A Prediction Method of Single Crystal Copper Micro Milling Force Based on Cutting Process Simulation

A technology of micro-milling force and cutting process, applied in the direction of program control, instrument, computer control, etc., can solve the problem of lack of single crystal copper micro-milling force prediction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

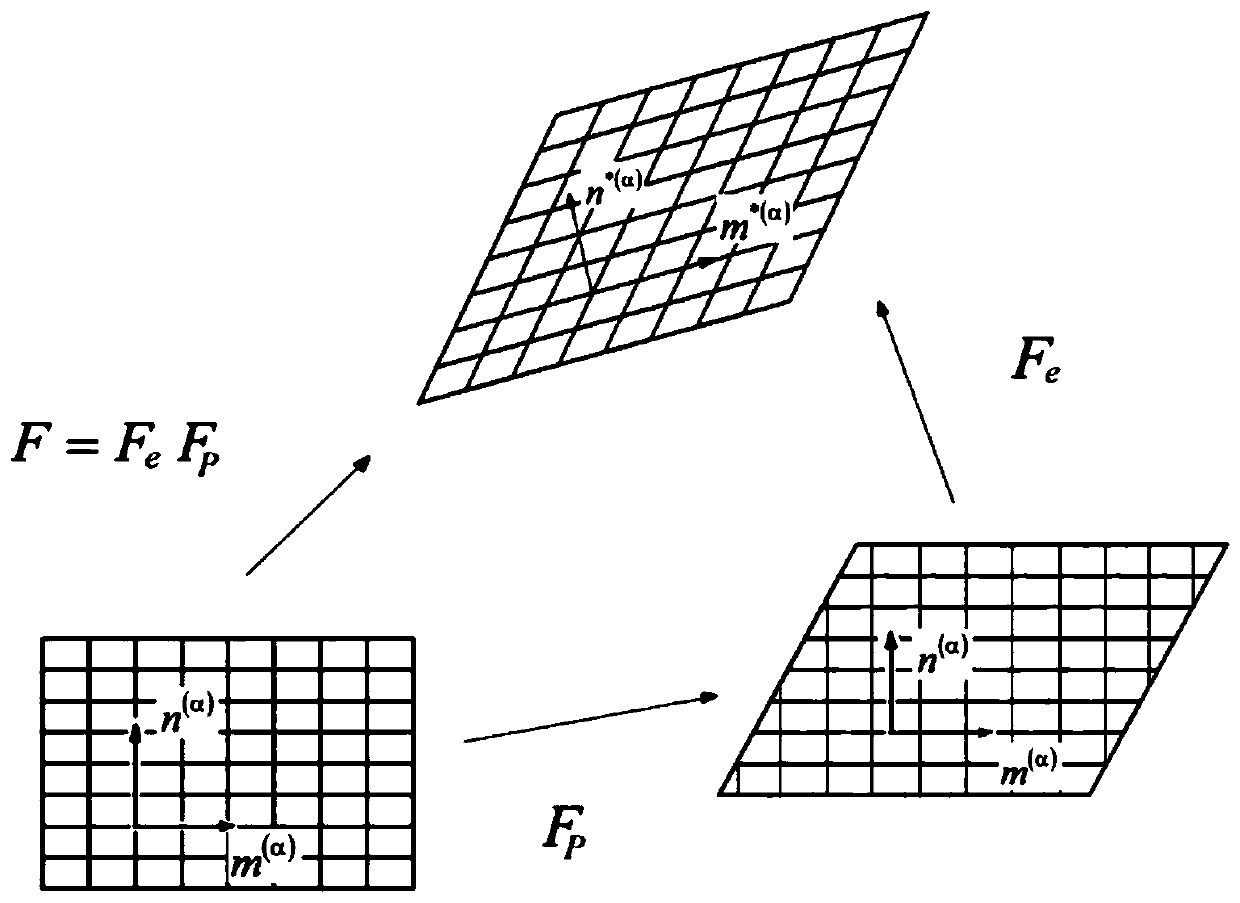

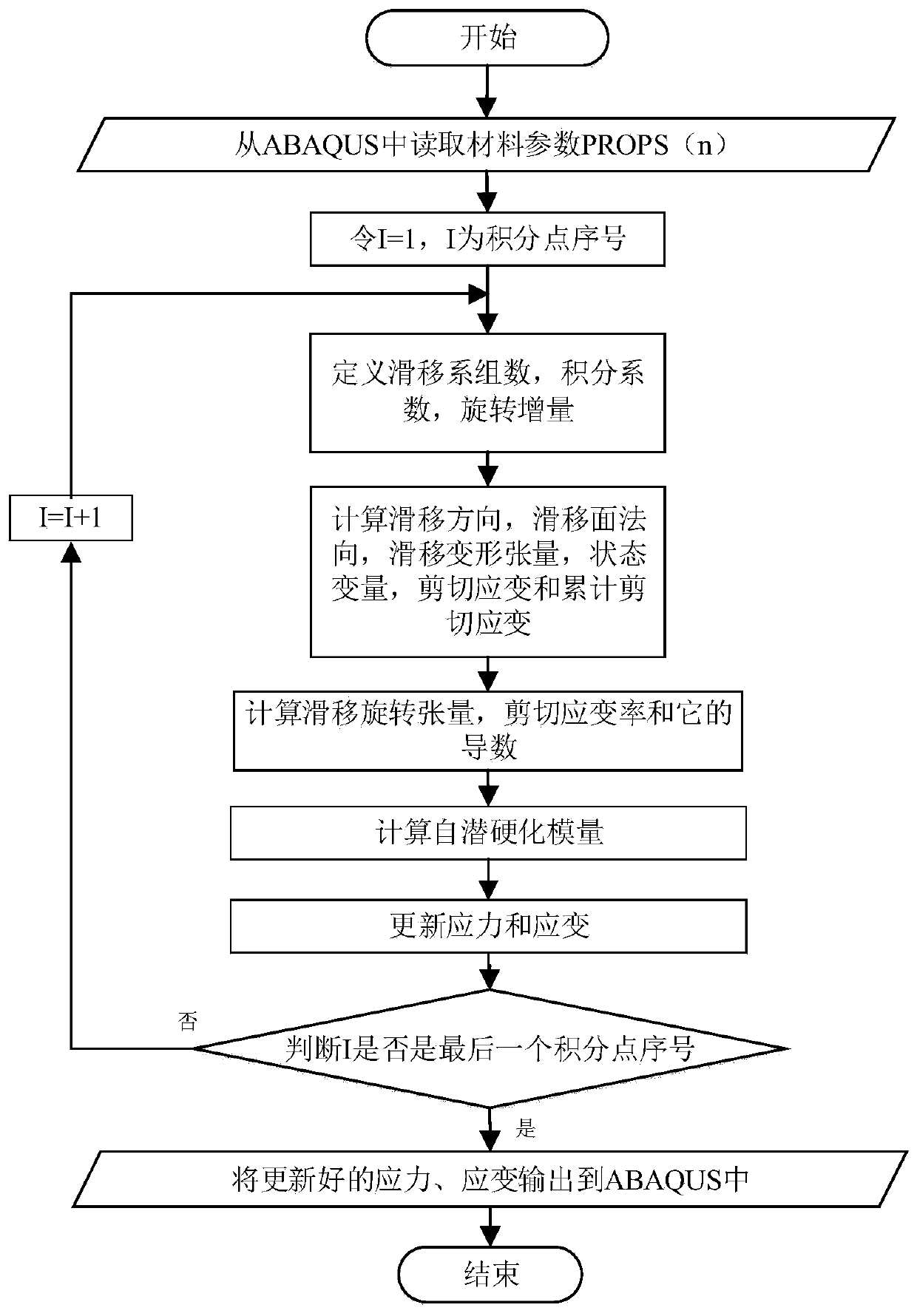

Method used

Image

Examples

Embodiment Construction

[0122] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

[0123] Considering that the micro-milling force is an important process parameter in the micro-milling process of single-crystal copper micro-parts, the research on the modeling method of single-crystal copper micro-milling force has an important guiding role in optimizing the micro-milling process of micro-parts and improving the processing quality. In addition, due to the anisotropy of single crystal copper material, it has a certain influence on the change of cutting force during micro-milling. Accordingly, aiming at the problem of predicting the micro-milling force of single-crystal copper micro-parts, a method for predicting the micro-milling force of single-crystal copper based on cutting process simulation was invented.

[0124] Taking the micro-milling of straight slots with two-edged flat milling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com