Oily solid cleansing cosmetics

A cosmetic, solid technology, applied in the direction of cosmetics, cosmetics, cosmetic preparations, etc., can solve the problems of decreased hardness, difficulty in taking into account the usability and storage stability, insufficient storage stability, etc., and achieves excellent solubility and sufficient storage. Stability and hardness are not easily changed Effect of storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Preparation of the cosmetic base material includes a method of mixing the above-mentioned (A) component, (B) component, (C) component, (D) component, and other components added as needed while heating.

[0055] The mixing method is not particularly limited, and for example, a disperser, a homomixer, etc. can be used. Heating temperature can be set to more than the melting point of (A) component and (B) component.

[0056] The curing of the cosmetic base can be performed, for example, by a method of cooling the filled cosmetic base to room temperature.

[0057] As the specified container, a bottle, a tube, a can, a sachet container, etc. are mentioned.

Embodiment 1~15、 comparative example 1~7

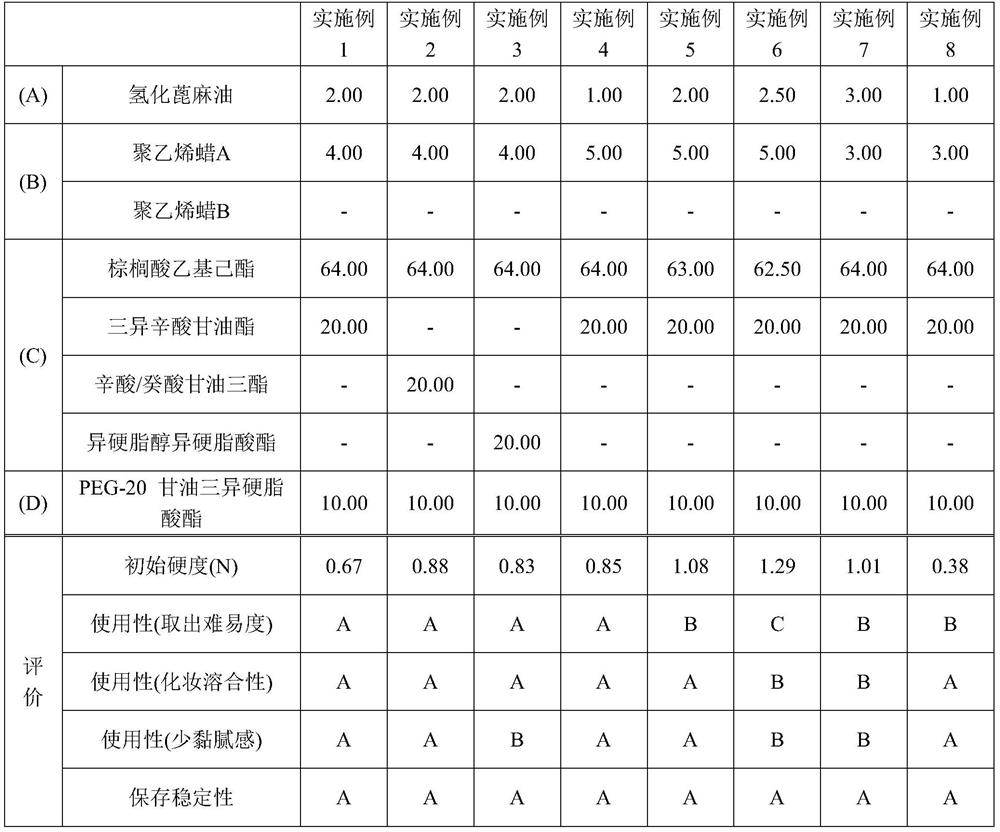

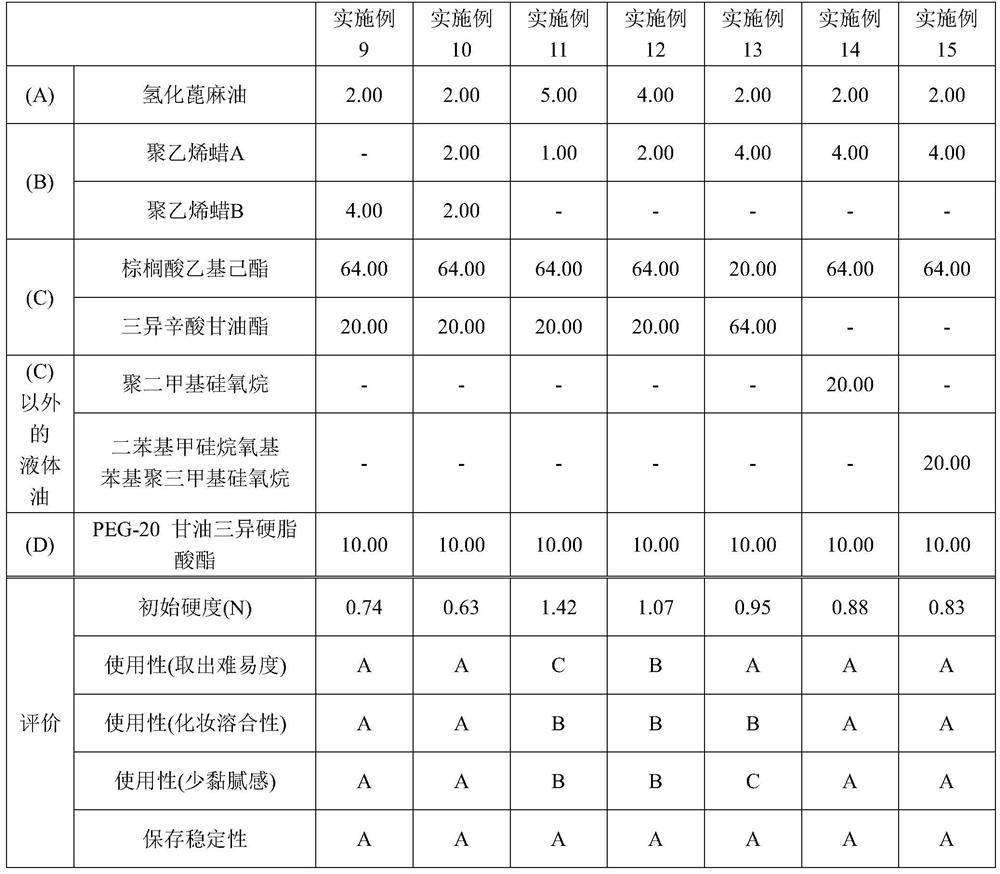

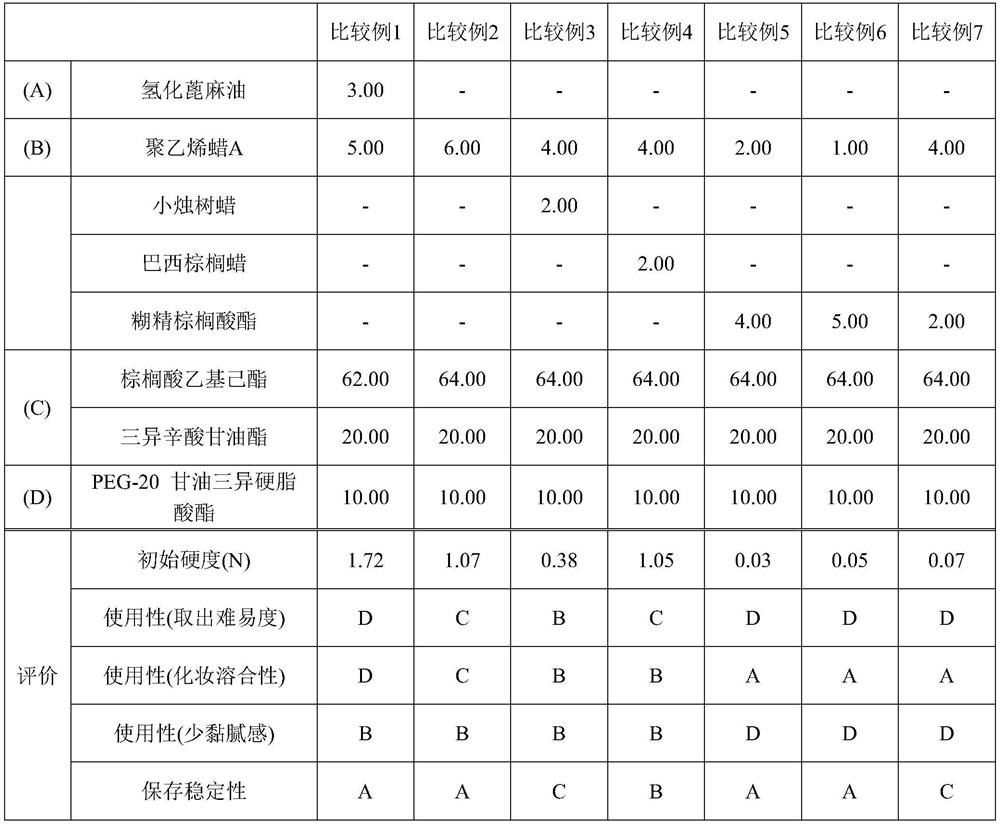

[0062] The components shown in Tables 1 to 3 were mixed at 105° C. at the ratio (mass %) shown in the same table using a disperser to obtain an oily solid cleansing cosmetic.

[0063] In addition, the detail of each component shown in Tables 1-3 is as follows.

[0064] Hydrogenated castor oil: melting point 85~87℃

[0065] Polyethylene wax A: PERFORMALENE 500 POLYETHYLENE (manufactured by Baker Petrolite LLC, product name, melting point 83.8° C.)

[0066] Polyethylene wax B: PERFORMALENE 655 POLYETHYLENE (manufactured by Baker Petrolite LLC, product name, melting point 96.7° C.)

[0067] Candelilla wax: melting point 75-85°C (catalogue value)

[0068] Carnauba wax: melting point 80-86°C (catalogue value)

[0069] Ethylhexyl palmitate: viscosity 11mPa·s (25°C)

[0070] Glyceryl triethylhexanoate: viscosity 31mPa s (25°C)

[0071] Caprylic / capric triglyceride: viscosity 26mPa s (25°C)

[0072] Isostearyl isostearate: viscosity 36mPa s (25°C)

[0073] Polydimethylsiloxane ...

Embodiment 16

[0110]

[0111] The details of each component are the same as above. Note that the viscosity of octyldodecanol at 25°C is 49 mPa·s.

[0112]

[0113] Components 1 to 5 were mixed at 105° C. using a disperser to obtain an oily solid cleansing cosmetic.

[0114]

[0115] After carrying out the same evaluation as above for the obtained oily solid cleansing cosmetics, the initial hardness was 0.66N, usability (ease of taking out was "A", makeup compatibility was "B", less sticky feeling "A"), storage stability is "A" results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com