LED (light-emitting diode) wall wash lamp and assembling method thereof

A technology of an LED wall washer and an assembly method, applied in the lighting field, can solve the problems of inability to disassemble, cannot be disassembled again, poor sealing, etc., and achieves the effects of avoiding short service life, improving utilization, and facilitating disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

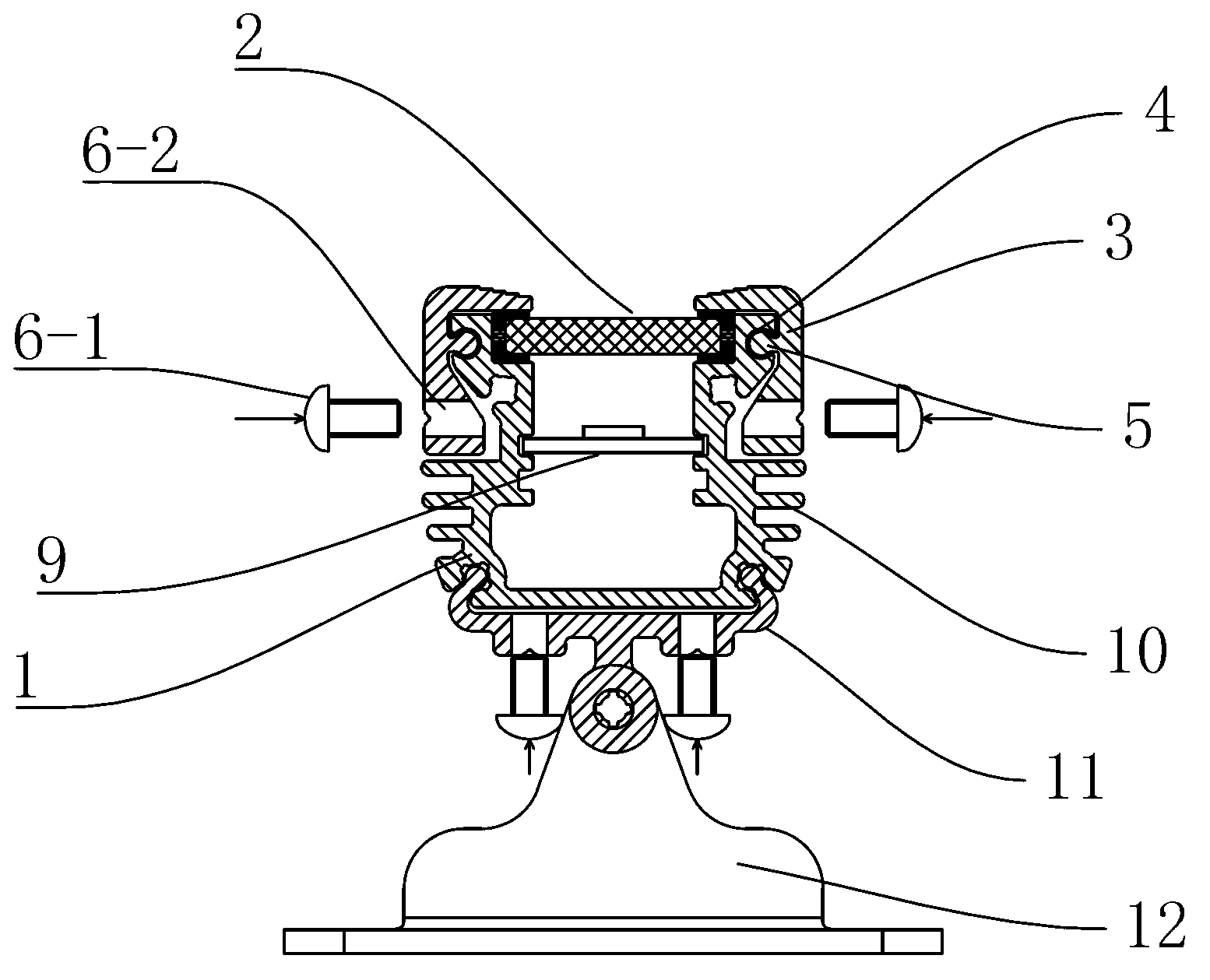

[0057] See figure 1 , 2 , an LED wall washer lamp, comprising: a lamp body 1, a light-transmitting plate 2 arranged on the top light outlet of the lamp body 1, and two "F"-shaped hinge bars 3 symmetrically installed on both sides of the lamp body , the hinge bead 3 is distributed along the length direction of the lamp body 1; a circular groove 4 is arranged on the outside of the top adjacent to the lamp body 1, and the circular groove 4 is distributed along the length direction of the lamp body 1; The inner surface of the neck of the hinge bead 3 is provided with ribs 5 distributed along the length direction, the ribs 5 are cylindrical, and are suitable for rotating with the circular groove 4; The end extending inwardly is suitable for compressing the edge of the light-transmitting plate 2; the lower end of the hinge bar 3 is provided with a bolt for controlling the end to compress the light-transmitting plate 2; Next, the lower end of the hinge bar 3 is adapted to leave the...

Embodiment approach 1

[0059] Embodiment 1: the bolt is a locking bolt 6-1, and a threaded hole 6-2 is opened on the lower end of the hinge bead 3, and the locking bolt 6-1 is drilled into the threaded hole 6-2, And control the size of the gap between the lower end of the hinge bead 3 and the side of the lamp body 1, so that the end presses the light-transmitting plate 2; the bolts can also be round-headed bolts or flat-headed bolts, and the bolts can also be called for the screws.

Embodiment approach 2

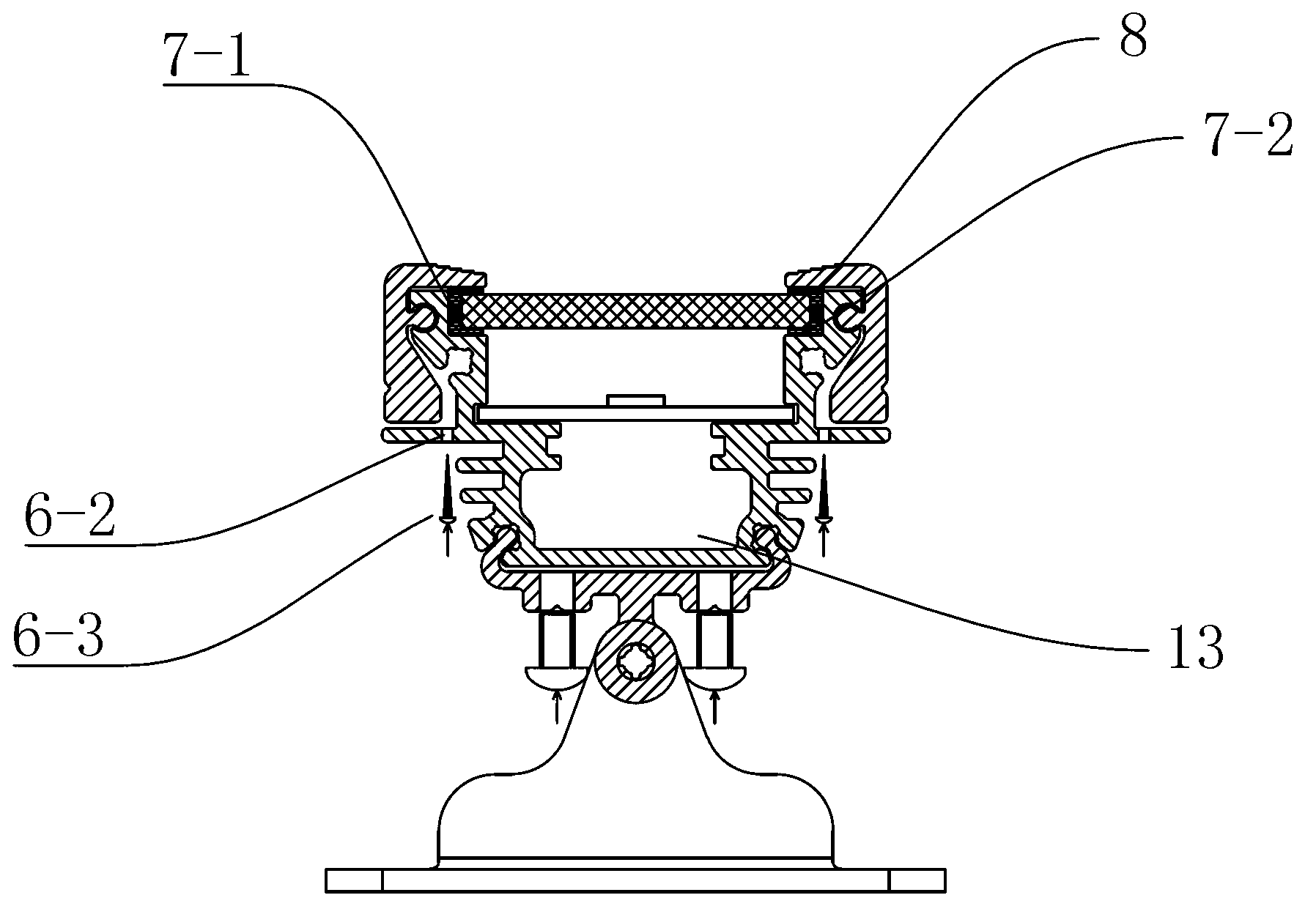

[0060] Embodiment 2: The bolt is a self-tapping bolt 6-3, and a threaded hole 6-2 is provided on the lamp body 1 and below the gap between the lower end of the hinge bead 3 and the side of the lamp body 1. The self-tapping bolt 6-3 is drilled into the threaded hole 6-2, and the size of the gap between the lower end of the hinge bar 3 and the side surface 1 of the lamp body is controlled, so that the end presses the light-transmitting plate 2 tightly.

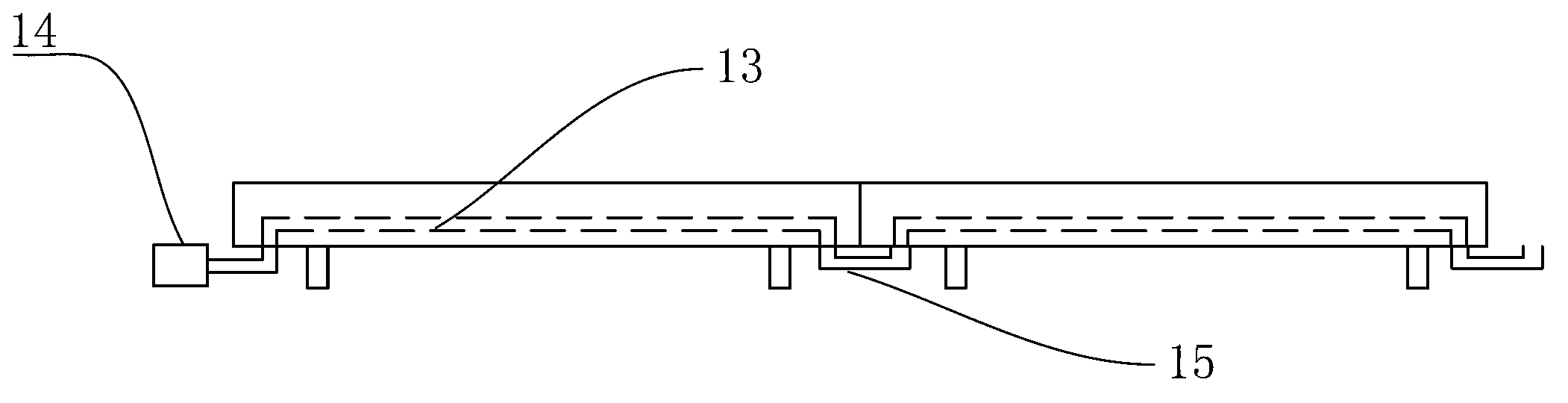

[0061] The lamp body 1 is provided with a support portion suitable for placing the light-transmitting plate, and the first support surface 7-1 and the second support surface 7-2 included in the support portion are provided with a lower waterproof strip groove (in the figure Not marked), the lower waterproof strip groove is suitable for placing the lower waterproof strip, and the lower waterproof strip groove body is distributed along the length direction of the lamp body 1 .

[0062] The lower waterproof strip can be an L-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com