Permanent magnet linear voice coil motor with high thrust-weight ratio for direct drive valve

A permanent magnet linear and voice coil motor technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of underutilization of permanent magnet performance, unreasonable magnetic circuit design, large volume of voice coil motor, etc., to reduce mechanical time constant, reduced electrical time constant, uniform thrust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

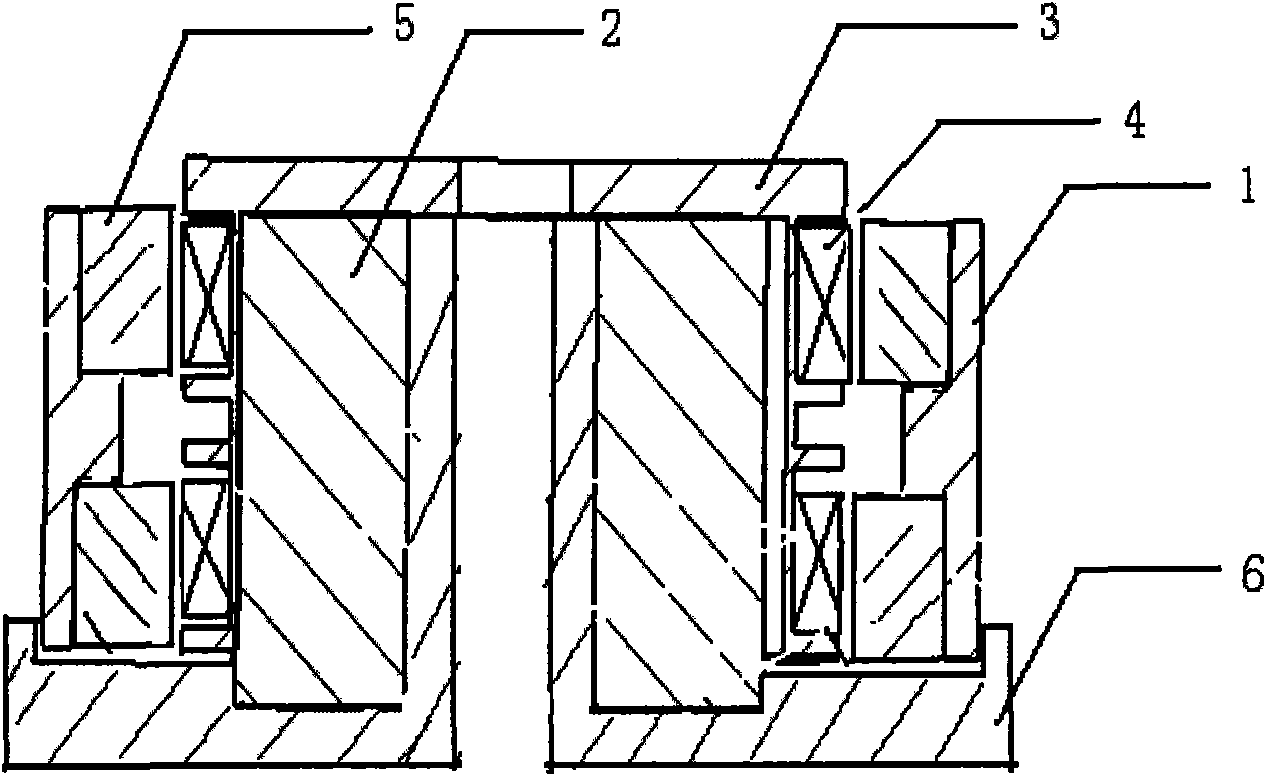

[0031] Such as figure 1 As shown, the high thrust-to-weight ratio permanent magnet linear voice coil motor of the present invention includes: an outer stator 1 , an inner stator 2 , a moving coil support 3 , a moving coil winding 4 , a magnetic steel assembly 5 , and an end cover 6 .

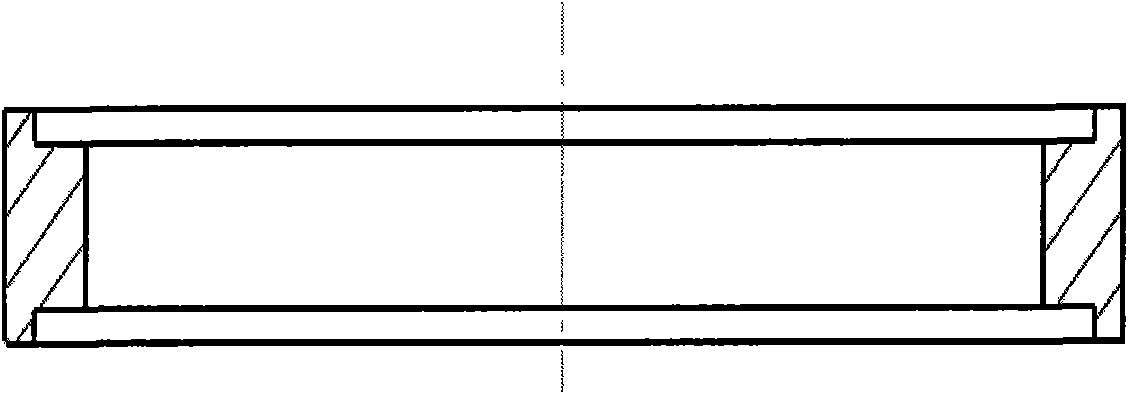

[0032] Among them, the outer stator 1 is made of high-permeability electrical pure iron rod DT4 through turning. Such as figure 2 As shown, the inner wall of the outer stator 1 has two annular grooves processed by turning to realize the mechanical cooperation between the outer stator 1 and the two annular magnetic steel assemblies of the magnetic steel assembly 5 .

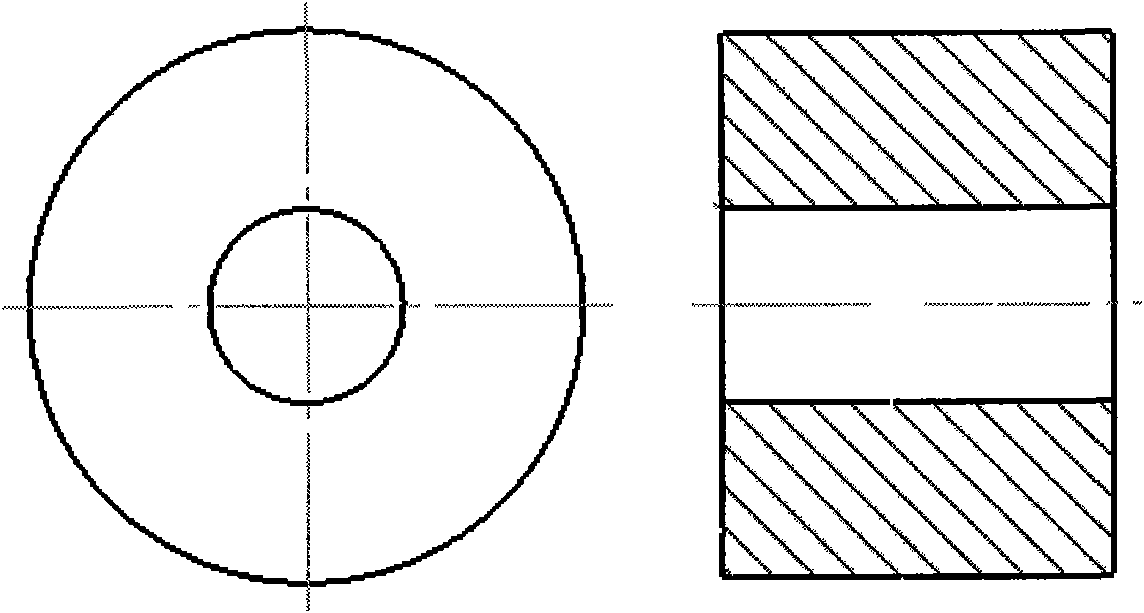

[0033] Among them, the inner stator 2 is made of high-permeability electrical pure iron rod DT4 through turning. Such as image 3 Through holes are processed on the inner wall of the inner stator 2 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com