Yield statistic device of textile machine

A textile machinery and output technology, applied in textiles and papermaking, etc., can solve the problems of troublesome wiring, large amount of thread consumption, cumbersome wiring, etc., and achieve the effect of easy wiring, reduced thread consumption, and simple wiring method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

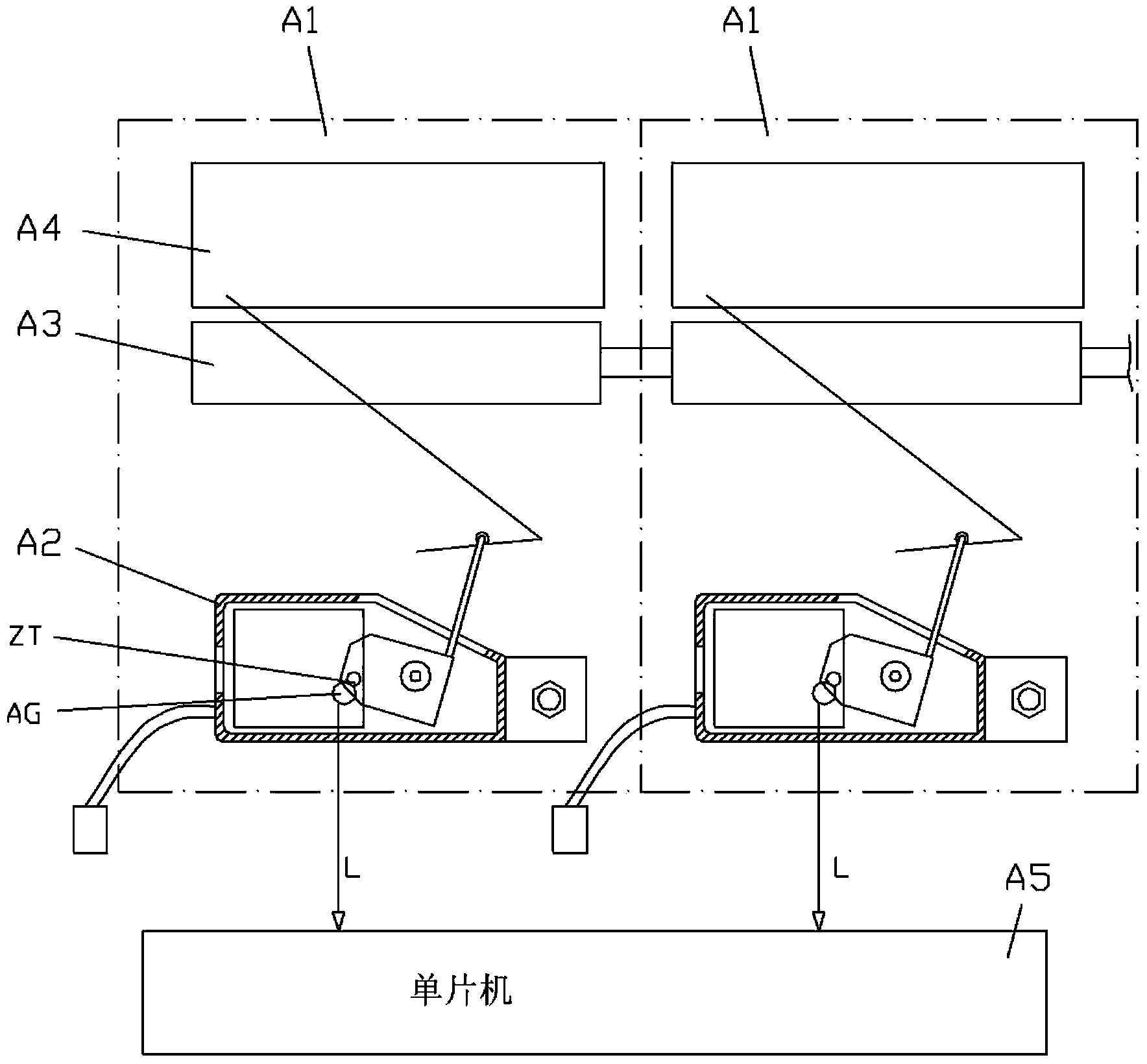

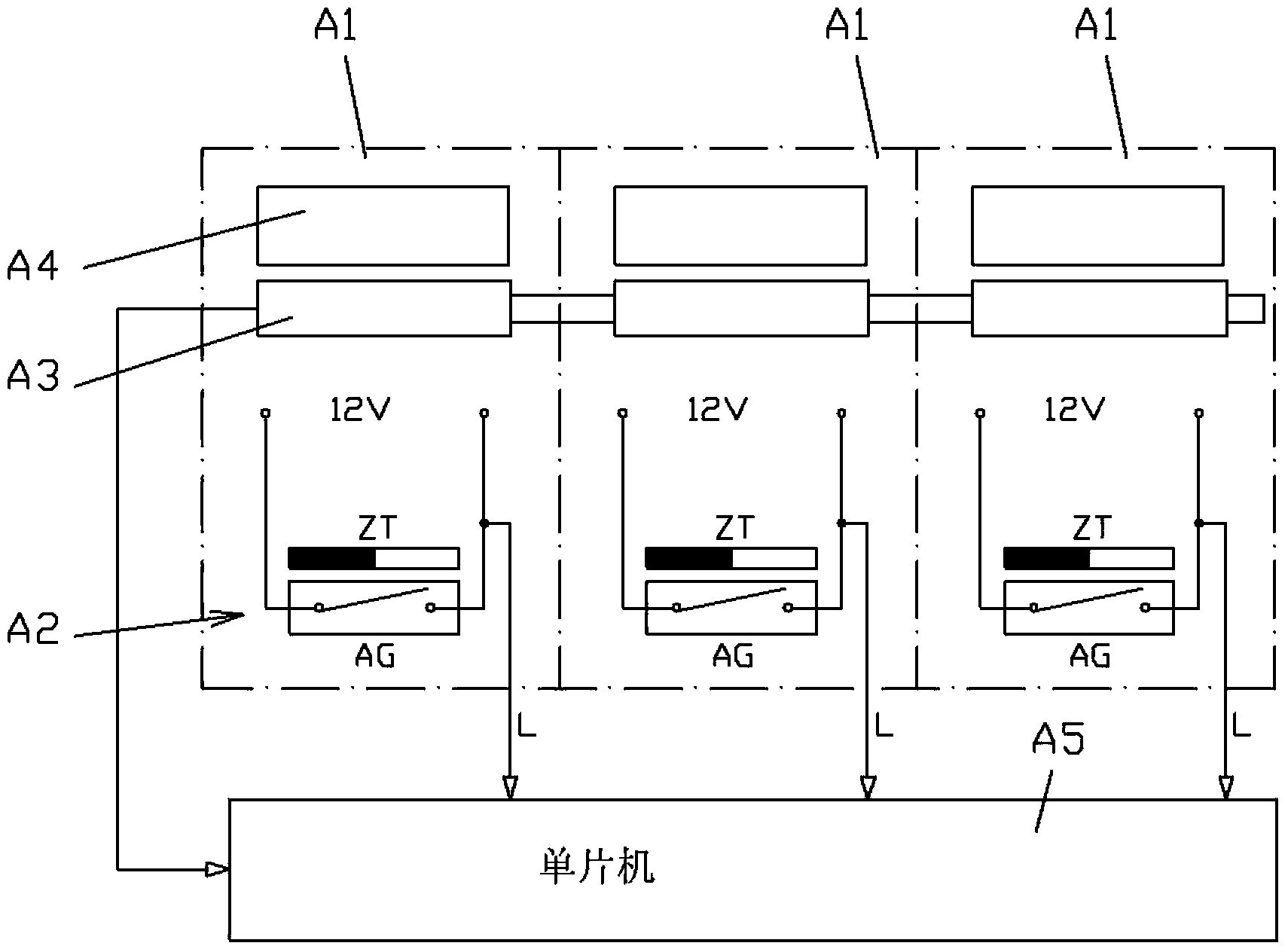

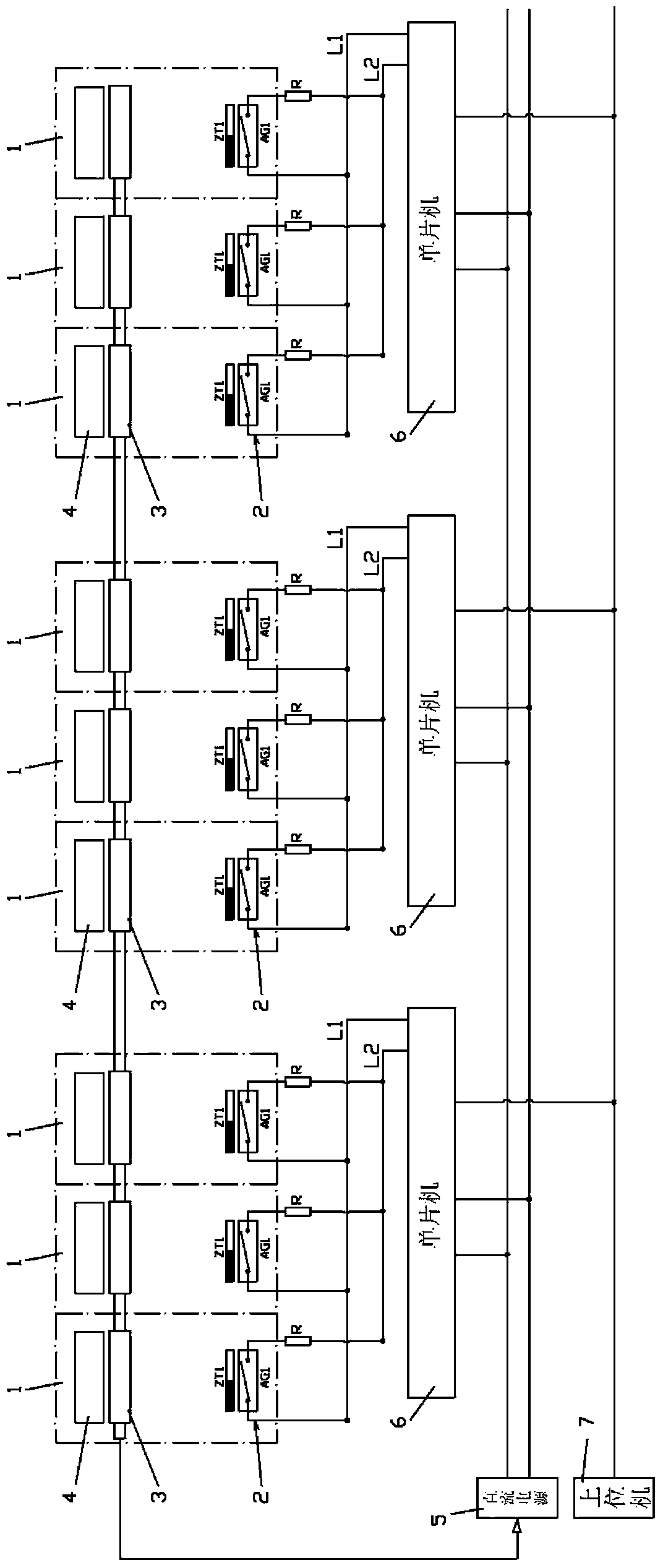

[0016] Example: see image 3 , 4 As shown, the textile machinery output statistics device includes the single-spindle production unit 1 of the textile machine, and each single-spindle production unit 1 includes a yarn detector 2, winding driving roller 3 and winding roller 4, and each single-spindle production unit 1 The winding driving roller 3 is coaxially fixed together, the winding roller 4 elastically presses on the winding driving roller 3, the yarn detector 2 is composed of a magnet ZT1 and a clarinet AG1,

[0017] A DC power supply 5 supplies power to several single-chip microcomputers 6, and each single-chip microcomputer 6 is electrically connected to the clarinet AG1 of the yarn detector 2 of 8 to 16 single-spindle production units 1, and a resistor R is connected in series on the power supply circuit of each clarinet AG1;

[0018] The rotation speed signal of the winding driving roller 3 is sent to the single-chip microcomputer 6, and the on and off signals of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com