Large flow liquid oxygen supercooling method based on supersonic ejector

A liquid oxygen subcooling and ejector technology, which is applied in the direction of machine operation, refrigerators, refrigeration components, etc., can solve the problem of fast subcooling heat exchangers with large flow of liquid oxygen, low subcooling degree, and supercooling Low traffic and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

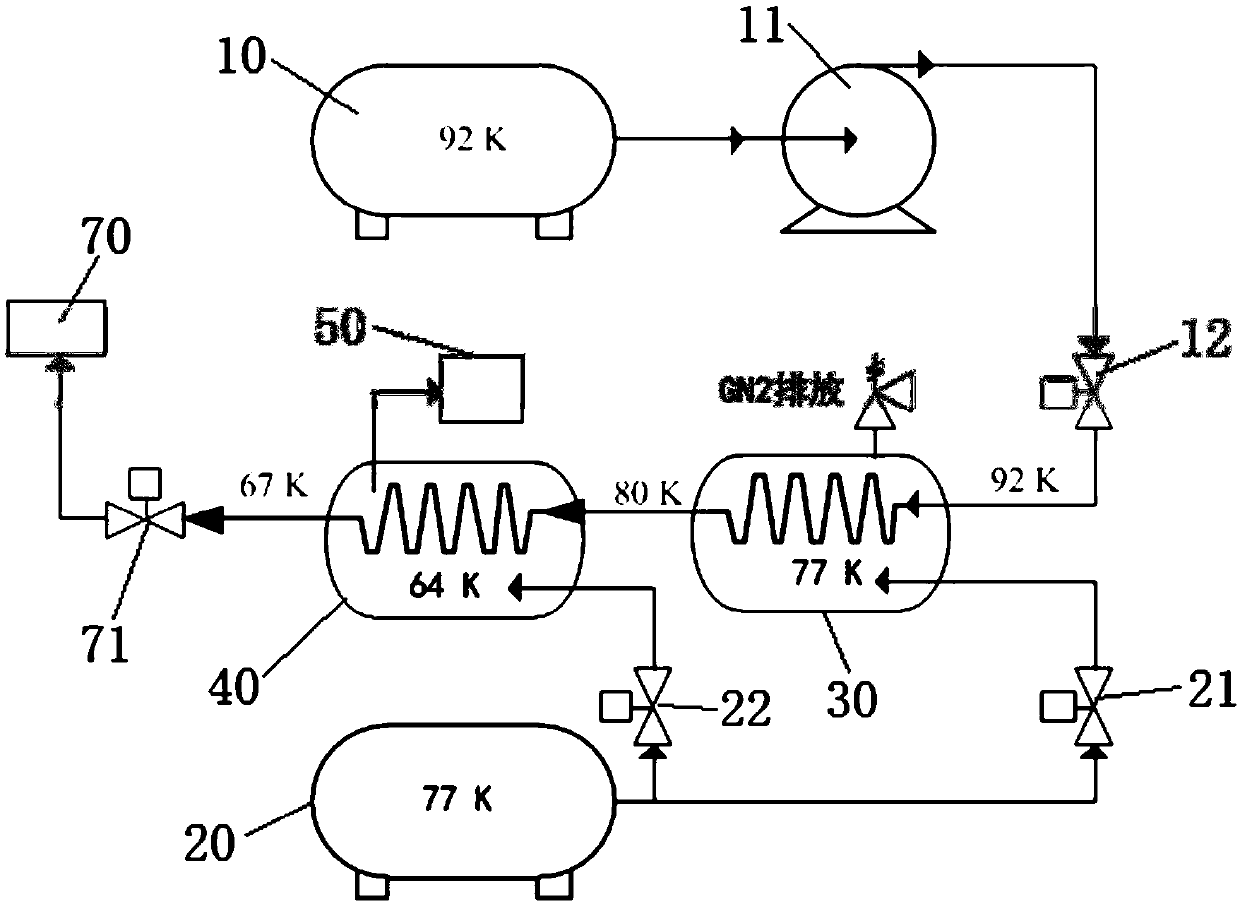

[0098] Such as figure 1 As shown, a large-flow liquid oxygen subcooling method based on a supersonic ejector uses the heat exchanger used for supercooling liquid oxygen with conventional saturated liquid nitrogen as the primary heat exchanger 30, and the primary heat exchanger can Subcool the liquid oxygen with a subcooling flow rate greater than 4500L / min from 92K to 80K.

[0099] The liquid oxygen in the liquid oxygen tanker 10 is connected to the inlet of the heat exchange tube in the primary heat exchanger 30 through the liquid oxygen pump 11 and the liquid oxygen filling valve 12 respectively. Among them, the liquid oxygen temperature in the liquid oxygen tank car is about 92K.

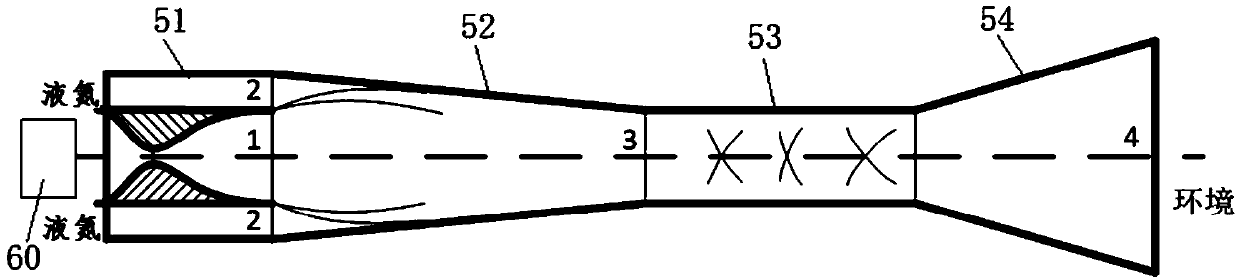

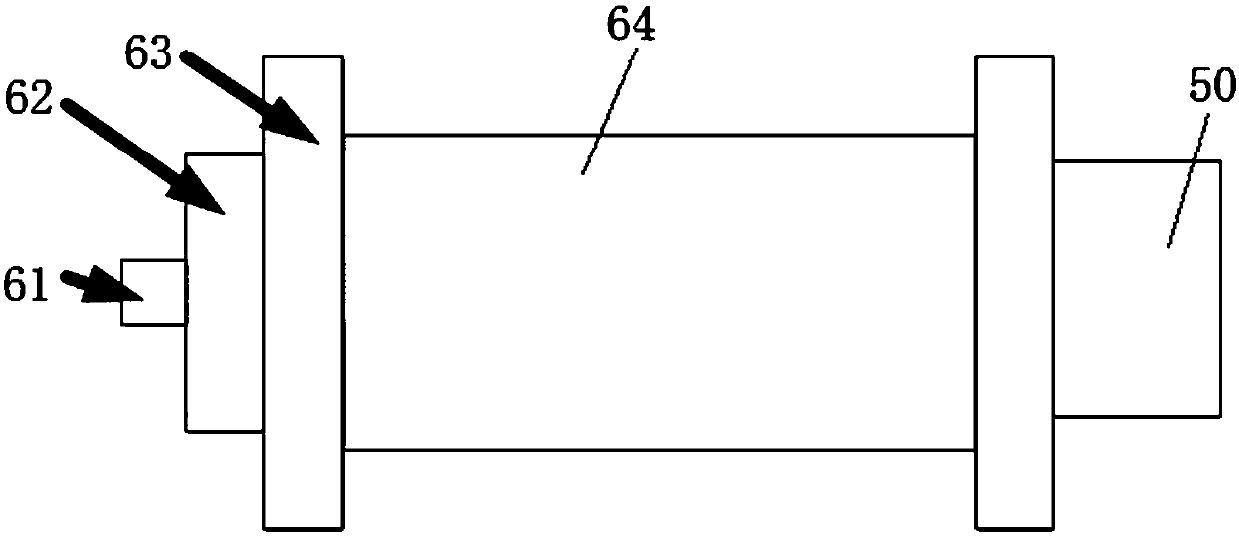

[0100] A secondary heat exchanger 40 is arranged downstream of the primary heat exchanger. This secondary heat exchanger can supercool the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com