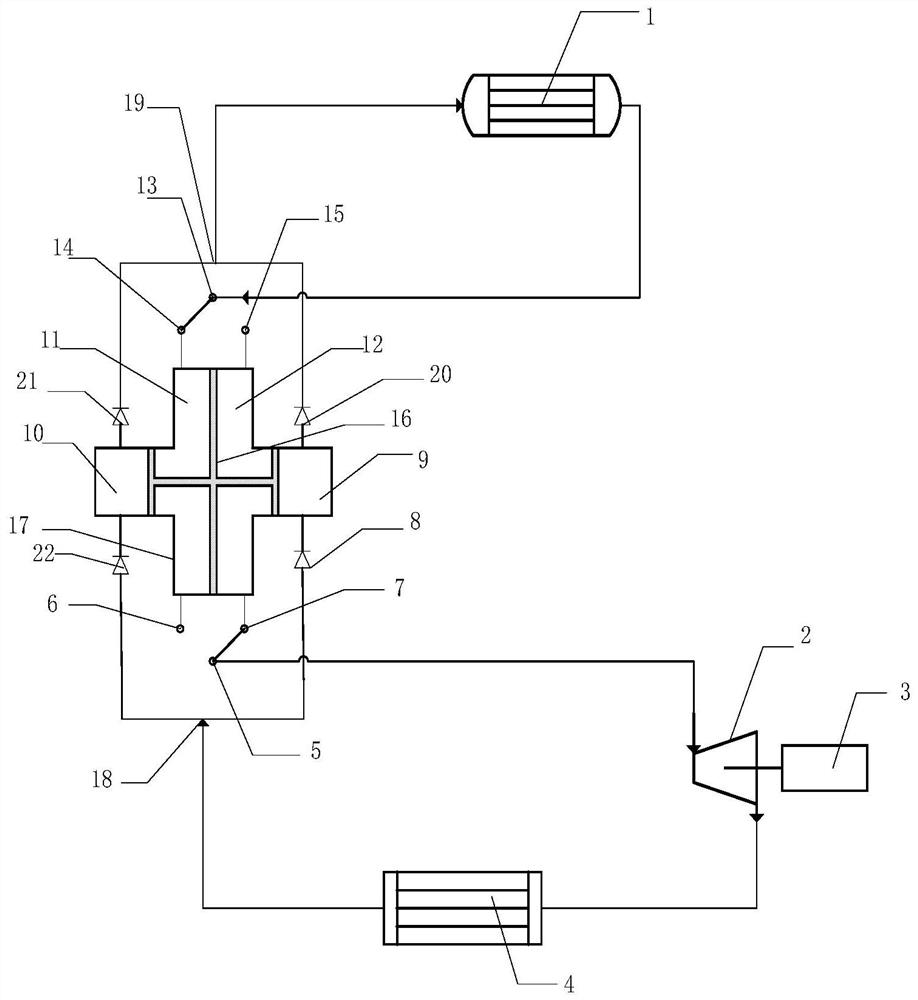

A Small Pressure Difference Steam Direct Drive High Boost Ratio Working Medium Pump for Organic Rankine Cycle

A technology of Rankine cycle and working medium pump, which is applied to parts, pump components, mechanical equipment, etc. of the pumping device used for elastic fluid, and can solve the problems of shaft seal vulnerability, low efficiency of working medium pump, performance attenuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] In the organic Rankine cycle, the outlet of the evaporator is connected to the inlet of the working fluid pump, the outlet of the working fluid pump is connected to the inlet of the expander, the outlet of the expander is connected to the condenser, the outlet of the condenser is connected to the liquid inlet of the working fluid pump, and the liquid outlet of the working fluid pump is connected. Connect the evaporator. When the port a of the three-way valve A is connected to the port b, the port d of the three-way valve B is connected to the port f, which means that the cylinder A is connected to the evaporator, and the cylinder B is connected to the expander. The pressure in the cylinder A is greater than that in the cylinder B. At this time, the volume of the cylinder A expands and the pressure decreases, the second inlet check valve is opened, the second outlet check valve is closed, and the working medium is sucked into the cylinder A. ; The working medium in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com