Air exhaust device for ultrasonic engine jet pipe exhaust simulation experiment

A technology of exhaust device and simulation test, which is applied in the direction of engine test, measurement device, internal combustion engine test, etc., and can solve the problems of high cost, inability to meet the requirements of various engine tests, and huge structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

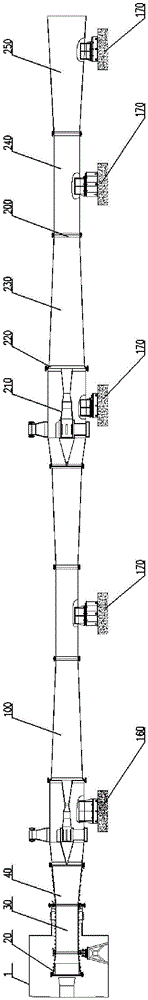

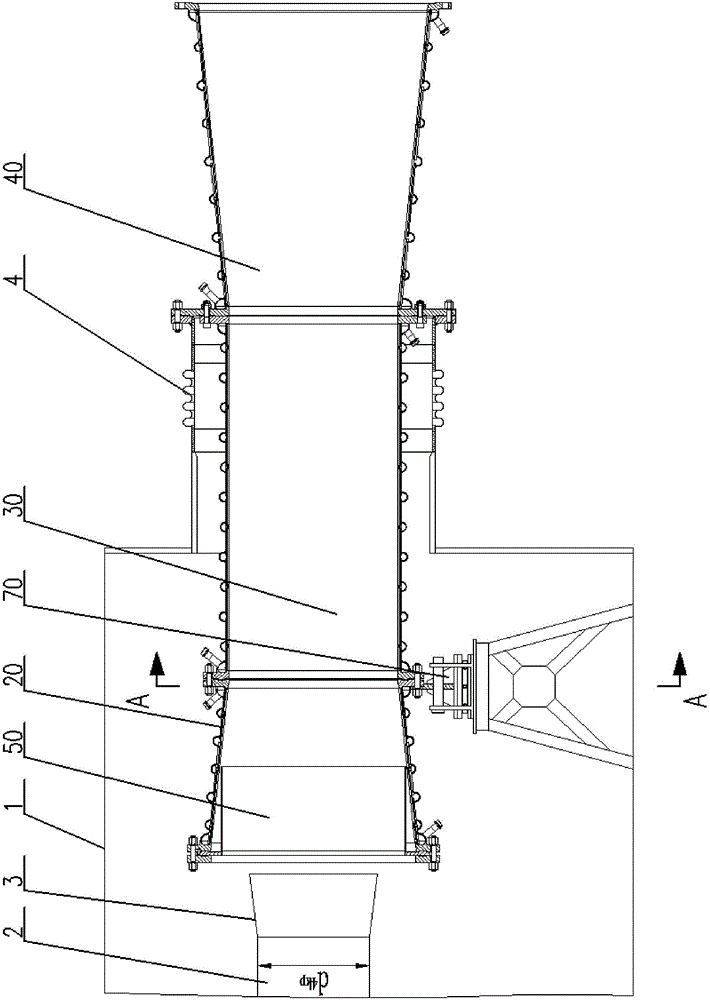

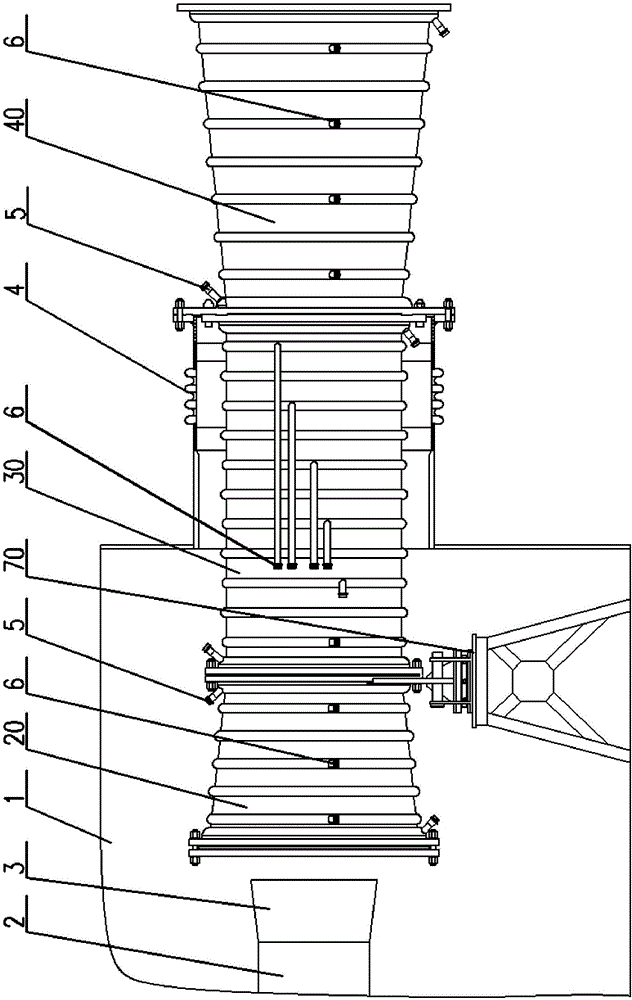

[0096] see Figure 1-25, a kind of exhaust device of supersonic engine tail nozzle exhaust simulation test, according to engine tail nozzle 3 outlet exhaust gas flow direction, described exhaust device comprises the tail chamber that coaxial fixedly connects successively, ejector 100 and The secondary ejector 200, the tail chamber includes a fixed large tail chamber and a replaceable small tail chamber 50. According to the flow direction of the exhaust gas at the outlet of the engine tail nozzle 3, the fixed large tail chamber includes a coaxial and sequentially fixed connection through flanges. The converging section 20 of the tail chamber, the straight section 30 of the tail chamber and the expansion section 40 of the tail chamber, the replaceable small tail chamber 50 includes a small tail chamber flange 52 and a small tail chamber cylinder 51 that are coaxially fixedly connected, and the small tail chamber barrel The body 51 is arranged coaxially with the converging sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com