Composite contactor

A composite contact and contactor technology, applied in the field of electrical switches, can solve the problems of limited inrush current suppression, long working time, large eddy current loss, etc., and achieves small contact bounce time, short conduction time, no Effect of Eddy Current Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

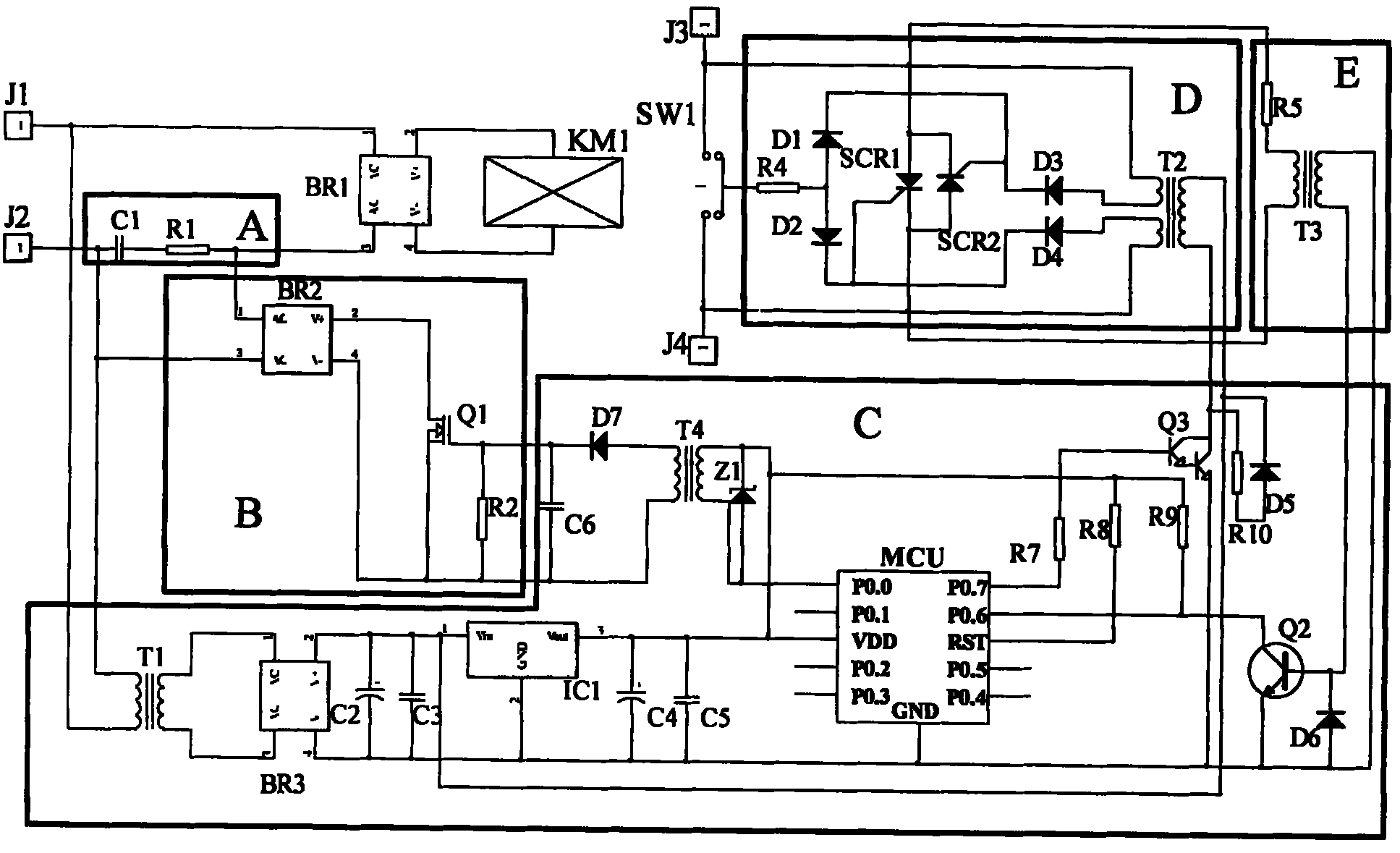

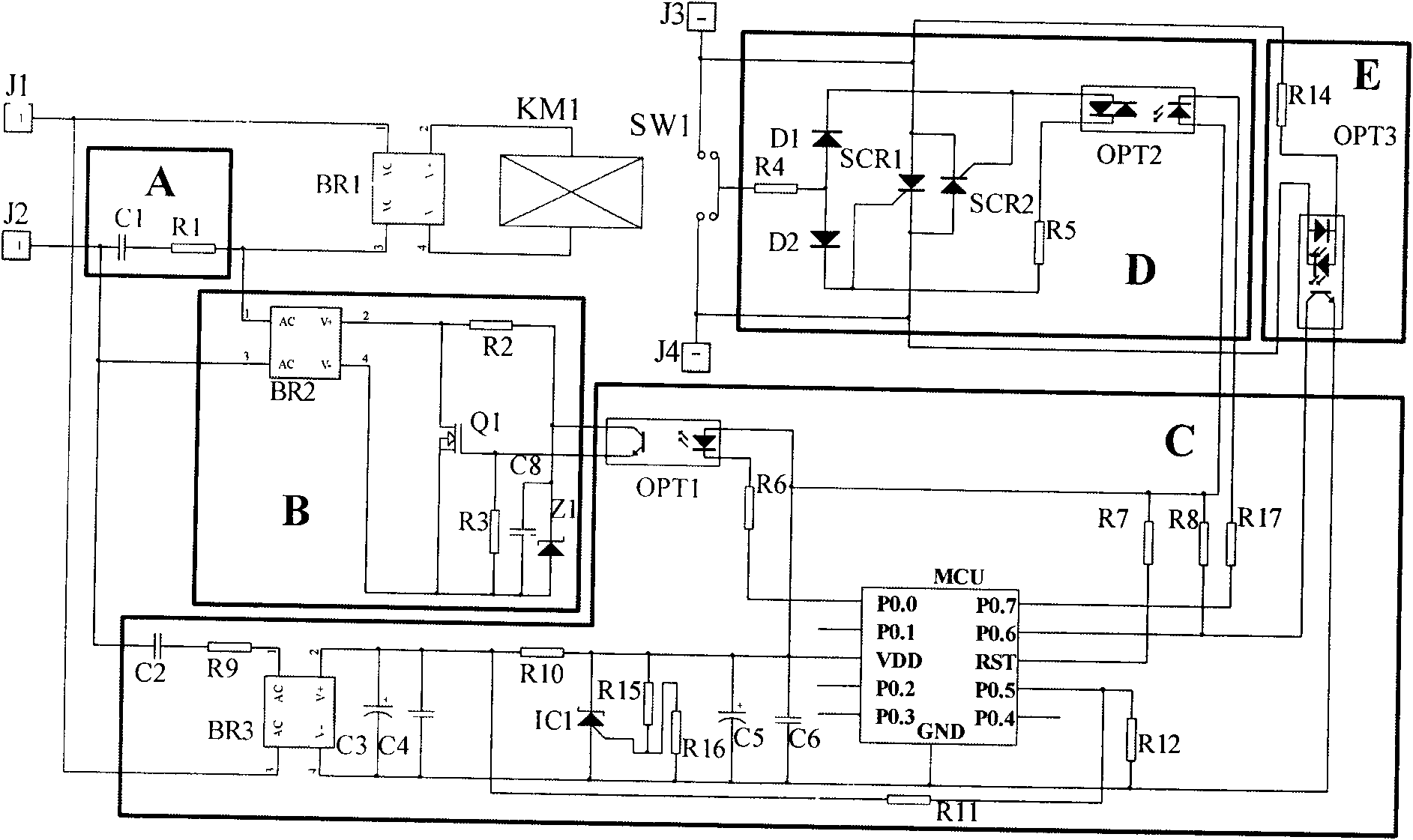

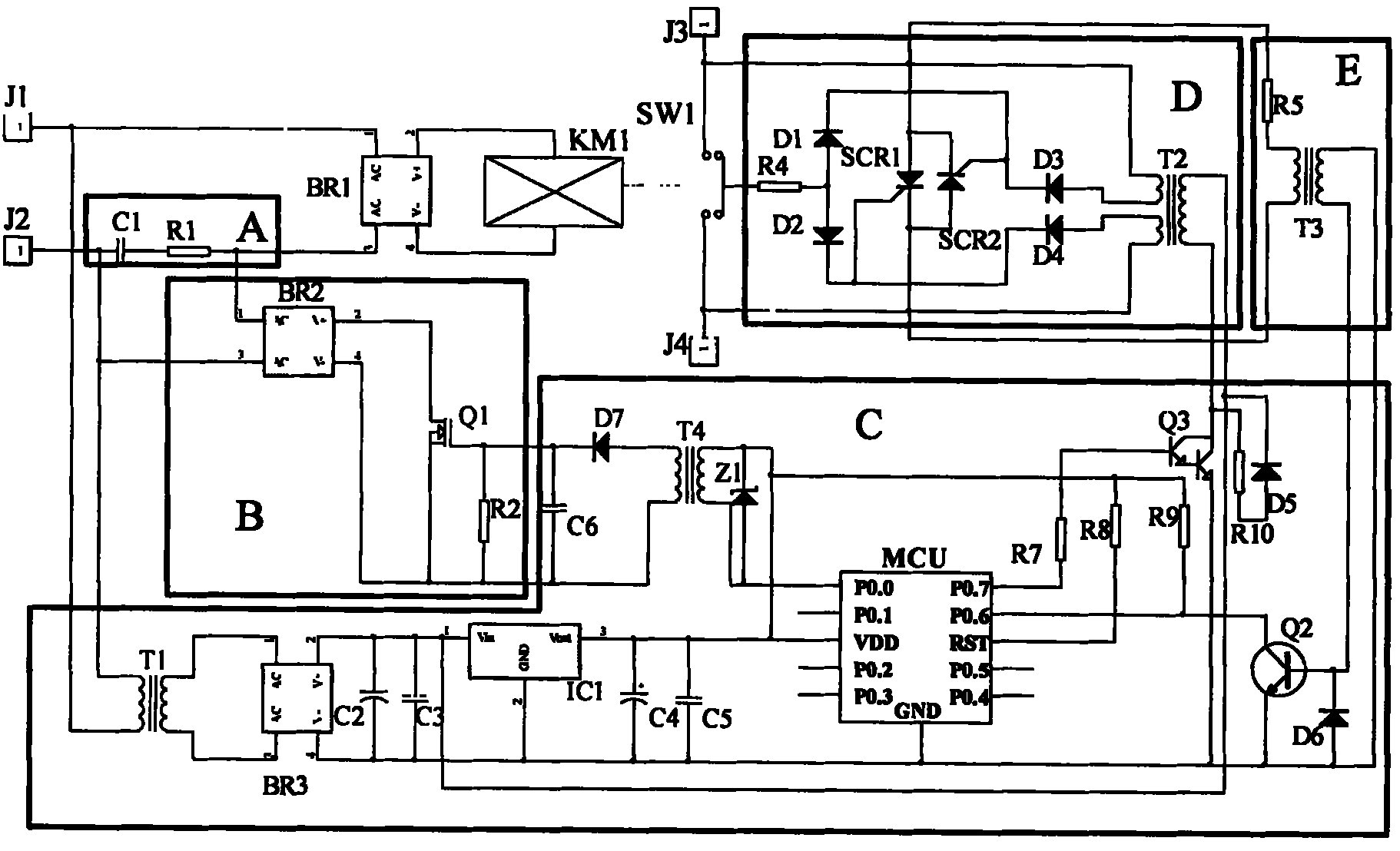

[0013] as attached figure 1 As shown, the AC power is input through the J1 and J2 ports, and then the current is limited by the capacitor voltage drop circuit (A), rectified by the rectifier circuit BR1 to supply power to the contactor control coil KM1, and the capacitor voltage drop circuit (A) is connected in parallel with the starting electronic switch (B ), start the electronic switch (B) and connect the control end to the control circuit (C), connect the working power end of the control circuit (C) to the power input ports J1 and J2, and the voltage zero-crossing detection circuit (E) and the thyristor circuit ( D) Connected in parallel at both ends of the input and output terminals J3 and J4 of the mechanical contacts of the contactor, the output terminal of the voltage zero-crossing detection circuit (E) and the conduction control terminal of the thyristor circuit (D) are connected to the control circuit (C), which can be controlled The other conduction control end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com