Direct-current micro-grid power transmission system applied to petroleum drilling machine

A DC micro-grid and power transmission system technology, which is applied to DC network circuit devices, parallel operation of DC power supplies, and conversion of irreversible AC power input into DC power output, etc. Improve efficiency and equipment service life, no need for treatment costs, and obvious energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

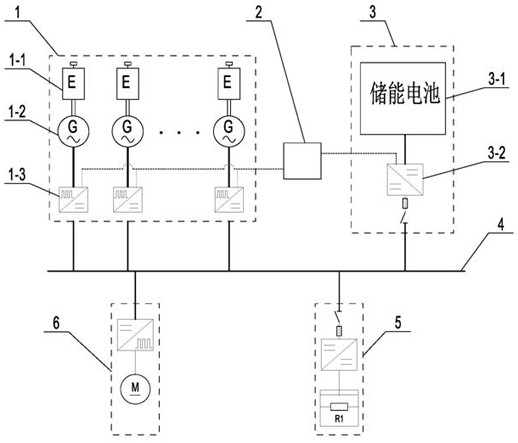

[0025] Such as figure 1 As shown, the permanent magnet synchronous generator set is equipped with a PWM rectification control device: the engine 1-1 rotates to drive the permanent magnet synchronous generator set 1-2 to generate alternating current, and then the PWM rectification control device 1-3 outputs direct current to the common DC bus 4 for energy storage The unit 3 is connected in parallel to the common DC bus 4 through the energy storage control device 3-2, and the common DC bus 4 provides DC power for the load unit 6 to drive the drilling equipment to run. The central controller 2 establishes communication with the PWM rectification control device 1-3 and the energy storage control device 3-2, and the common DC bus 4 provides DC power for the inverter controller of the load unit 6 to drive the load unit 6 to run; the braking unit 5 is Consume excess power on the bus when needed.

[0026] In order to realize the normal operation of the DC microgrid in both steady sta...

Embodiment 2

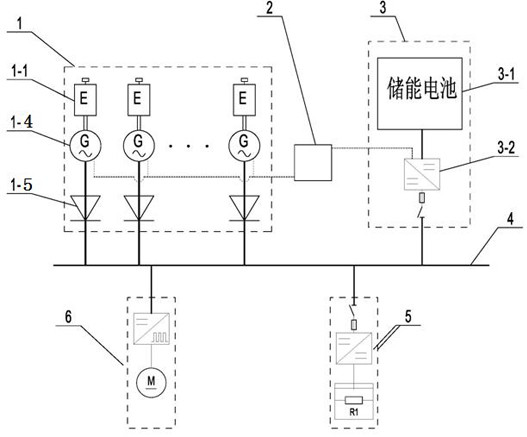

[0029] Such as figure 2 As shown, the 12-phase generator set 1-4 is equipped with a 24-pulse rectifier device 1-5. The 12-phase generator 1-4 and the 24-pulse rectifier device 1-5 are commercially available products, and will not be repeated here. The engine 1-1 drives the 12-phase generator 1-4 to run, and the 12-phase generator 1-4 sends out alternating current, which is rectified by the 24-pulse rectification device 1-5, and the output direct current is connected in parallel to the common direct current bus 4. The energy storage unit 3 is connected in parallel on the common DC bus 4, the central controller 2 establishes communication with each 12-phase generator and the energy storage control device 3-2, and the common DC bus 4 provides DC power for the load unit 6 inverter.

[0030] In order to realize the normal operation of the DC microgrid in both steady state and dynamic state, the central controller 2 coordinates the power generation unit and the energy storage unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com