Method for predicting dual-scale creep fatigue life of discontinuous structure

A fatigue life prediction, discontinuous technology, applied in special data processing applications, geometric CAD, computer-aided design, etc., can solve problems such as stress-strain behavior and damage mechanism evolution that cannot be described at the microscopic level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

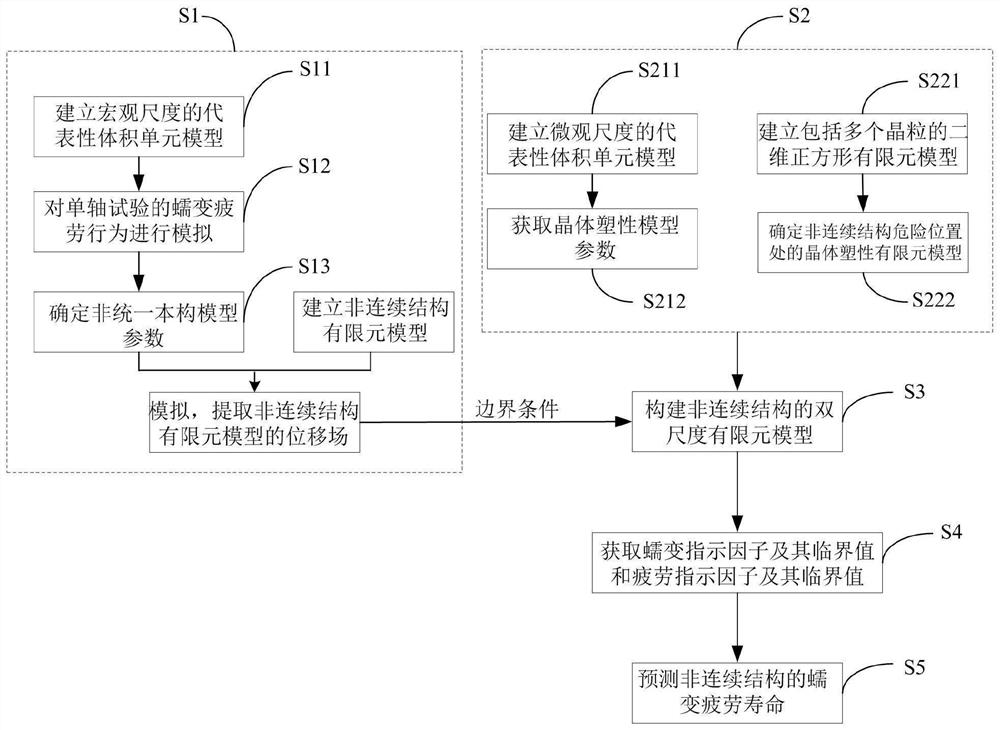

[0045] Such as figure 1 As shown, according to a kind of discontinuous structure double-scale creep fatigue life prediction method of the present invention, comprises the following steps:

[0046] Step S1, obtain the non-uniform constitutive model parameters corresponding to the material to be tested, and use Abaqus software to establish a discontinuous structure finite element model, and analyze the creep fatigue behavior of the discontinuous structure finite element model according to the obtained non-uniform constitutive model parameters The simulation is carried out to extract the displacement field of the discontinuous structure finite element model under different creep fatigue conditions. Among them, the steps of obtaining the parameters of the non-uniform constitutive model include:

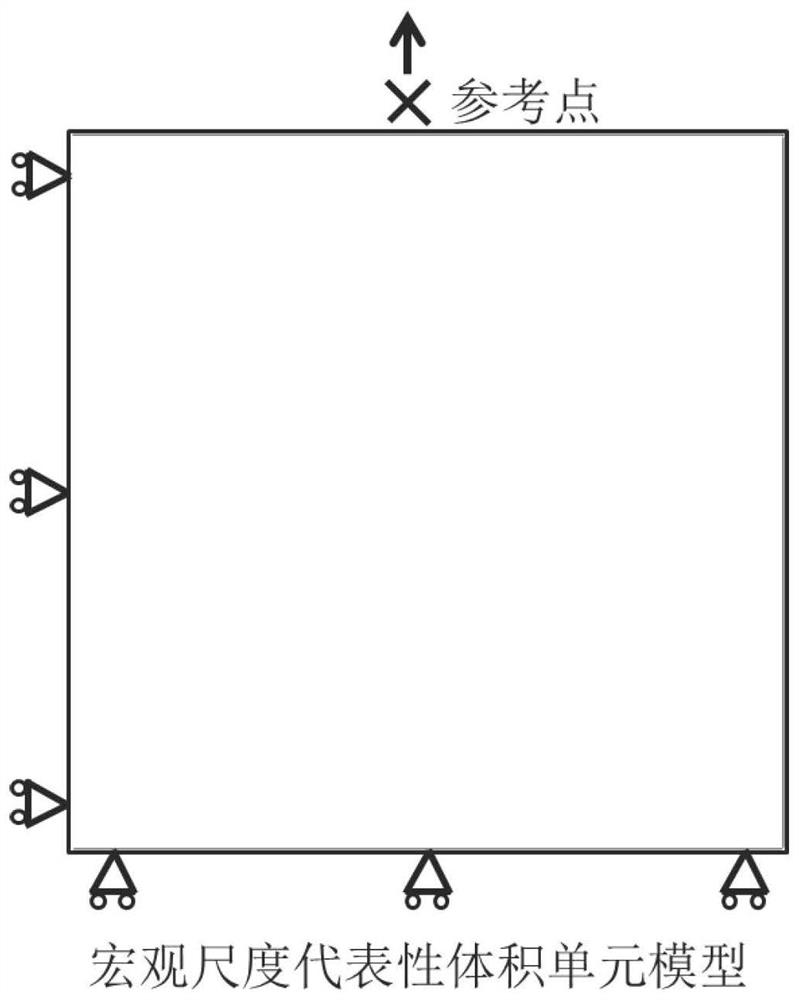

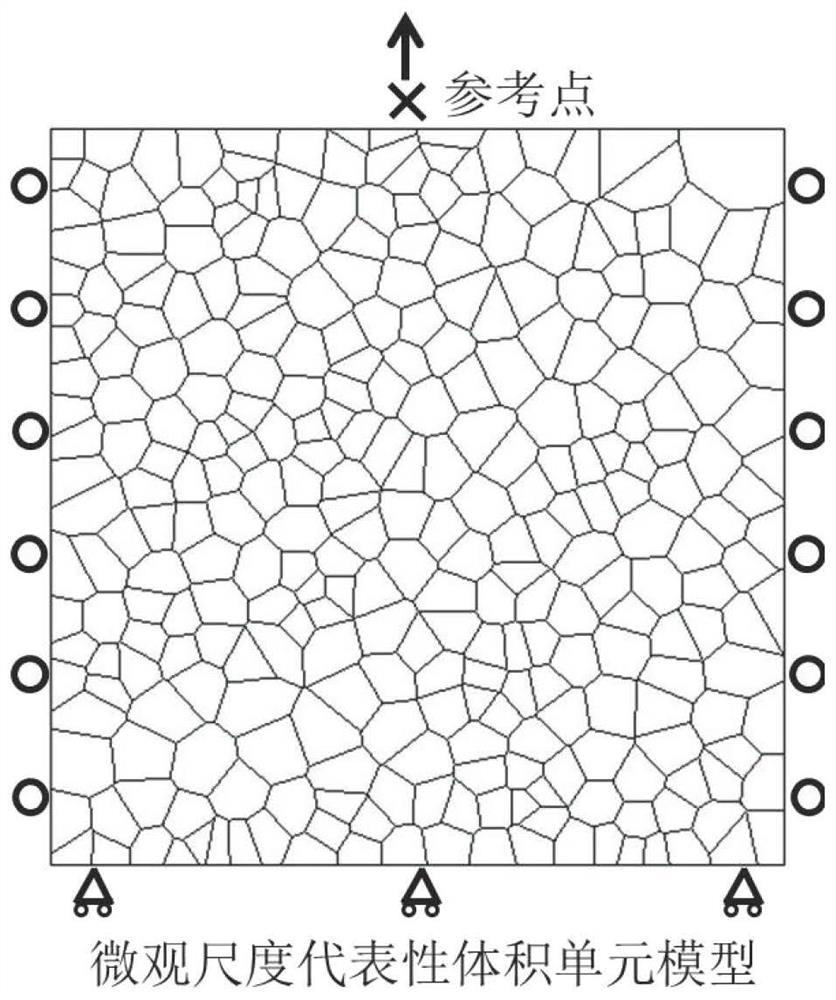

[0047]Step S11, using Abaqus software to establish a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com