Die possessing twice exit mode slide block

A slider and mold technology, applied in the field of molds, can solve the problems of high mold cost and cumbersome structure, and achieve a good ejection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments:

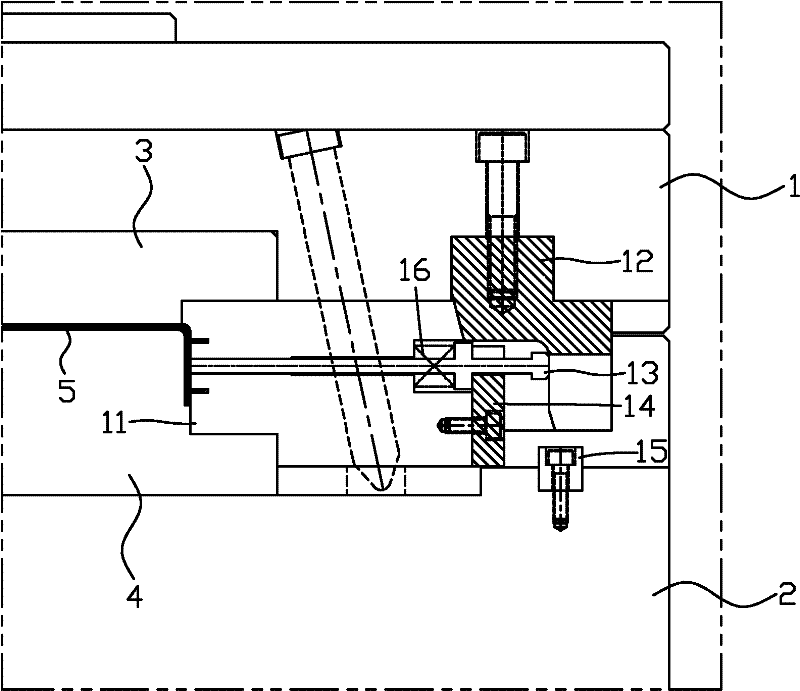

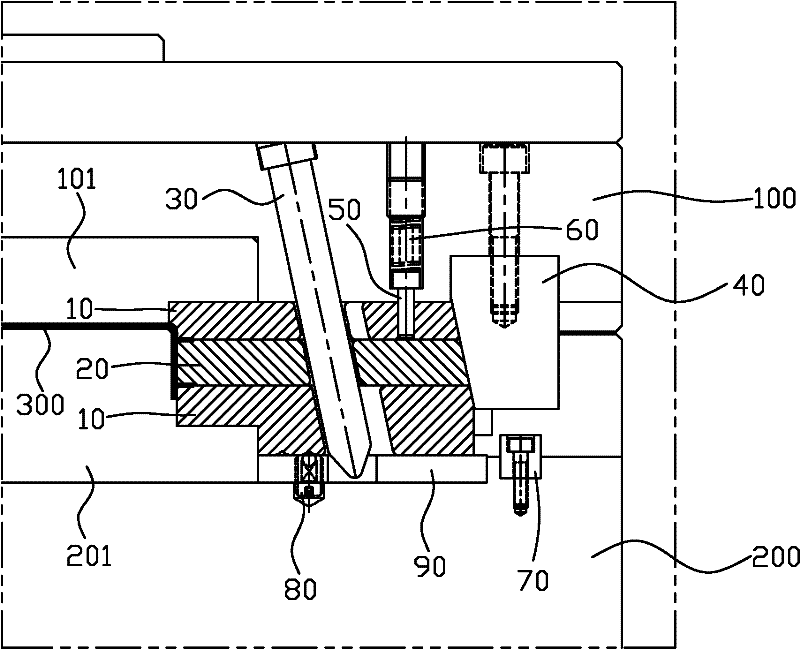

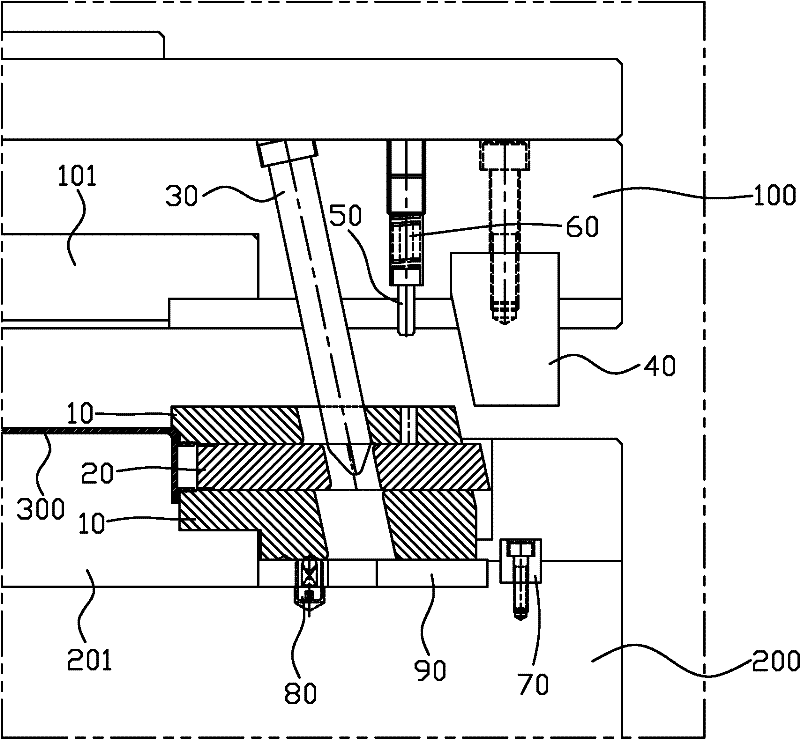

[0015] Please refer to figure 2 and image 3 , the present invention has a preferred embodiment of the mold of the secondary exit type slider, including a female template 100, a male template 200, a female mold core 101, a male mold core 201, a slider body 10, a slider input Sub 20, an inclined guide post 30, a slider beam block 40, a limit thimble 50, a spring 60, a slider stopper 70, a positioning steel ball 80 and a resistant module 90. The mold of the present invention with a double exit slider is used to produce a product 300 .

[0016] The slider body 10 is arranged in the male template 200, and a groove is arranged in the slider body 10 for placing the slider insert 20, and the slider body 10 and the slider insert 20 can be opposite to each other. Movement, its movement method is similar to the principle of sleeve movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com