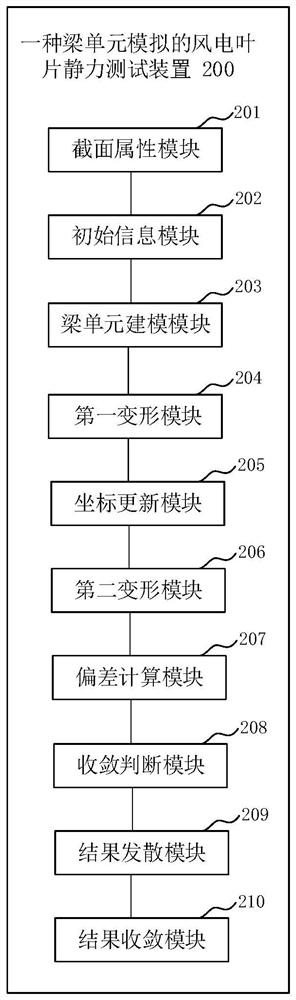

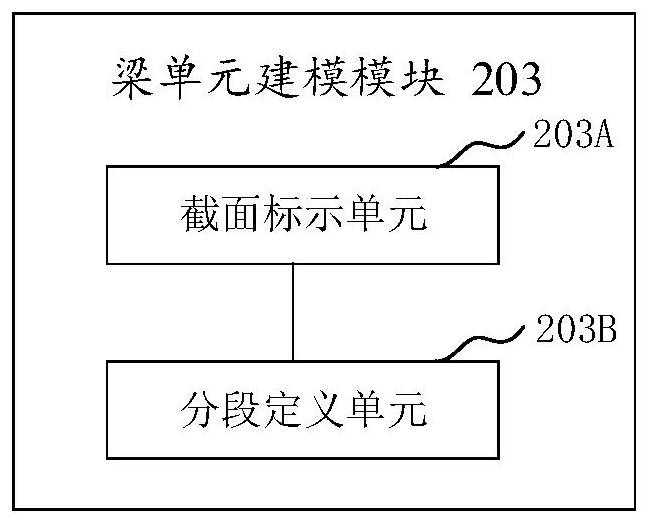

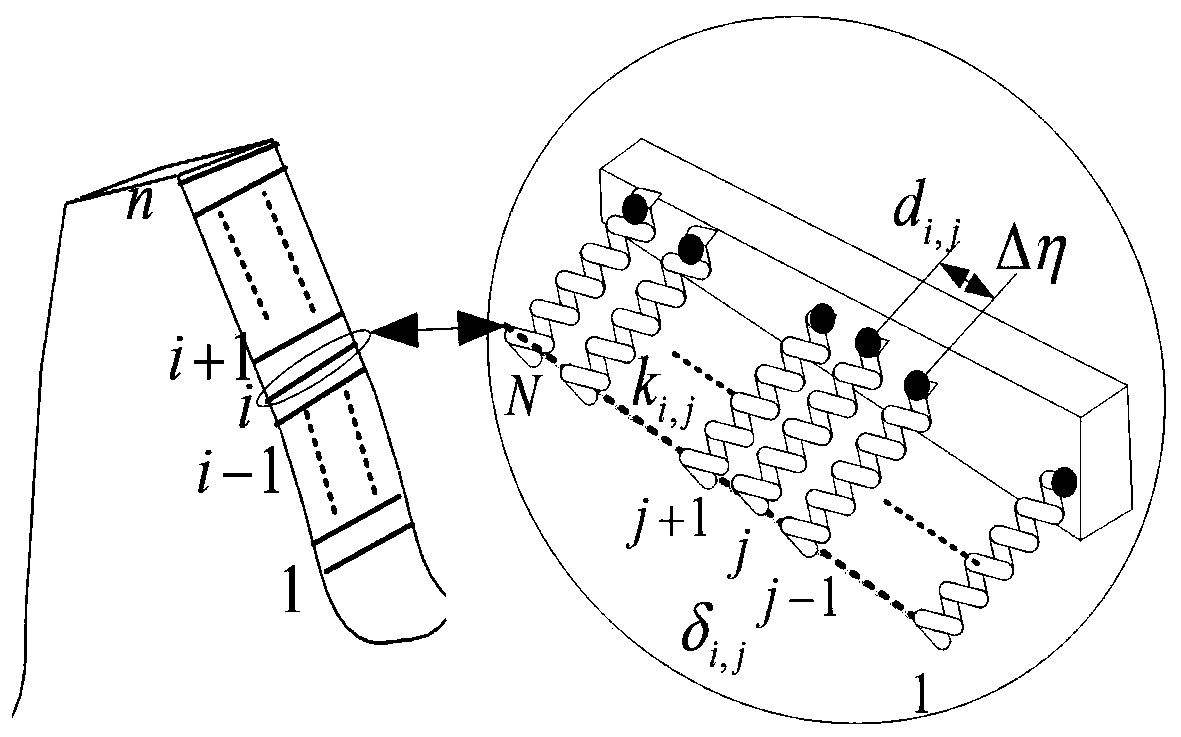

Beam unit simulated wind power blade static test method, device and equipment

ActiveCN111859690AFast convergenceEasy to operateGeometric CADDesign optimisation/simulationMetamodelingFinite element analysis software

The invention provides a beam element simulated wind power blade static test method, device and equipment. The method comprises the steps: carrying out the layering modeling on a wind power blade to obtain section attribute information, and storing the section attribute information and target load information required to be verified by design in an Excel document to serve as initial information for standby application; carrying out the modeling on the wind power blade in a beam element modeling mode, and calculating the bending moment and deformation of the wind power blade under the action ofloading force; and then, according to software prompts, adjusting the magnitude and direction of the loading force until deformation convergence and bending moment meet target load verification requirements, and completing the simulation of the static test scheme of the wind turbine blade. According to the scheme, the operation is easy, the ratio of the load of each iteration to the target load and the change of blade deformation along with the loading force can be displayed in real time, and simulation intuition is provided; the convergence speed of the calculation result is high, the calculation speed is increased, a self-made programming program is adopted as a whole to replace previous finite element analysis software, and the cost is reduced.

Owner:JILIN CHONGTONG CHENGFEI NEW MATERIAL

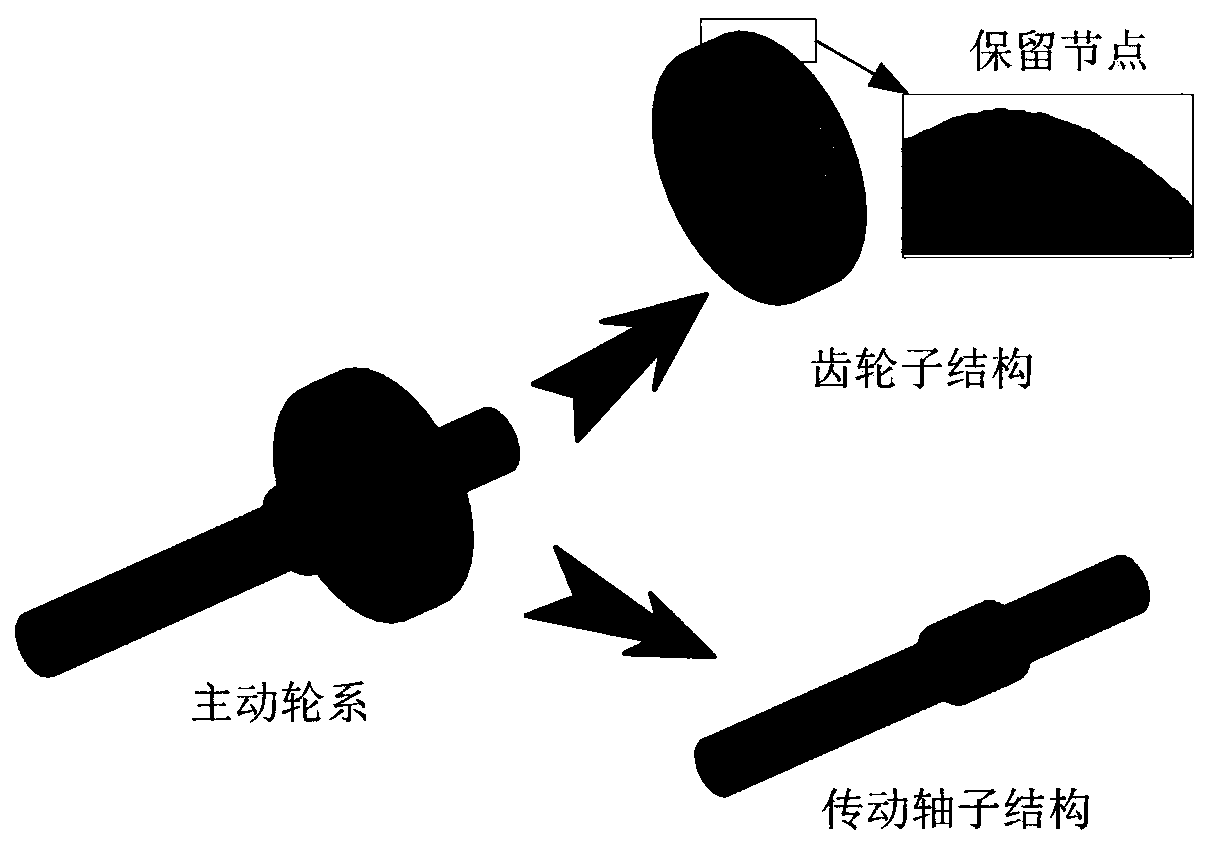

Three-dimensional entity unit modeling method of gear system

ActiveCN110807278AGuaranteed accuracyImprove computing efficiencyGeometric CADDesign optimisation/simulationAlgorithmGear wheel

A three-dimensional entity unit modeling method of a gear system comprises the steps that firstly, according to the structural characteristics of the gear transmission system, HYPERMESH software is used for preprocessing a complex structure, three-dimensional entity unit models of a gear substructure and a transmission shaft substructure are established respectively, and accurate division and optimization of grids are carried out; then, ANSYS software is used for carrying out modal analysis and extracting a mass matrix and a rigidity matrix; then, nonlinear factors such as time-varying rigidity are considered, and gear tooth meshing of the gear transmission system is modeled through the Pasternak elastic foundation beam theory; finally, according to the interface displacement coordinationcondition, integrating, coupling and dimensionality reduction are conducted on the models of the transmission shaft, the gear and the bearing system through a modal synthesis method, and a high-precision gear transmission system dynamic model matched with the dynamic characteristics of the equipment is established. According to the method, the model precision can be guaranteed, and the calculationefficiency can be remarkably improved, so that a more efficient and accurate method is provided for quantitative analysis of the vibration of the gear transmission system.

Owner:XI'AN PETROLEUM UNIVERSITY

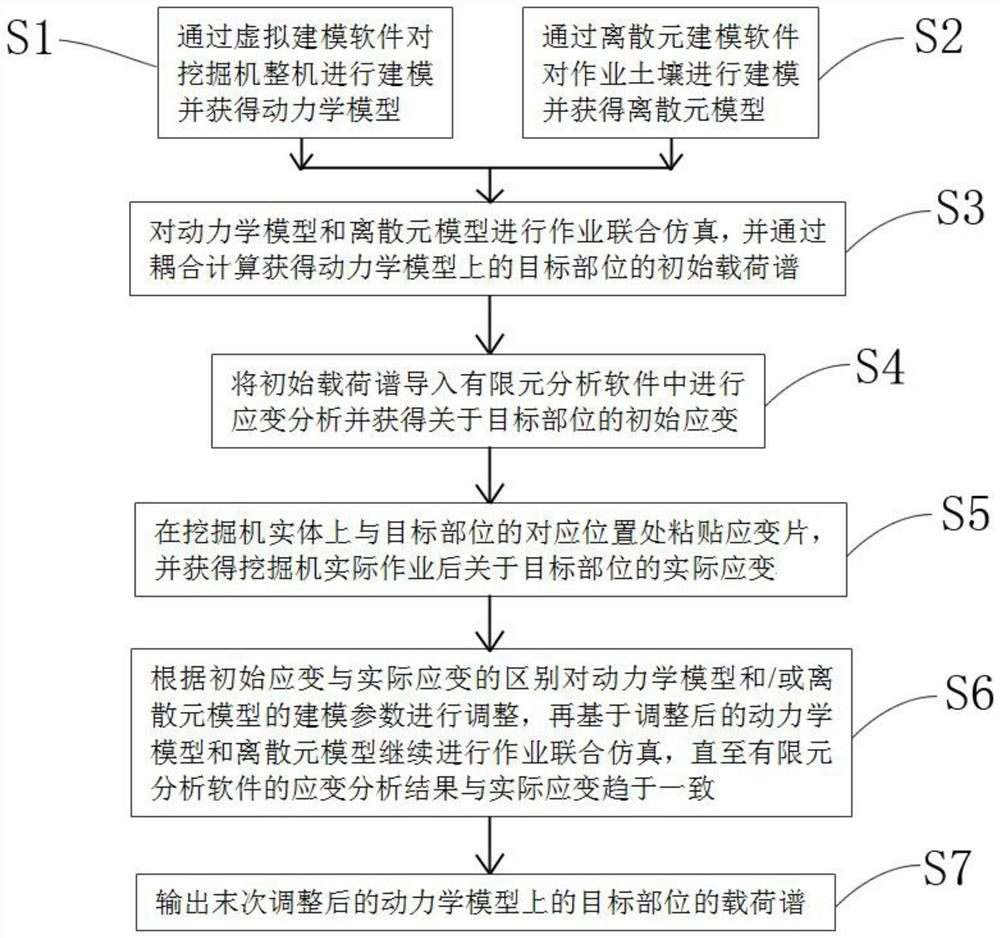

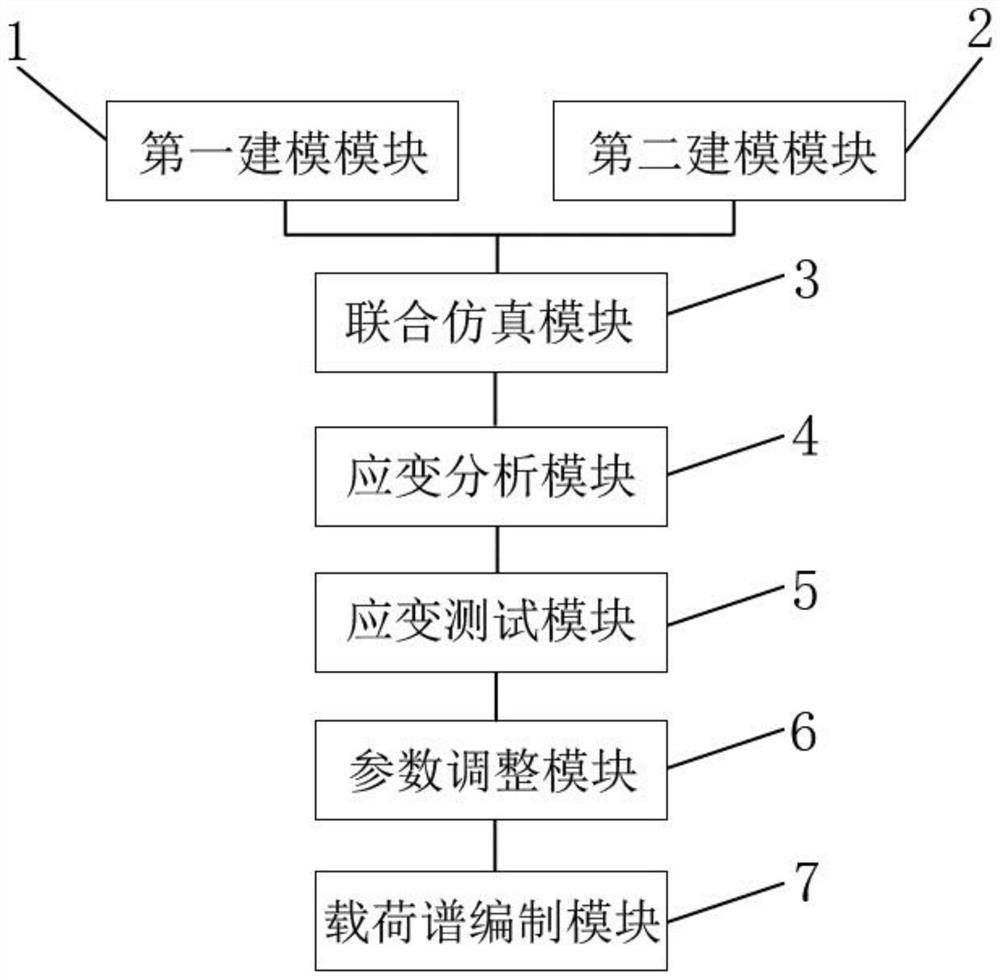

Excavator load spectrum compilation method and system

PendingCN114330058AImprove extraction accuracyReduce extraction costsGeometric CADDesign optimisation/simulationDynamic modelsMetamodeling

The invention discloses an excavator load spectrum compilation method and system. The excavator load spectrum compilation method comprises the steps that modeling is conducted on a whole excavator through virtual modeling software, and a dynamic model is obtained; modeling operation soil through discrete element modeling software and obtaining a discrete element model; performing operation joint simulation on the dynamical model and the discrete element model, and obtaining an initial load spectrum of a target part on the dynamical model through coupling calculation; the initial load spectrum is imported into finite element analysis software for strain analysis, and initial strain about the target part is obtained; a strain gauge is pasted to the position, corresponding to the target part, of the excavator entity, and the actual strain of the excavator about the target part after actual operation is obtained; adjusting modeling parameters of the dynamical model and / or the discrete element model according to the difference between the initial strain and the actual strain; and outputting the load spectrum of the target part on the dynamical model after the last adjustment. The method can improve the extraction precision and accuracy of the load spectrum, and reduces the extraction cost.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

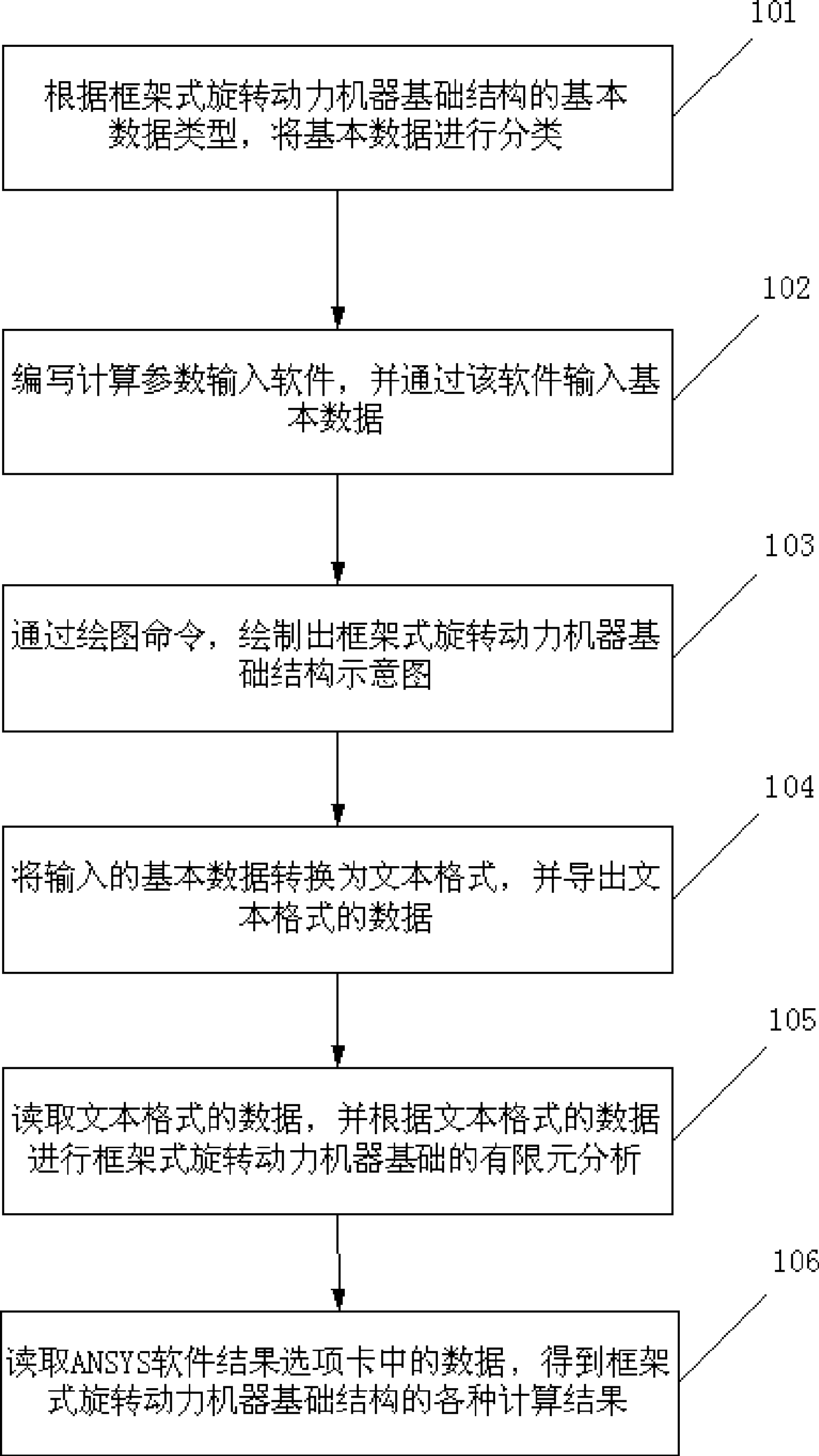

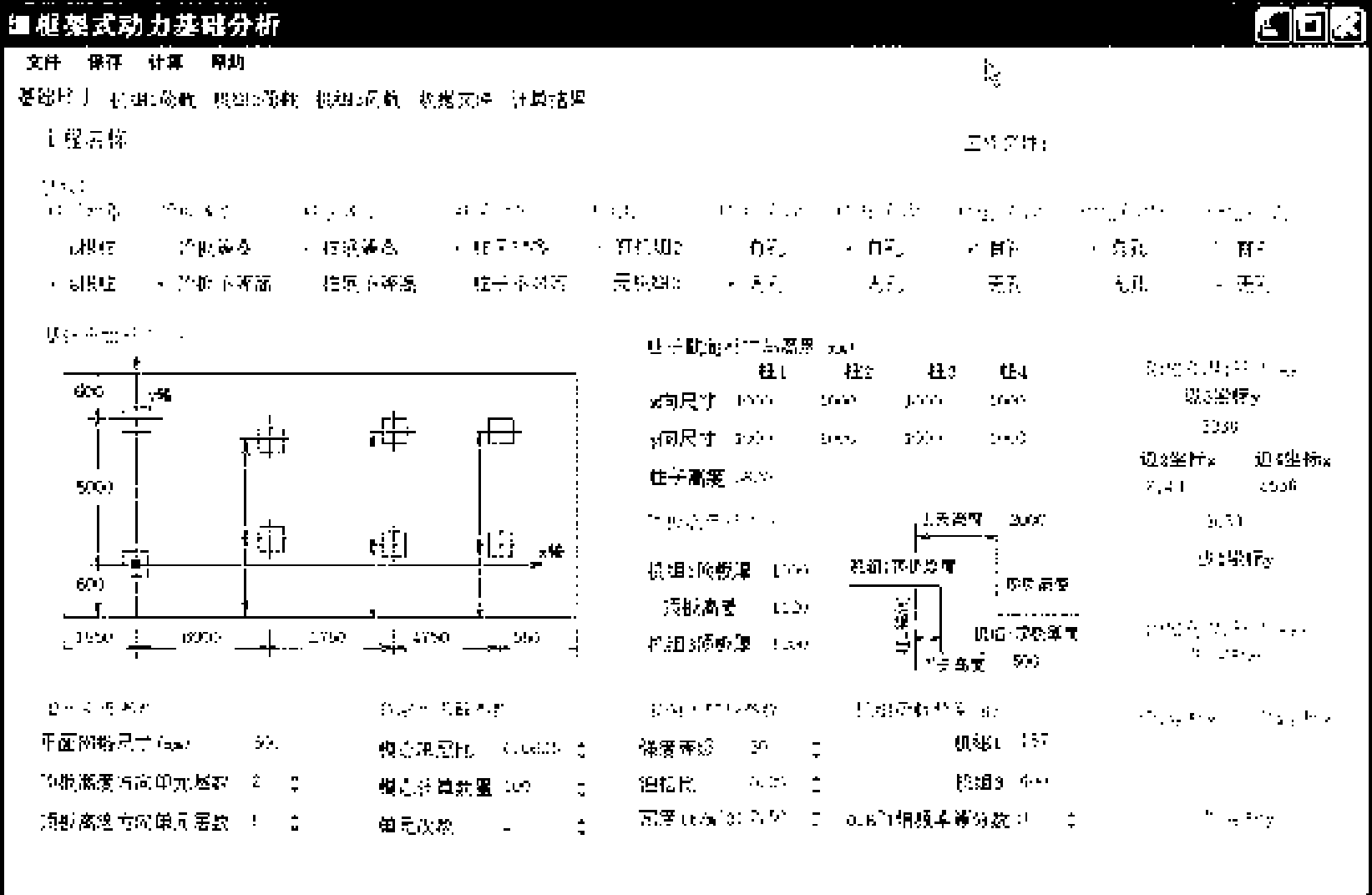

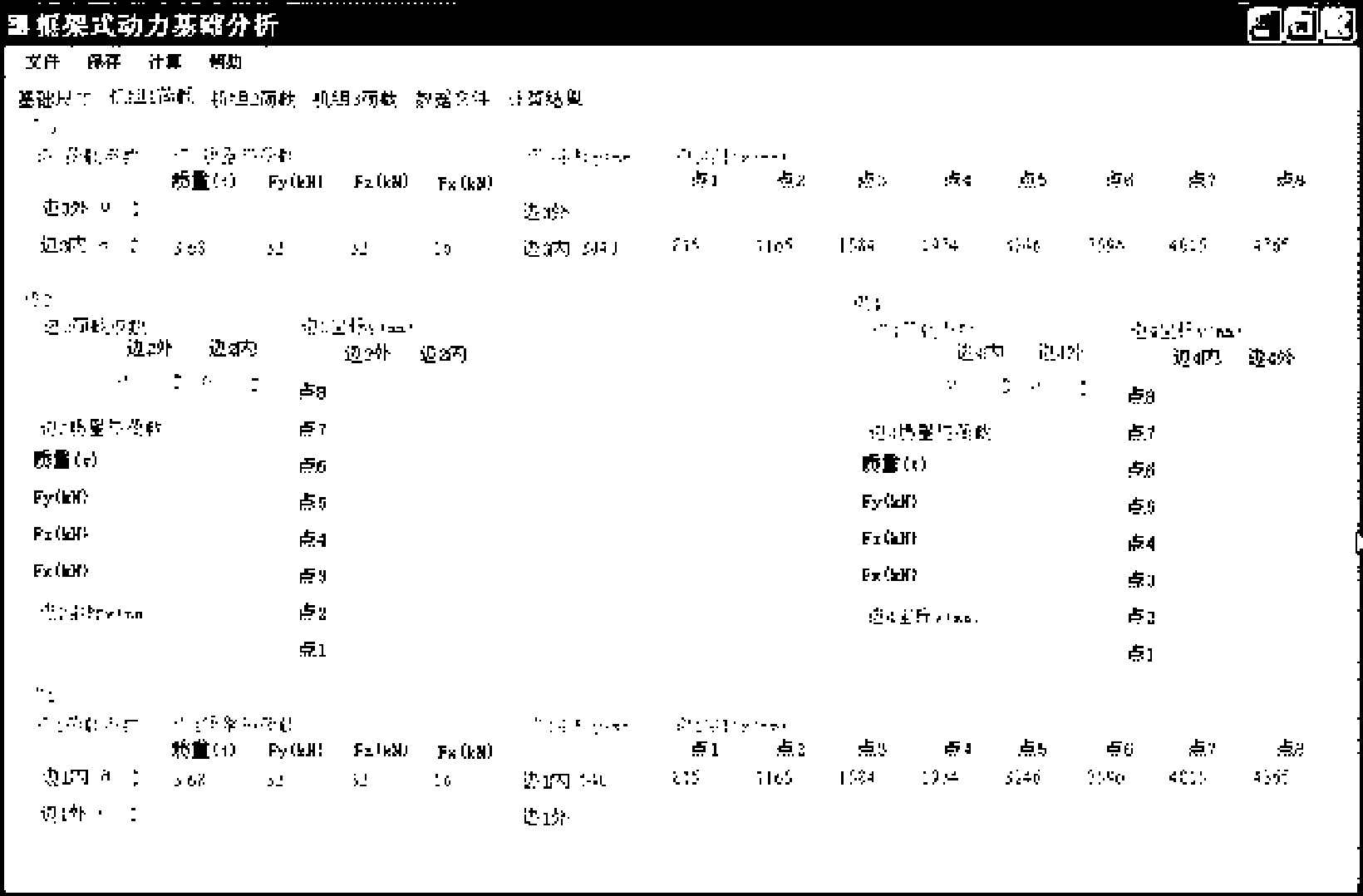

Data processing method and system of frame type rotating power machine foundation physical design

InactiveCN101458737ASpecial data processing applicationsElement analysisFinite element analysis software

The invention discloses a data processing method and a system therefore, for frame-type rotating dynamical machine foundation structure design, belonging to the data processing technical field. The method comprises: according to the basic data types of frame-type rotating dynamical machine foundation structure, classifying basic data; inputting the basic data; converting the basic data into text format and deriving out the data of text format; reading the data of text format, and processing finite element analysis of the frame-type rotating dynamical machine foundation structure on the data of text format. The system comprises: a classifying model, an input model, a conversion derivation model and a read analysis model. The invention classifies basic data to convert complex calculation parameter input and finite element modeling processes of finite element analysis software into simple interactive data input process, therefore, the designers not familiar with finite element analysis software can quickly complete the finite element analysis of frame-type rotating dynamical machine foundation.

Owner:WISDRI ENG & RES INC LTD

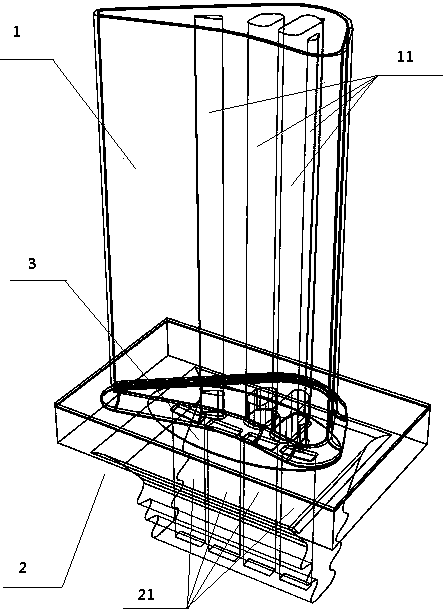

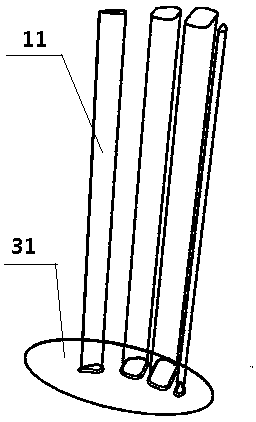

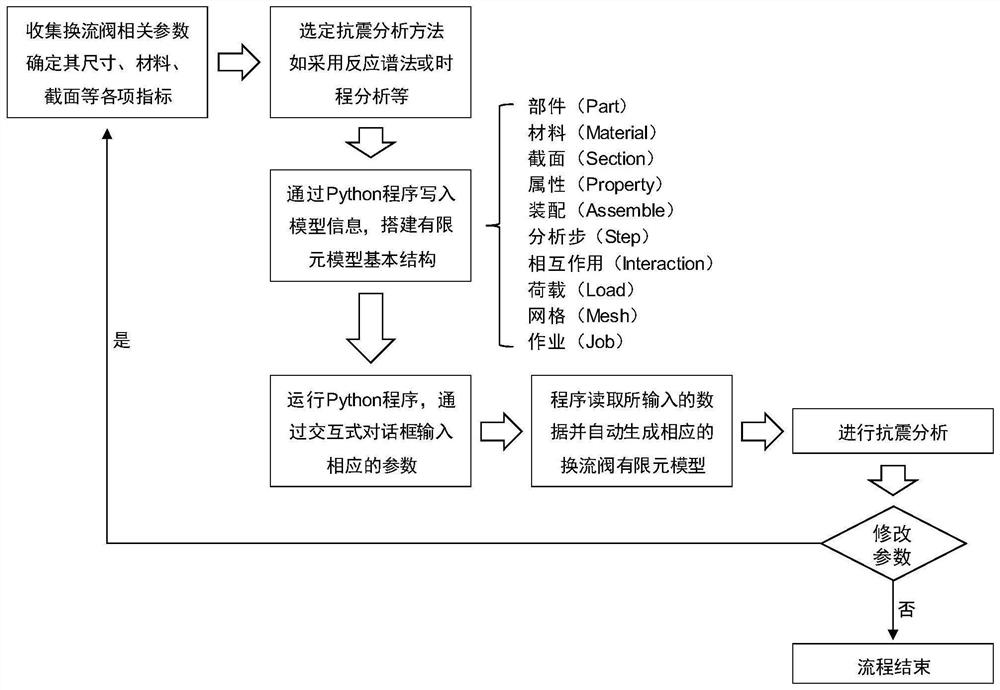

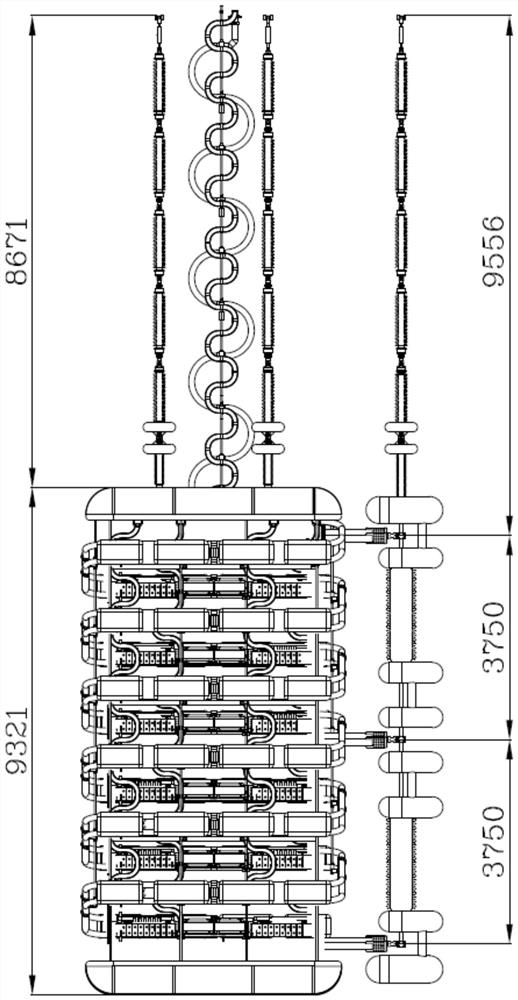

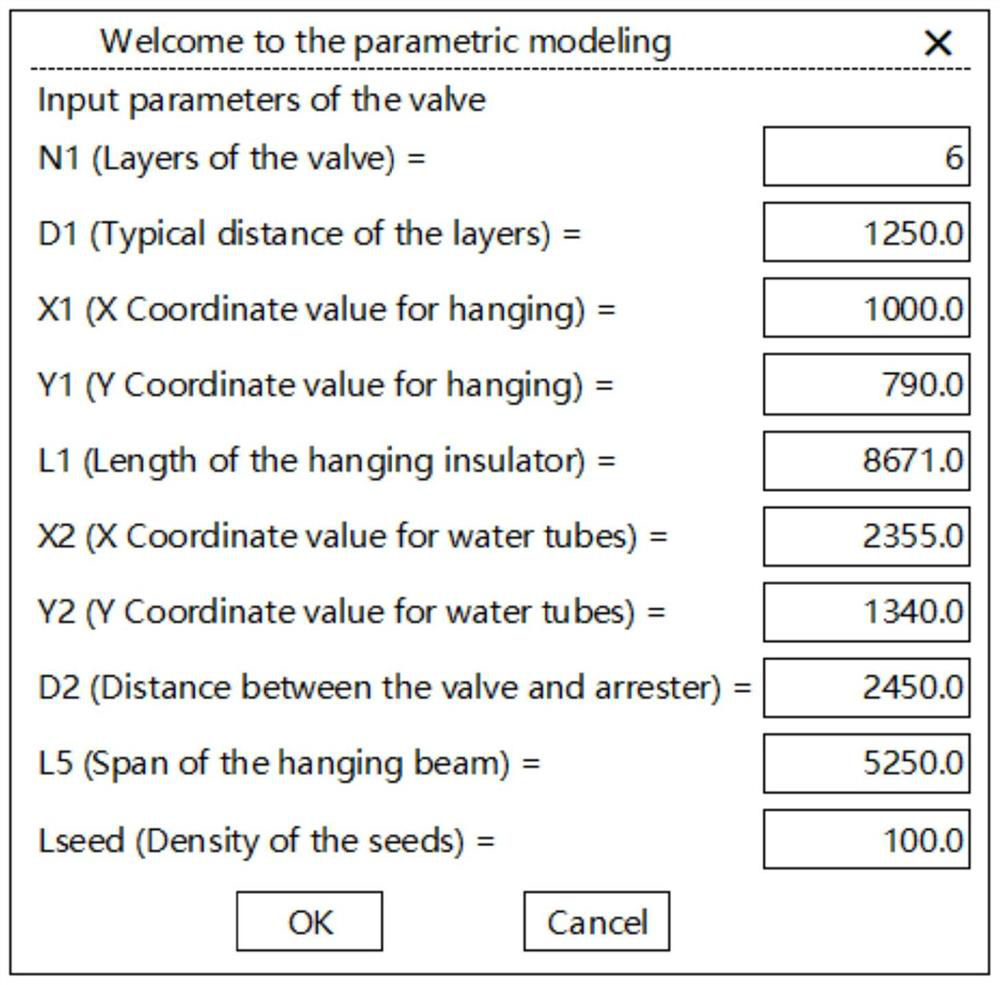

Converter valve anti-seismic analysis Abaqus parametric modeling method based on Python and storage medium

PendingCN114329843AReduce dependenceReduce modeling timeGeometric CADDesign optimisation/simulationElement modelMetamodeling

The invention relates to the technical field of finite element modeling and numerical simulation, and discloses a Python-based converter valve anti-seismic analysis Abaqus parametric modeling method and a storage medium, and the method comprises the following steps: 1, determining the size, material and mechanical property parameters of a converter valve according to actual engineering, and determining a required anti-seismic analysis method; 2, corresponding modeling information is written in through a Python script program, and a basic structure of a finite element model is built; 3, running the Python script program in the step 2, and inputting the parameters determined in the step 1 into an interactive dialog box; and 4, reading the parameters input in the step 3 by Abaqus software, automatically generating a corresponding finite element model through a Python program, and carrying out response spectrum or seismic wave time history analysis as required. According to the method, rapid and automatic modeling can be carried out on converter valves with different parameter sizes, the modeling efficiency and accuracy are greatly improved, and anti-seismic analysis can be conveniently carried out on various converter valves.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

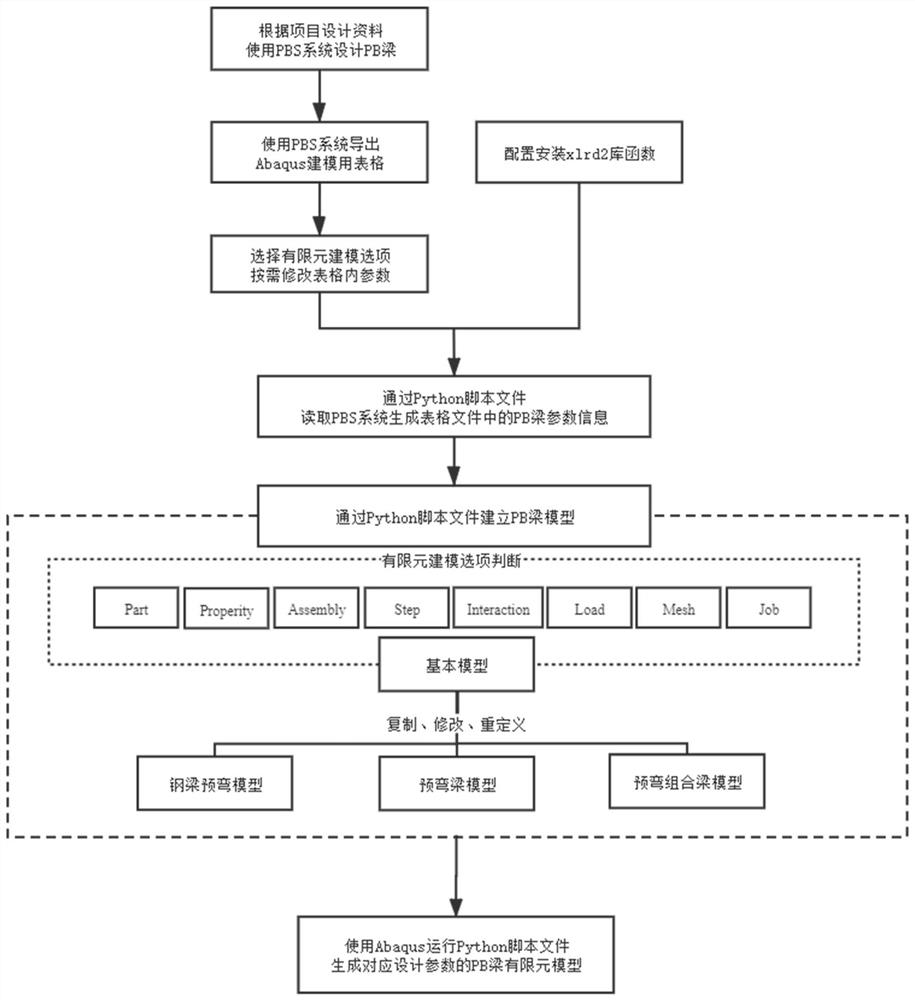

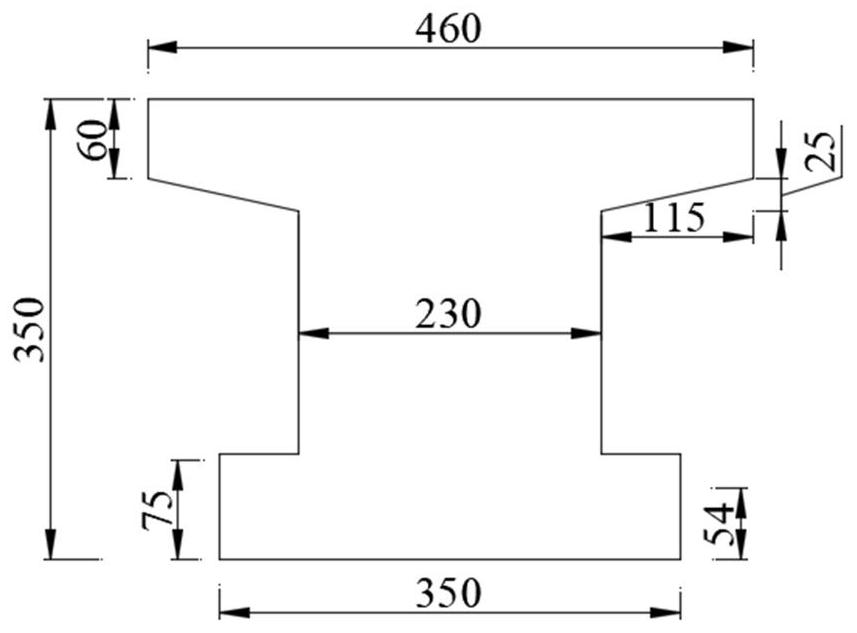

PBS system-based pre-bent composite beam Abaqus rapid modeling method

PendingCN114329699AEasy to analyzeModify table parameters directlyGeometric CADDesign optimisation/simulationThird partySystems design

The invention relates to a PBS system-based Abaqus rapid modeling method for a pre-bent and pre-stressed composite beam, and belongs to the technical field of three-dimensional finite element modeling of bridge engineering. Designing a PB main beam by using a pre-bending pre-stress composite beam design checking calculation system, and running the main beam Abaqus modeling table in the step 1 by adopting a Python program provided with a third-party library function xlrd2; reading PB main beam parameter information in a PBS generation table file of a pre-bending prestressed composite beam design checking calculation system through a Python program script file; the Python is operated by using Abaqus (Abaqus); a basic model, a steel beam pre-bending model, a pre-bending beam model and a pre-bending composite beam model; and generating a PB beam basic model, a steel beam pre-bending model, a pre-bending beam model and a pre-bending composite beam model corresponding to the design parameters. According to the method, after the PB beam is designed by the pre-bending prestressed composite beam design checking calculation system, the form file is directly exported, the automatic rapid modeling process is achieved, and construction stage analysis, bearing capacity analysis and parameterization analysis of the pre-bending prestressed composite beam are conveniently achieved.

Owner:SOUTHEAST UNIV

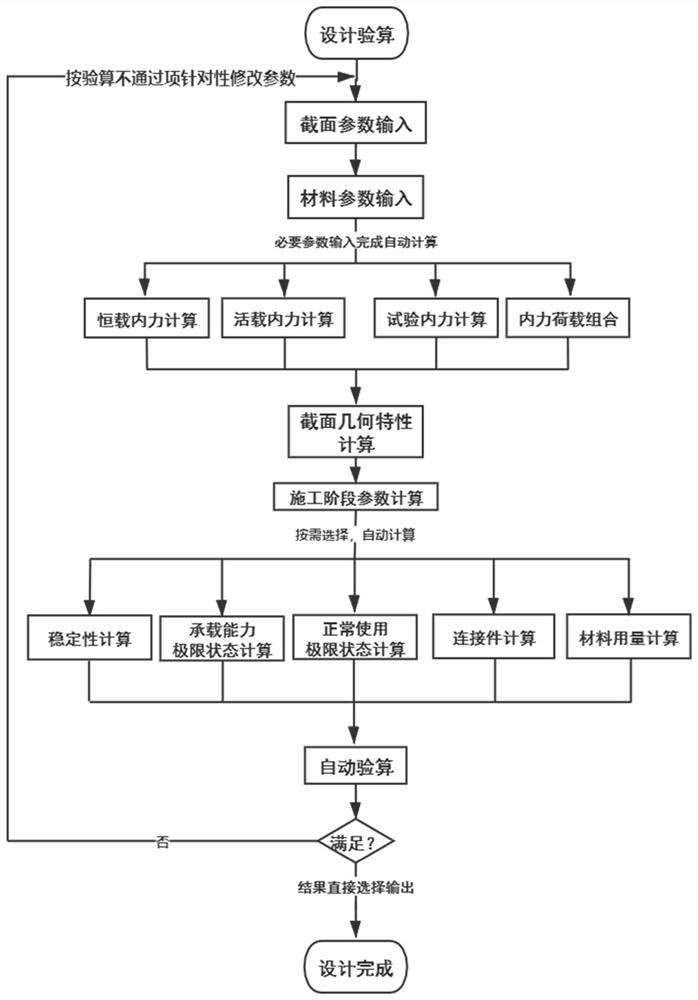

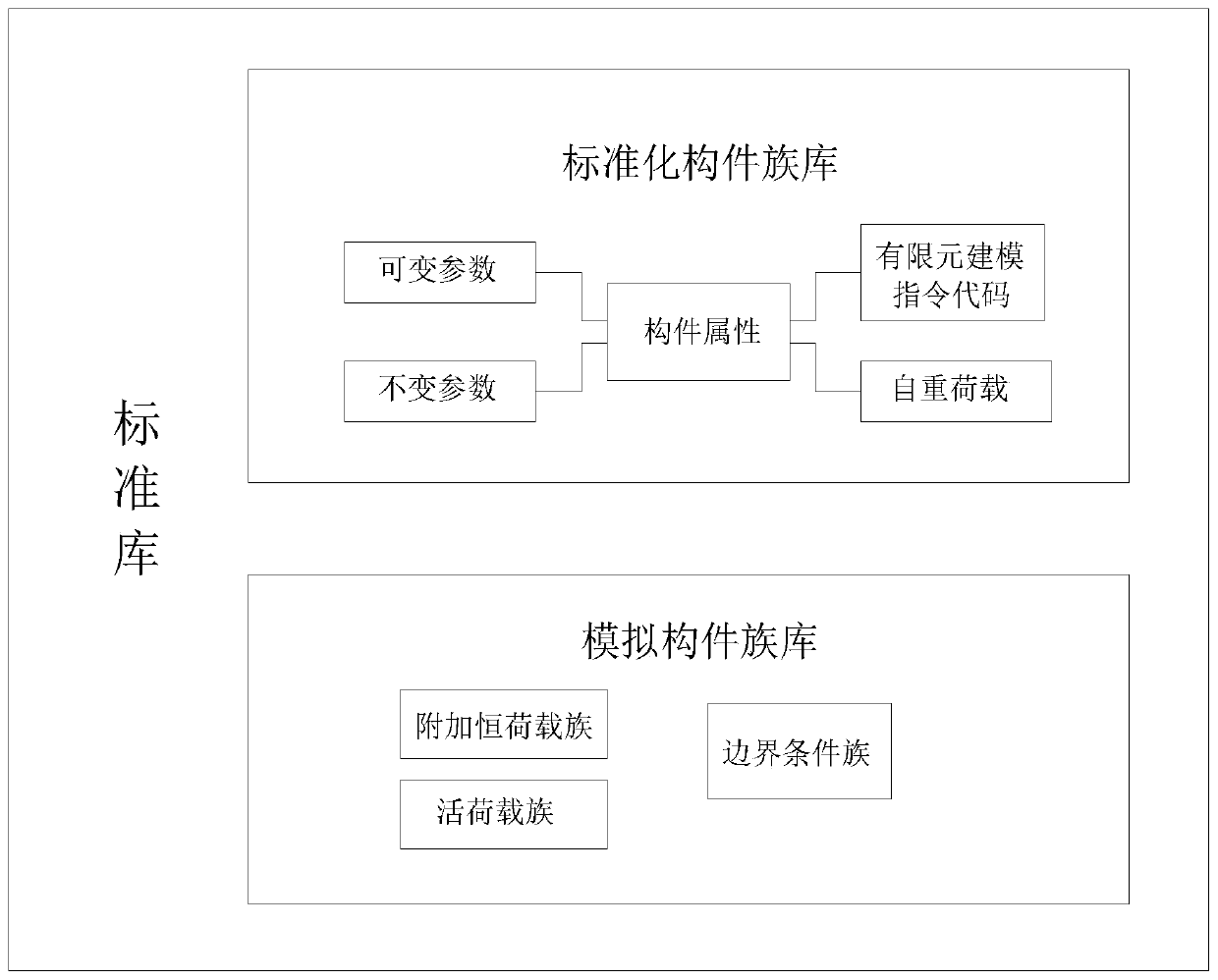

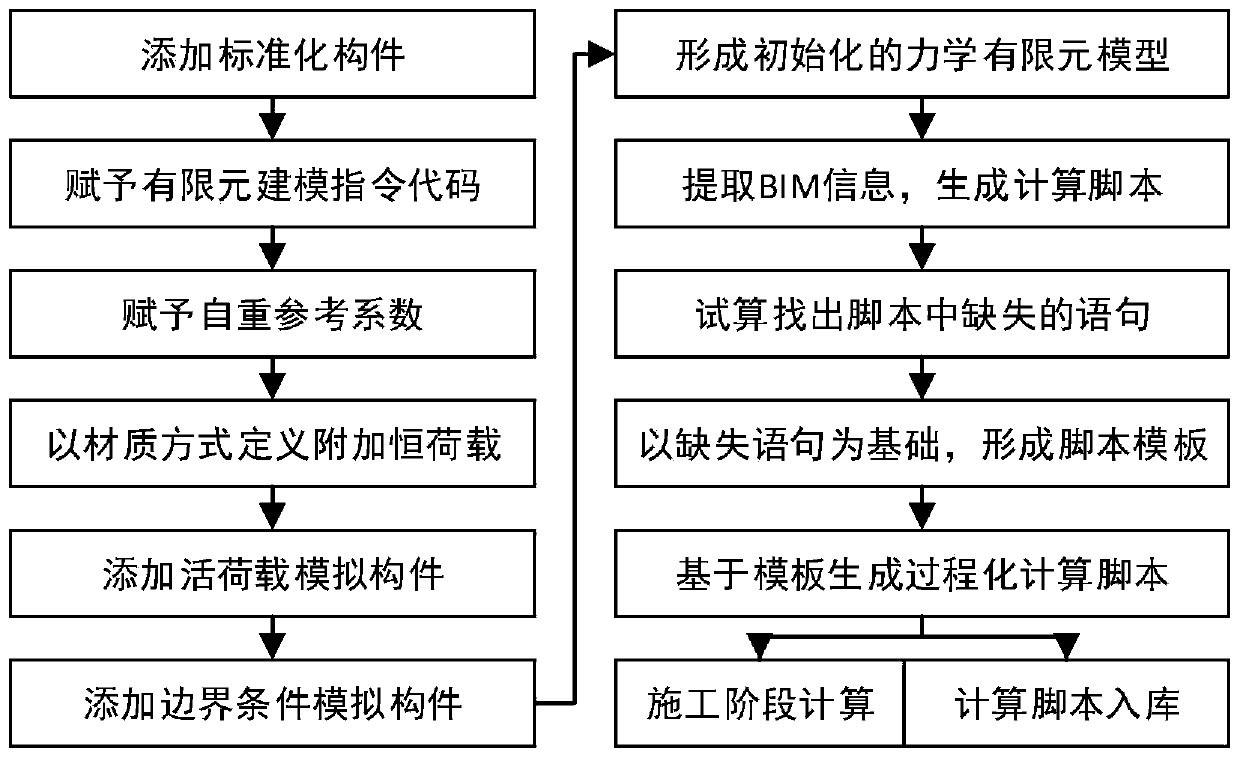

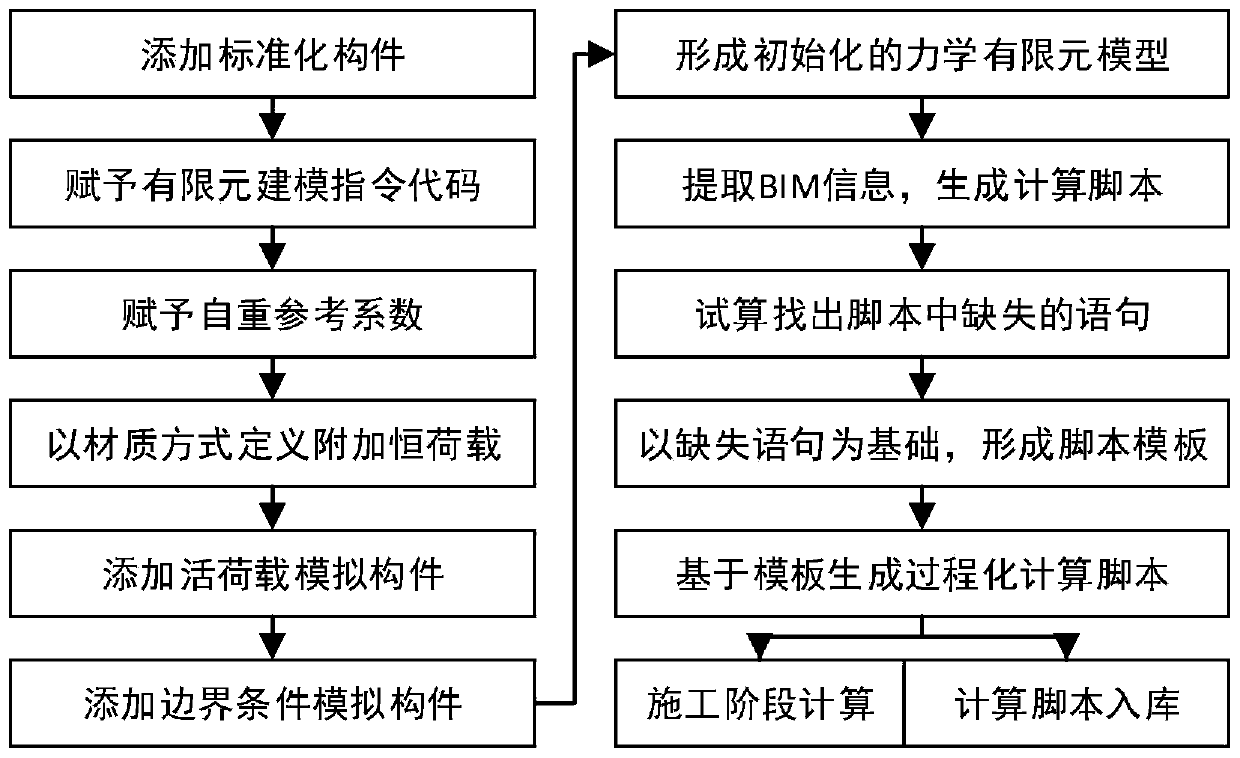

BIM-based universal modeling method for mechanical model

ActiveCN111159797AImprove modeling efficiencyImprove modeling accuracyGeometric CADDesign optimisation/simulationConstant loadElement model

The invention discloses a BIM-based universal modeling method for a mechanical model. The method comprises the following steps of 1, establishing a standard library for converting a BIM model into a mechanical finite element model; and 2, establishing an initialized mechanical finite element model on the basis of the standard library; wherein the standard library comprises a standardized componentfamily library and a simulated component family library, component attributes of the standardized component family library comprise variable parameters, invariant parameters, finite element modelinginstruction codes and dead load, and the simulated component family library comprises an additional constant load family, a live load family and a boundary condition family. Forming finite element modeling instruction codes and self-weight loads of the BIM model and the components based on the standardized component family library; and giving additional constant load, live load and boundary conditions to the BIM model based on the simulation component family library. According to the method, the conversion problem from the BIM model to the mechanical model is solved, and the efficiency and precision of establishing and optimizing the mechanical finite element model can be improved.

Owner:SHANGHAI CONSTRUCTION GROUP

A New Combat Effectiveness Simulation Modeling Method

ActiveCN107967134BSupports semantic compositionEfficiently buildSoftware designVisual/graphical programmingMetamodelingModelSim

Owner:NAT UNIV OF DEFENSE TECH

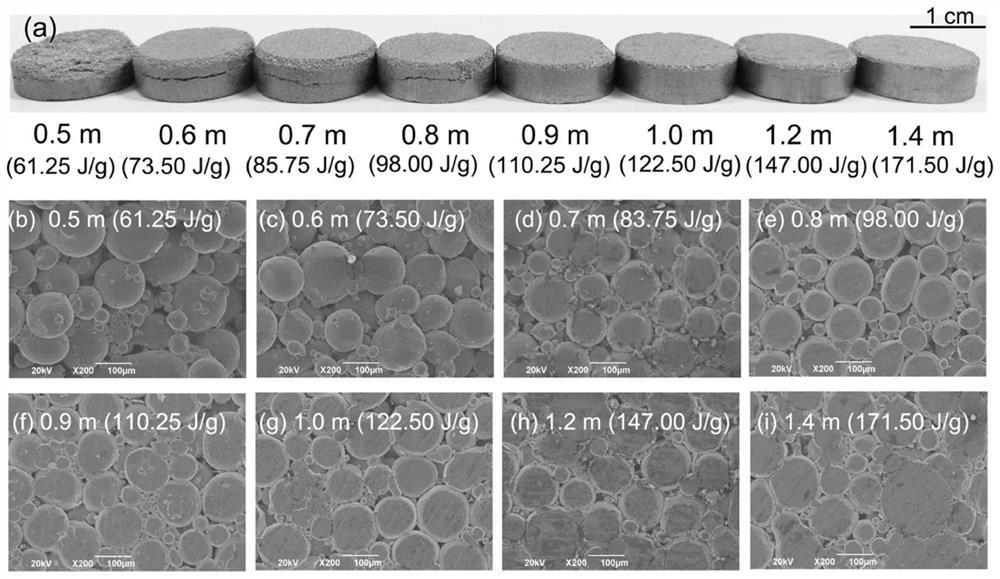

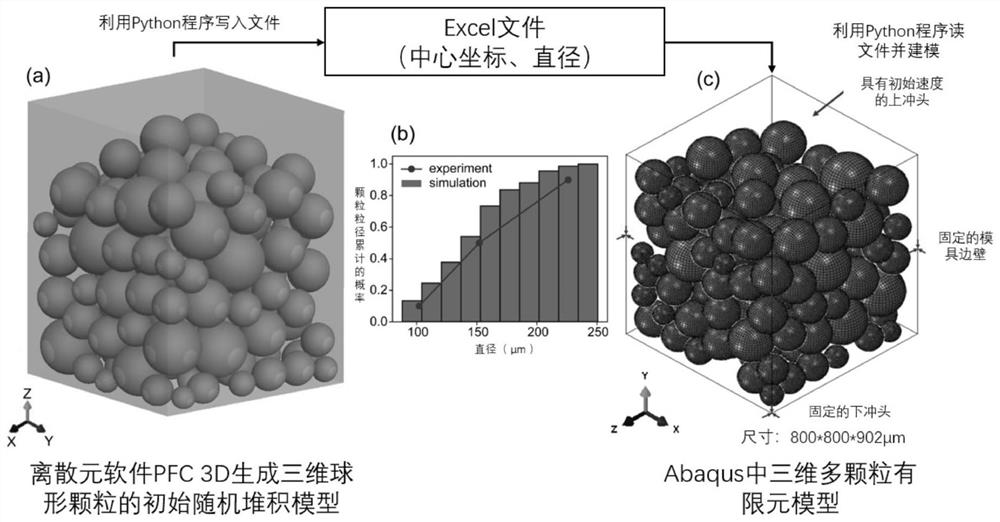

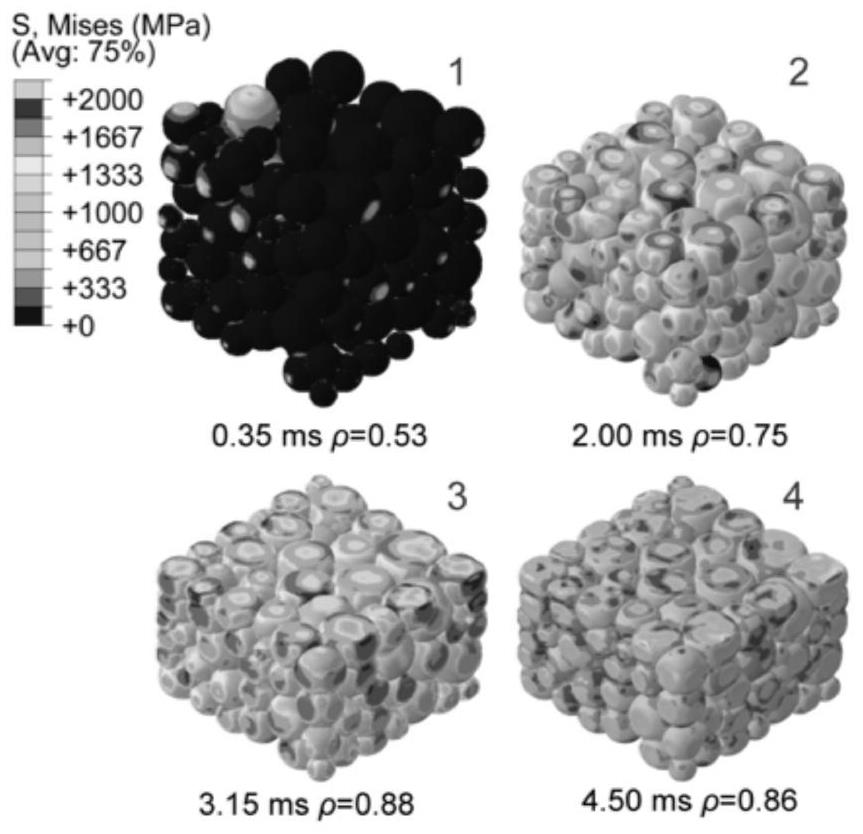

Three-dimensional multi-particle finite element simulation method for predicting high-speed pressing forming performance of metal powder

PendingCN114492100AImprove integrityAchieve correctnessDesign optimisation/simulationSpecial data processing applicationsMetamodelingElement modeling

The invention relates to a three-dimensional multi-particle finite element simulation method for predicting high-speed pressing forming performance of metal powder, which comprises the following steps of: generating an initial random stacking model of three-dimensional spherical particles by using discrete element software, and extracting central coordinates and corresponding diameter data of the spherical particles; running a python script program in finite element software Abaqus, automatically completing modeling of spherical particle parts with different diameters, and generating an assembly; setting material attributes of the particles; each powder particle part is automatically divided into hexahedral structure grids with a reasonable number; setting and displaying dynamic analysis steps; setting boundary conditions; automatically setting contact attributes and contact pairs between metal powder balls and between the balls and the side wall of the mold; and solving, calculating and post-processing. According to the method, a large amount of complex finite element modeling work such as generation and assembly of a multi-particle part, grid division and contact setting is automatically completed, the modeling efficiency is greatly improved, the modeling correctness is guaranteed, the micro-mechanical characteristics of powder pressing are comprehensively analyzed, and the method is suitable for large-scale popularization and application. And the quantitative relation between the compact density and the impact energy per unit mass is accurately established, so that the purpose of predicting the high-speed pressing performance of the metal powder is achieved.

Owner:HEFEI UNIV OF TECH

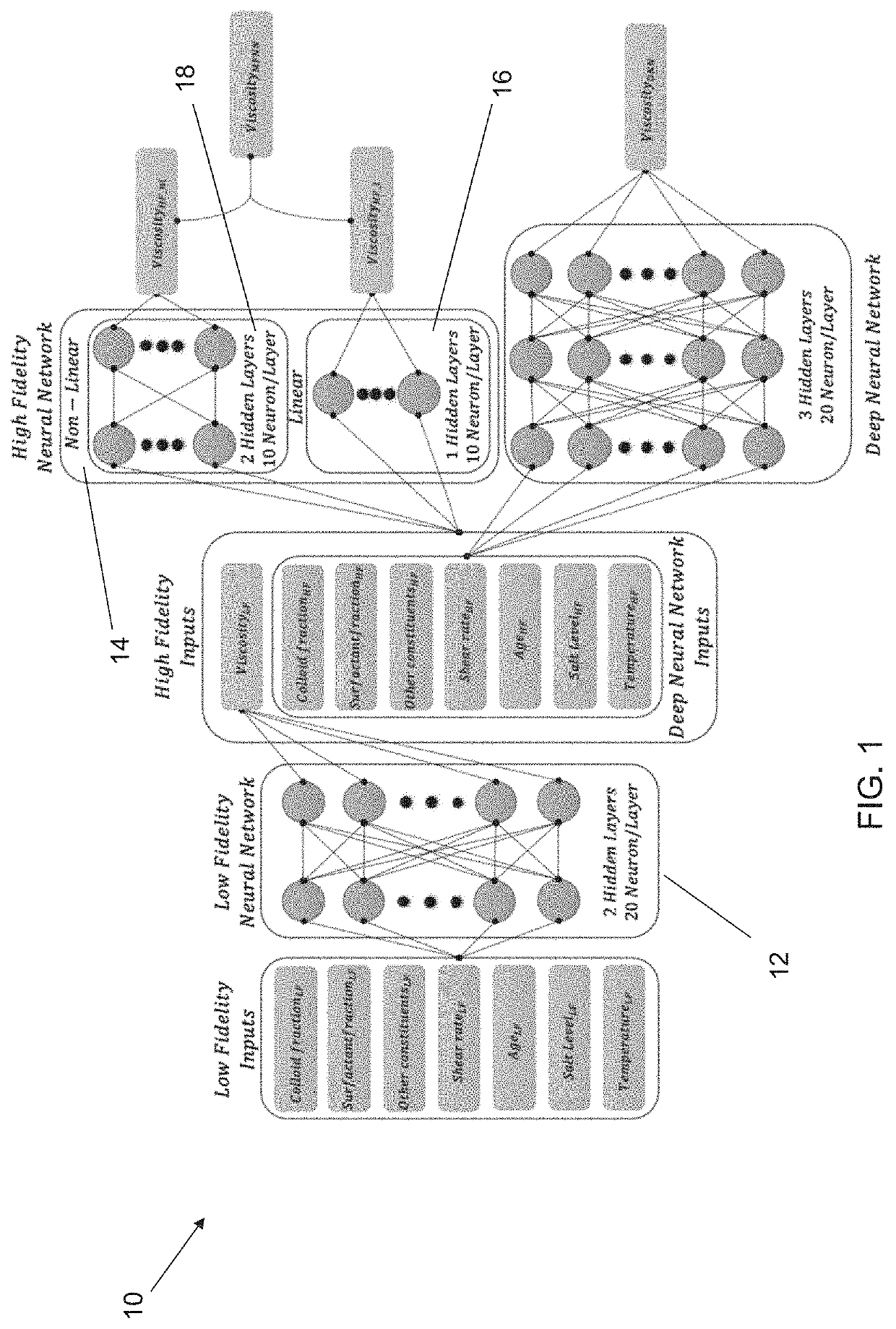

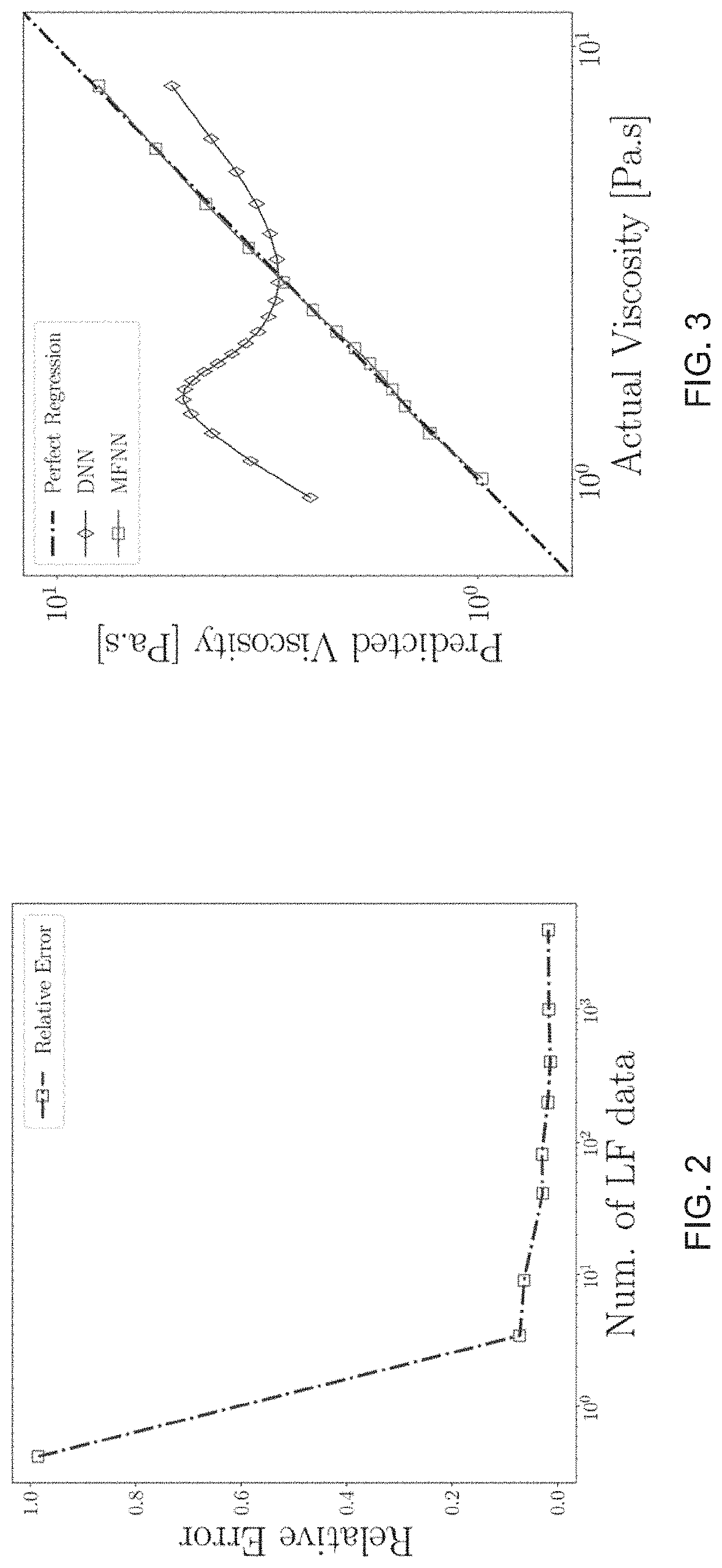

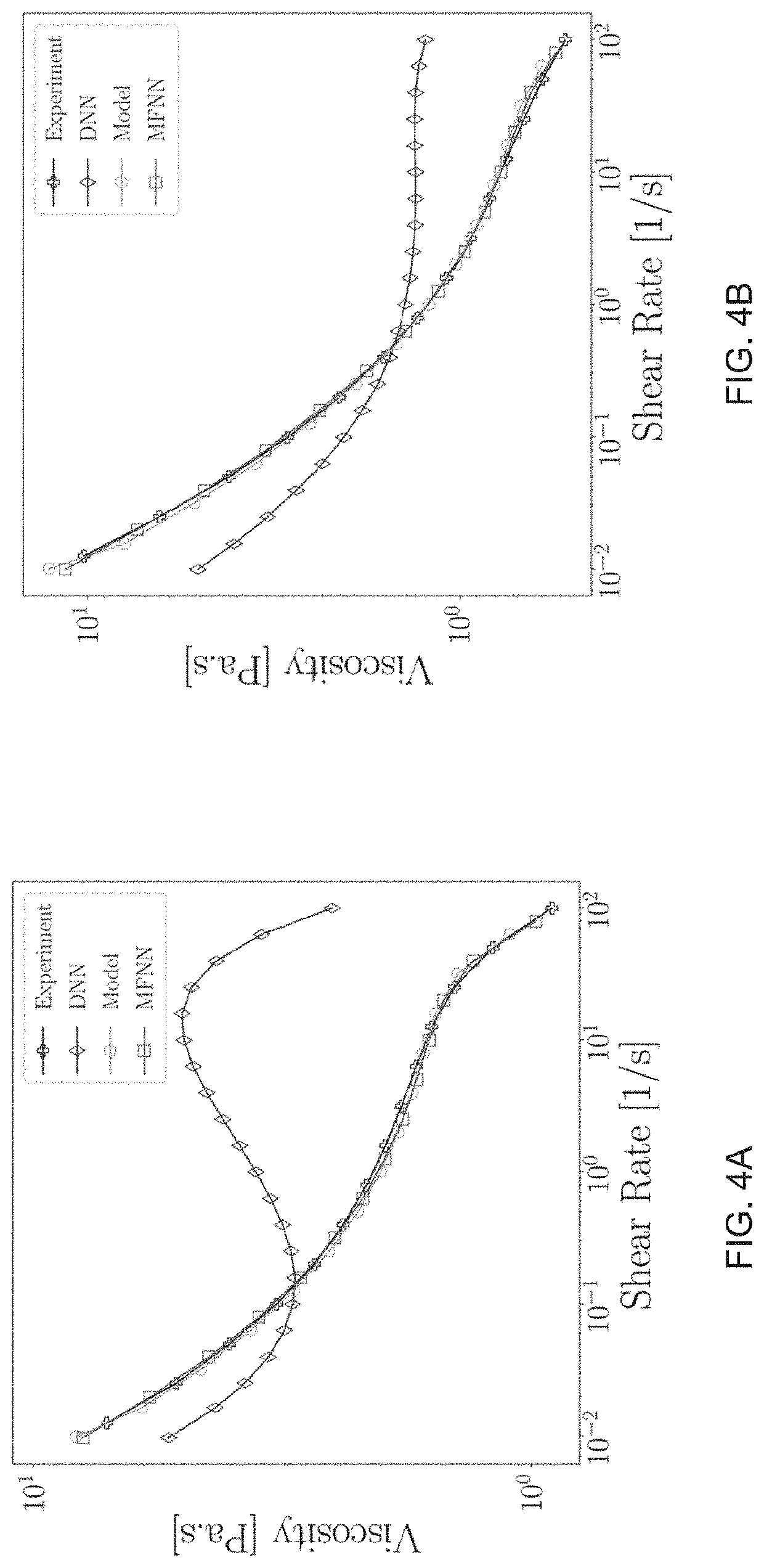

Rheology-informed neural networks for complex fluids

A comprehensive machine-learning algorithm, namely a Multi-Fidelity Neural Network (MFNN) architecture, is disclosed for data-driven constitutive meta-modelling of complex fluids. The physics-based neural networks are informed by underlying rheological constitutive models through synthetic generation of low-fidelity model-based data points.

Owner:NORTHEASTERN UNIV

A general modeling method and system for heterogeneous disaster events

ActiveCN103440347BTo achieve a unified descriptionConducive to unified archivingSpecial data processing applicationsData informationMetamodeling

The invention relates to a common modeling method and system of heterogeneous disaster events. The method comprises the steps of building a disaster event meta-modeling frame, building a mode structure of a disaster event meta-model and building a heterogeneous disaster event information model. The method and the system have the advantages and positive effects that the problems that existing heterogeneous disaster events lack effective description means and information models are not uniform are solved; the disaster event meta-model is built; four metadata components and eight-tuple node information description models are developed and the mapping relations between the geography markup language, the sensor model language, the event pattern markup language, sensor network common data information models and an event meta-model are designed; compared with existing disaster event management modes, the disaster event meta-model in the method and system provided by the invention comprehensively describes related information of the heterogeneous disaster events, thus providing supports for unified management and accurate discovery of the disaster events and proving that the method is beneficial to modeling of the heterogeneous disaster events and is more practical and reliable in disaster even management.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com