Multi-channel ejector for gas cooker, burner and gas cooker

A gas cooker and ejector technology, which is applied to gas fuel burners, burners, combustion methods and other directions, can solve problems such as poor ejection effect of the ejector, and achieves improved ejection capability, improved mixing effect, and improved mixing effect. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

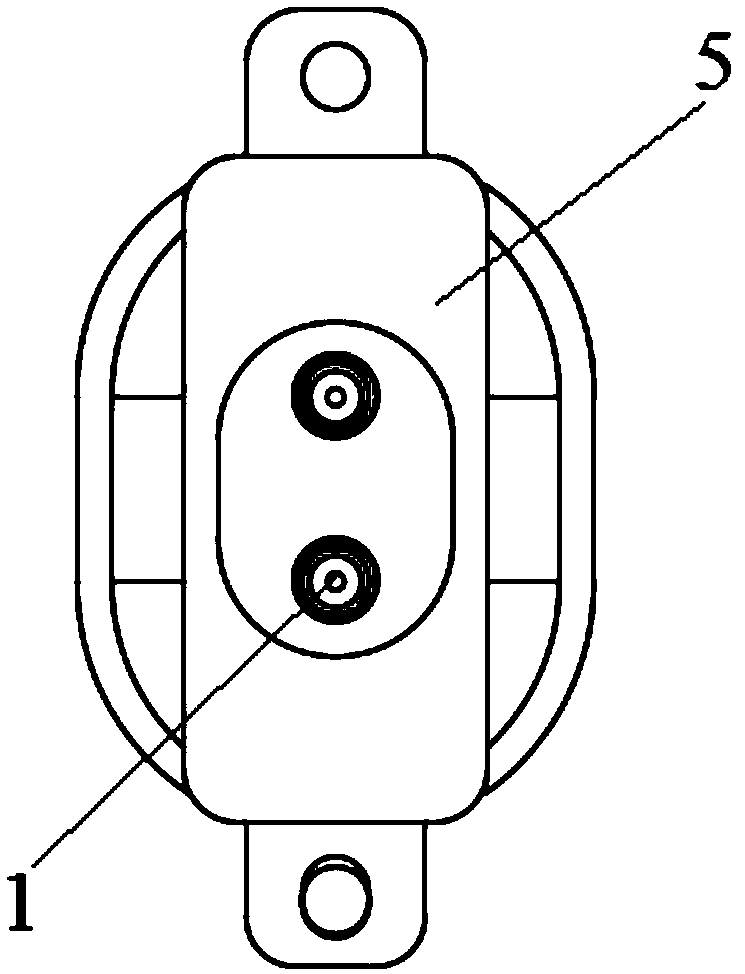

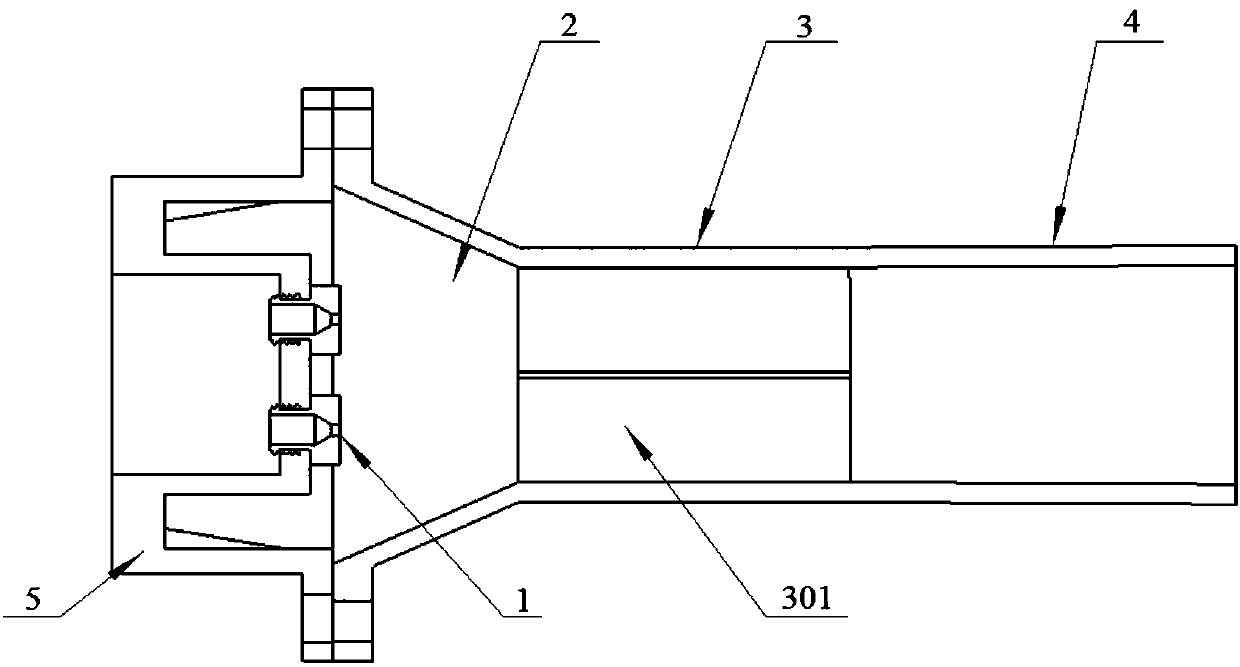

[0025] Embodiment 1: as image 3 As shown, the mixing tube 3 is composed of two sub-mixing tubes 301 , correspondingly, two nozzles 1 are arranged on the nozzle mounting base 5 , and each nozzle 1 is set corresponding to the position of a sub-mixing tube 301 .

Embodiment 2

[0026] Embodiment 2: as Figure 4 As shown, the mixing tube 3 is composed of three sub-mixing tubes 301 , correspondingly, three nozzles 1 are arranged on the nozzle mounting base 5 , and each nozzle 1 is set corresponding to the position of a sub-mixing tube 301 .

[0027] The second technical scheme provided by the present invention is:

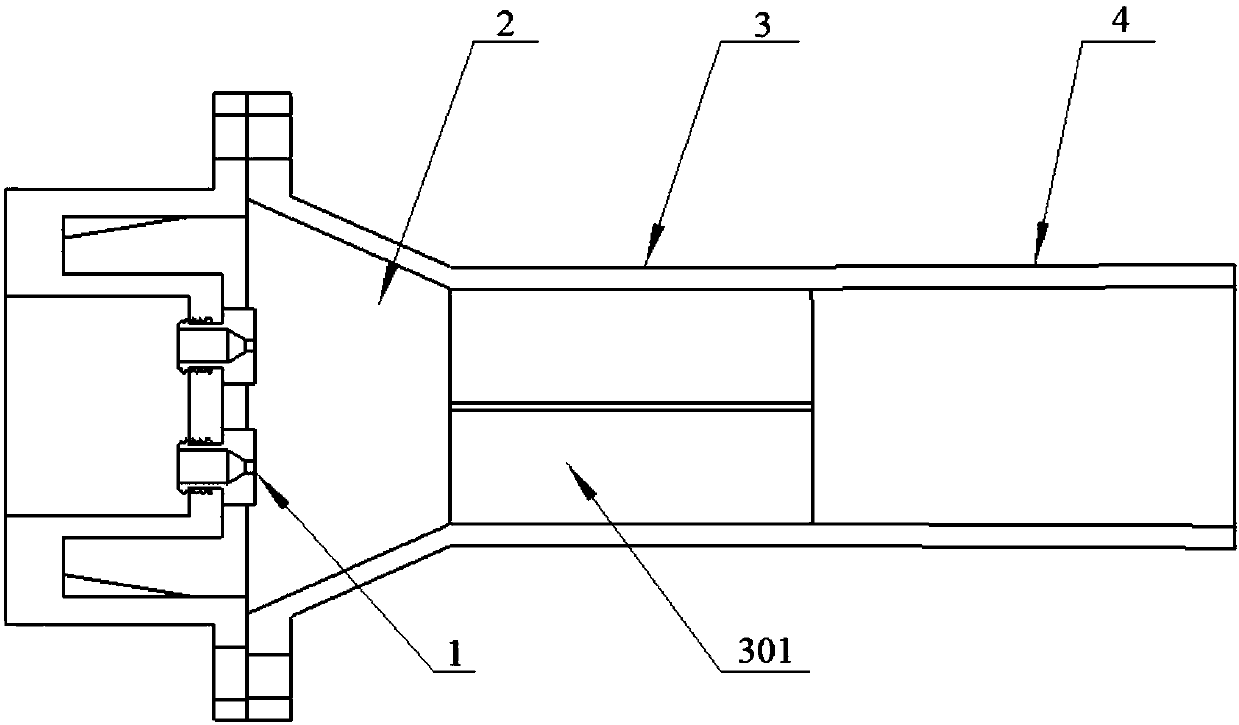

[0028] A burner comprising a burner head, a heating body and a gas distribution plate, the heating body is located in the gas distribution plate, the burner head is located below the gas distribution plate, an ejector is arranged on the burner head, The structure of the ejector is: as figure 1 As shown, it includes nozzles 1 and ejector pipes arranged in sequence along the direction of gas flow, and at least two nozzles 1 are arranged and docked with the ejector pipes; The suction shrinkage tube 2, the mixing tube 3 and the diffuser tube 4 are composed, the mixing tube 3 is composed of the same number of sub-mixing tubes 301 as the number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com