Electromagnet ultrasonic changer of on-line dynamic detection for defect of rolling stock wheel set

An electromagnetic ultrasonic and dynamic detection technology, applied in wheel testing, using ultrasonic/sonic/infrasonic, instruments, etc., can solve the problems of easy falling off of filling materials, damage to high-frequency coils, low coupling efficiency, etc., and achieve long service life and weaken The impact force and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

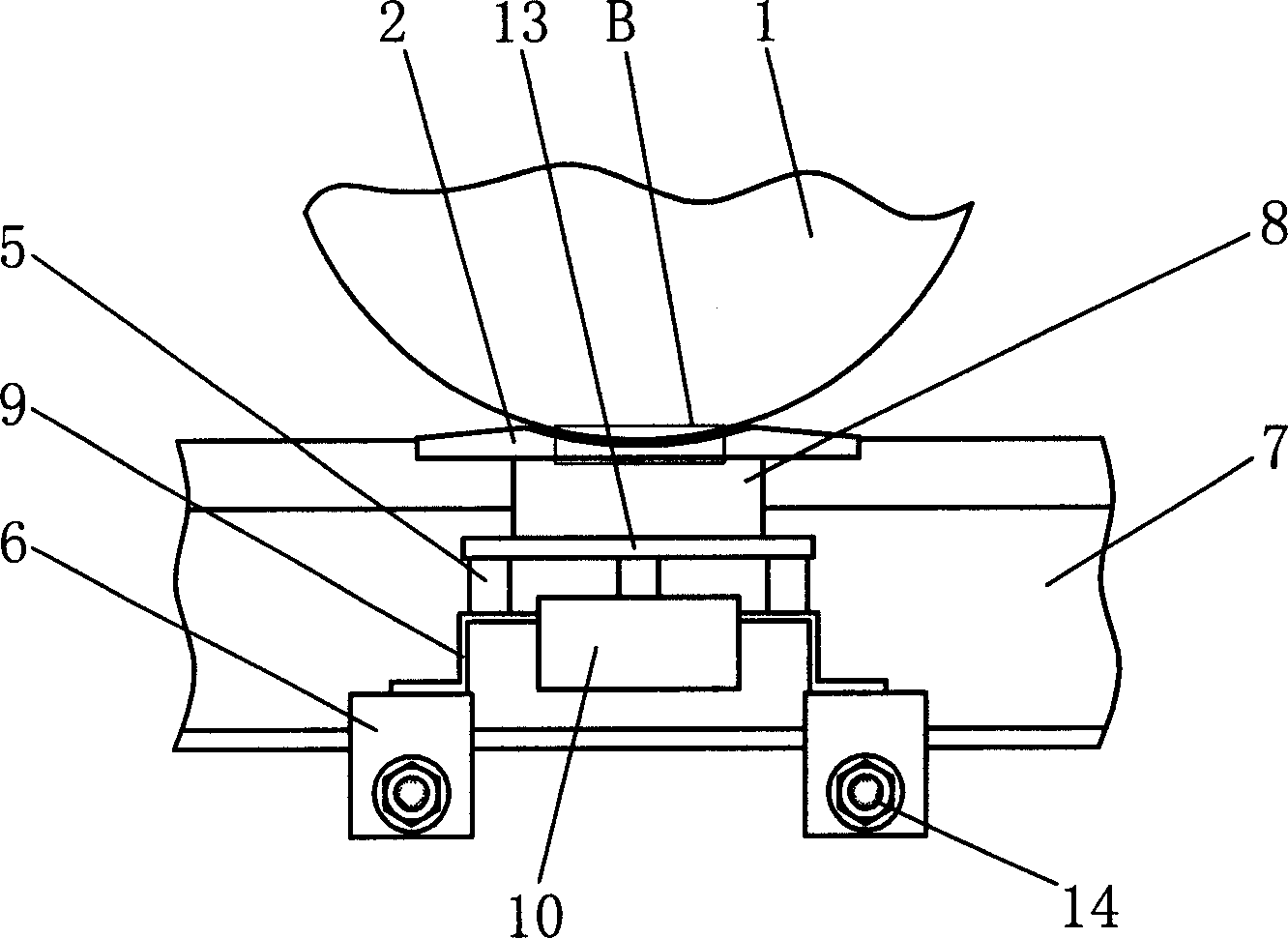

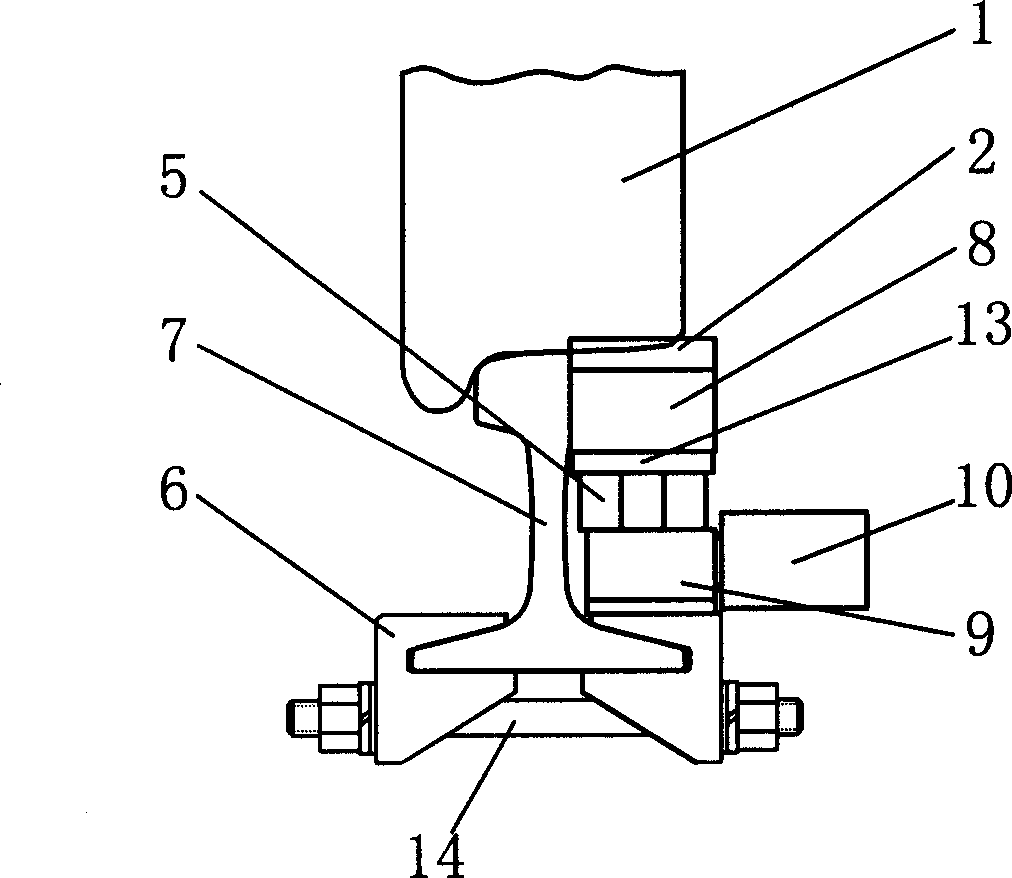

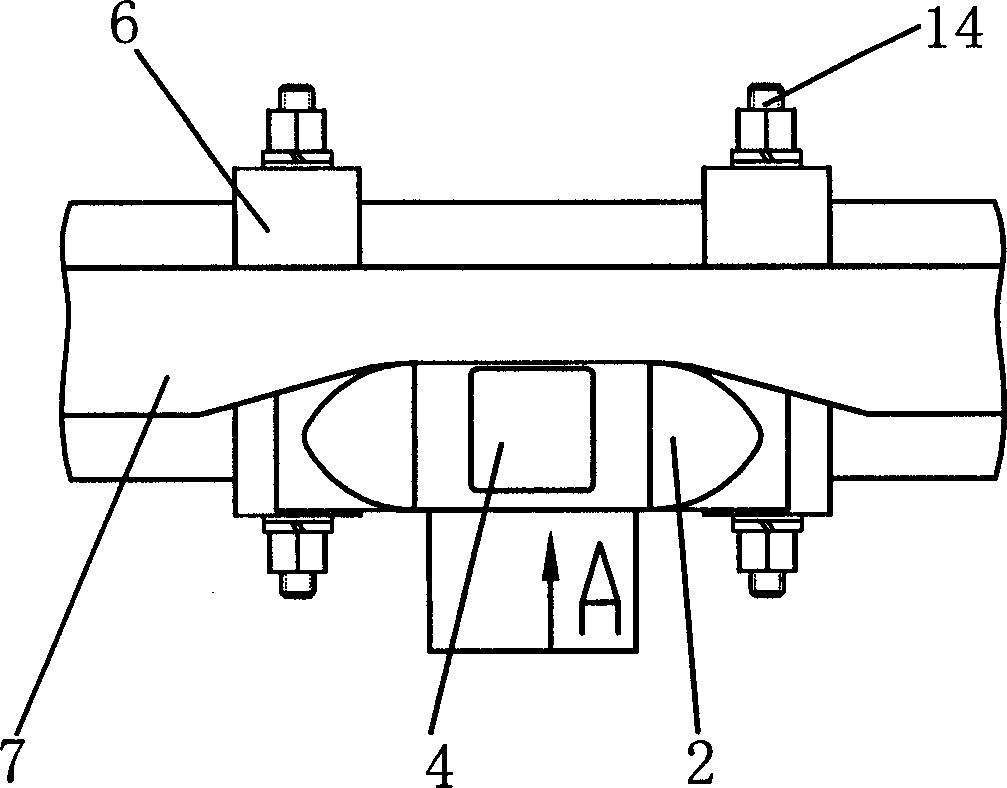

[0019] Figure 1-5 It is shown that a specific embodiment of the present invention is: an electromagnetic ultrasonic transducer for on-line dynamic detection of vehicle wheelset defects, including a panel 2, a bottom plate 13 and a magnet box 8 between the panel 2 and the bottom plate 13, A magnet 11 is fixed inside the magnet box 8; the skeleton 4 is set in the rectangular groove of the panel 2, and the high-frequency coil 3 is wound on the skeleton 4. Next, the high-frequency coil 3 is wound on the E-shaped groove of the skeleton 4; the upper surface 12 of the skeleton 4 is an arc-shaped concave surface adapted to the tread profile of the wheel 1; Shock spring 5 links to each other.

[0020] The distance between the bottom of the E-shaped groove and the arc-shaped concave surface 12 is ≤1mm. The bracket 9 is fixed on the deck 6, and the deck 6 is clamped and fixed on the bottom of the rail by bolts 14. Of course, in actual use, holes can also be drilled on the rail waist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com