Push plate demoulding mechanism

A demoulding mechanism and push plate technology, applied in the field of push plate demoulding mechanism, can solve problems such as uneven demoulding, uneven thrust, and easy deformation of rubber parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

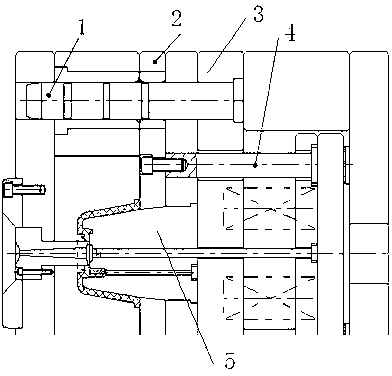

[0011] Such as figure 1 As shown, the push plate demoulding mechanism includes side nail 1, push plate 2, fixed plate 3, return needle 4 and core 5, push plate 2 is connected with fixed plate 3, return needle 4, side nail 1 and push plate 2 It is connected with the fixed plate 3, the push plate 2 and the return needle 4 are connected by screws, and the matching structure between the push plate and the core should be a conical surface; this can reduce movement scratches and play an auxiliary guiding role; the inclination of the conical surface should be 3~10°, the inner hole of the push plate should be 0.2~0.3mm larger than the core forming part (one side). The wire cutting process causes the core to overcut, and the push plate and the back needle are connected by screws. After the push plate is demoulded, it must be ensured that the plastic parts do not stay on the push plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com