Upper air inlet combustor and gas stove equipped with upper air inlet combustor

A technology for burners and gas passages, which is applied in the field of upward-inlet burners and gas stoves equipped with upward-inlet burners, and can solve the problems of burners with large thermal loads, limited increase in the length of ejector tubes, and large nozzle mounting bases. and other problems, to achieve good cleaning function, enhanced ejection effect, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The burner main body and burner mounting base of this embodiment are all formed by aluminum die-casting.

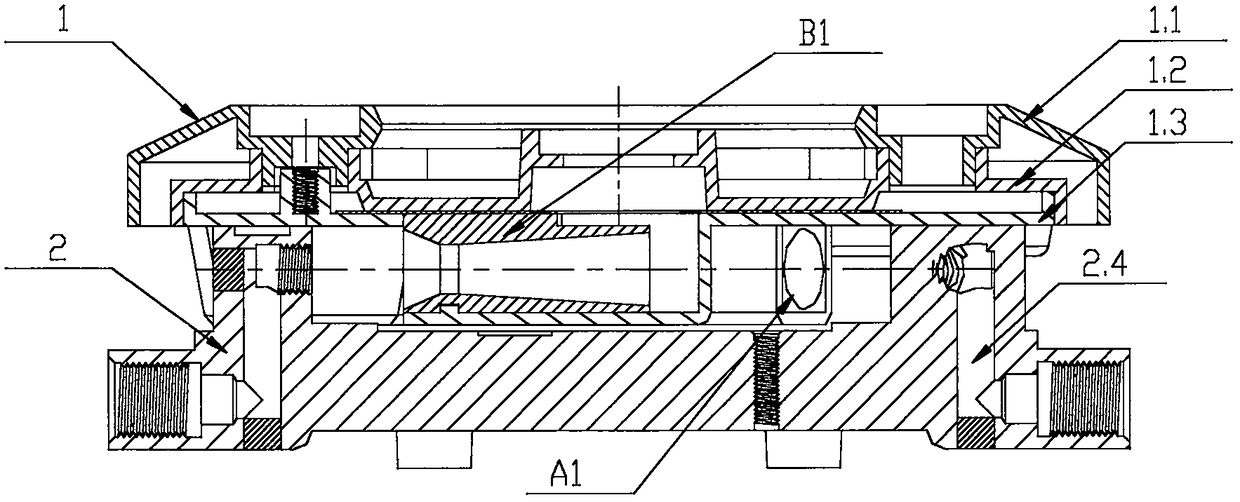

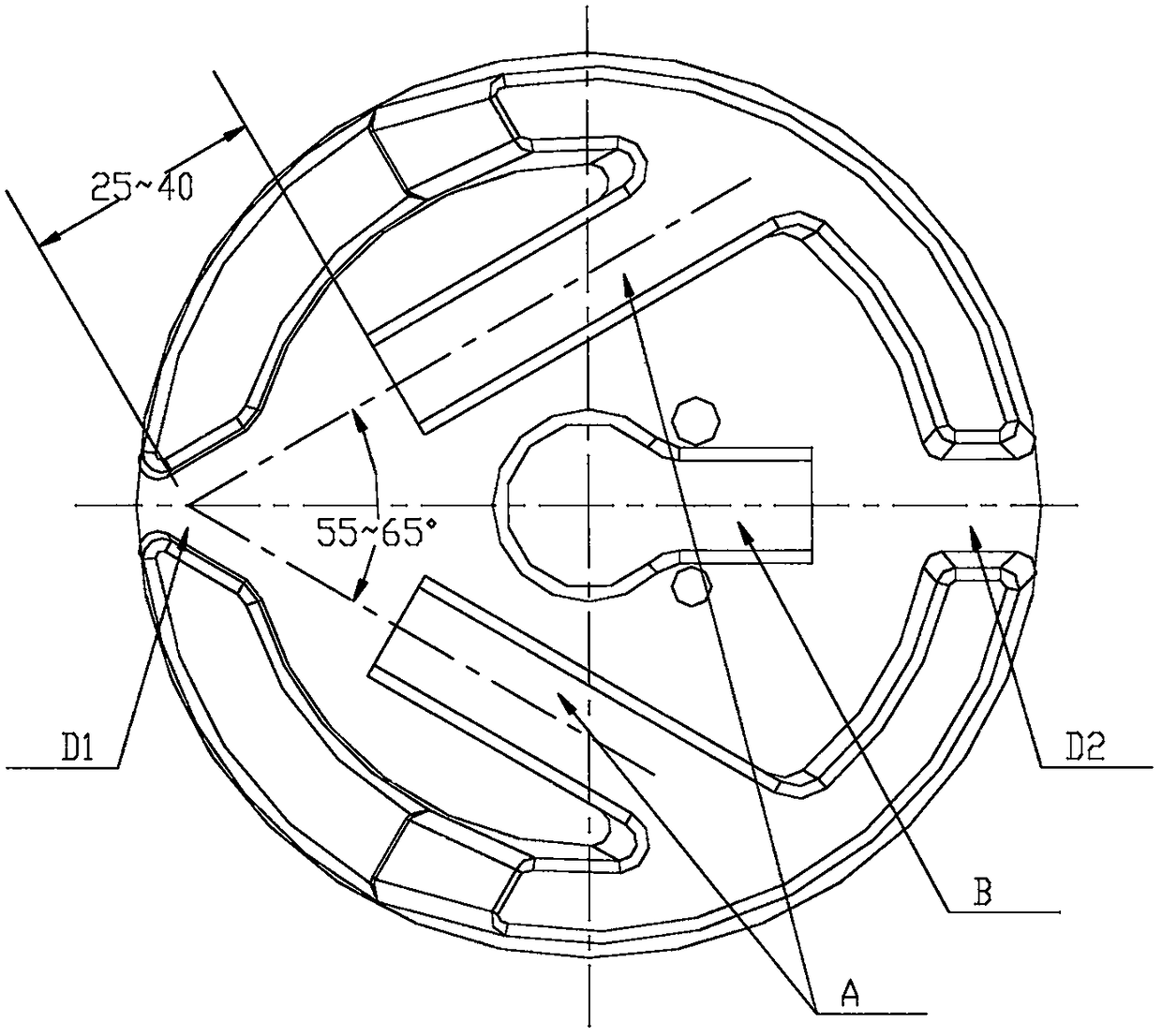

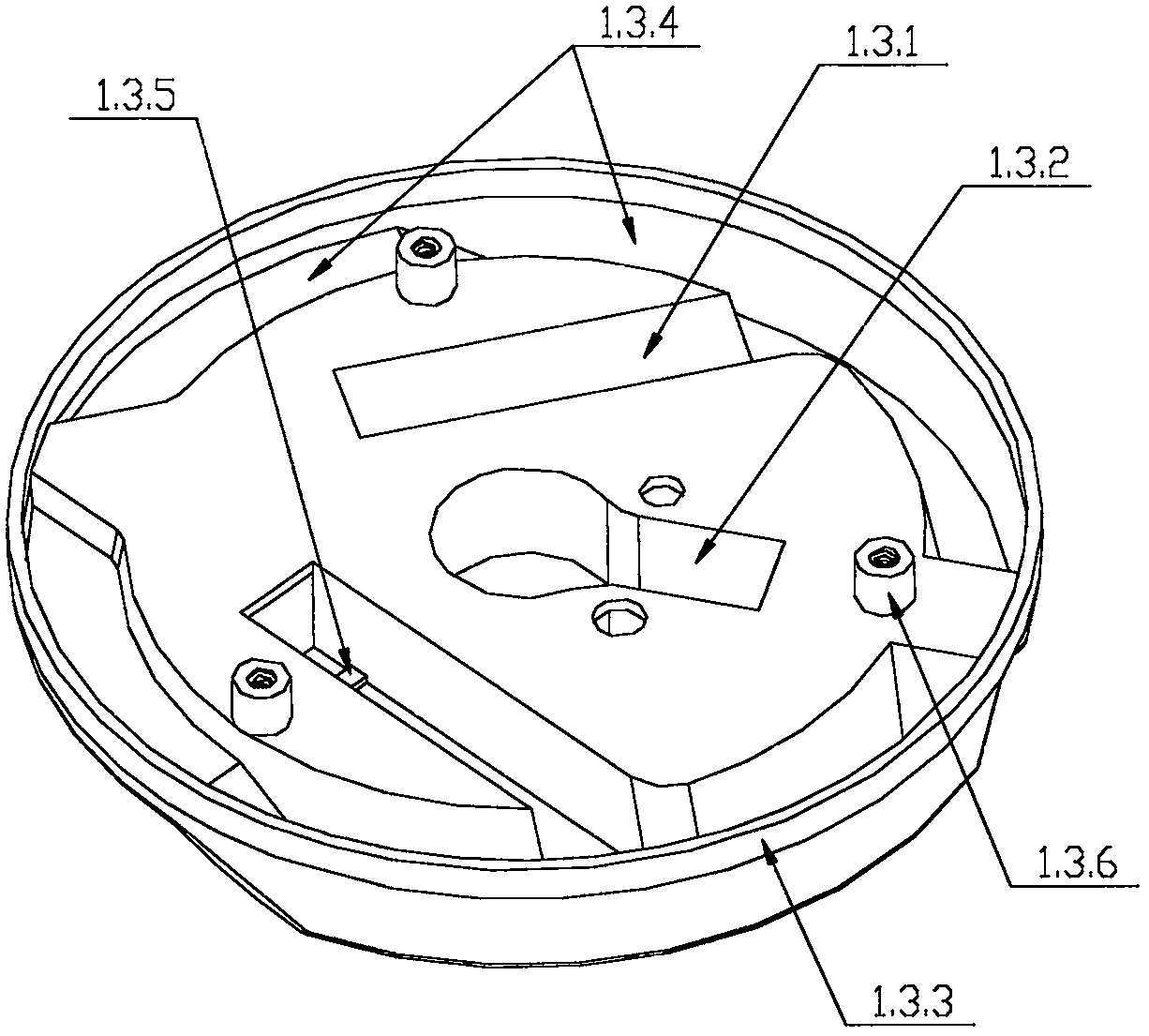

[0049] Such as Figure 1-9 As shown, the upper air inlet burner described in this embodiment 1 at least includes a burner body 1 and a burner mounting base 2. The burner body has two angles between 55° and 65° at the bottom of the burner body. °, and symmetrically distributed outer ring ejector A, the intersection of the center axes of the two outer ring ejectors is located close to the outside of the burner body, at a distance of 25 to 40 mm from the inlet end of the ejector; eject in the two outer rings Between the burners, there is an inner ring ejector B. The center axis of the inner ring ejector coincides with the angle symmetry plane of the two outer ring ejectors; below the burner body, it corresponds to the inlet of the outer ring ejector The burner main body installation and positioning grooves D1 and D2 are respectively provided at the end and the inlet end o...

Embodiment 2

[0063] This is another typical structure of the upper air inlet burner of the present invention. The burner body is made of stainless steel sheet metal parts, and the ejector tube and the burner fixed mounting seat are made of aluminum die casting.

[0064] This embodiment differs from embodiment 1 only in that the burner body is stretched and formed from stainless steel sheet; the mounting boss with threaded holes on the lower part of the burner body is formed by a welding structure; the upper part of the burner body and The diversion boss on the central part of the burner body has a circular structure; the shape of the fitting position of the upper part of the burner body and the outer ring fire cover can be determined according to the structure of the outer ring fire cover; for the central part of the burner body, the inner ring The fire cover mounting seat and the main part of the burner body are a combined structure, and the shape of the matching position with the inner fire ...

specific Embodiment approach

[0067] This is a typical structure of the gas stove of the present invention, and its specific implementation is as follows:

[0068] Such as Picture 10 As shown, the gas stove described in this embodiment is composed of a gas stove main body and an upper air inlet burner in either embodiment 1 or embodiment 2. The gas stove main body has a tempered glass panel and contains liquid On the plate 3, there are two openings 3.1, 3.2 corresponding to the nozzle mounting seat on the burner mounting base. The shape of the opening is compatible with the nozzle mounting seat shape and the nozzle auxiliary mounting boss shape; the burner is installed The base is fixed on the bottom shell of the gas stove. The ignition needle and flameout protection probe are fixed on the burner installation base through the limit pressure plate. The liquid pan is installed on the top surface of the burner installation base, and the burner body is installed on the burner. Install the top of the base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com