Burner, combustor and gas stove

A burner and burner technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of low combustion efficiency, high smoke emission, gas flow obstruction, etc., to improve the ejection effect, reduce Effects of flue gas emission and improvement of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

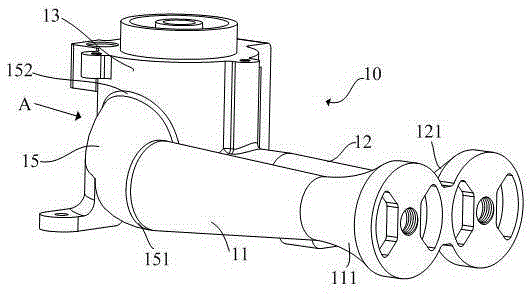

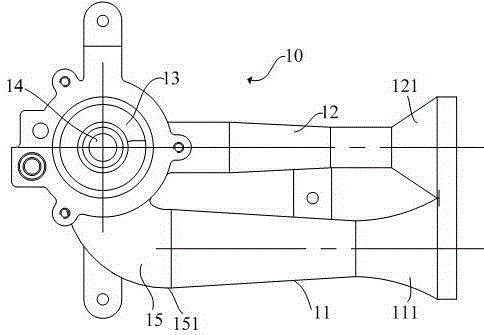

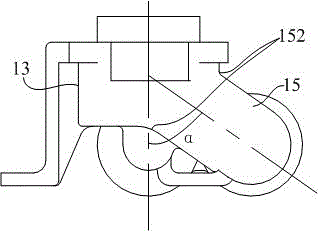

[0021] refer to Figure 1 to Figure 5 , a furnace head 10, including a main injection tube 11, a secondary injection tube 12, a main mixing chamber 13 connected to and communicated with the main injection tube 11, and a secondary mixing chamber connected to and communicated with the secondary injection tube 12 14. The auxiliary mixing chamber 14 is located inside the main mixing chamber 13 and coaxially arranged with the main mixing chamber 13, that is, the two are concentrically sleeved, and the main ejector pipe 11 and the auxiliary ejector pipe 12 are both located in the main mixing chamber Outside the body 13, the main injection tube 11 is located on one side of the auxiliary injection tube 12. The structure, positional relationship and effect of the above-mentioned components are the same as those of the prior art; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com