Buffer starting type permanent magnet coupling direct drive device

A permanent magnet coupling, permanent magnet technology, applied in the direction of permanent magnet clutch/brake, electromechanical device, electric brake/clutch, etc., can solve the problem of additional electronic components, etc., to achieve the effect of small starting current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

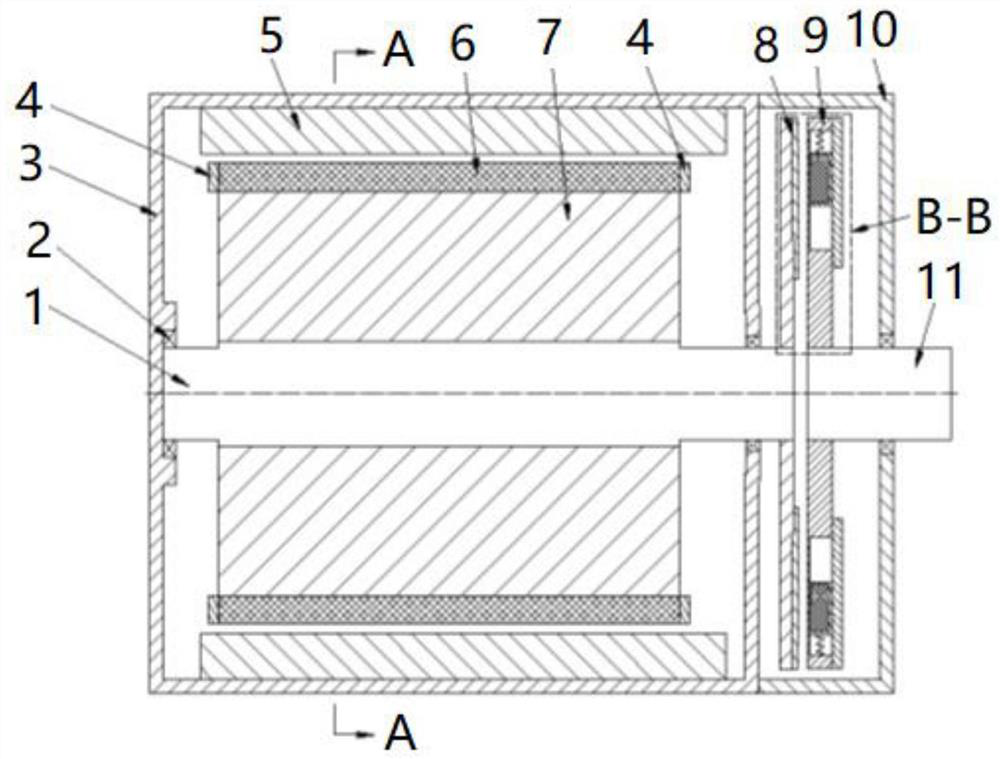

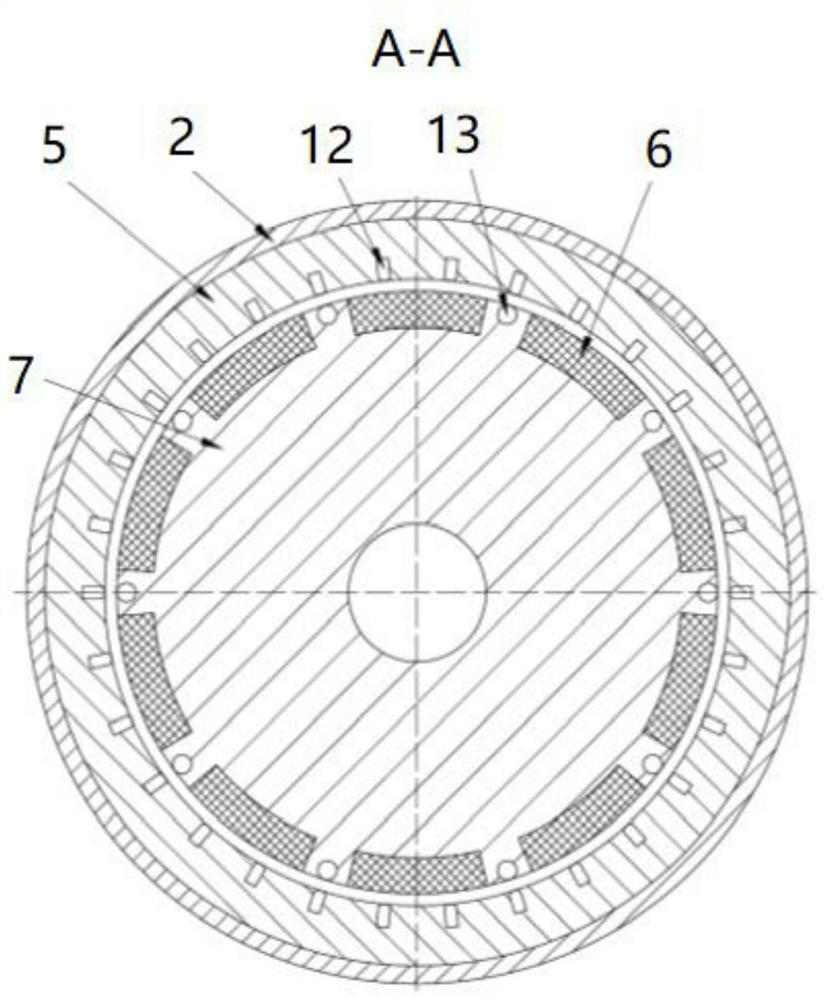

[0040] see Figure 1 to Figure 3 , this embodiment provides a buffer start type permanent magnet coupling direct drive device, including a casing, and a stator assembly, a rotor assembly, a conductor disk assembly 8, a permanent disk assembly 9, a main shaft 1 and an output shaft 11 arranged in the casing . The main shaft 1 and the output shaft 11 are respectively rotatably connected to the casing, and the main shaft 1 and the output shaft 11 are arranged concentrically with a gap between them.

[0041] The rotor assembly and the conductor disk assembly 8 are sheathed and fixedly connected to the main shaft 1 respectively, and the conductor disk assembly 8 is arranged on the side of the rotor assembly close to the output shaft 11 . The stator assembly is sleeved on the rotor assembly, and the stator assembly is fixedly connected to the casing. The permanent disk assembly 9 is sheathed and fixedly connected to the output shaft 11 .

[0042] The stator assembly receives exter...

Embodiment 2

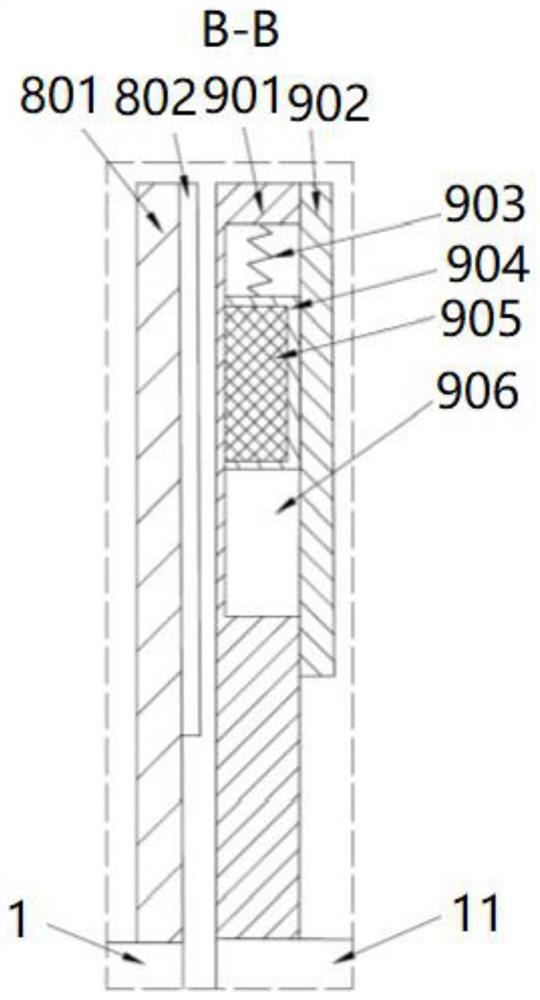

[0053] see Figure 1 to Figure 3 , this embodiment provides a buffer start type permanent magnet coupling direct drive device, which is based on the first embodiment of the permanent magnetic disk assembly 9 of the optimal improvement.

[0054] In this embodiment, the permanent magnetic disk assembly 9 includes a permanent magnetic disk back iron 902 , several second permanent magnets 905 , a fixing frame 901 and an elastic member. The fixing frame 901 is sheathed and fixed on the output shaft 11 , and the permanent magnet back iron is fixed on the side of the fixing frame 901 away from the main shaft 1 .

[0055] The fixing frame 901 is provided with a plurality of accommodation grooves facing the side of the permanent magnet back iron, and the plurality of accommodation grooves are respectively matched with the permanent magnet back iron to form a plurality of slideways 906, and a plurality of second permanent magnets 905 are radially slidably connected to the plurality of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com