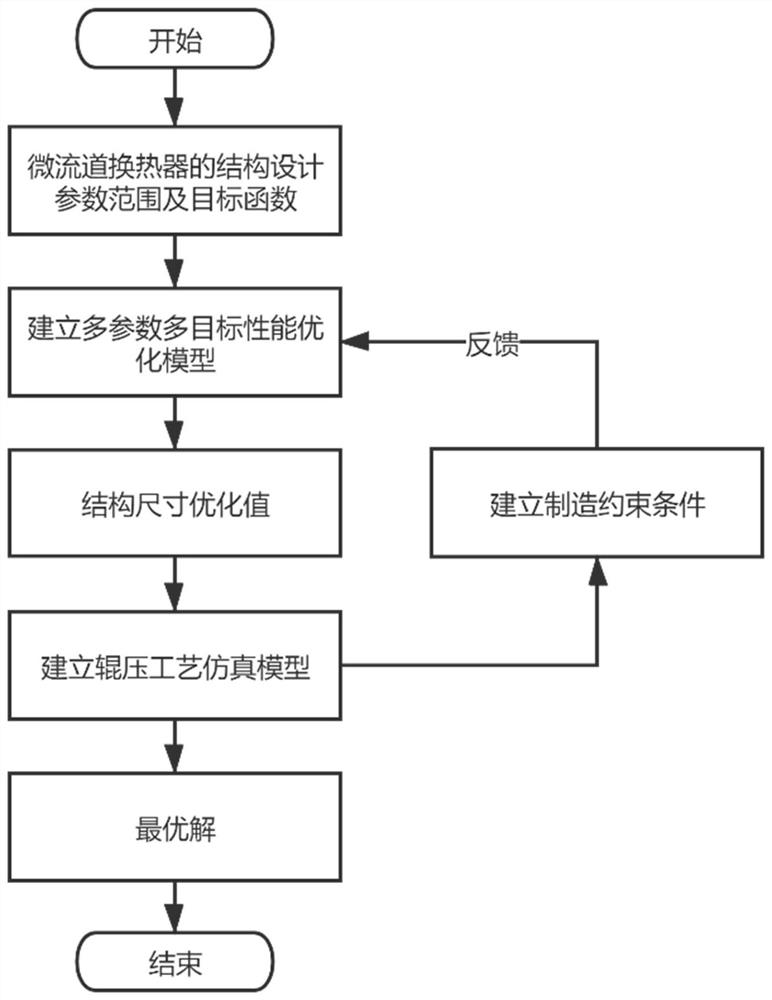

Array micro-channel heat exchanger performance optimization method considering manufacturing constraints

An optimization method and heat exchanger technology, applied in the direction of constraint-based CAD, design optimization/simulation, sustainable manufacturing/processing, etc., can solve problems such as the contradiction between the design and manufacture of array microchannel heat exchangers, and shorten research and development. Cycle time, good manufacturability, and the effect of reducing field test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

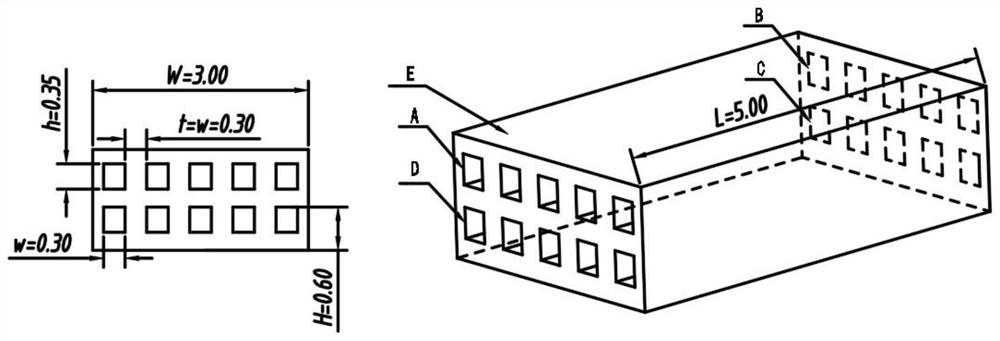

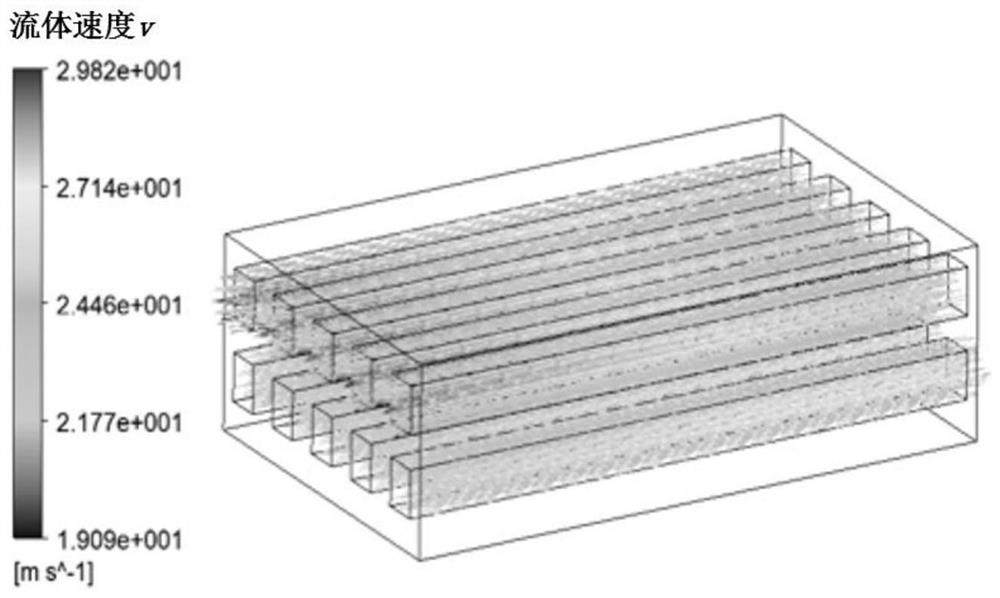

[0060] Multi-Parameter Multi-Target Heat Exchanger Performance Optimization Simulation Model Selection The selection of parameter ranges is mainly based on the design goals of the array micro-track heat exchangers, namely high efficiency, low resistance, and small volume. The design of the array micro track heat exchanger mainly solves two problems, which are the size of the heat exchanger and the examination of the heat exchanger. The size of the heat exchanger involves the structural size and heat transfer area of the heat exchanger micro track; the test problem of the heat exchanger involves the performance heat transfer and voltage drop in heat exchanger. For the size problem of the heat exchanger, the size of the micro track is mainly involved in the overall size of the heat exchanger. According to the current existing array micro-track heat exchanger, it is possible to determine the width of the micro track. [0.1, 0.3], the height h ∈ [0.25, 0.4] of the micro track [0.25, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com