Structure and manufacturing method of explosion-proof foldable AMOLED display screen

A production method and display technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of weak impact resistance of ultra-thin glass, unfavorable folding screen, increased thickness, etc., to improve production Yield, good effect, enhanced toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

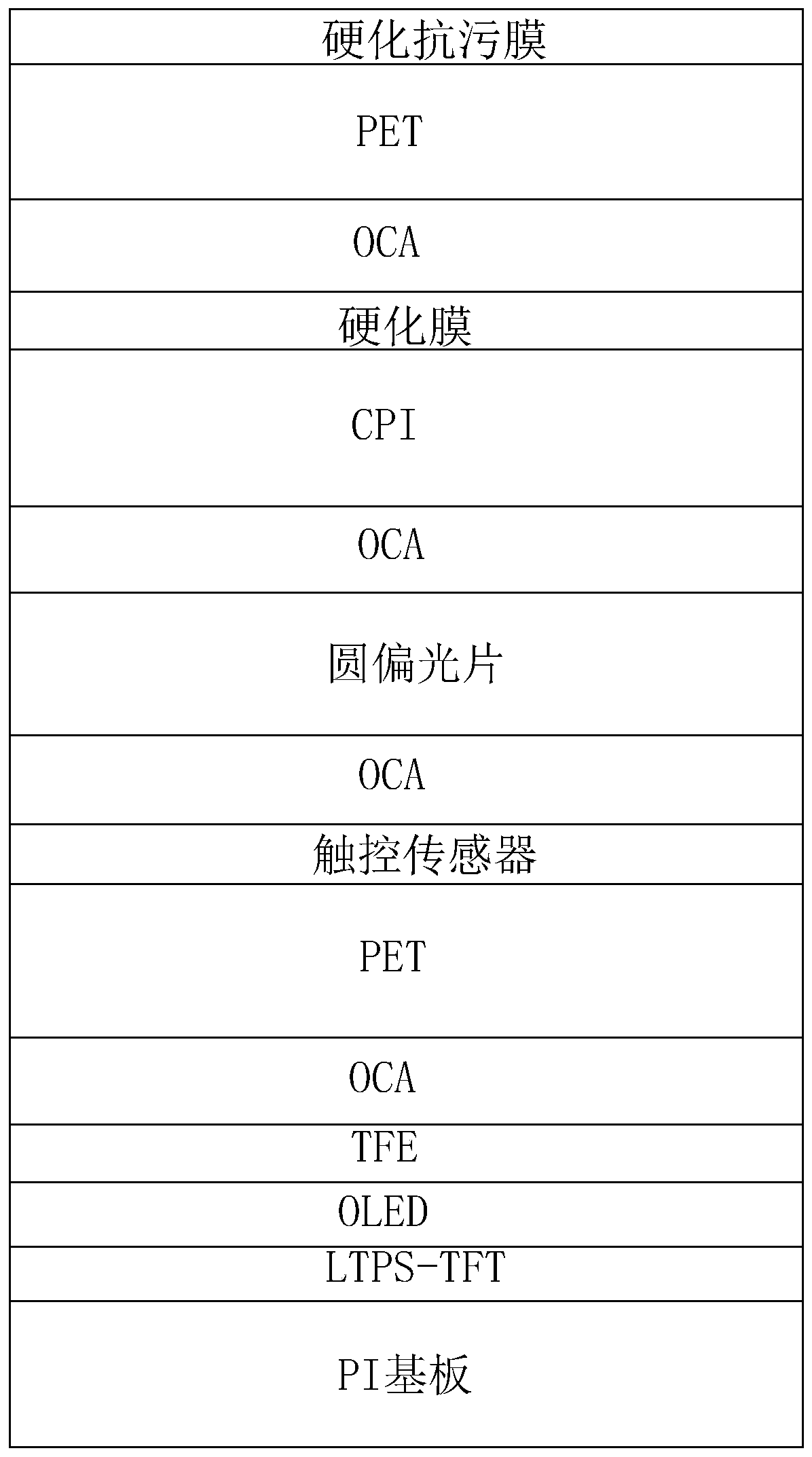

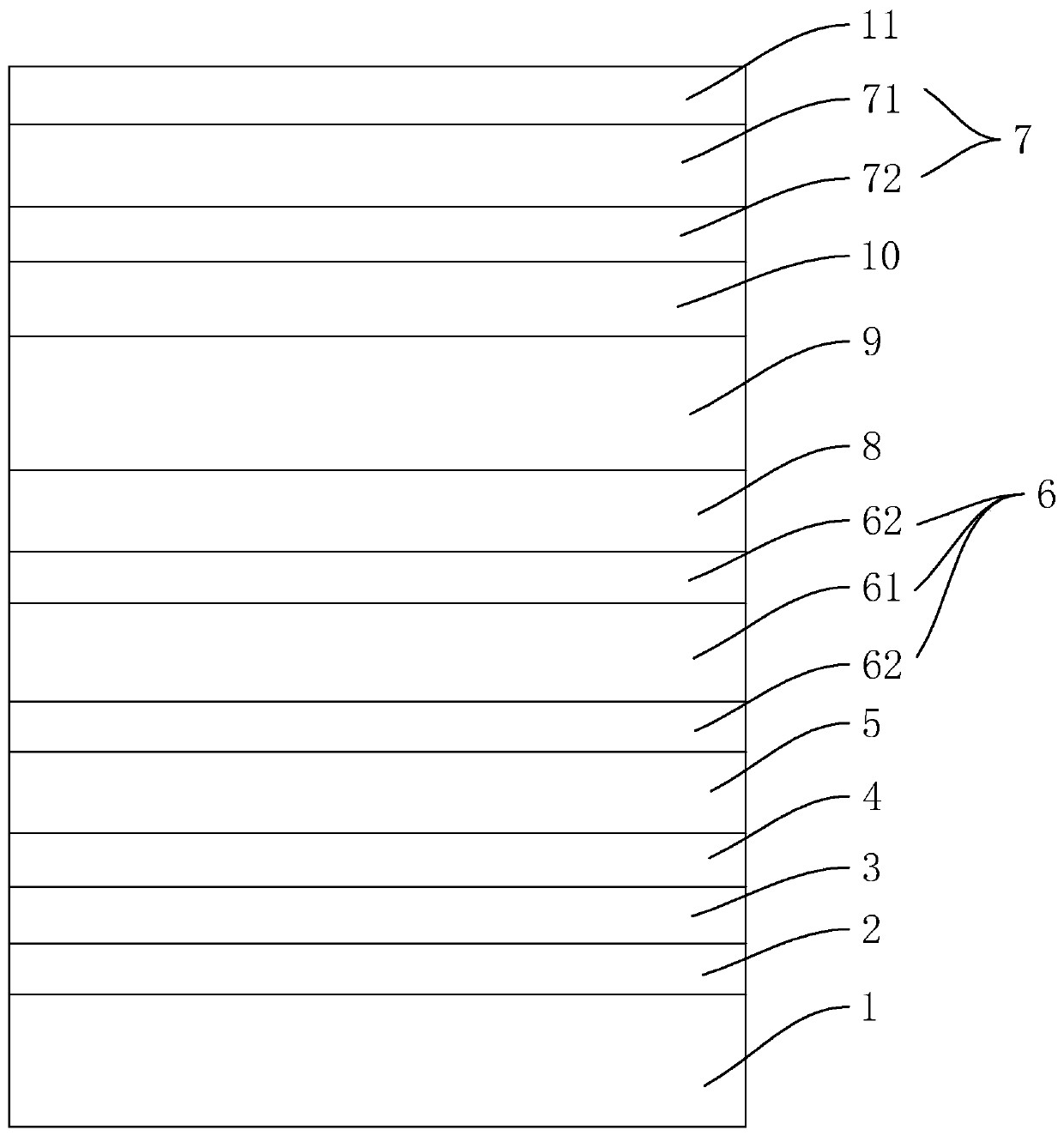

[0047] A structure of an explosion-proof foldable AMOLED display screen, which sequentially includes a PI substrate 1, a circuit driving layer 2, and an OLED layer 3 from bottom to top, and a multilayer thin film encapsulation layer 4 is arranged above the OLED layer 3, and the multilayer thin film encapsulation layer 4 is pasted with an ultra-thin glass layer 6, and the ultra-thin glass layer 6 includes ultra-thin glass 61 and an explosion-proof film 62 on the surface of the ultra-thin glass 61, and a circular polarizer 9 is pasted on the top of the ultra-thin glass layer 6, and the circular polarizer A PET layer 7 with a touch sensor 72 is pasted on the top of the sheet 9 , the touch sensor 72 is located under the PET 71 , and a hardened antifouling film 11 is arranged on the top of the PET layer 7 .

[0048] The circuit driving layer 2 in this embodiment is a TFT made of LTPS, the OLED layer 3 is RGB_OLED, and the TFT and OLED form an AMOLED.

[0049] In this embodiment, th...

Embodiment 2

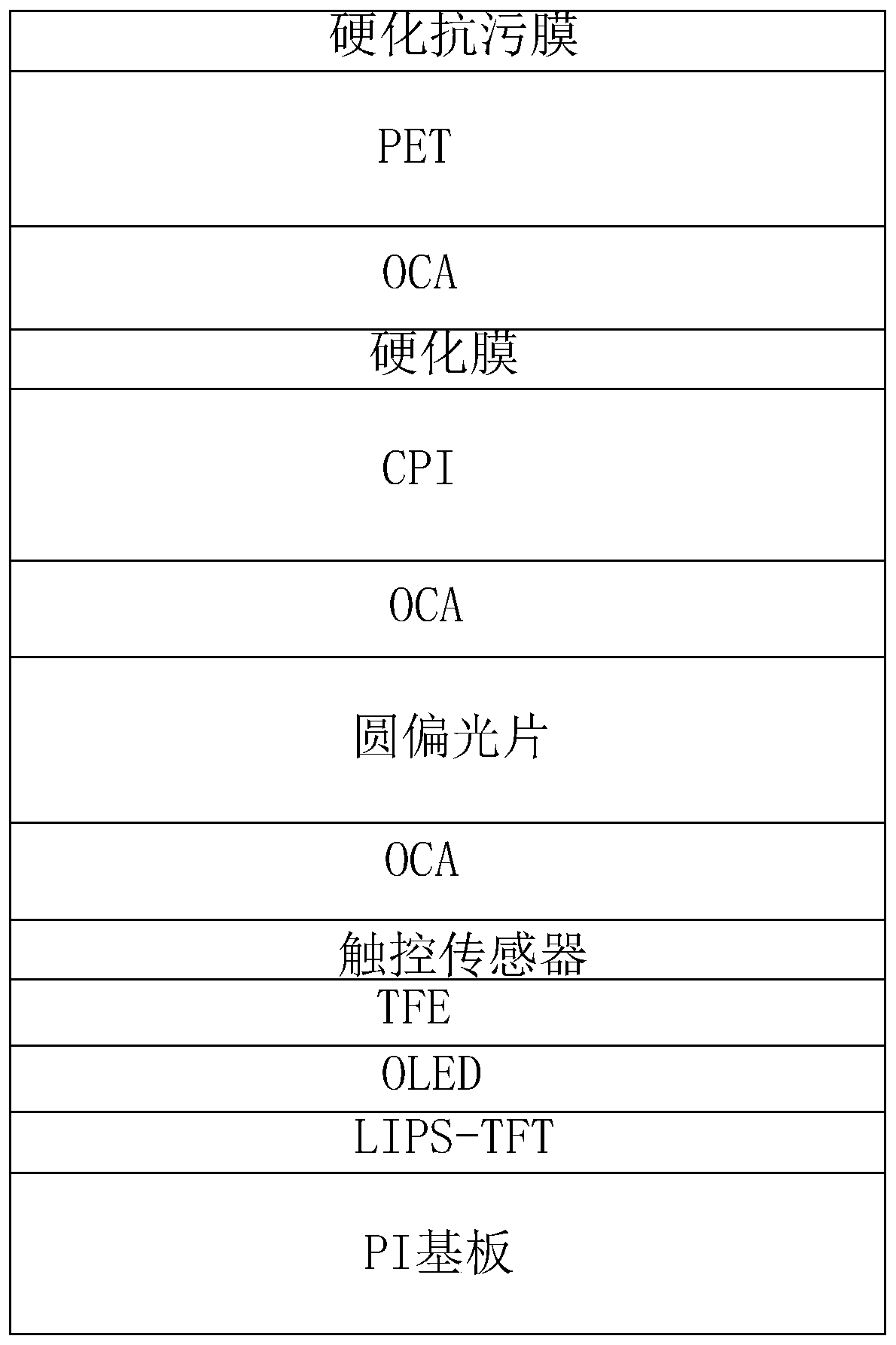

[0063] A structure of an explosion-proof foldable AMOLED display screen, which sequentially includes a PI substrate 1, a circuit driving layer 2, and an OLED layer 3 from bottom to top, and a multilayer thin film encapsulation layer 4 is arranged above the OLED layer 3, and the multilayer thin film encapsulation layer 4, a circular polarizer 9 is pasted on the top of the circular polarizer 9, and an ultra-thin glass layer 6 is pasted on the top of the circular polarizer 9. The ultra-thin glass layer 6 includes ultra-thin glass 61 and an explosion-proof film 62 on the surface of the ultra-thin glass 61. The ultra-thin glass A PET layer 7 with a touch sensor 72 is pasted on the top of the layer 6 , the touch sensor 72 is located below the PET 71 , and a hardened antifouling film 11 is arranged on the top of the PET layer 7 .

[0064] The explosion-proof film 62 is the same as the first embodiment, and is formed by printing the transparent explosion-proof ink on the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com