Low-heat-leakage and low-temperature container

A low-temperature container and low heat leakage technology, which is applied to pressure vessels, container filling methods, container discharge methods, etc., can solve the problems of eddy current loss, large heat leakage, and more absorbed radiant heat, and achieve good electrical insulation and reduce Effect of radiant heat and no eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

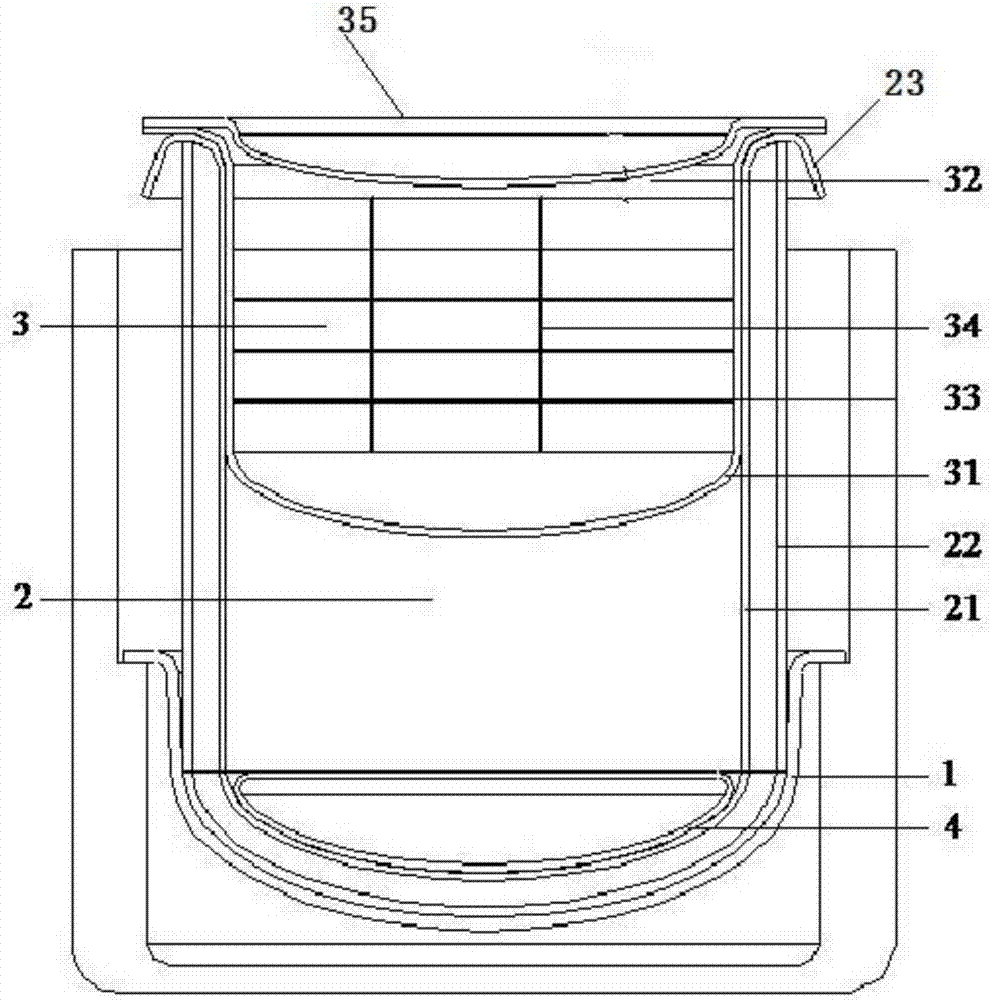

[0028] see figure 1 , is a schematic cross-sectional structure diagram of a low heat leakage cryogenic container provided in the present application.

[0029] The low-temperature container with low heat leakage comprises: a ground support 1 for a basin body, a container body 2 and a cover 3 .

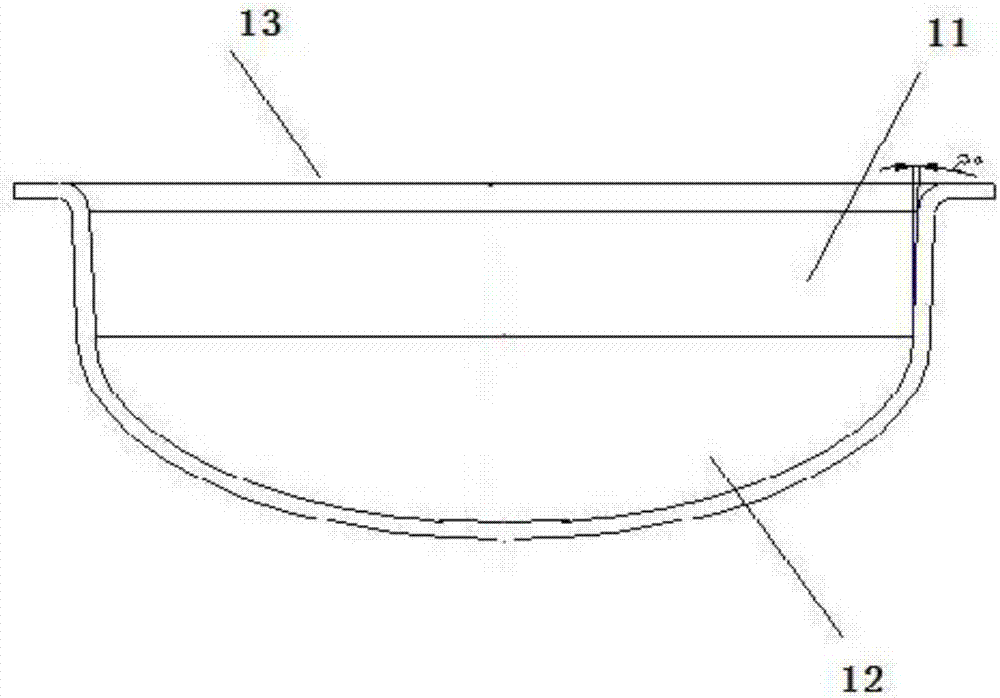

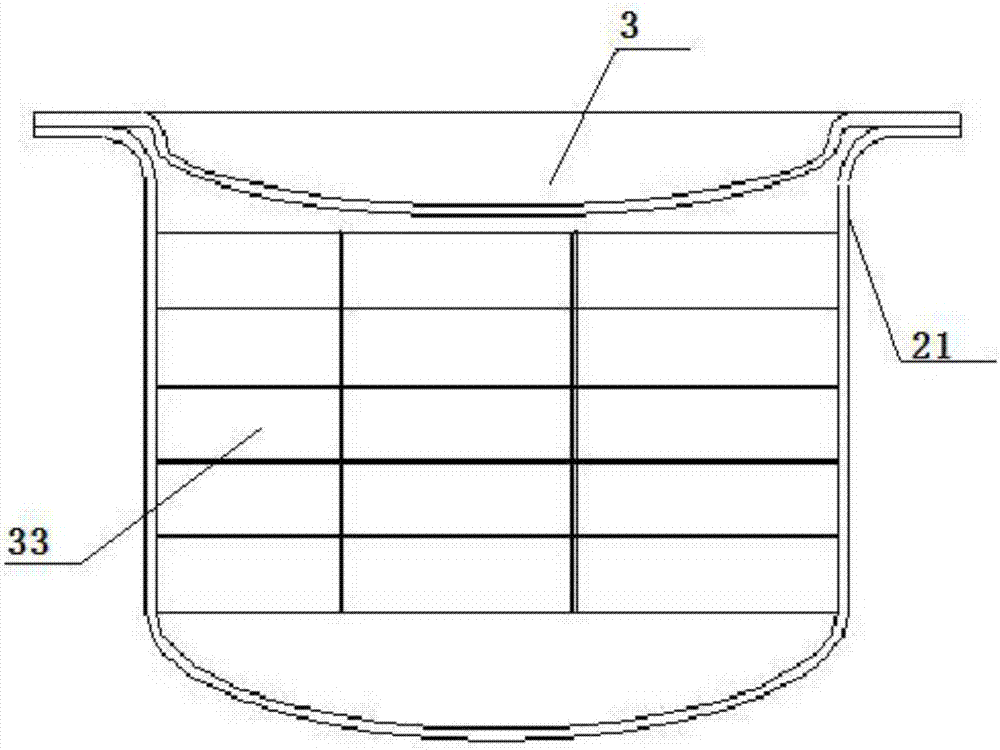

[0030] Wherein, the container body 1 includes a cylindrical inner cylinder 21 whose bottom surface is an ellipsoidal shell and a cylindrical outer cylinder 22 whose bottom surface is an ellipsoidal shell, the cylindrical inner cylinder 21 is arranged on the inner bottom surface of the cylindrical outer cylinder 22, and the cylinder inner cylinder 21 The upper part of the wall is bent outwards to form a flash edge 23; the cylindrical inner cylinder 21 is bonded to the wall of the cylindrical outer cylinder 22 through the flash edge 23 to form a double-layer vacuum chamber sealed space; the cover 3 includes a lower basin body 31 located at the bottom of the cover And the upper basin body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com