Quickly locked opening shrinking patterned sleeve of porous special-shaped mold core and application method thereof

An anisotropic core technology, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems of unsatisfactory positioning effect of porous anisotropic cores, difficult parts production, and high implementation costs, so as to simplify mold development costs and improve production. Efficiency, the effect of reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

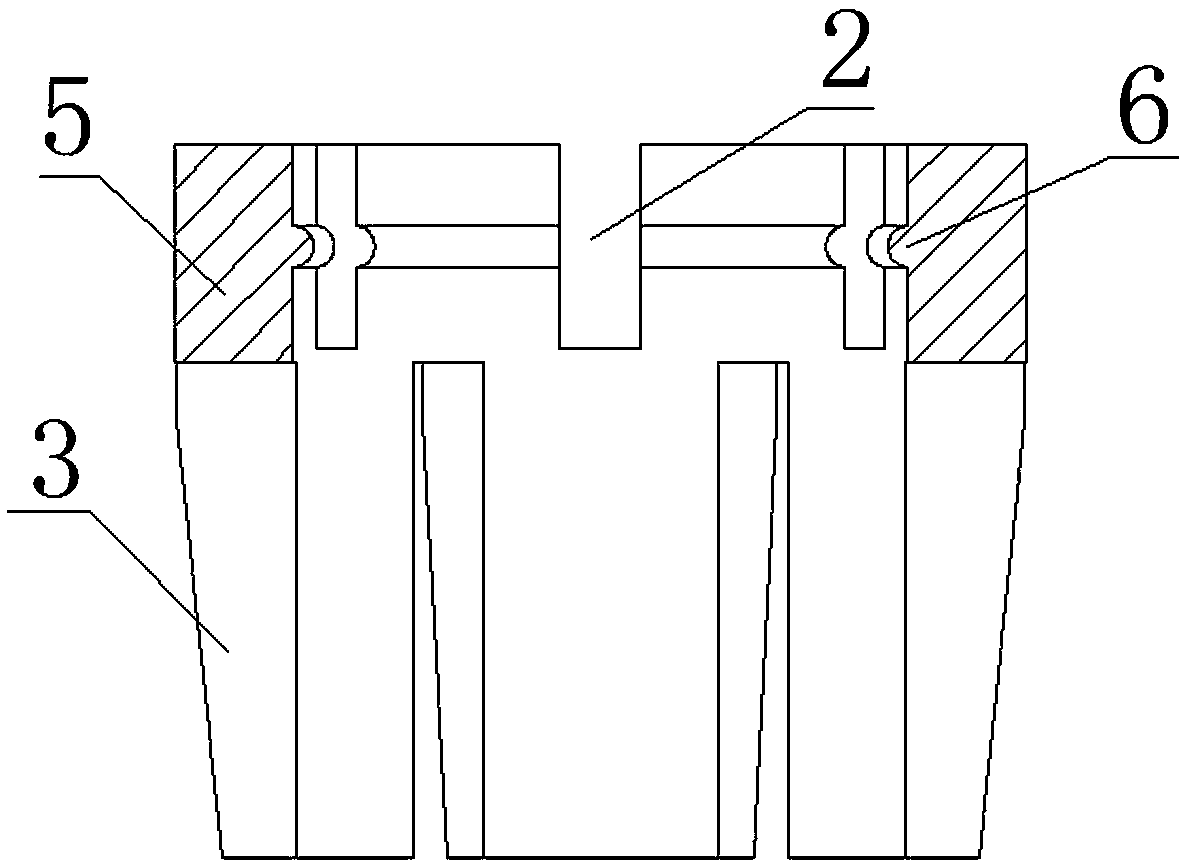

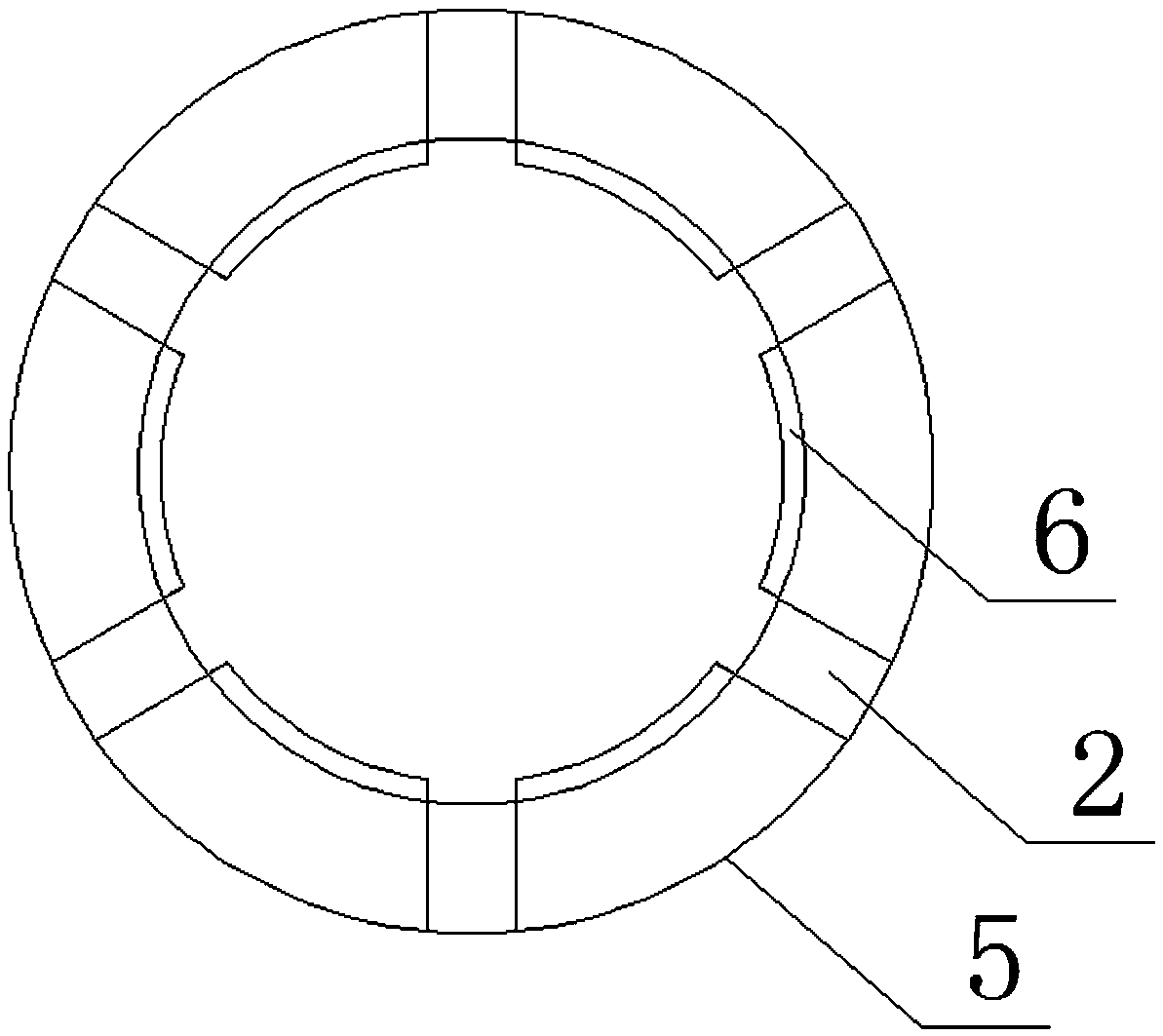

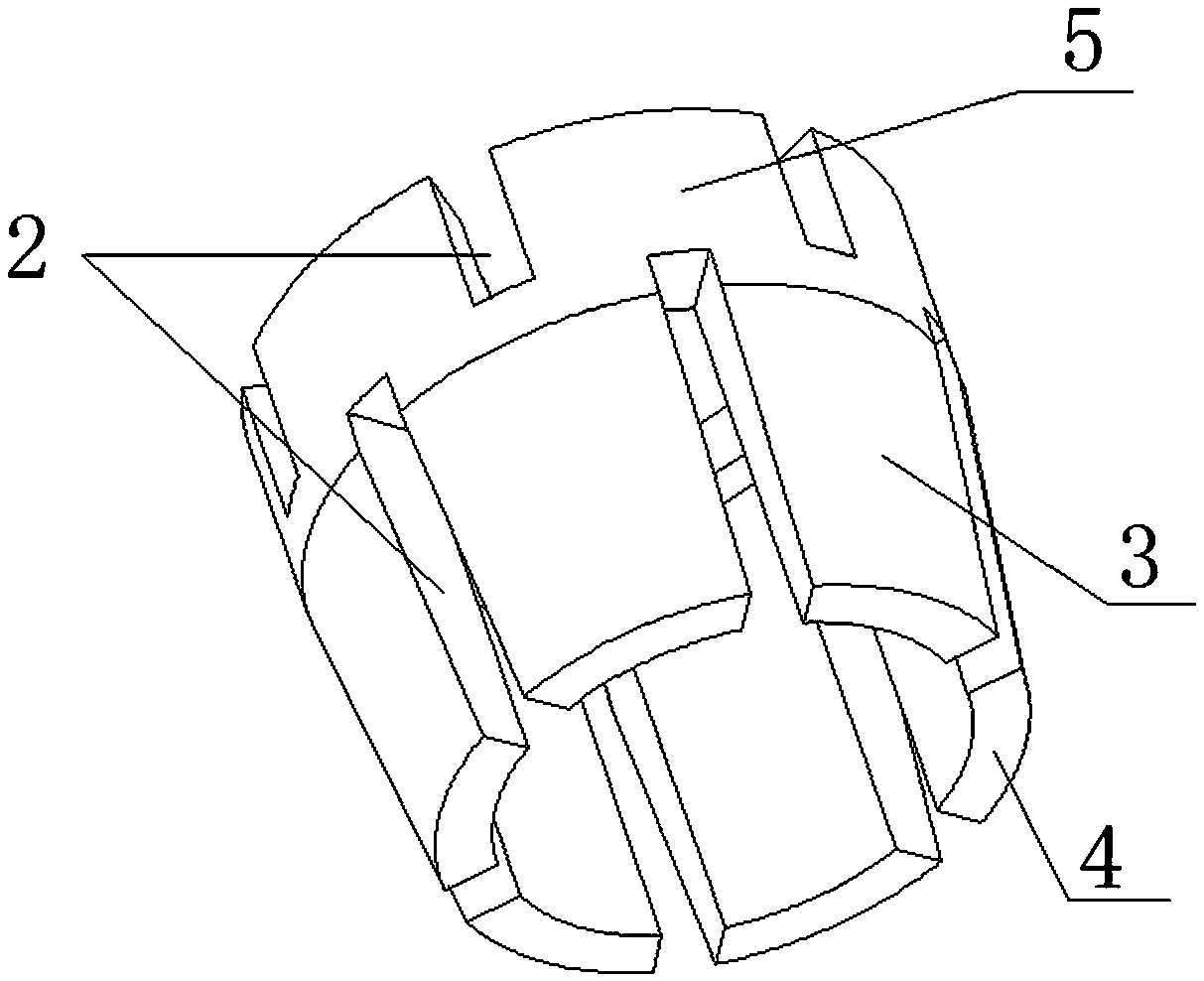

[0034] The present invention proposes a quick-lock opening shrinkable cover for a porous heterogeneous core. The entrance end 4 for the positioning post 1 to extend into has at least two gaps 2 at the entrance end 4 for the positioning post 1 to extend into, so that the side wall corresponding to the entrance end 4 of the sleeve is formed to shrink inward and hold tightly when used. The holding claw 3 of the porous heterogeneous core positioning column 1.

[0035] The flower sleeve is a barrel structure with one end open or a tubular structure with both ends open.

[0036] When the flower sleeve is a barrel-shaped structure with one end open, the opening end of the barrel-shaped structure is an inlet end, and a clasp 3 is formed on the side wall of the inlet end.

[0037] The other end of the barrel-shaped structure is a plug end, and at least one through hole is arranged on the end face of the plug end. (It is convenient to nail the flower sleeve into the positioning hole w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com