Cluster optimization control system for air compressor

An optimized control and air compressor technology, applied in the general control system, control/regulation system, program control, etc., can solve the problems of lack of production planning information, difficulty in guaranteeing control schemes, poor enforceability of cluster optimization control schemes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

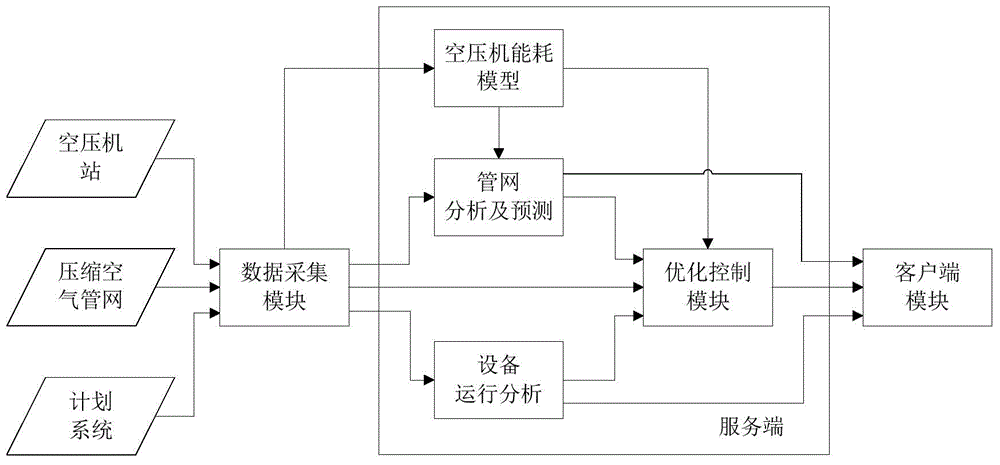

[0058] The present invention includes a data acquisition module, an air compressor energy consumption model, a pipe network analysis and prediction module, an equipment operation analysis module, and an optimization control module. Four server modules, a client module, and the relationship between each module are as follows: 4 services The terminal modules exchange data information through inter-process message calls, the data acquisition module and the server module exchange data information through network message calls, and the client module connects to the server module through network messages. Such as figure 1 shown.

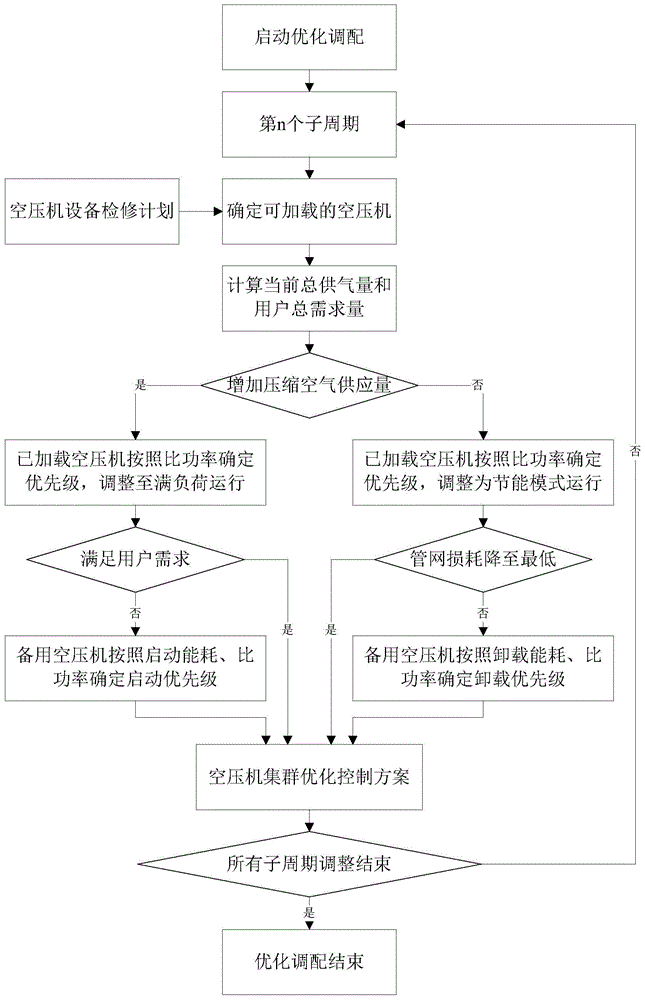

[0059] The implementation process of the present invention is illustrated by taking the optimal control of an air compressor cluster of an enterprise as an example. The enterprise has 4 centralized air compressor stations and more than 30 air compressors. The average power consumption of compressed air is 0.1219m3 / kwh, and the loss rate of the pipe networ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com