Nail head assembly for tst stapler for treating hemorrhoids

A stapler and component technology, applied in the direction of surgical fixation nails, etc., can solve the problems that the positioning accuracy cannot be further improved, affect the stability of the anvil seat assembly, and affect the formation of staples, etc., to achieve shortened operation time, large transmission force, and thrust uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

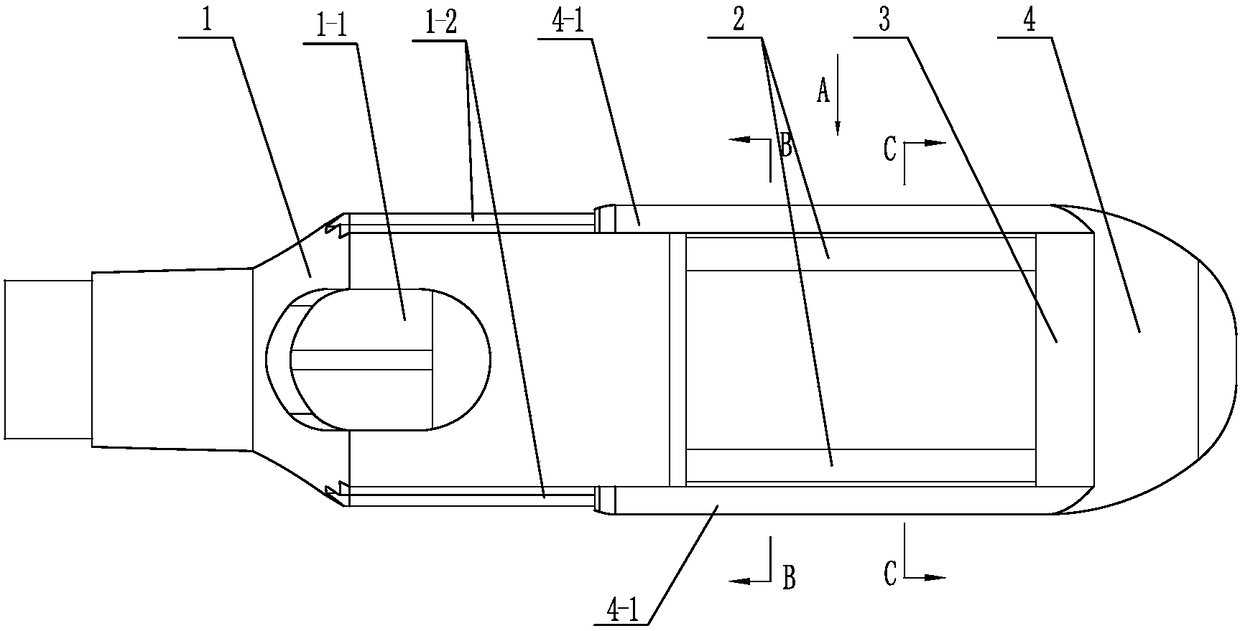

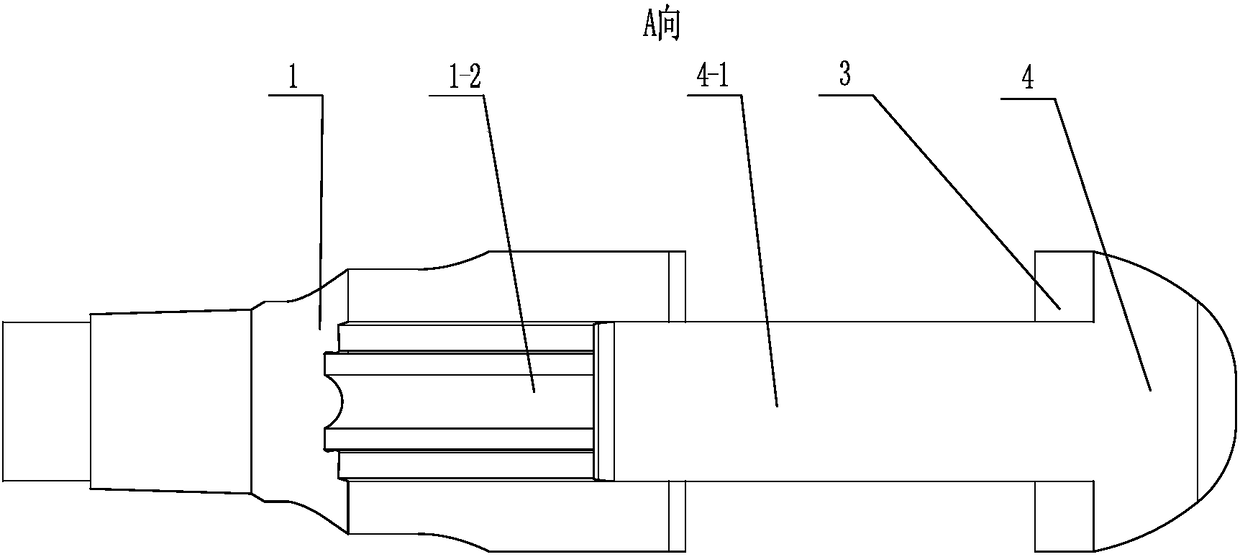

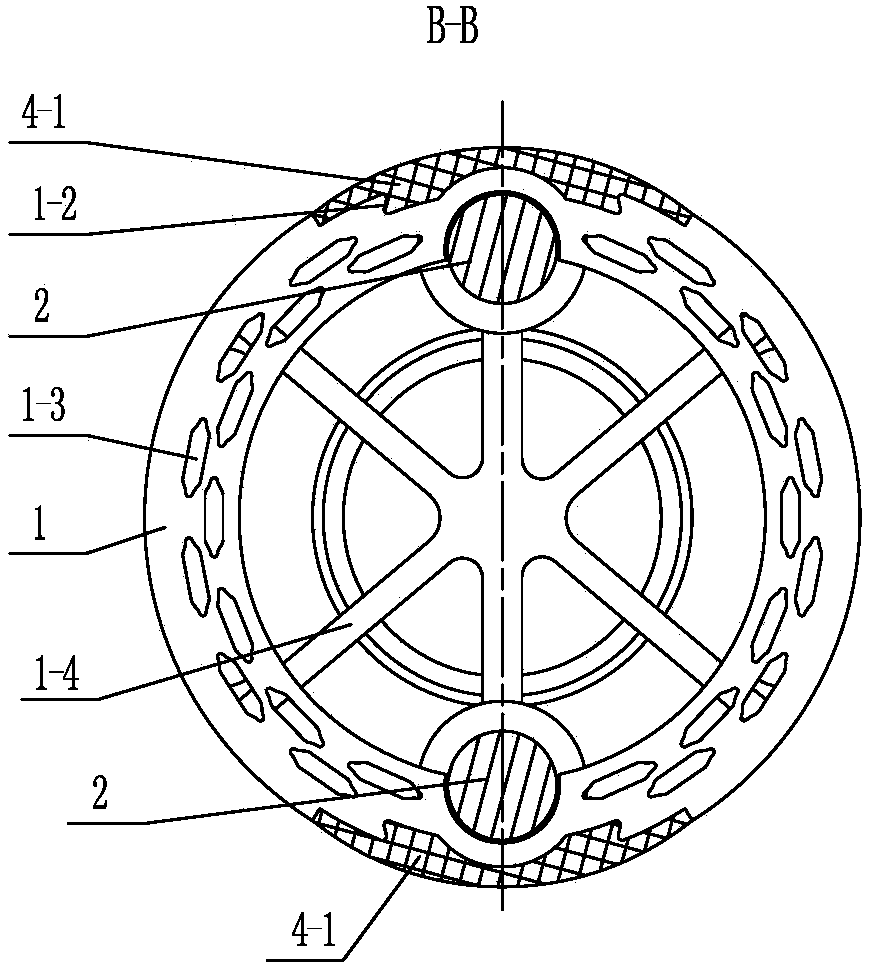

[0018] See Figure 1-7 As shown, the nail head assembly of the TST stapler for treating hemorrhoids of the present invention includes an abutment seat assembly and a nail cartridge assembly 1 with nail holes 1-3 at the front end. See Figure 1-7 As shown, the nail anvil assembly of the present invention includes a shield 4 with a spherical surface at the front and an anvil 3, and the shield 4 includes a connecting seat 4-3 at the front and at least two shields 4 extending backward for blocking tissue -1, it is convenient to introduce into the anus through the spherical surface, and the nail anvil 3 with the nail groove 3-1 is installed on the connecting seat 4-3. See Figure 5 As shown, the connecting seat 4-3 at the front portion of the shield 4 of the present invention is provided with a threaded hole, and the nail anvil 3 is provided with a corresponding nail hole, and the fastener 5 can be passed through the nail hole on the nail anvil 3 to Screwed on the connecting sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com