High-performance fiberglass composition and fiberglass

A glass fiber and composition technology is applied in the field of inorganic non-metallic materials to achieve the effects of low production difficulty, high modulus and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

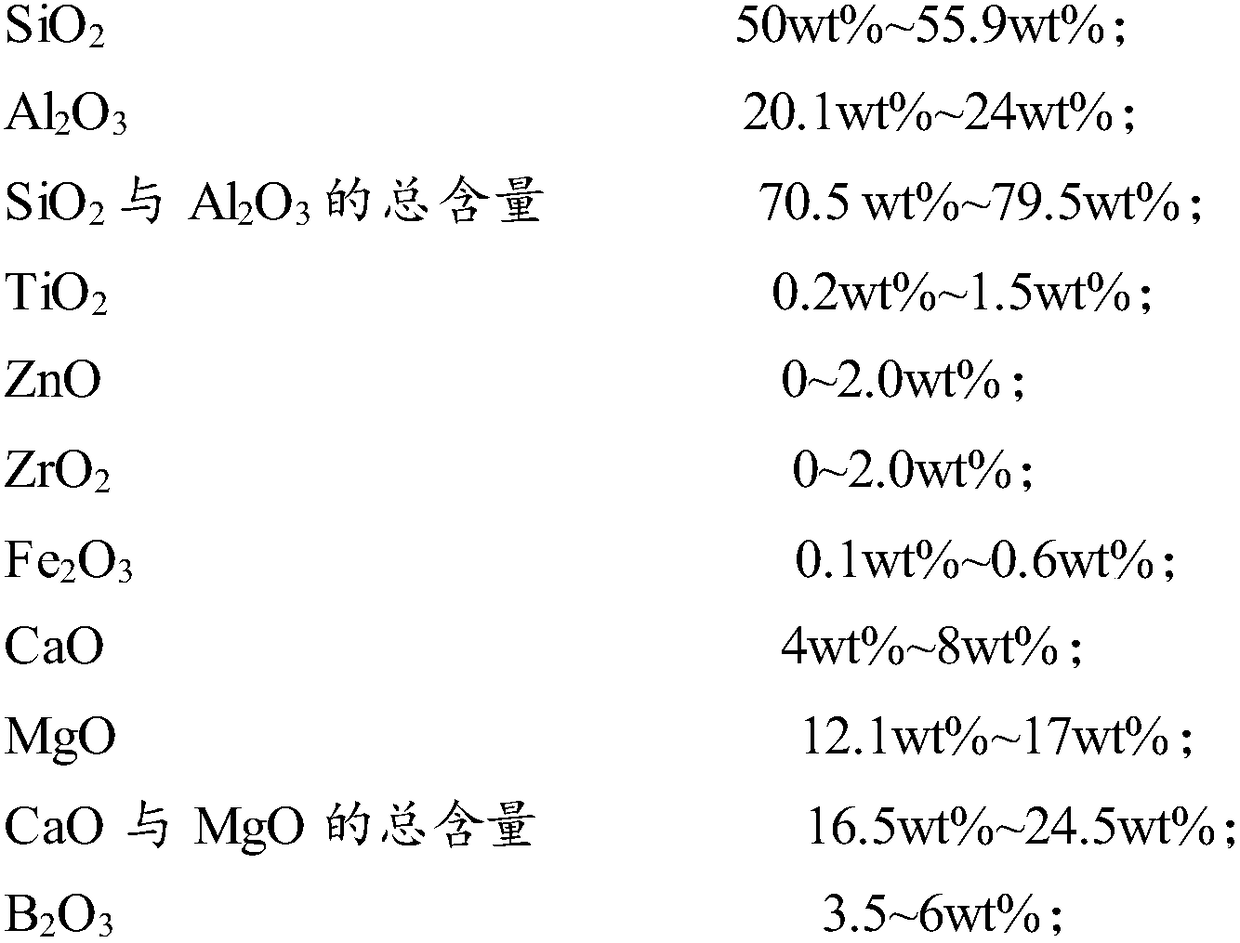

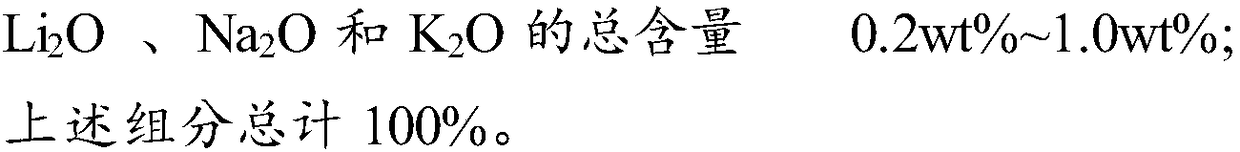

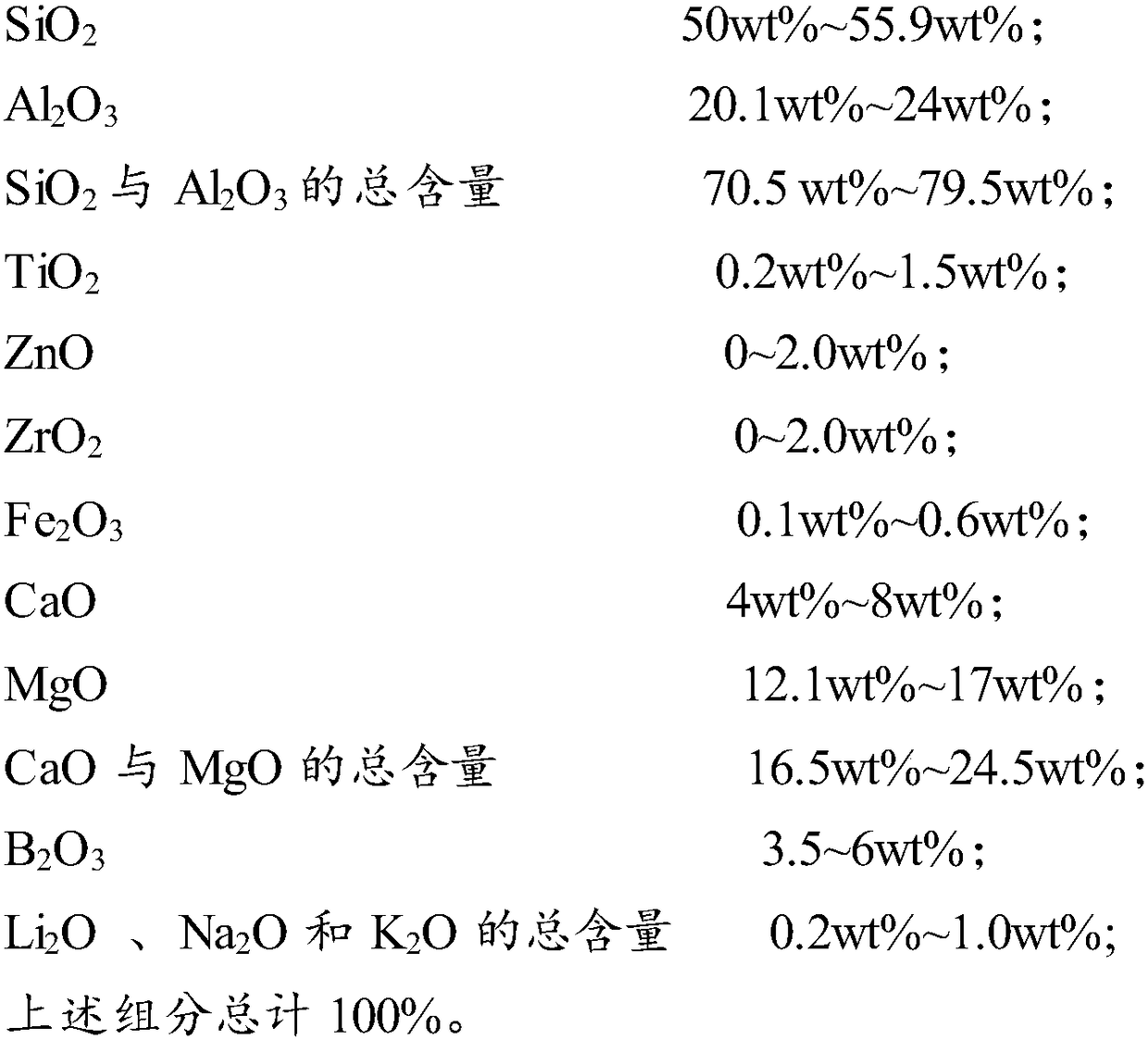

Method used

Image

Examples

preparation example Construction

[0038] The present invention has no special restrictions on the preparation method of the glass fiber, and it can be a method well known to those skilled in the art, preferably a tank kiln method, which can be prepared according to the following method:

[0039] According to the formula, the various raw materials are mixed uniformly and put into the kiln. After melting, clarification and homogenization, the glass liquid is obtained;

[0040] The glass fiber is obtained after temperature adjustment, flow out and wire drawing treatment of the molten glass.

[0041] The invention first mixes various raw materials in a mixing tank according to formula calculations, and after they are evenly mixed, they are transported to the tank kiln silo; then the tank kiln silo automatically puts the batch materials into the tank kiln in a quantitative manner at a temperature of 1400-1800°C Melt, clarify and homogenize under conditions to obtain qualified molten glass;

[0042] Cool the liquid glass to...

Embodiment 1

[0048] Transport the raw materials to the mixing tank according to the calculated formula, and after they are evenly mixed, they are transported to the kiln silo through the batching system. The formula is shown in Table 1

[0049] The batch materials in the silo of the tank kiln are automatically put into the tank kiln in a quantitative amount. In the tank kiln, the batch materials are gradually melted into molten glass at a high temperature above 1400 ℃. After clarification and homogenization, the stable and high-quality molten glass enters the drawing operation aisle;

[0050] After the glass liquid is cooled to a suitable temperature in the wire drawing channel, it flows out through the platinum drain plate, and is quickly drawn by the wire drawing machine into a glass wire with a diameter of 3-25μm. After the glass wire is spray-cooled, coated with a sizing agent, and bundled, it is wound into Silk cake

[0051] All silk cakes can be produced into various glass fiber products t...

Embodiment 2~6

[0054] The preparation method is the same as in Example 1, except that the glass formula content has changed, as shown in Table 1.

[0055] The performance test of the glass fiber was performed, and the results are shown in Table 1. Table 1 is a formula and performance data table of the glass fiber provided in the embodiment and the comparative example of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystallization upper limit temperature | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com