Automatic filling device for sausages

An automatic filling and sausage technology, which is applied in the sausage stuffing machine, sausage casing ligature equipment, etc., can solve the problems that affect the hygienic quality of the product, fail to meet the production standard, and the labor intensity is high, so as to achieve beautiful products and smooth speed , fast binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

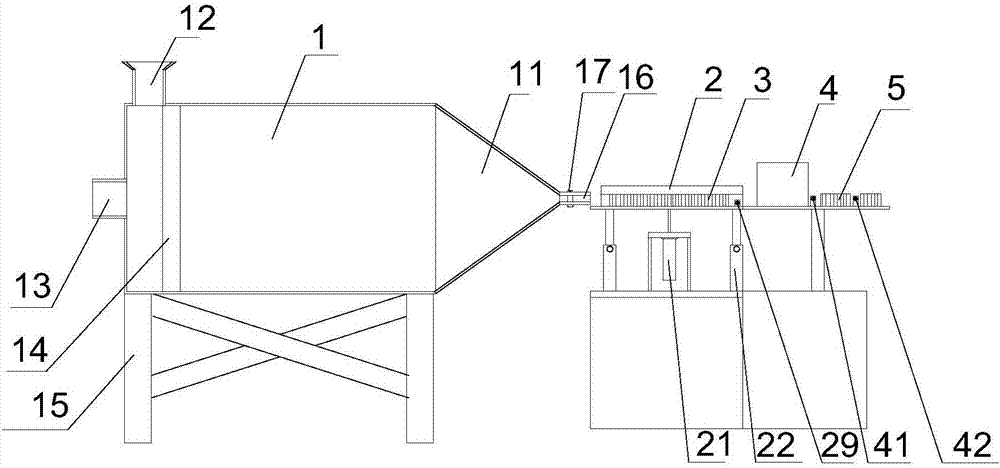

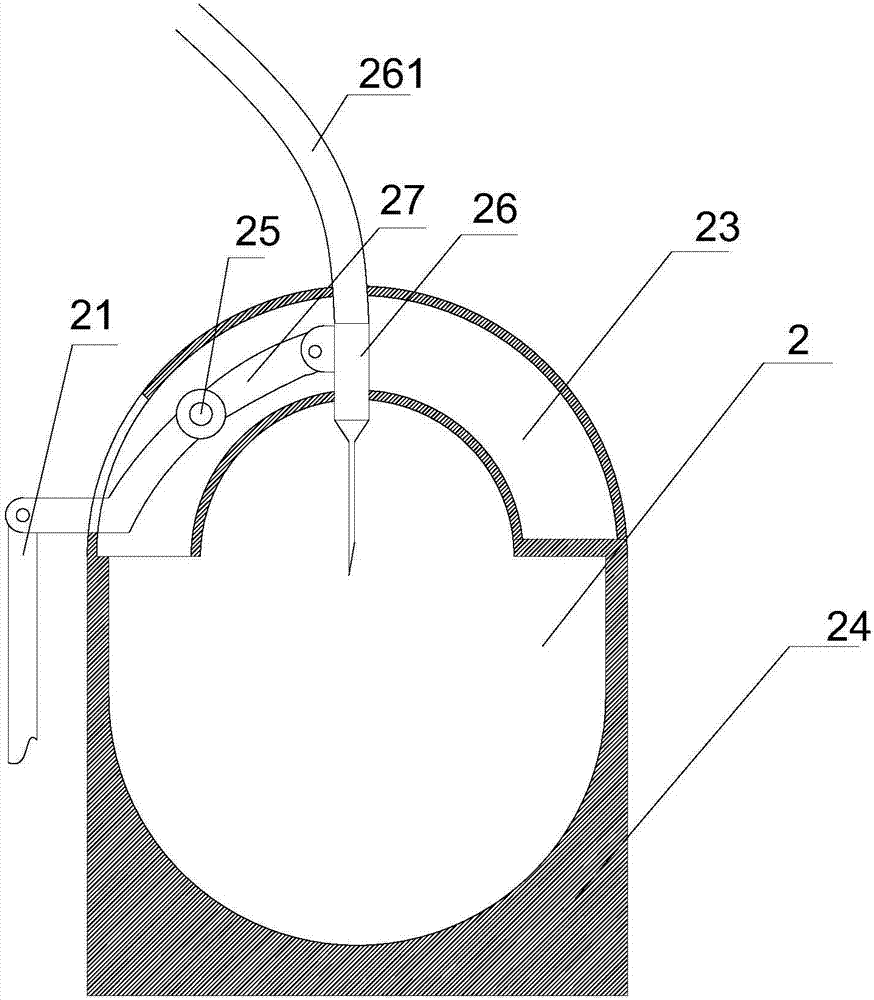

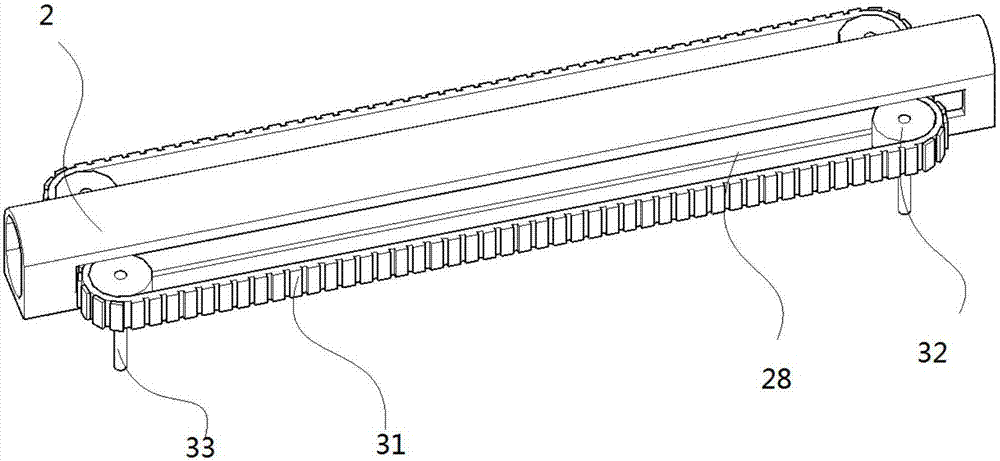

[0020] An automatic sausage filling device, comprising a storage bin 1, a deflation chamber 2, a feeding device 3, a binding chamber 4, and a discharge belt 5; the storage bin 1, the deflation chamber 2, a binding chamber 4, a discharge The belts 5 are installed sequentially, the feeding device 3 is arranged on both sides of the deflation chamber 2, and the front end, rear end, and upper end of the storage bin 1 are respectively equipped with a discharge hopper 11, an air inlet 13, and a feed inlet 12, A feeding push plate 14 is arranged in the storage bin 1 , and the storage bin 1 is installed on a bracket 15 , and a discharge nozzle 16 is arranged at the front end of the discharge hopper 11 . The material can be pushed into the casing through the feeding push plate in the storage bin. Since the push plate is driven by air pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com