Diamond line numerical control take-up and payoff device

A technology for retracting and paying out wire and diamond wire, which is applied to fine working devices, working accessories, manufacturing tools, etc., can solve the problem of reducing the strength and service life of diamond wire, wasting the amount of single diamond wire, and affecting the yield of silicon block slicing. and other problems, to achieve the effect of improving strength and processing efficiency, avoiding non-cutting loss, and facilitating wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

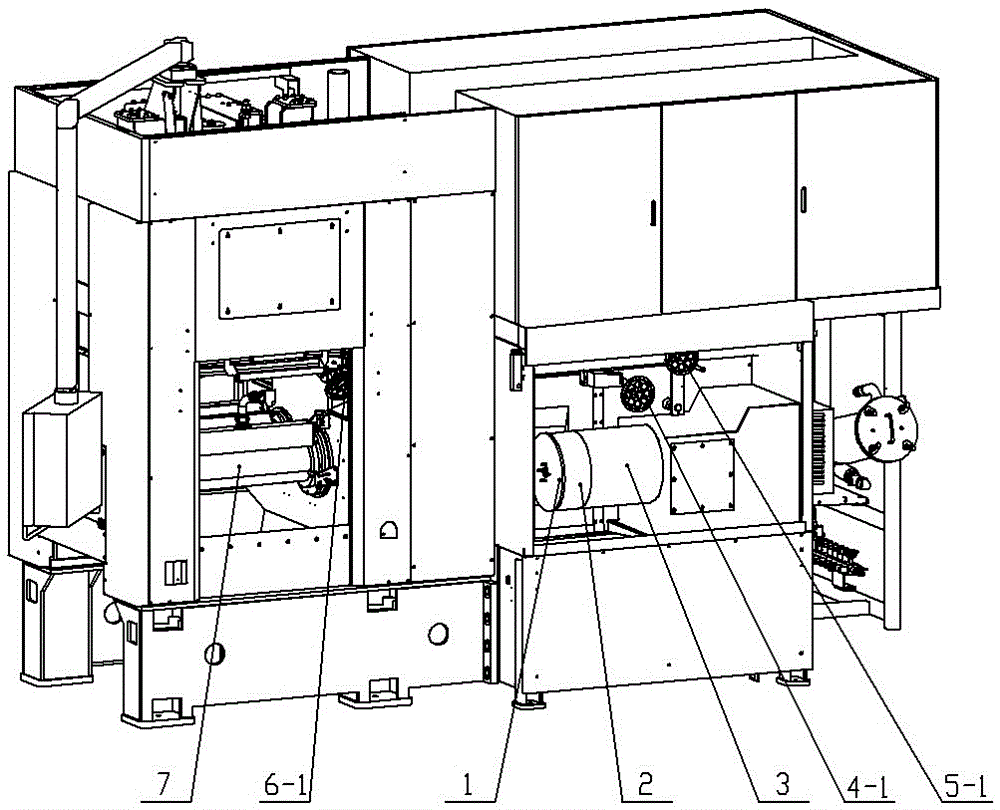

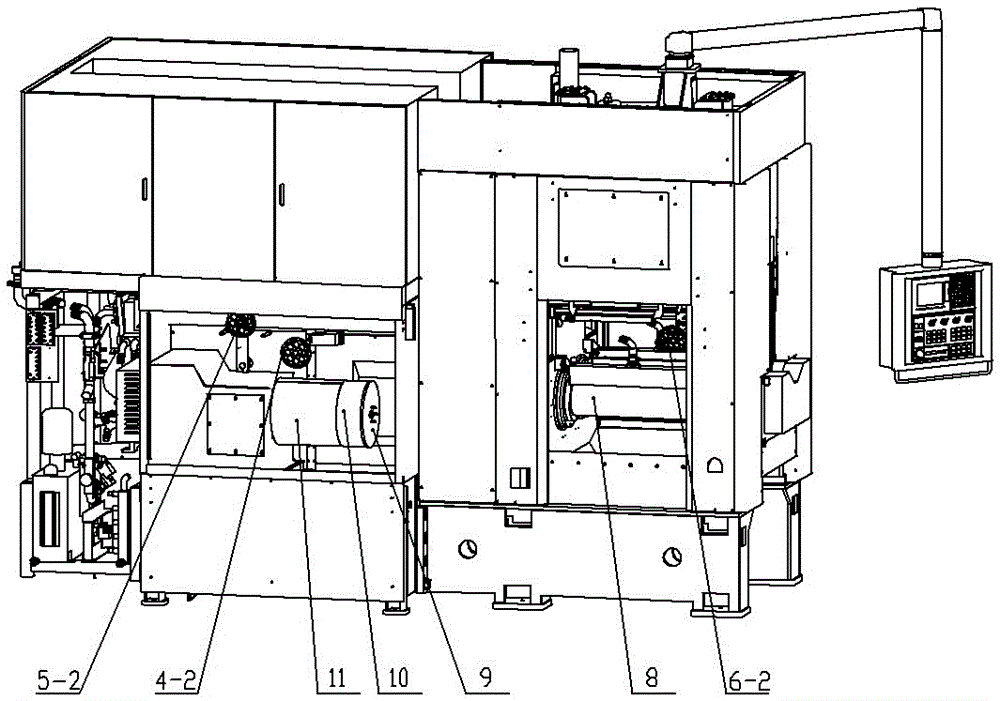

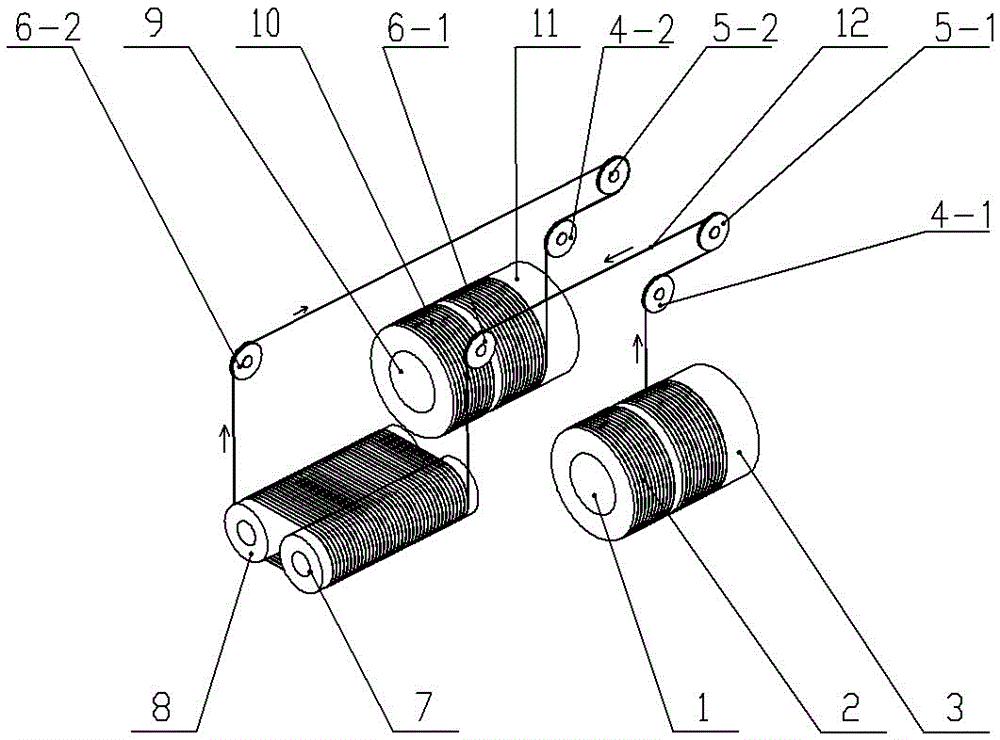

[0014] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a numerical control machine tool, through which the control box of the numerical control system is correspondingly connected with each working part on the machine tool, so as to realize the numerical control take-up and release of the diamond wire; the take-up management device 1 and the take-up management device 9 are arranged at one end of the machine On both sides, guide wheels 7 and 8 are respectively arranged on both sides of the other end in the machine tool, a pay-off wire wheel 4-1 and a wire-pay-off tension wheel 5-1 are arranged above the wire pay-off management device 1, and a wire take-up management device 9 is arranged above There are take-up line wheel 4-2, line take-up tension wheel 5-2, a line-passing wheel 6-1 is provided at the starting end of one guide wheel 7, and a line-passing wheel is provided above the end of the other guide wheel 8 Wheel 6-2, pay-off management de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com