Throat area adjustable static momentum-enhanced ejector

A throat area and injector technology, applied in the direction of injection devices, liquid injection devices, etc., can solve the problems of small adjustment range, loss of turbulent kinetic energy in the central flow field, fixed structural size, etc., to improve ejection performance and enhance momentum exchange , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

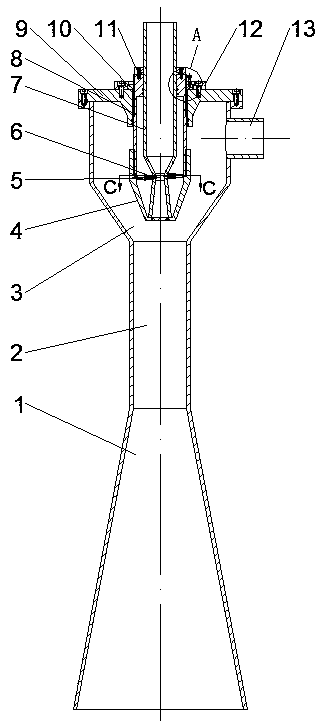

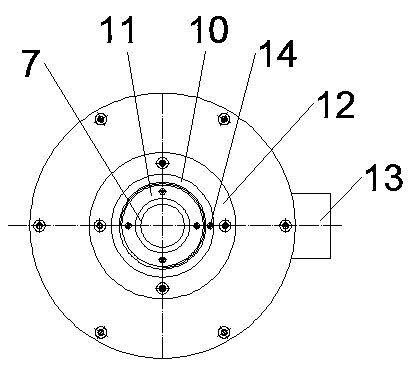

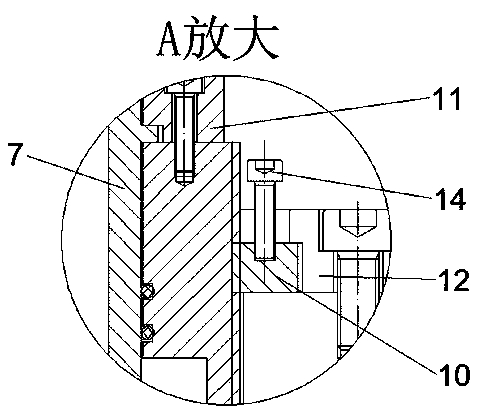

[0032] figure 1 , 2 , 3, 4, 5, 6 show the structural diagram of a static momentum enhanced injector with adjustable throat area. The static momentum enhanced injector with adjustable throat area includes a zoom-shaped working outer cavity and a main flow nozzle adjustment mechanism. The zoom-shaped working outer chamber includes the upper end surface 9 of the injector, the suction chamber 3 , the mixing chamber 2 , the expansion section 1 and the secondary inflow port 13 . The mainstream nozzle adjustment mechanism includes an adjustable base 4 , a rigid metal insert 5 , a driving nozzle base 7 and an axial adjustment base 8 . The axial adjustment base 8 is fixed at the center of the upper end surface 9 of the injector and extends into the suction chamber 3, the adjustable base 4 is screwed to the end of the axial adjustment base 8, the nozzle gland 11 drives the nozzle base 7 It is arranged in the axial adjustment base 8 in an axially limited and circumferentially rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com