Switching type turbine machine

A turbomachinery and switchable technology, which is applied in the direction of mechanical equipment, engines, non-variable pumps, etc., can solve the problems of large eddy current loss at the edge of the blade, inability to use switchable, loud noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

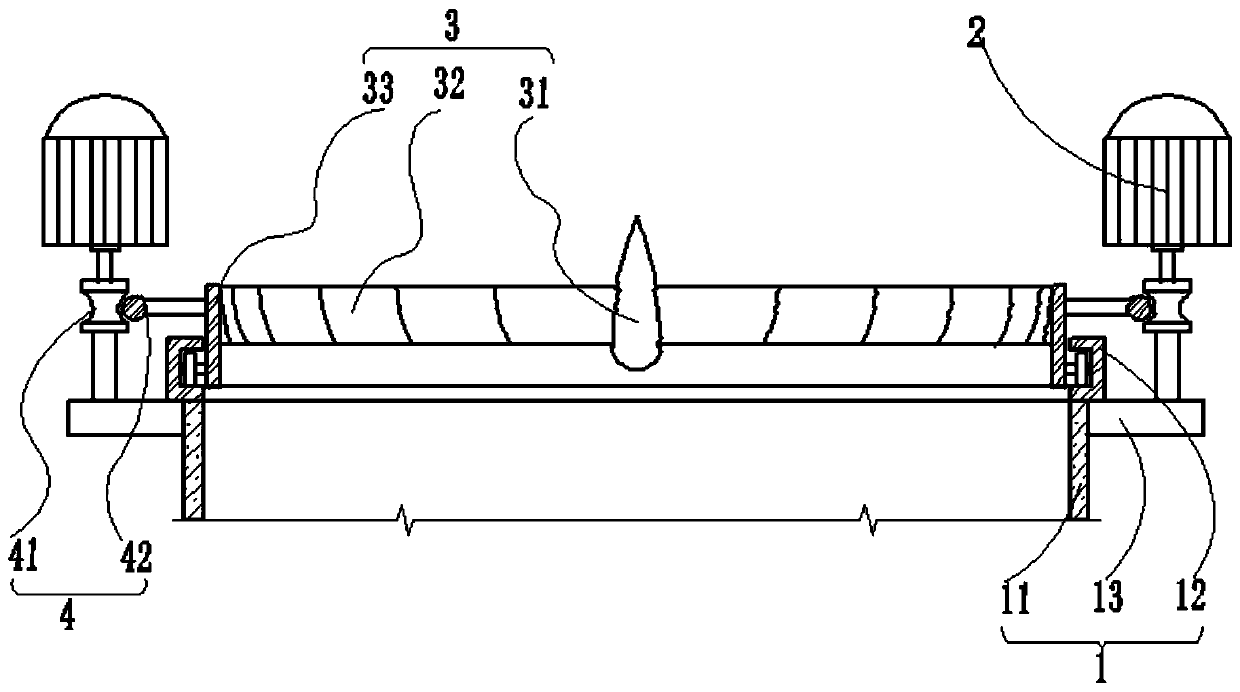

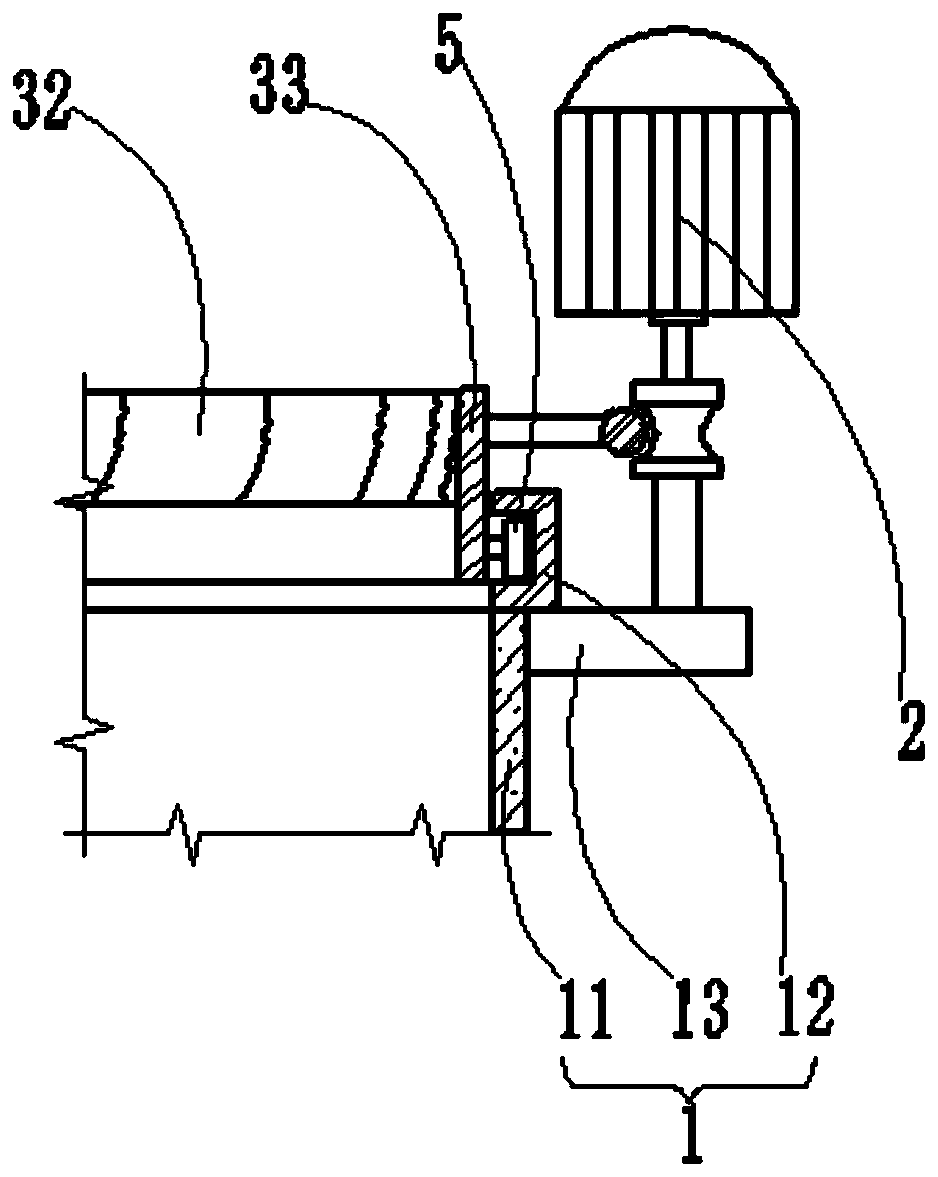

[0046] Please refer to Figure 1-3 , in a first embodiment of the invention, the switched turbomachine comprises:

[0047] Support sleeve 1;

[0048] An electromechanical device 2, the electromechanical device 2 is arranged on the support sleeve 1;

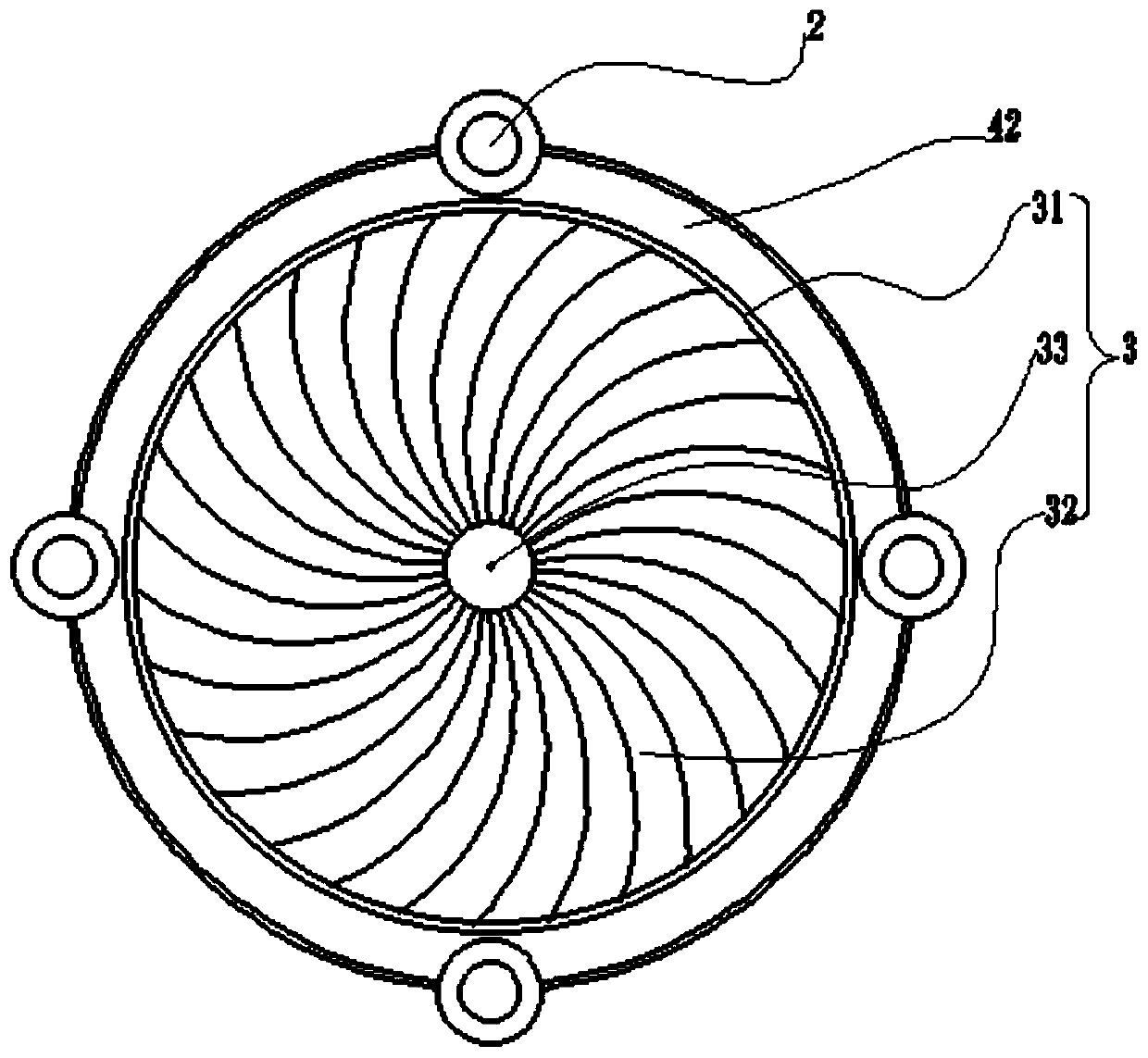

[0049] Rotating member 3, said rotating member 3 is suspended on the top of said supporting sleeve 1, said rotating member 3 includes installation shaft 31, rotating surrounding wall 33 and rotating blade 32, said rotating surrounding wall 33 surrounds said installation The shaft 31 is set, and the rotating blade 32 is connected to the installation shaft 31 and the rotating surrounding wall 33;

[0050] a transmission member 4, the transmission member 4 is used to drive and connect the rotating surrounding wall 33 and the electromechanical device 2;

[0051] Wherein, when the switchable turbomachine is switched to the wind outlet state, the electromechanical device 2 is a driving motor; the electromechanical device 2 drives the...

no. 2 example

[0071] see Figure 4 , based on the switching turbomachinery provided in the first embodiment, the difference of the switching turbomachinery provided in this embodiment is that the second transmission member 42 is arranged around the rotating wall 33, and the electromechanical device The number of 2 is one, and the switch-type turbomachine also includes a plurality of calibration wheels 6, which are arranged around the second transmission member 42, and the second transmission member 42 is transmission-connected.

[0072] In this embodiment, the calibration wheel 6 is a concentricity calibration wheel 6 .

[0073] Since the mounting shaft 31 is not provided with bearings, the concave chute structure 12 and the calibration wheel 6 can limit the fluctuation of the rotating wall 33 and the rotating blade 32 in a small space.

no. 3 example

[0075] see Figure 5 , based on the switchable turbomachinery provided in the first embodiment, the difference of the switchable turbomachinery provided in this embodiment is that the rotating member 3 also includes multiple sets of auxiliary blades 34, and multiple sets of auxiliary blades 34 are sequentially spaced It is provided on the installation shaft 31 .

[0076] In this implementation, the auxiliary blades 34 may be turbine blades; they are used to increase the wind receiving area of the rotating member 3 . The auxiliary blade 34 may be connected with the rotating surrounding wall 33 ; the auxiliary blade 34 may not be connected with the rotating surrounding wall 33 .

[0077] The top of the mounting shaft 31 can be designed to be streamlined.

[0078] Switchable turbomachines can be used as wind power plants for large cooling installations or as small ventilation fans.

[0079] Switching turbomachines can be used as wind power plants and thermal gas power plants...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com