Patents

Literature

35results about How to "Reduce on-site construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

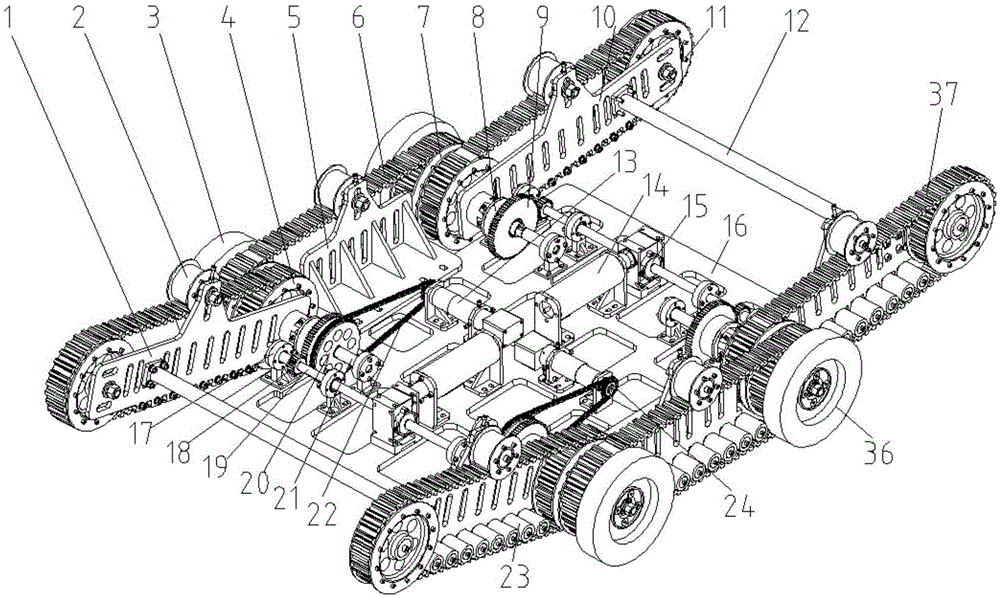

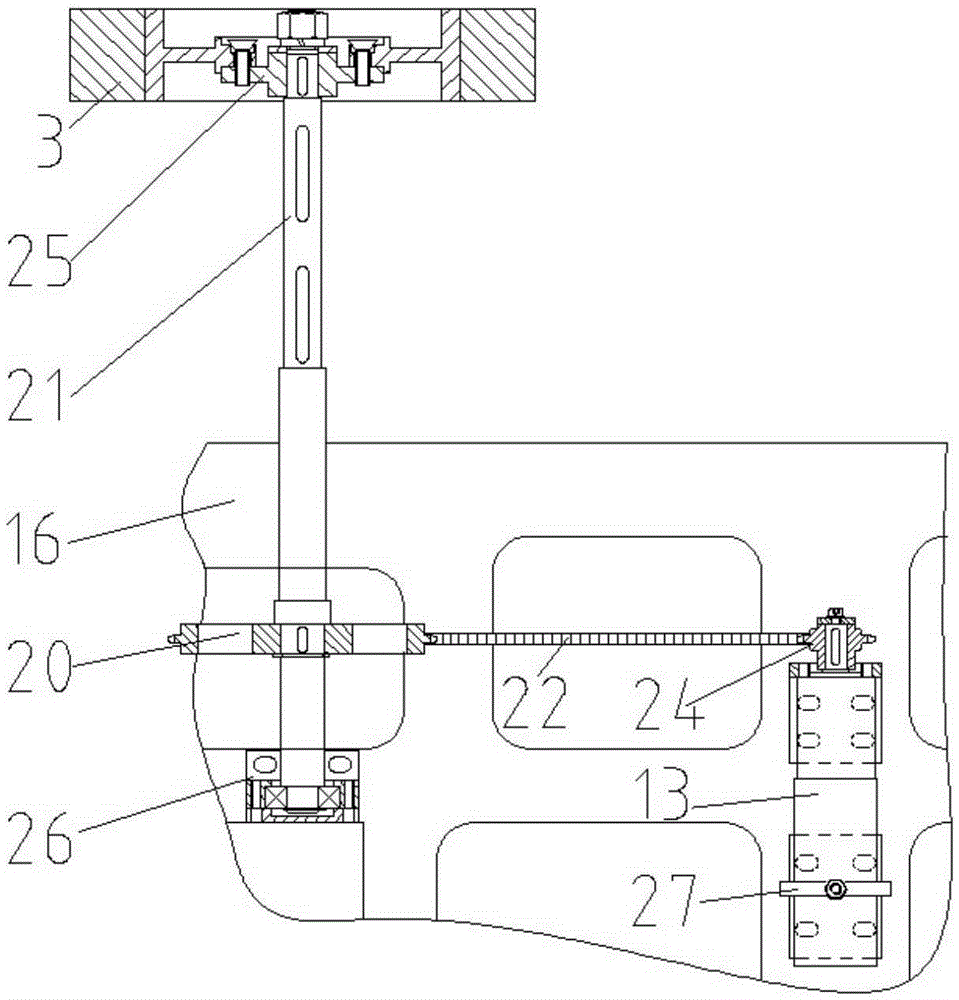

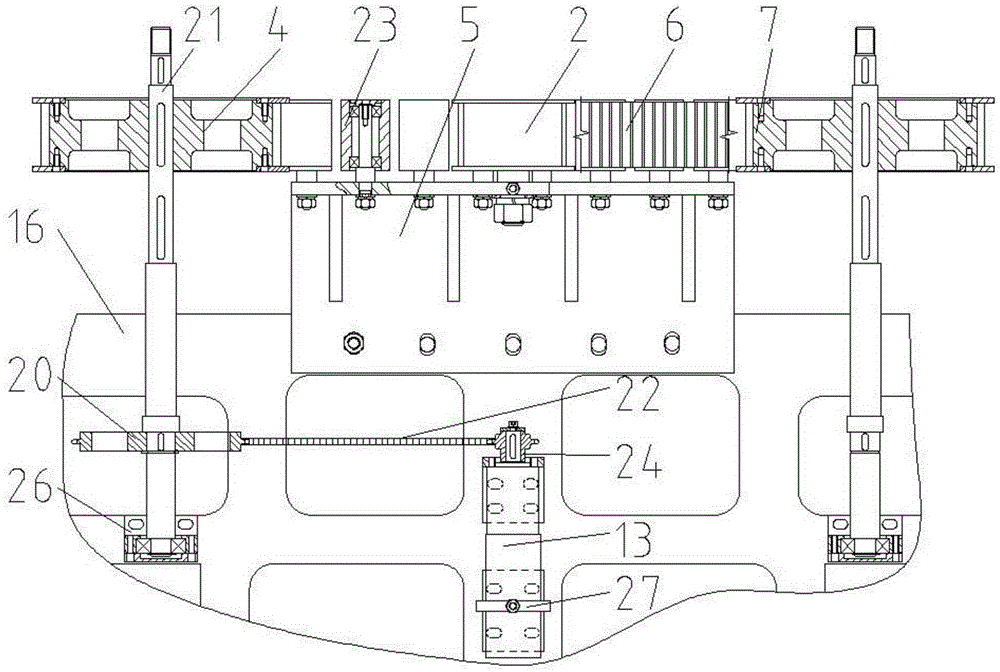

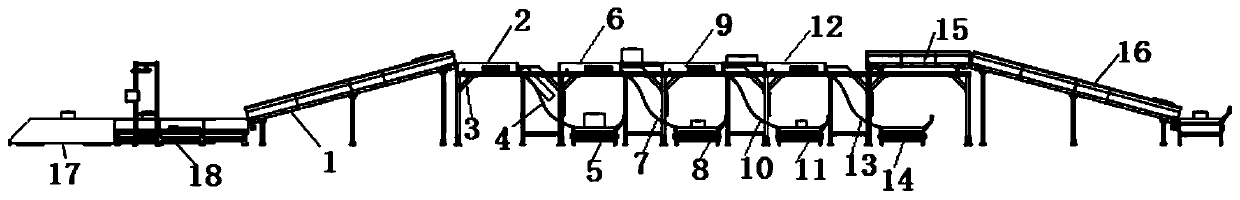

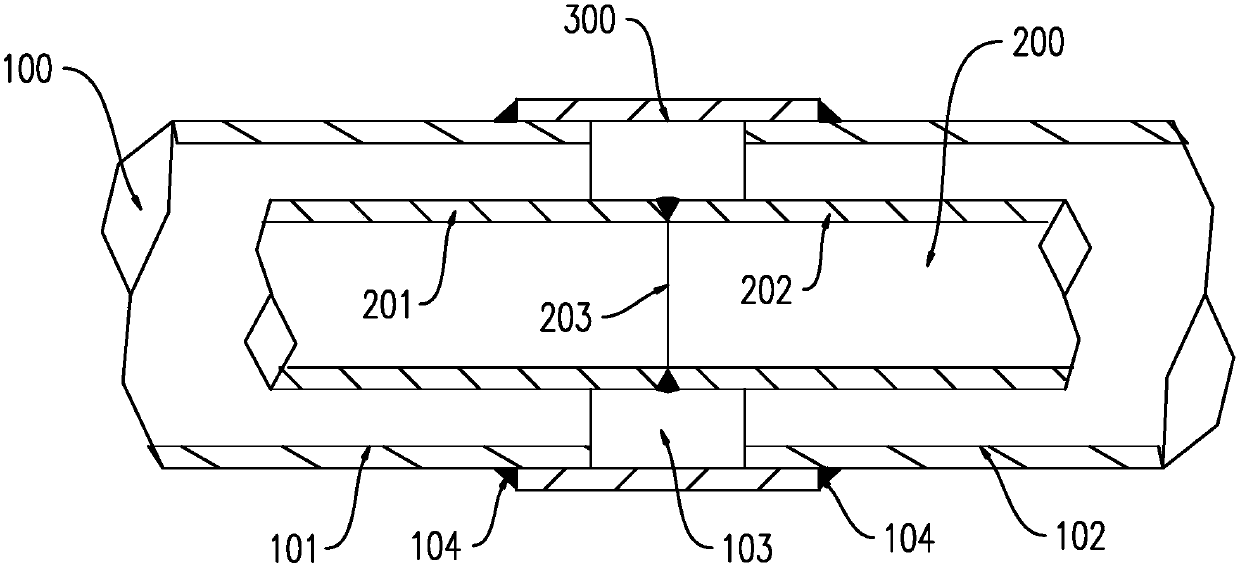

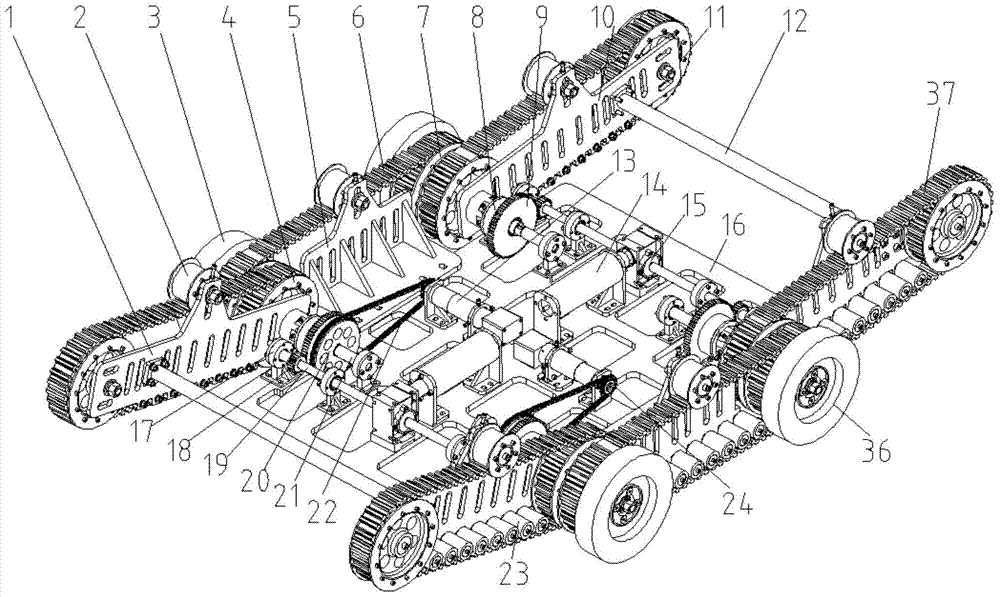

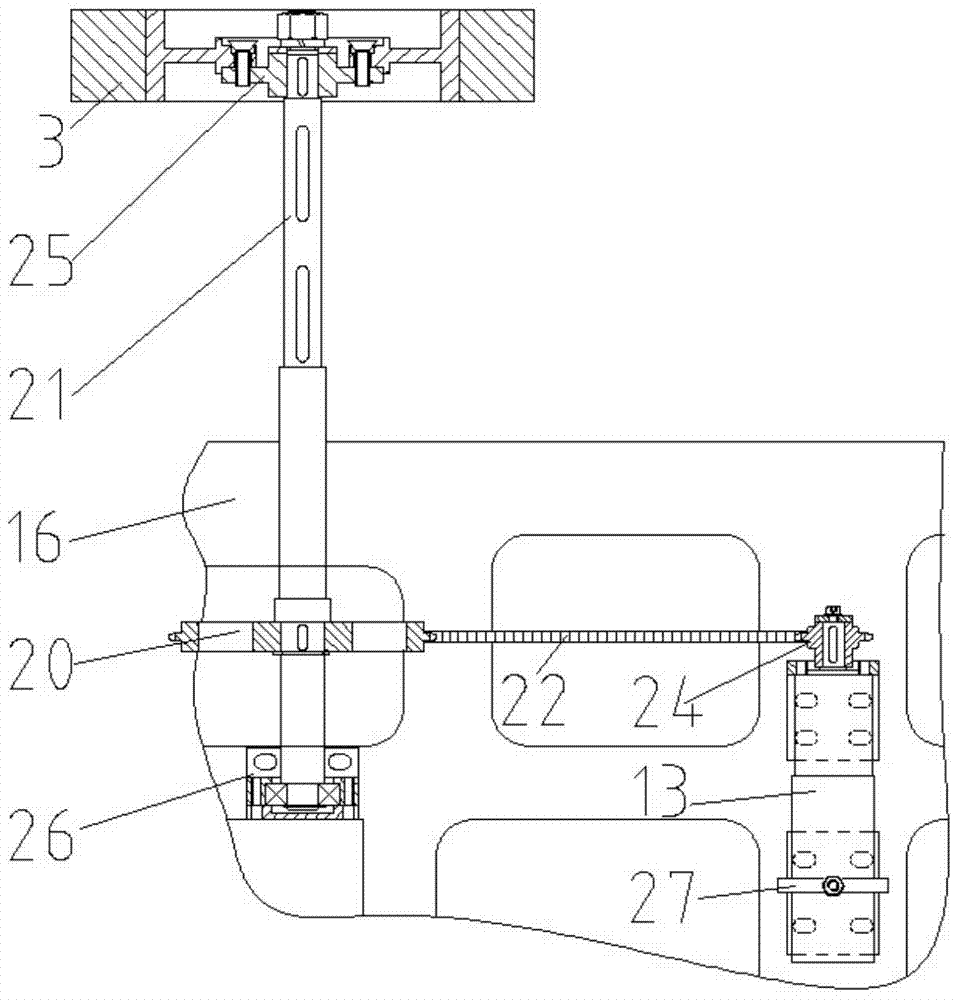

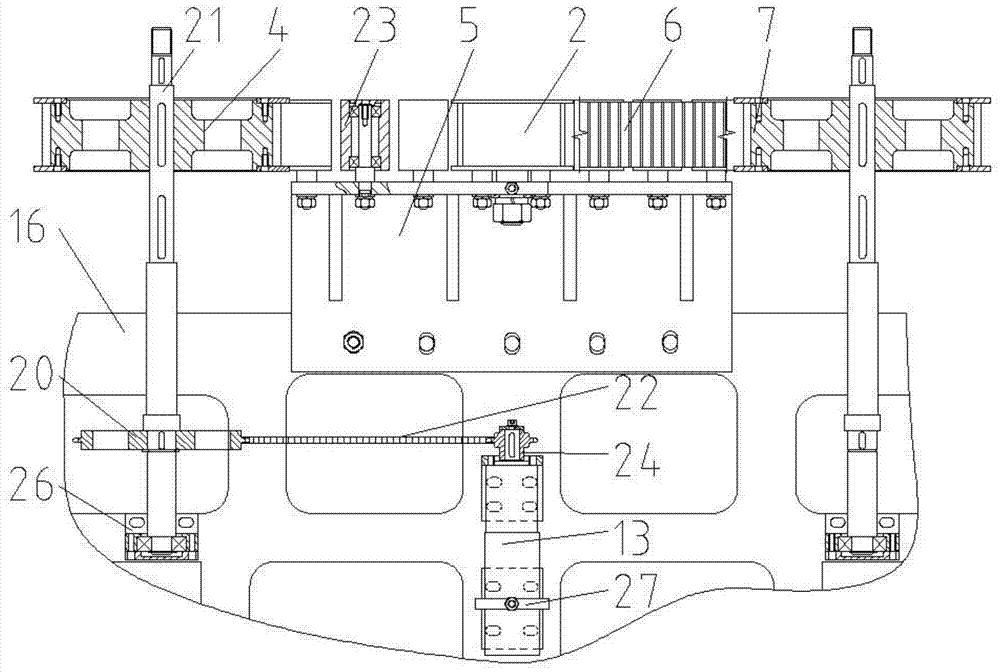

Patrol wheel-pedrail type obstacle-crossing robot for transformer substations

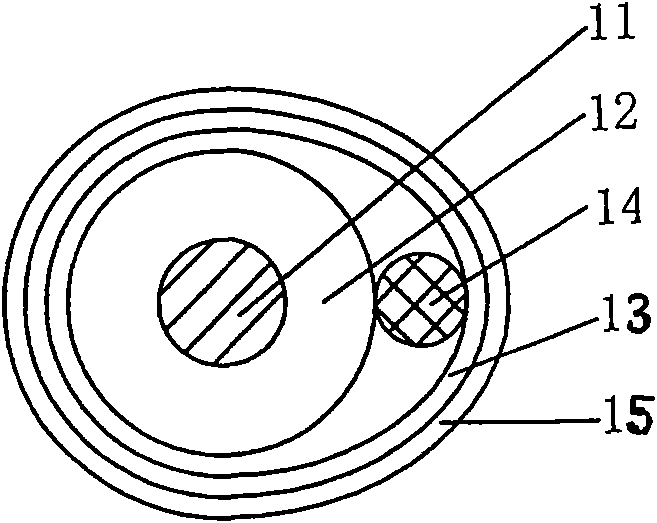

ActiveCN105292281AReduce on-site constructionImprove the ability to overcome obstaclesEndless track vehiclesEngineeringTransformer

The invention relates to a patrol wheel-pedrail type obstacle-crossing robot for transformer substations. The patrol wheel-pedrail type obstacle-crossing robot mainly comprises a chassis, a power mechanism and swing arms. The power mechanism is installed on the chassis and is provided with a walking power source and a swing arm power source, and the walking power source outputs power to walking wheels installed on two sides of the chassis through a transmission shaft. The swing arms are driven by the swing arm power source and are provided with a main walking belt wheel, a swing arm belt wheel and meshed walking pedrails, and the main walking belt wheel is coaxially assembled with the walking wheels. The swing arm power source drives the swing arms to swing for realizing the pedrail walking mode and / or the walking wheel walking mode of the robot. The patrol wheel-pedrail type obstacle-crossing robot can walk in different modes according to different road conditions and obtain the high obstacle-crossing ability through swinging of the swing arms.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

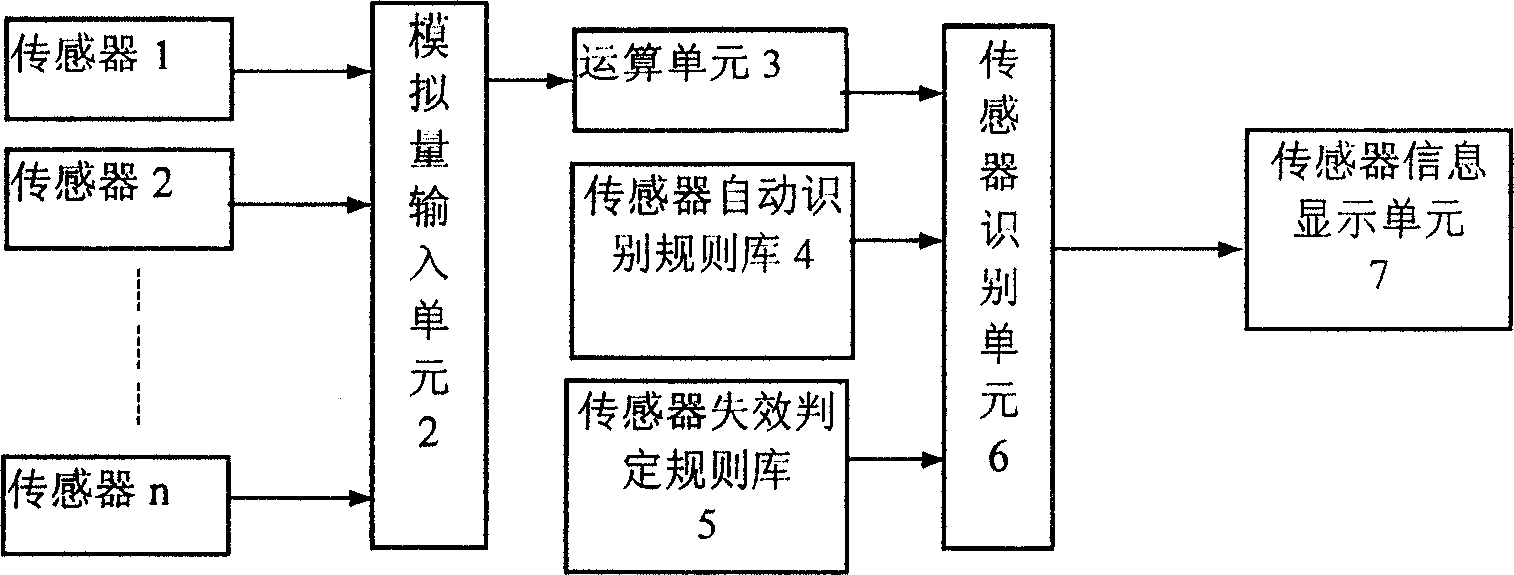

Automatically identifying device of sensor

InactiveCN1949110AGuaranteed uptimeReduce on-site constructionProgramme controlComputer controlData displayAutomatic control

The invention discloses sensor auto identification device. It includes sensor, read analog input unit, algorithm unit, sensor auto identification rule base, sensor failure decision rule base, sensor identification unit, and sensor data display unit. The output end of the sensor is connected with the input end of the read analog input unit of which output end is connected the input end of the algorithm unit. The output ends of the algorithm unit, sensor auto identification rule base, and sensor failure decision rule base are connected with the input end of the sensor identification unit of which output end is connected with the input end of the sensor data display unit. The invention needs no interface numbering mark, can automatically identify various sensor types and uses, ensure auto control device run as the given input-output relation to reduce site operation and debugging cost, increase work efficiency.

Owner:智勇 +1

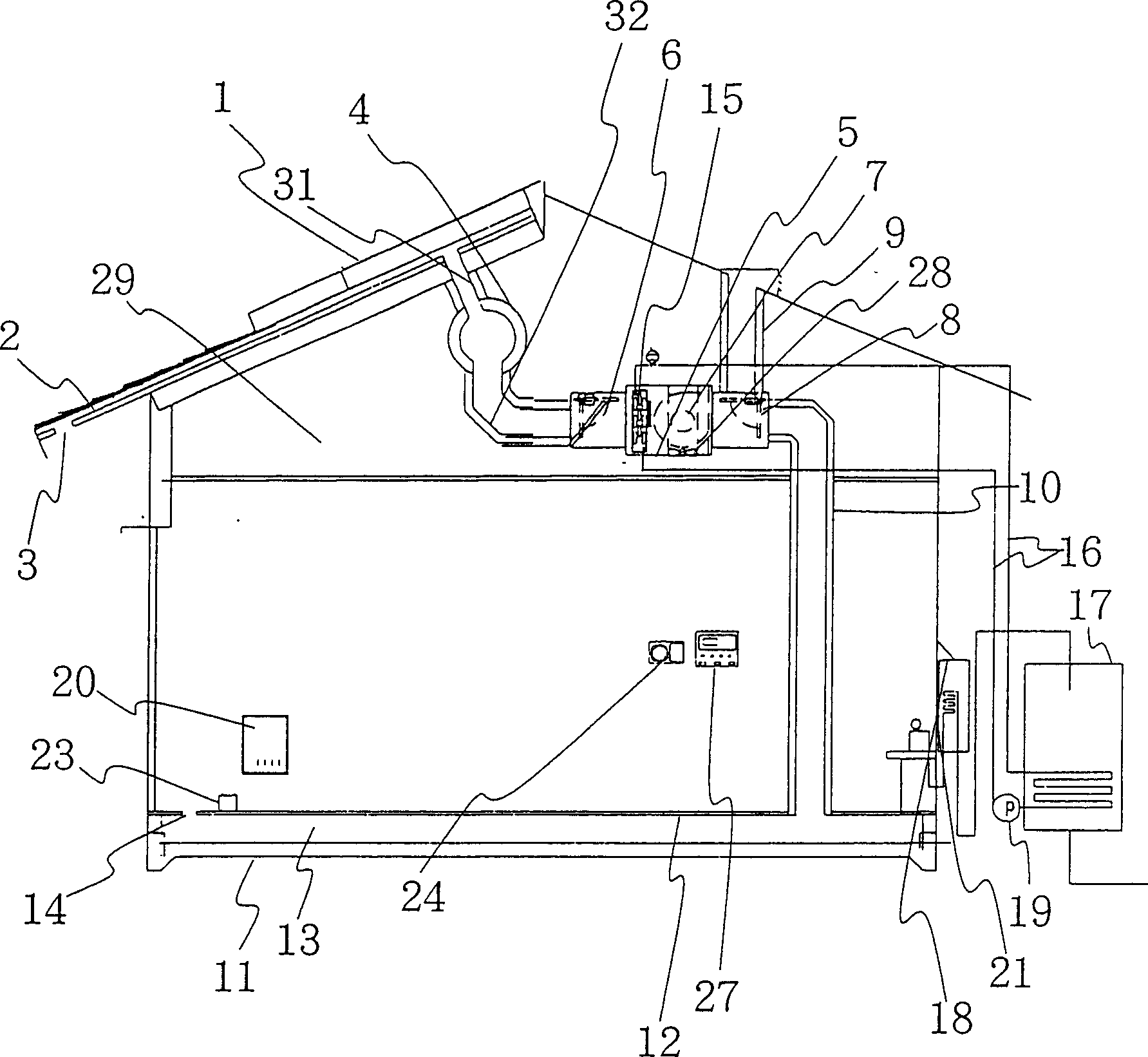

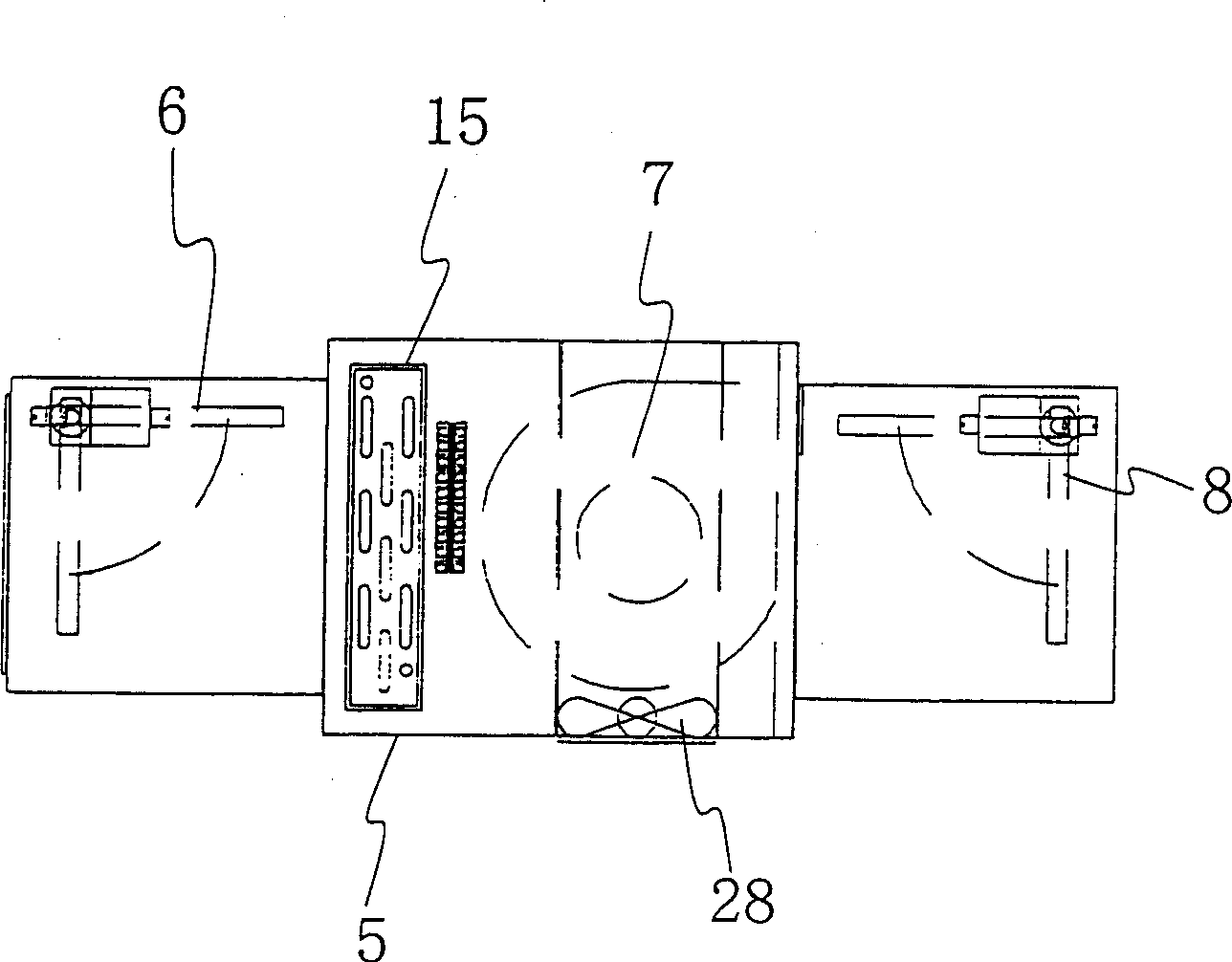

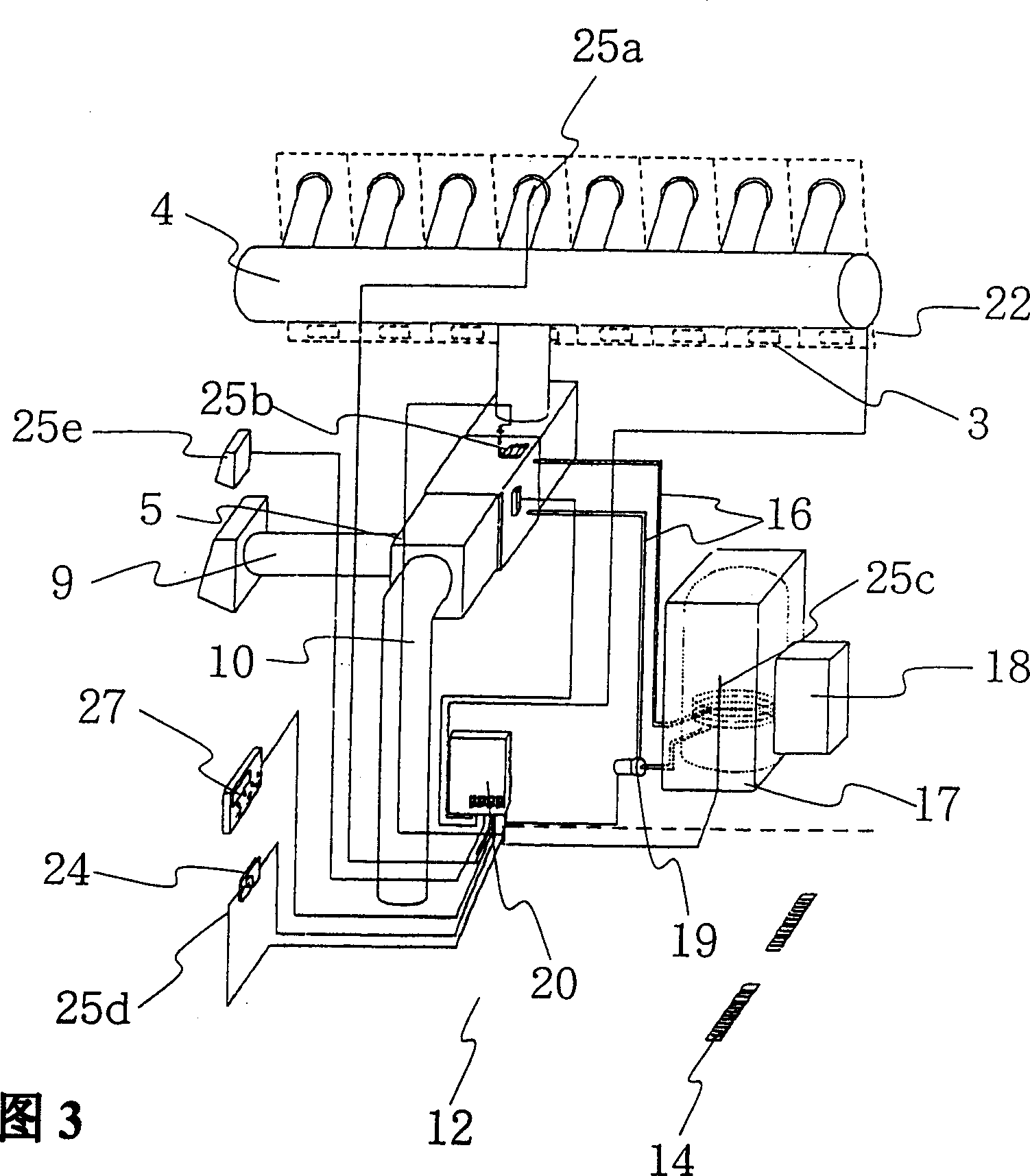

Building with solar ultilization system

InactiveCN1478973AReduce on-site constructionEasy constructionRoof covering using slabs/sheetsDucting arrangementsCounter currentSolar System

A building with a solar system for supplying heat or cold, exchanging air, removing moisture, and supplying hot water is composed of a solar heat collecting unit close to the metallic roof and with slope air channel, a treating box with check valve, switching valve between flowing down channel and exhaust channel, and heat-collecting fan installed between said check valve and switching valve, and the connecting pipelines for connecting solar heat collector with indoor heat collecting chamel, treating box and the flowing down and exhaust channels in turn. Its advantage is optimal use of solarenergy.

Owner:オーエムソーラー協会 +1

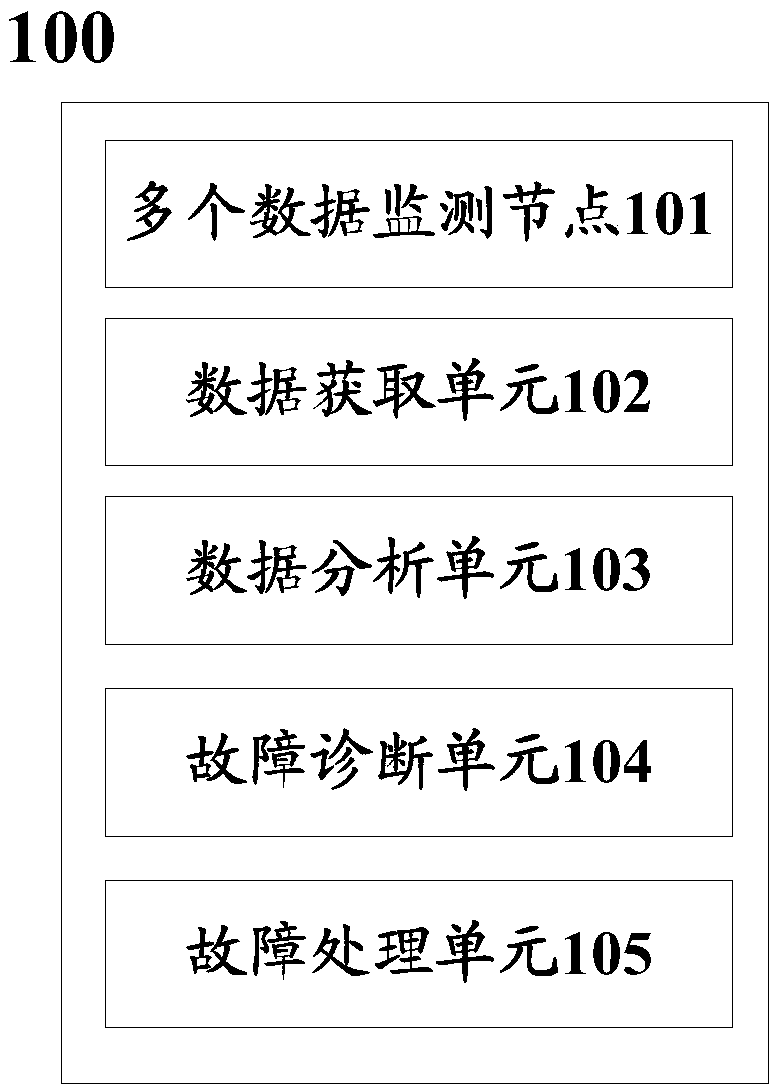

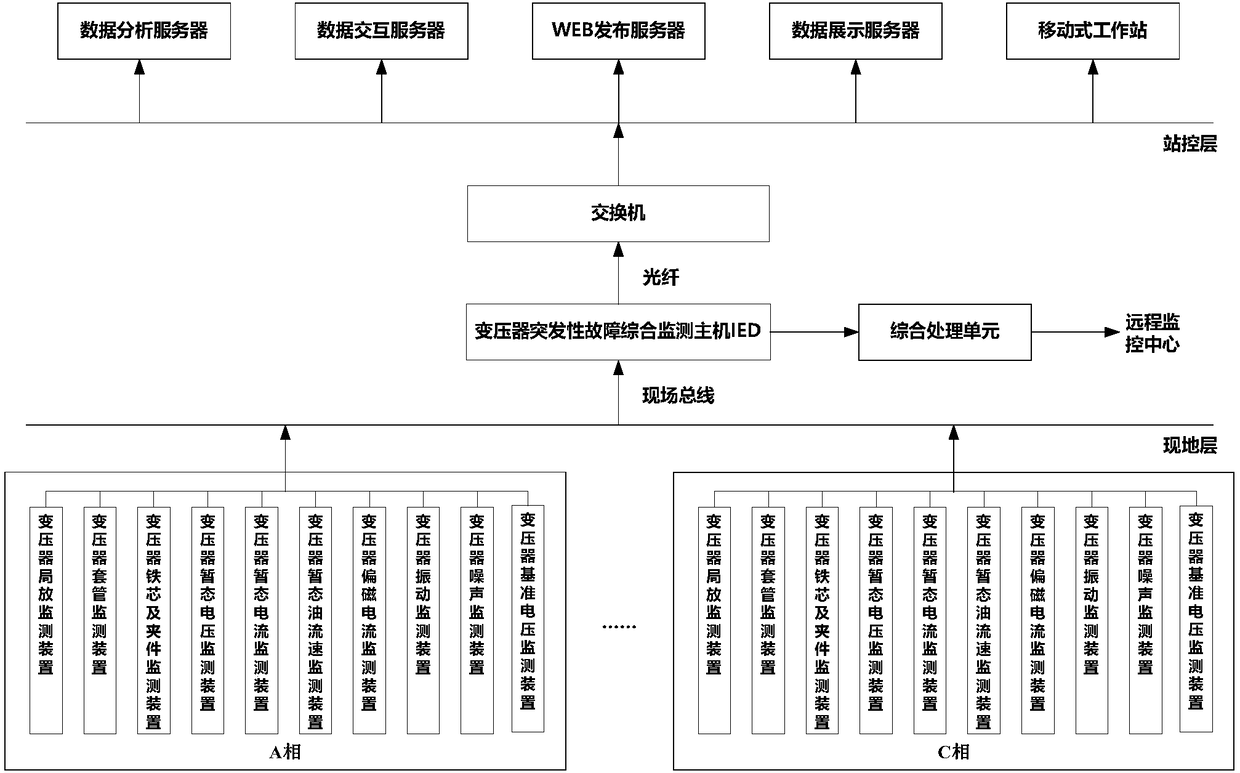

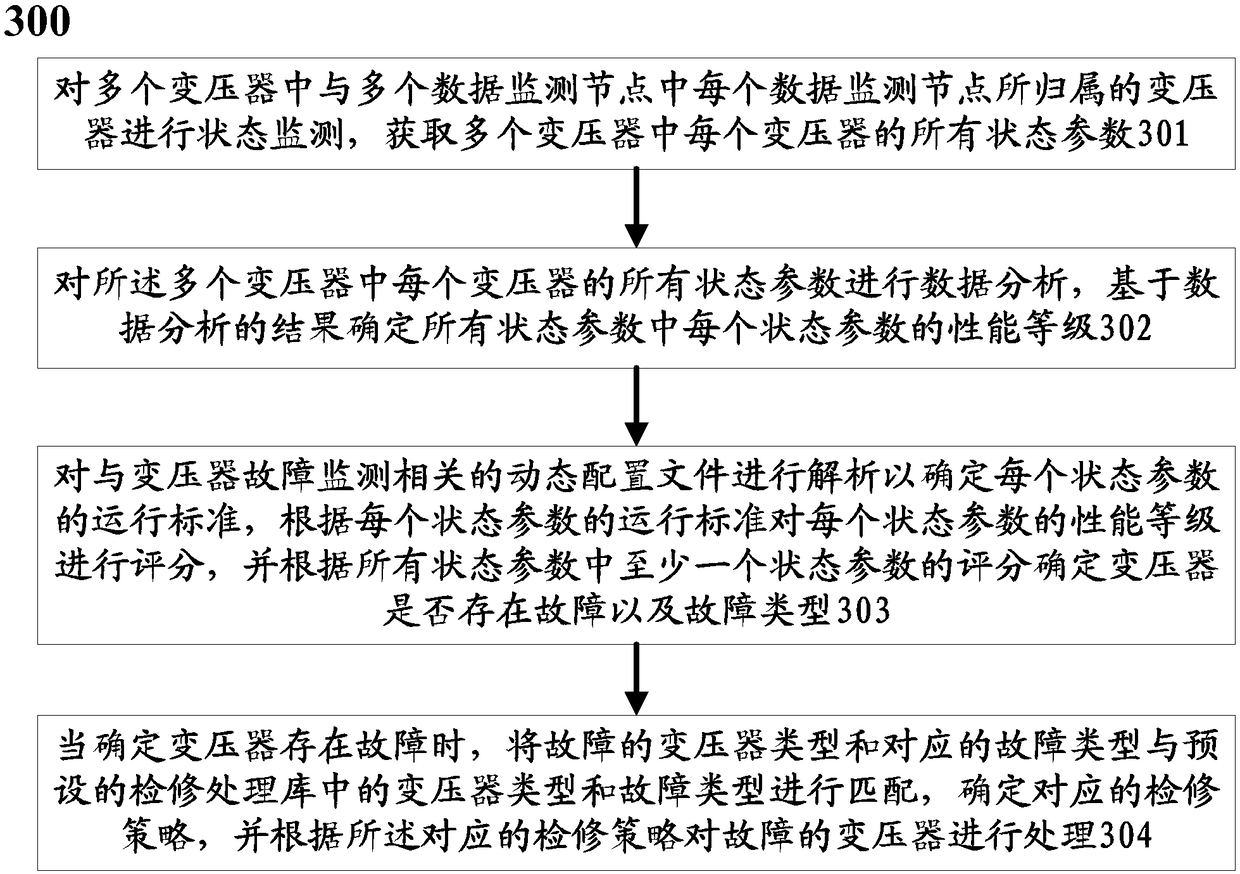

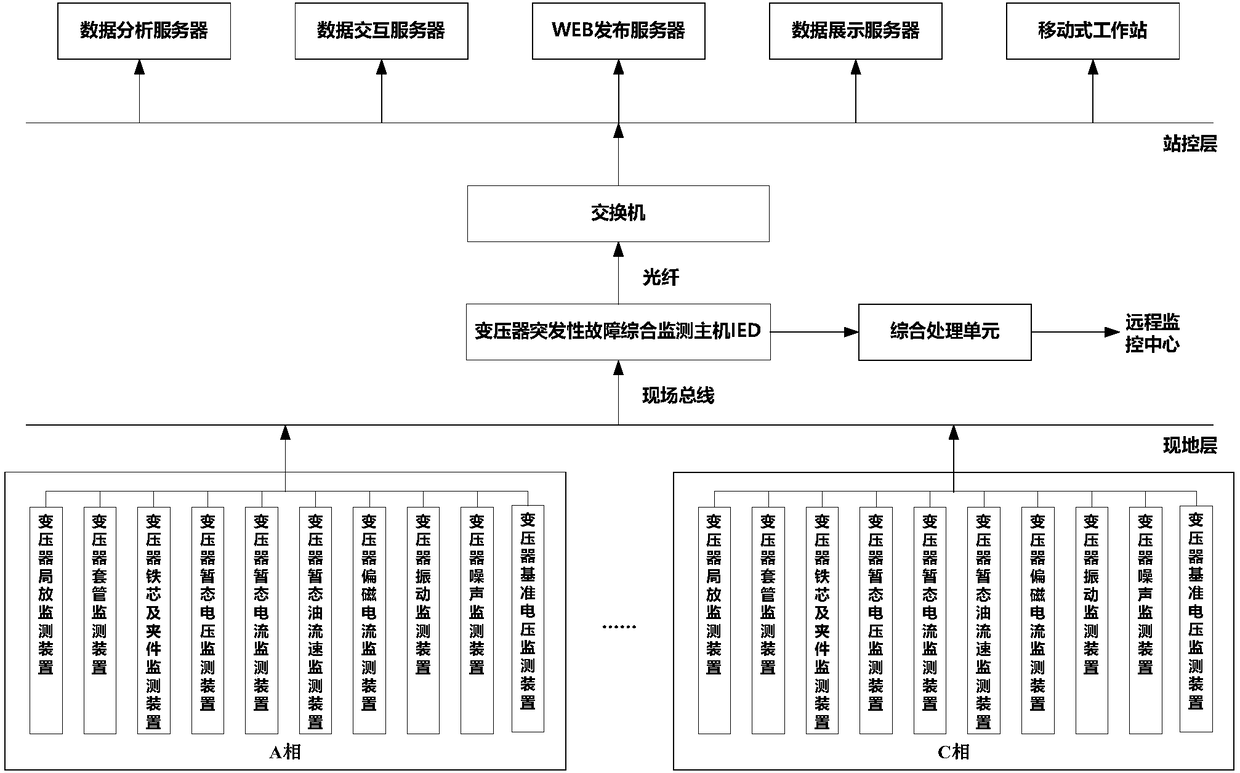

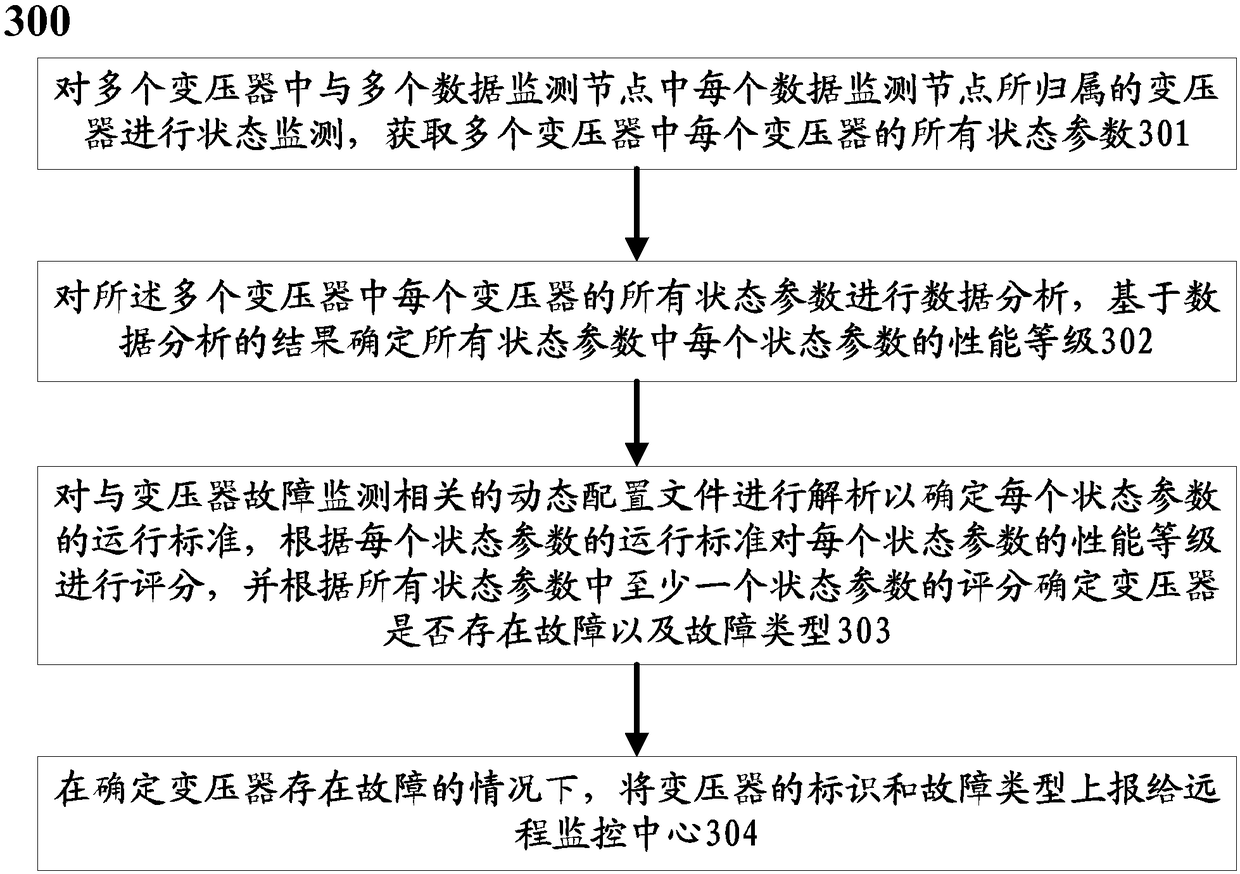

System and method of processing transformer faults

InactiveCN108490323ASimple wiringReduce on-site constructionTesting dielectric strengthState dependentData monitoring

The invention discloses a system of processing transformer faults. The system of processing transformer faults includes a plurality of data monitoring nodes, a data acquisition unit, a data analysis unit, a fault diagnosis unit and a fault processing unit, wherein each data monitoring node includes a plurality of monitoring devices; each monitoring device is used for monitoring state parameters related to an operating state of the assigned transformer; the data acquisition unit is used to acquire all the state parameters related to the operating state of the assigned transformer; the data analysis unit is used to perform data analysis on all the state parameters of each transformer, and analyze the performance level of each state parameter; the fault diagnosis unit is used to determine theoperating standard of each state parameter, perform scoring on the performance level of each state parameter according to the operating standard of each state parameter, and determine whether the transformer has a fault and determine the fault type according to the score of at least one state parameter in all the state parameters; and the fault processing unit is used for reporting the identifierand fault type of the transformer to a remote monitoring center in the case of determining that the transformer has a fault.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

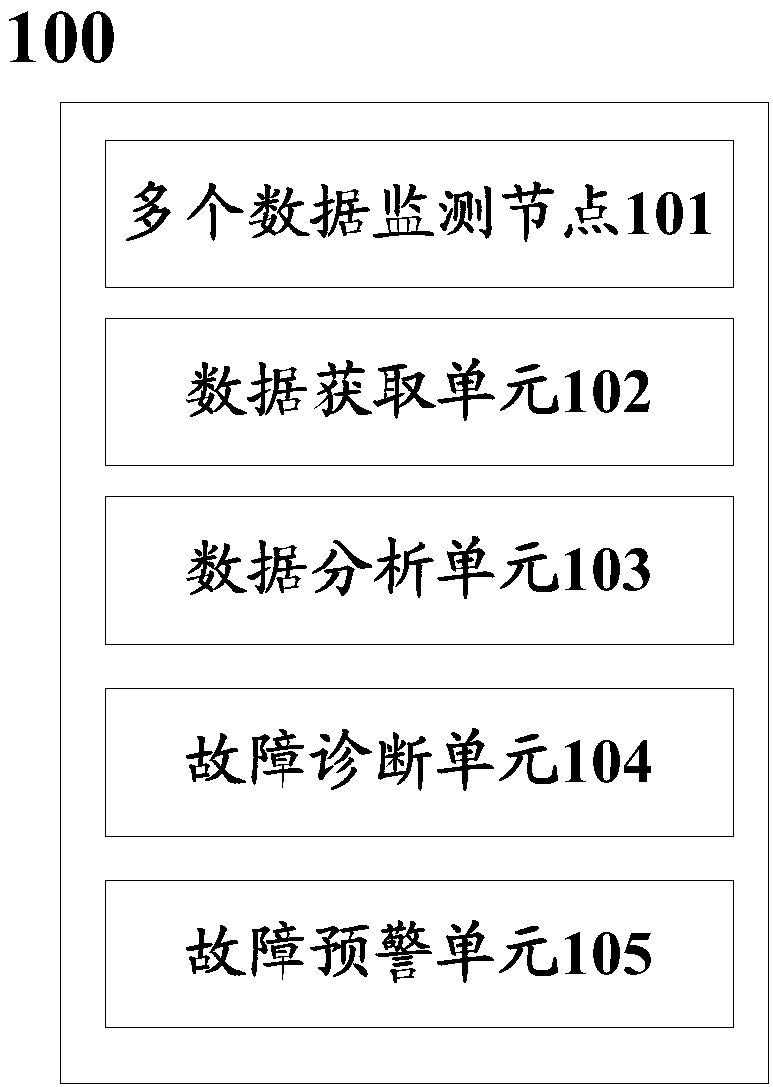

System and method of performing early warning on faults of transformers

InactiveCN108414877AEasy wiringReduce on-site constructionTesting dielectric strengthTransformers testingState dependentTransformer

The invention discloses a system of performing early warning on faults of transformers. The system includes a plurality of data monitoring nodes, a data acquisition unit, a data analysis unit, a faultdiagnosis unit and a fault early warning unit, wherein each data monitoring node includes a plurality of monitors and each monitor is used for monitoring the state parameters related with the operation state of an owned transformer; the data acquisition unit is used for acquiring all the state parameters related with the operation state of the owned transformer; the data analysis unit is used forperforming data analysis on all the state parameters of each transformer to determine the performance level of each state parameter; the fault diagnosis unit is used for determining the operation standard of each state parameter, performing scoring on the performance level of each state parameter according to the operation standard of each state parameter, and determining whether each transformerhas a fault and determining the fault type according to the scores of at least one state parameter of all the state parameters; and the fault early warning unit is used for reporting the identifier and the fault type of each transformer to a remote monitoring center when determining that the transformers have faults.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

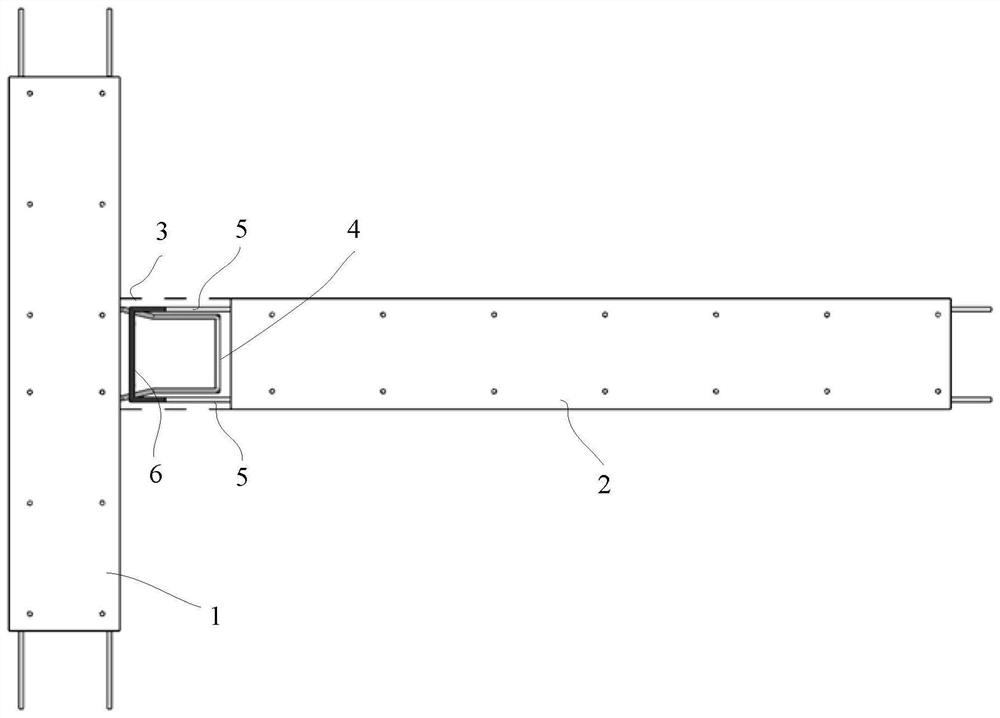

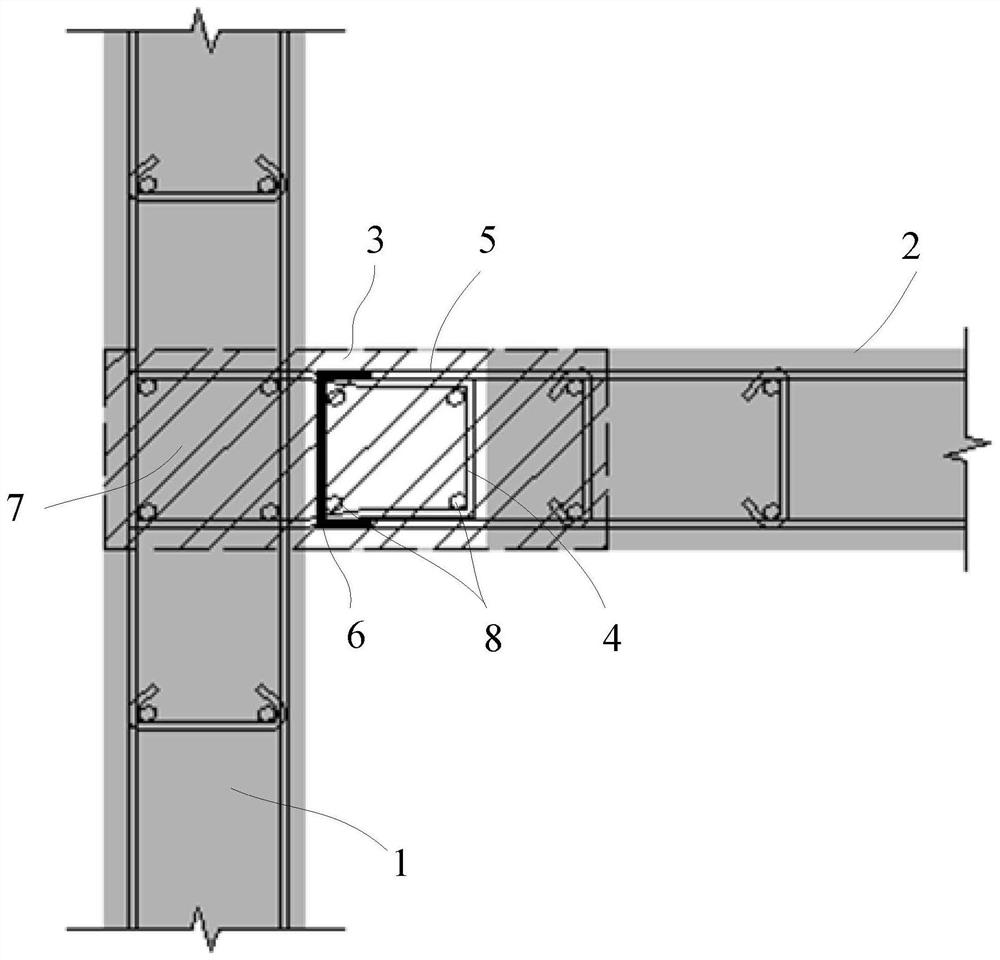

Assembled fireproof combined building component and construction method thereof

PendingCN108118796AShorten the construction periodEasy to installStrutsFire proofingArchitectural engineeringSteel bar

The invention relates to an assembled fireproof combined building component and a construction method thereof. The assembled fireproof combined building component comprises H-shaped steel, the H-shaped steel comprise a web and flanges which are arranged at the two ends of the web and are perpendicular to the web; a pulling steel bar is welded between the flanges; concrete is casted between the flanges and at the two sides of the web, and is casted to be flush with the sides of the flanges; an embedded part is welded to each flange; fireproof boards are hung on the embedded parts, and the portion between the fireproof boards and the flanges is cemented through polymer mortar; a plastering mortar layer is arranged outside the concrete; the plastering mortar layer is flush with the outer edges of the fireproof boards. By means of the assembled fireproof combined building component and the construction method thereof, the purposes that the construction is safe and reliable, convenient, andlow in cost can be achieved.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

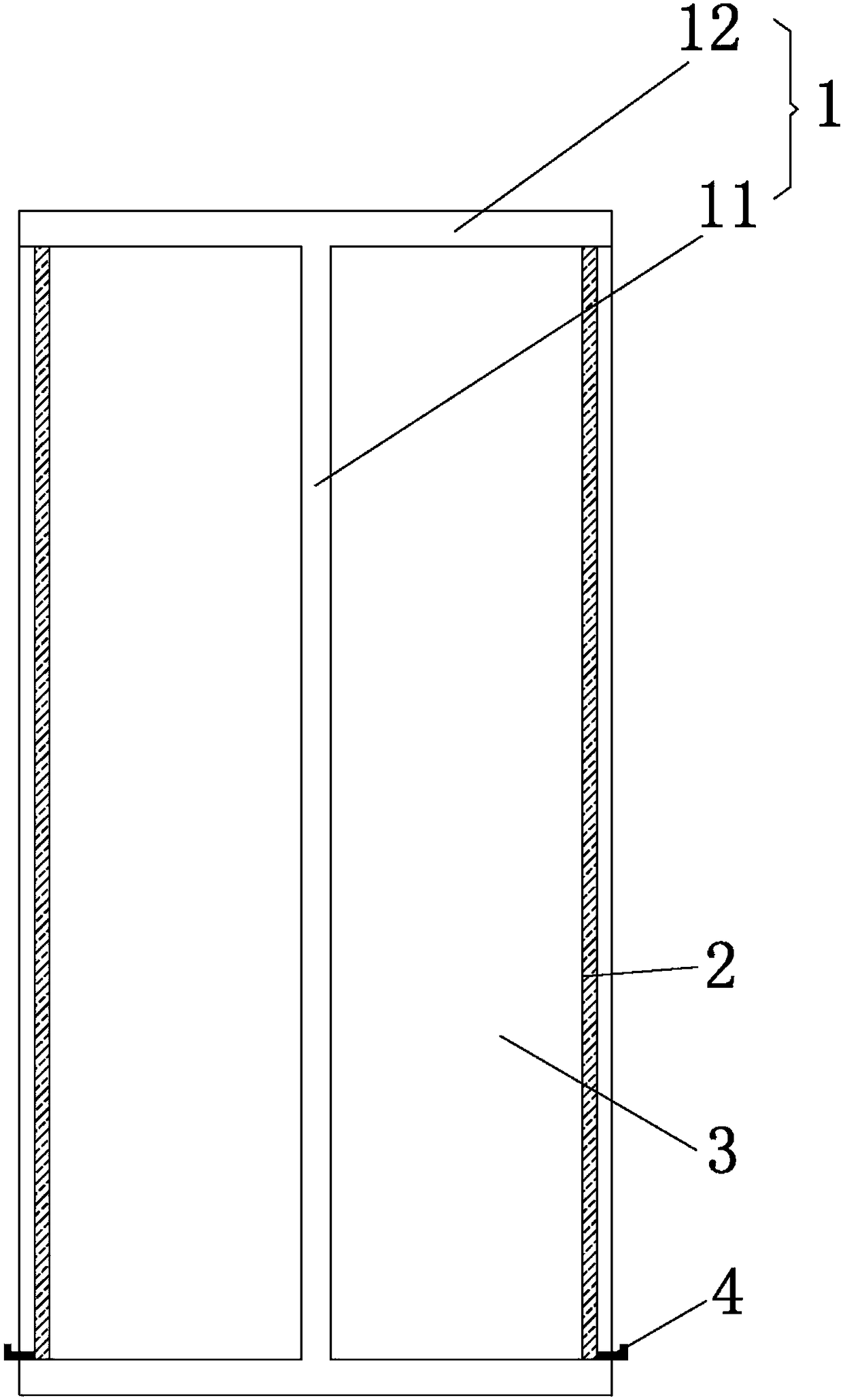

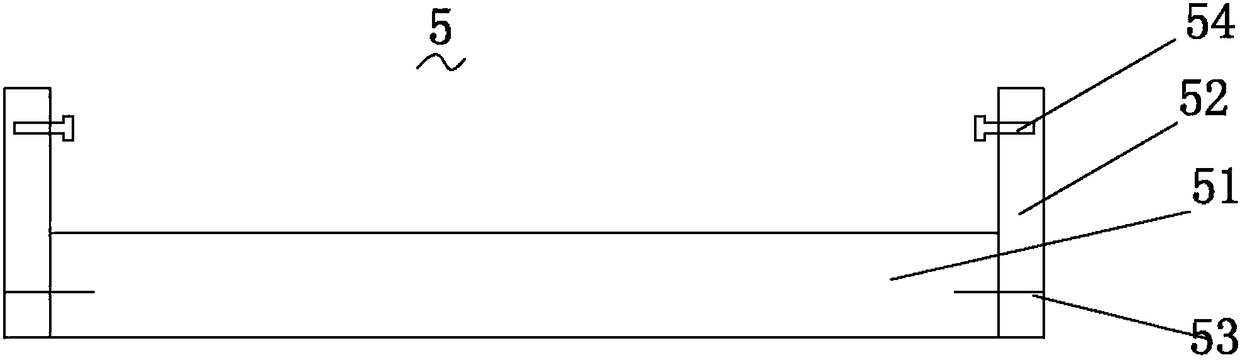

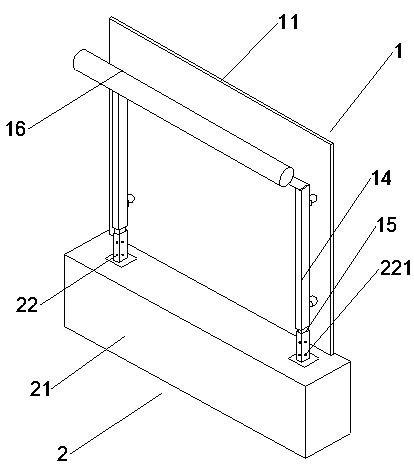

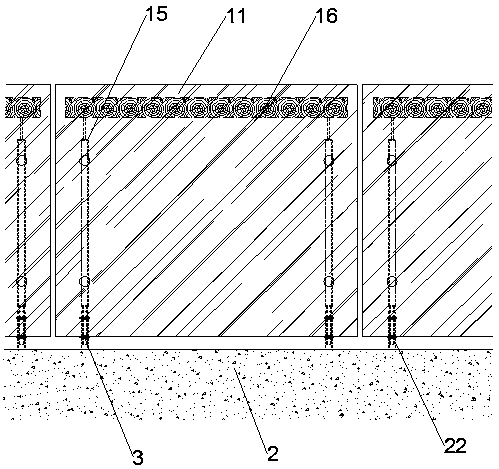

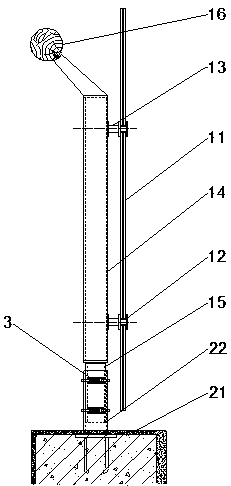

Assembled indoor glass balustrade structure

The invention relates to an assembled indoor glass balustrade structure which comprises a plurality of glass balustrade units. The glass balustrade units are mounted on fixed base units below the glass balustrade units, and each comprise tempered laminated glass; and one side of the tempered laminated glass is connected with vertically-arranged stand columns through connectors and fixing claw parts. Each fixed base unit comprises a base and a sleeve arranged on the corresponding fixed base unit. Connecting rods which is cooperatively inserted into the sleeves are arranged at the lower ends ofthe stand columns in the radial direction of the stand columns. The connecting rods are of a hollow structure and internally provided with spring pins horizontally arranged. The connecting rods provided with the spring pins are inserted into the sleeves, so that the glass balustrade units are mounted on the fixed base units, and assembling is completed. The assembled indoor glass balustrade structure is simple and convenient and fast to mount, saves labor and resources, and greatly shortens the construction period.

Owner:JIANGSU NANFANG XIONGSHI CONSTR ENGCO

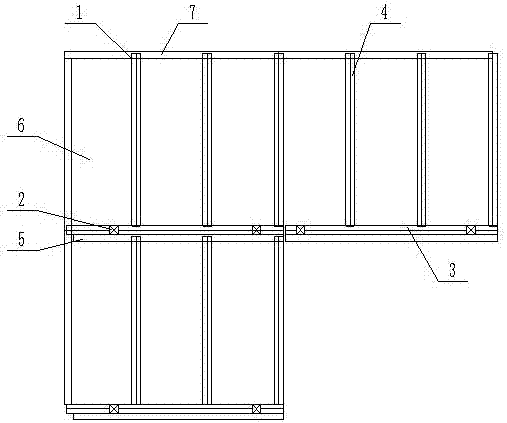

Integrated modularization flat top and construction method thereof

The invention relates to an integrated modularization flat top and a construction method thereof and belongs to the technical field of gypsum board ceilings. The integrated modularization flat top is simple in structure, is constructed conveniently, can effectively improve the working efficiency, and reduces building garbage. According to the technical scheme, the flat top comprises edge keels which are fixed to a wall body and a plurality of flat top modules which are mutually spliced, the flat top modules are fixed to a roof through flat top adjustment parts, and the flat top modules are mainly composed of horizontal false keels, vertical false keels, connection edge keels and gypsum boards; a plurality of the vertical false keels are vertically distributed on one side of each horizontal false keel, the connection edge keels are fixed to the other side of each horizontal false keel, and the connection edge keels have outward openings; the gypsum boards are fixed to the horizontal false keels, the vertical false keels and the connection edge keels, the vertical false keels, close to the wall body, of the flat top modules are inserted into the edge keels, and the vertical false keels of other flat top modules are inserted into keel grooves of the corresponding connection edge keels. The integrated modularization flat top and the construction method thereof are widely applied to installation of the flat top.

Owner:韩合桥

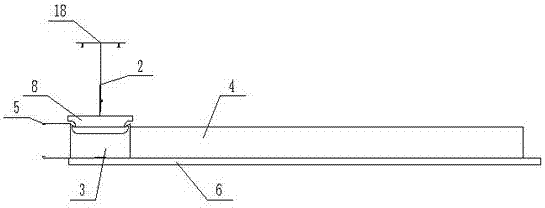

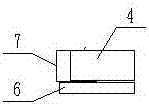

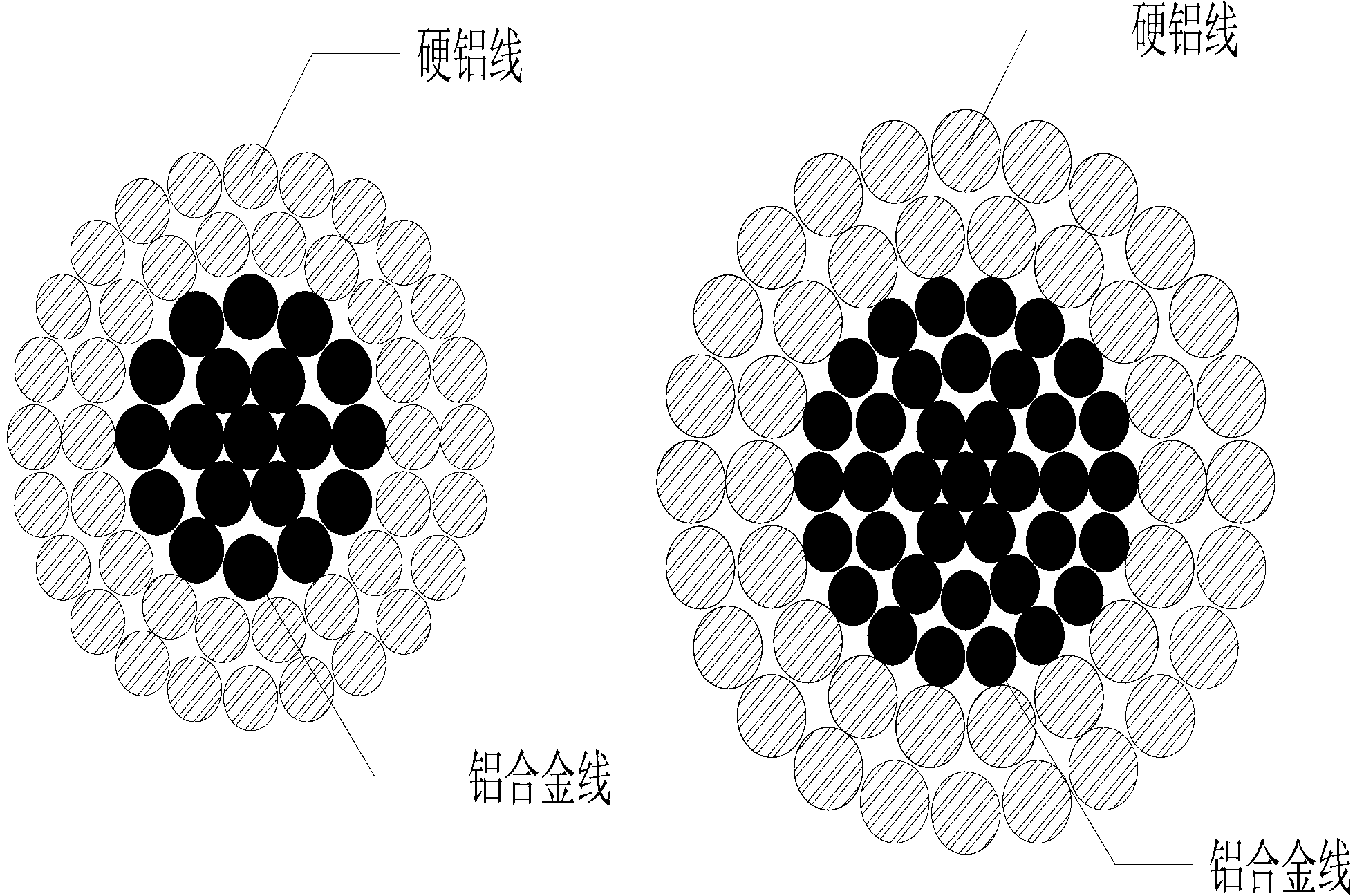

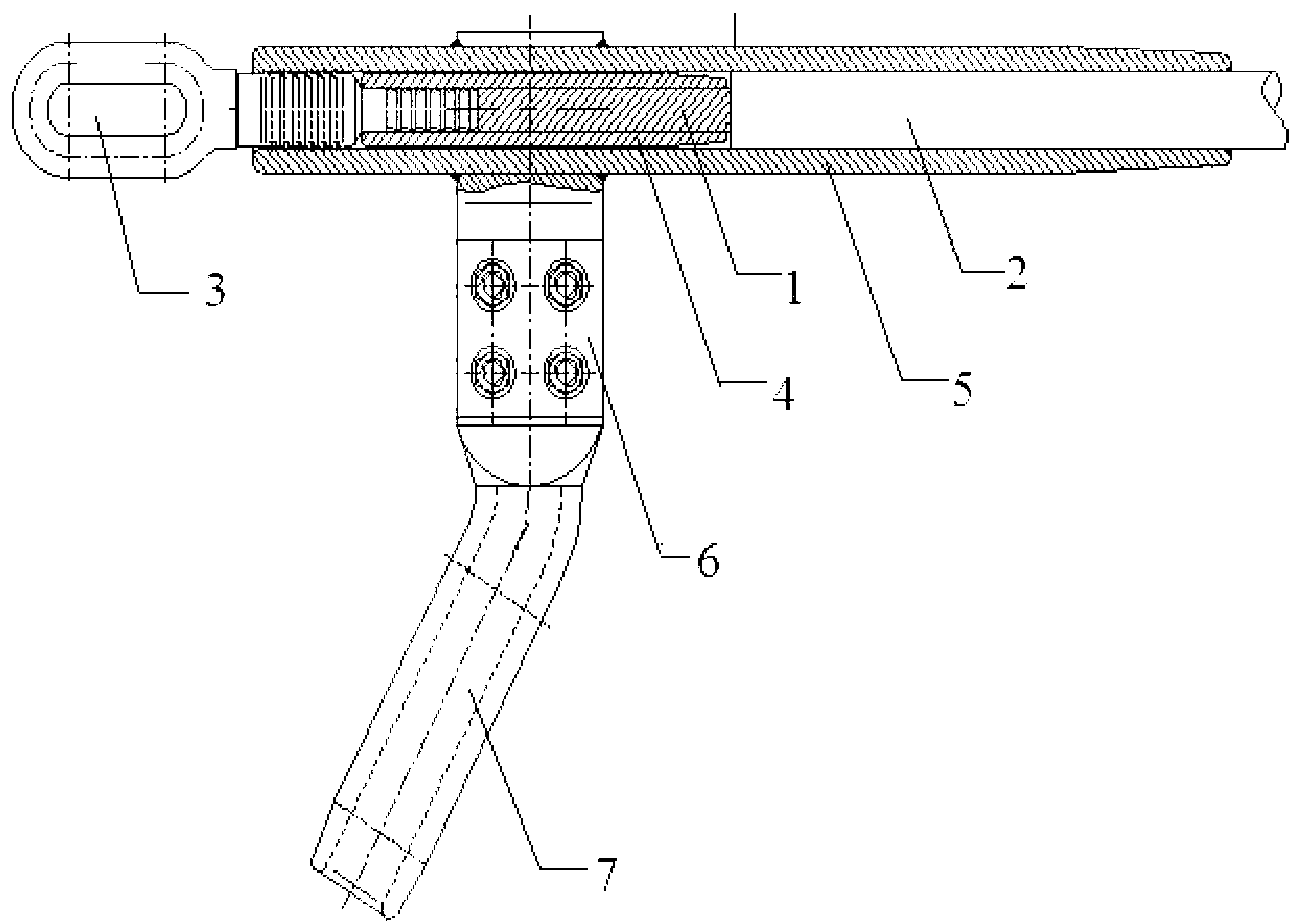

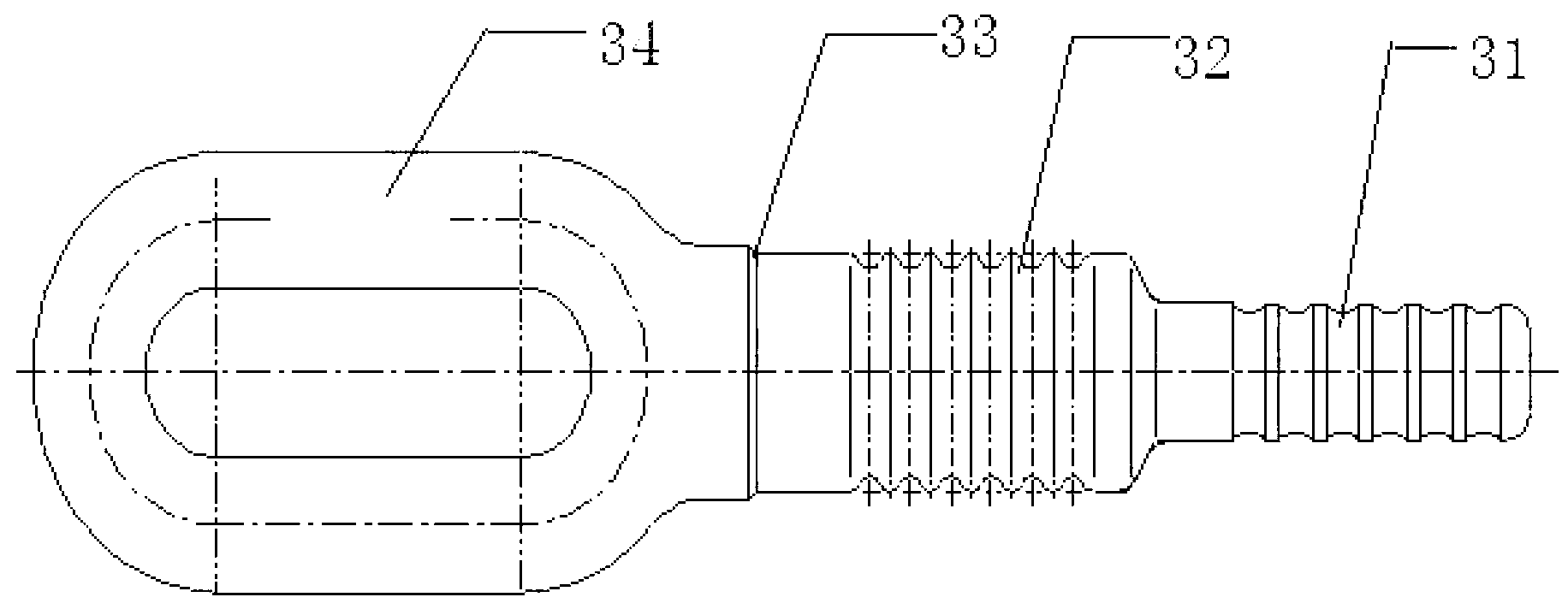

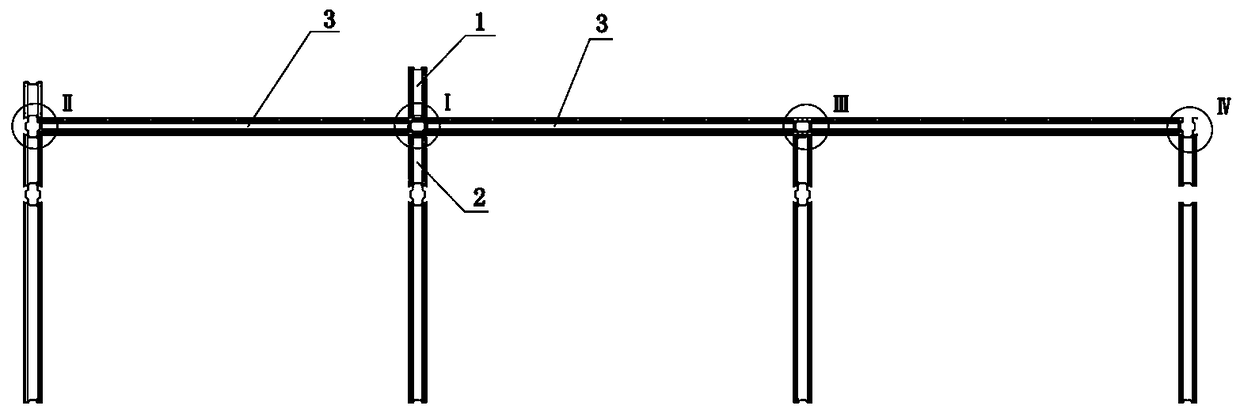

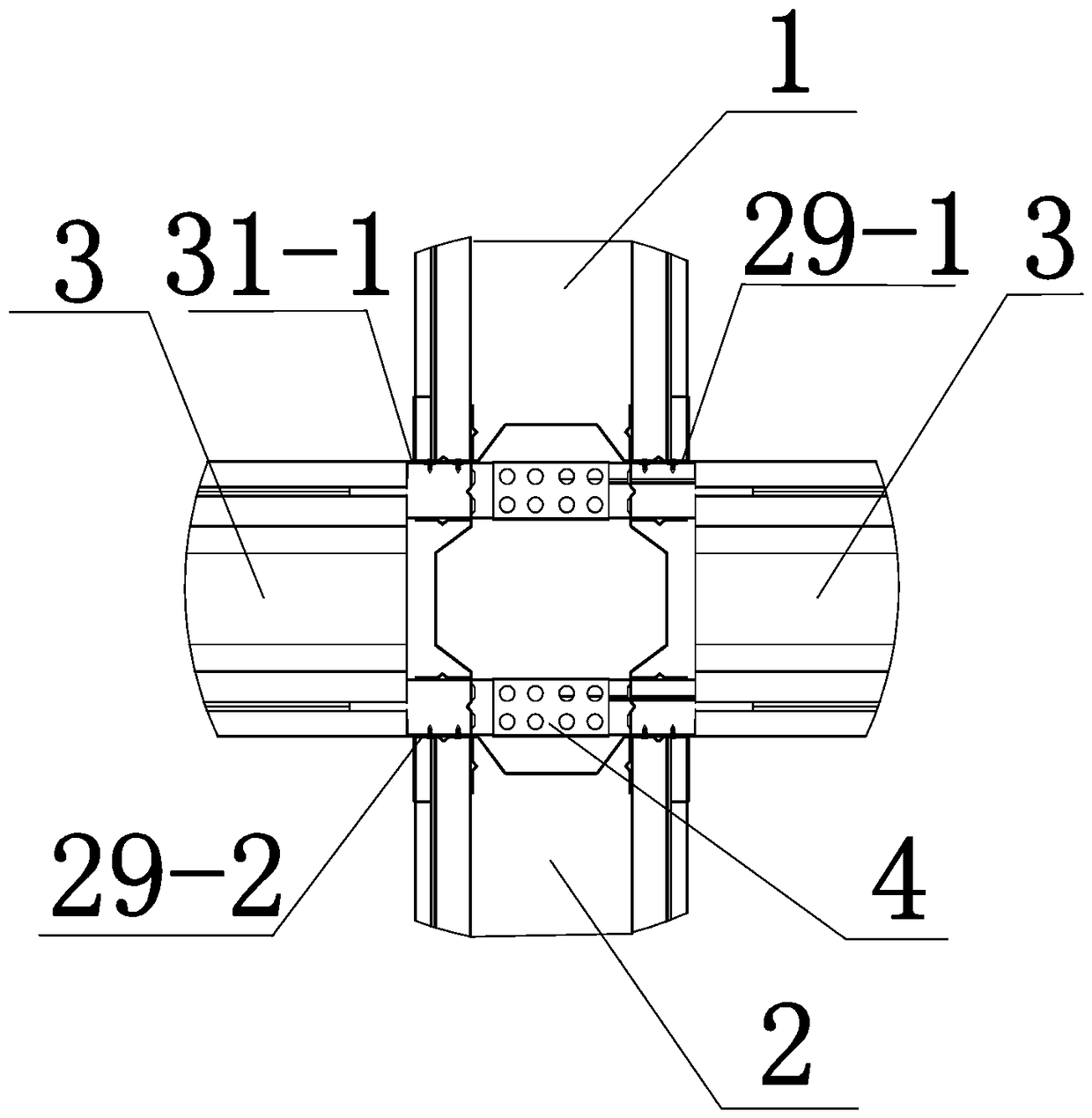

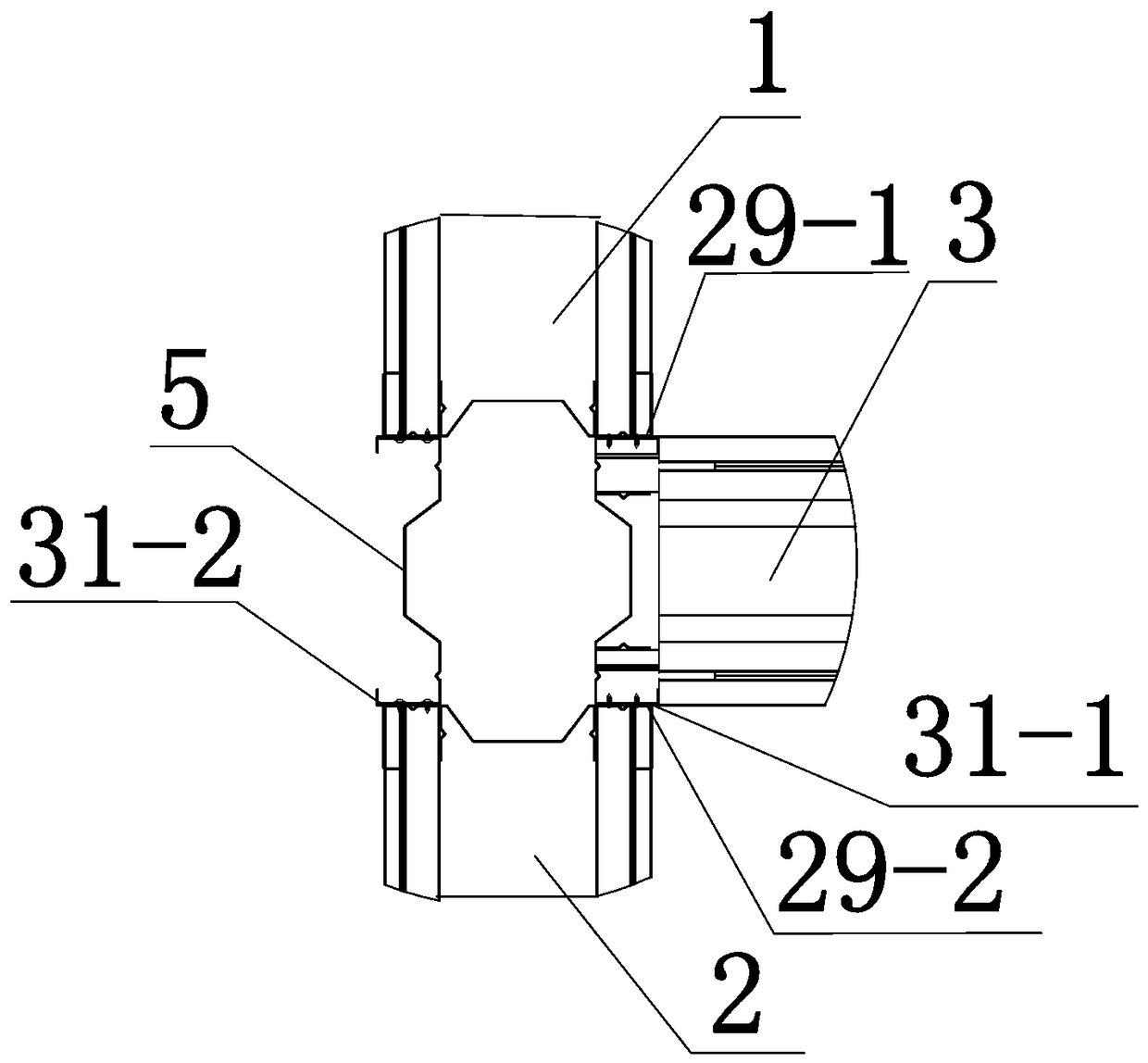

Strain clamp for aluminum alloy core aluminum stranded wire

InactiveCN103326296AThe crimping process is matureReduce on-site constructionAdjusting/maintaining mechanical tensionMechanical propertyCorrosion

The invention provides a strain clamp for an aluminum alloy core aluminum stranded wire. The strain clamp comprises a drainage plate 6, a drainage wire clip 7 which is connected with the drainage plate 6, a strain steel anchor 3, and an aluminum alloy tube 4 and a strain aluminum 5 which are orderly sleeved outside the strain steel anchor 3. Sleeve crimped parts are an anchor head 31 and a middle connecting part 32 of the strain steel anchor 3. One end which is not crimped of the aluminum alloy tube 4 is contained with a cavity for containing an inner core 1 of the aluminum alloy core aluminum stranded wire. One end which is not crimped of the strain aluminum 5 is provided with a cavity for containing a stranded wire 2. The middle part of the strain aluminum 5 is provided with the drainage plate 6. The aluminum alloy core aluminum stranded wire, the strain steel anchor 3, the aluminum alloy tube 4 and the strain aluminum 5 are coaxially arranged. The strain steel anchor 3 and the aluminum alloy tube 4 are pressed in advance. According to the strain clamp, mature hydraulic technology pressing is employed, the strain steel anchor and the aluminum alloy tube are pressed in a factory, the field construction is reduced, parts are few, an operation is convenient, the pressing quality is easy to be ensured, the corrosion resistance performance is good, high quality materials are selected, the installation is simple, the construction is facilitated, mechanical properties and electrical properties are good, and the quality is stable.

Owner:STATE GRID CORP OF CHINA +2

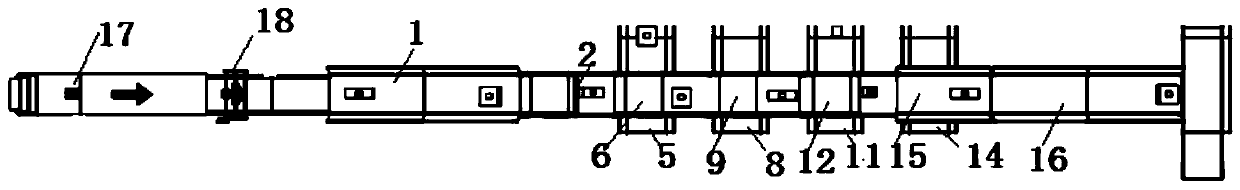

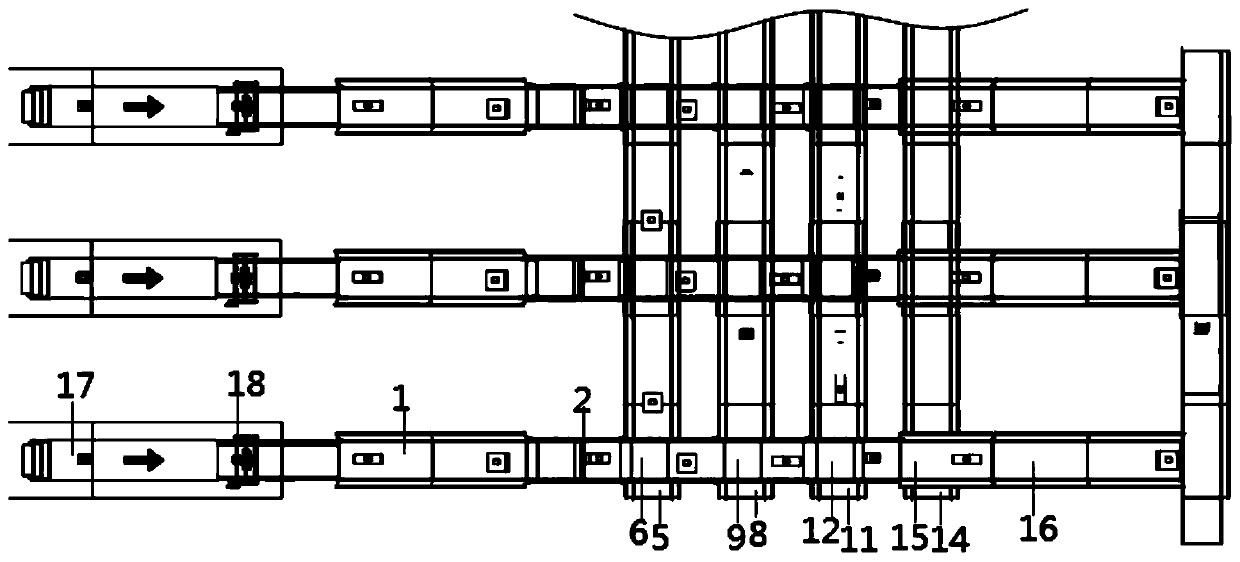

Sorting method of intelligent goods sorting device

ActiveCN109954683AReduce breakage rateSolve the problem that the woven bags cannot be sortedSortingComputer science

Owner:立际物流科技(上海)有限公司

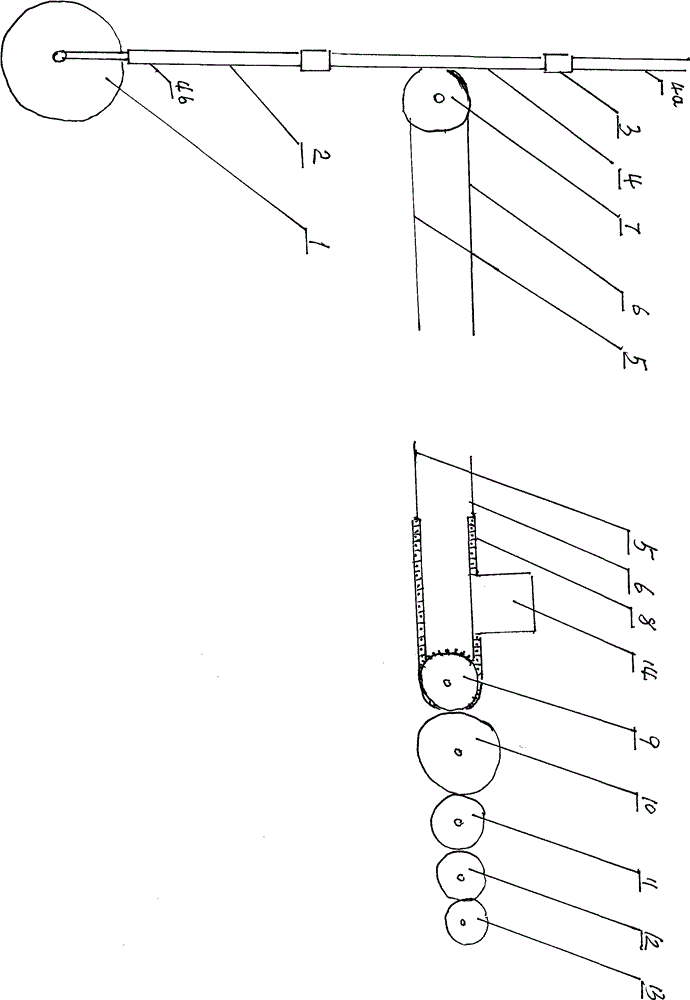

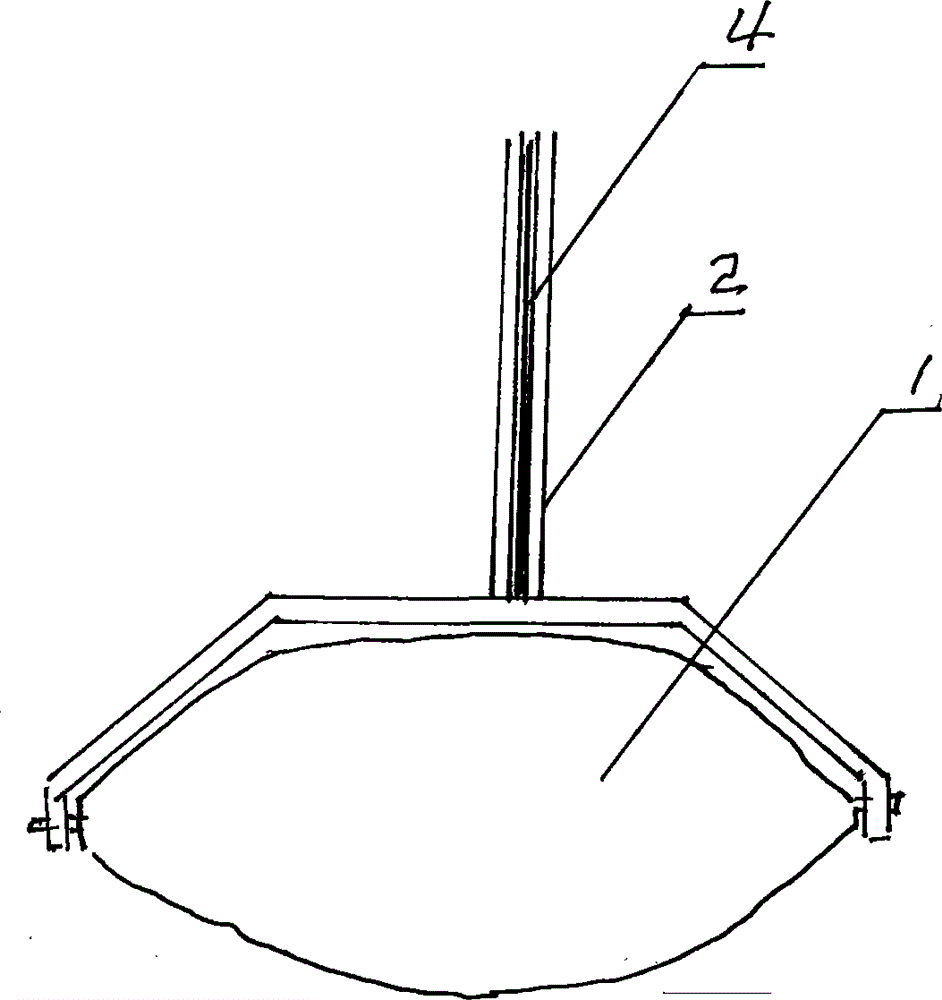

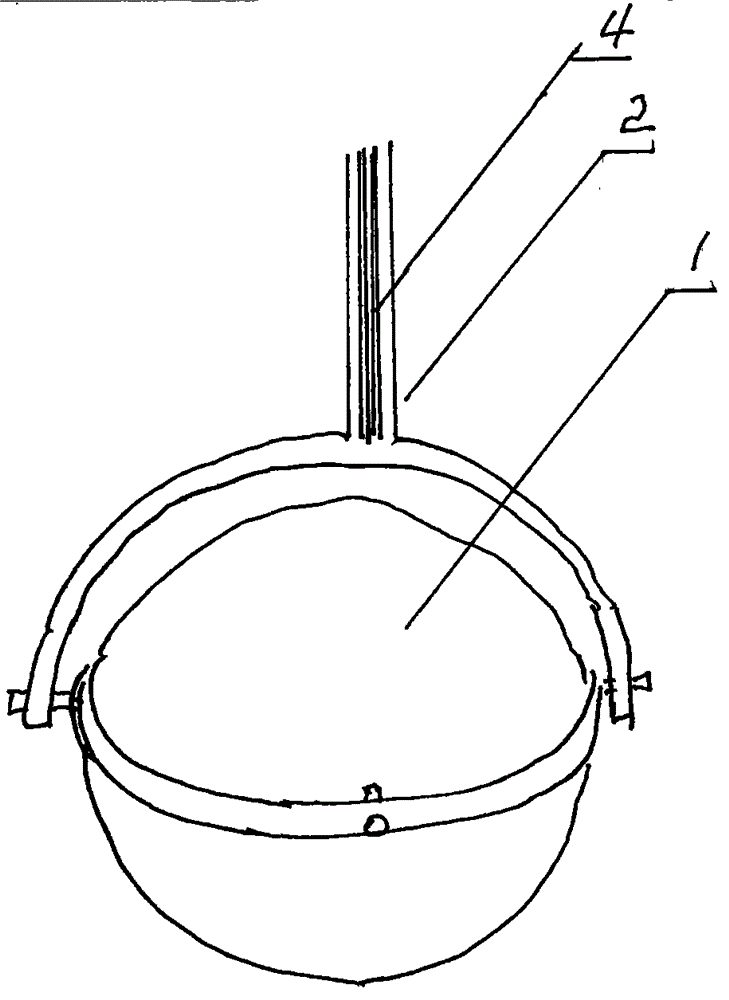

Rolling floater cable moving type shoreside wave power generation device

InactiveCN104100445ASimple structureThin bodyMachines/enginesEngine componentsWave power generationEngineering

The invention relates to a power generation device, in particular to a rolling floater cable moving type shoreside wave power generation device taking sea shoreside wave energy as a power source. The device comprises a rolling floater which is positioned on shoreside sea surface and can convert complex and changeable shoreside wave motion into simple vertical mechanical motion of a transmission rod regardless of raising tide or falling tide. The simple vertical mechanical motion of the transmission rod is converted into back and forth motion of a pulling cable; the back and forth motion of the pulling cable drives a unidirectional chain wheel meshed with the pulling cable to perform back and forth rotation through a connecting chain; the back and forth rotation of the unidirectional chain wheel continuously transfers power to a coaxial clockwork; the clockwork drives a speed increaser to drive a generator to efficiently and stably generate power at high speed and to output constant current. The rolling floater can be pulled up from the sea surface so as to avoid risk in violent typhoon weather. The device requires that a plurality of single wave power generation devices are combined to generate power and output powerful constant current. The device has the advantages that the structure is simple, plants are built on the land, no moving components exist in the water, the device can resist typhoon, and large wave power stations can be built.

Owner:何学应

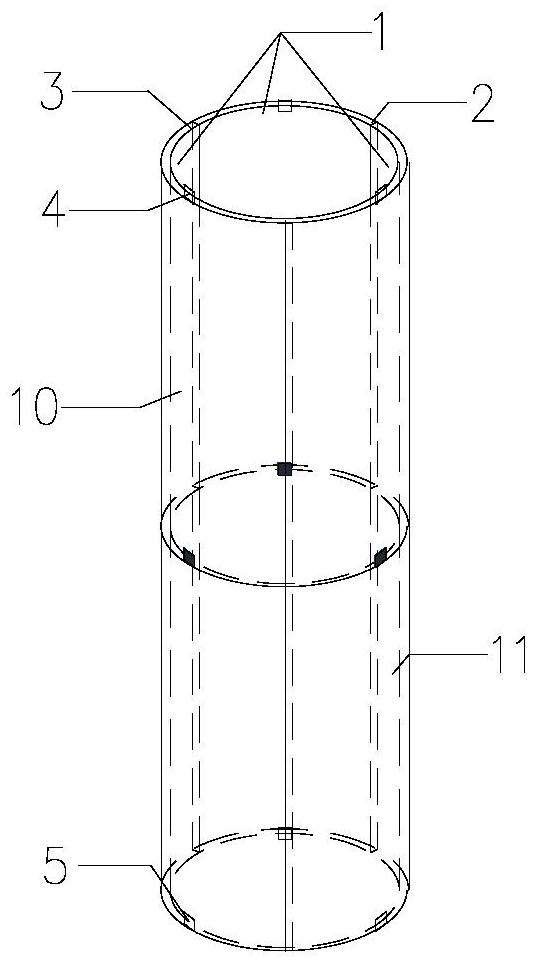

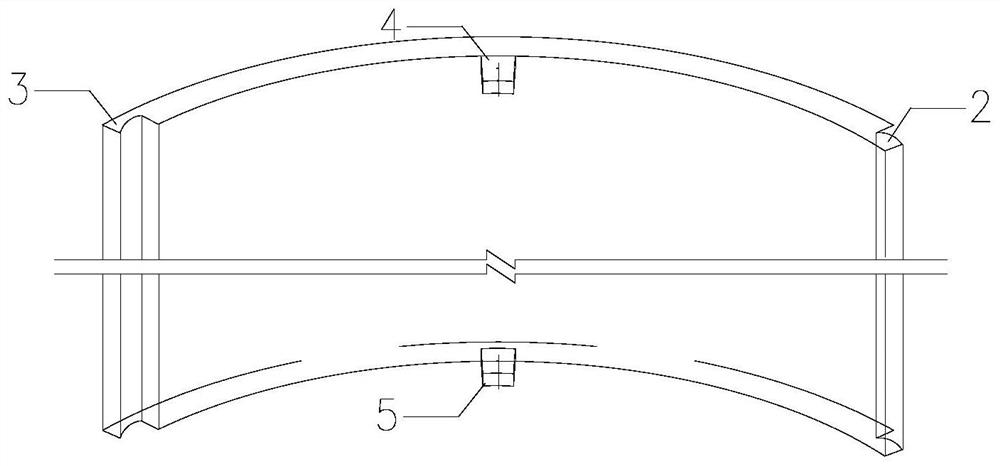

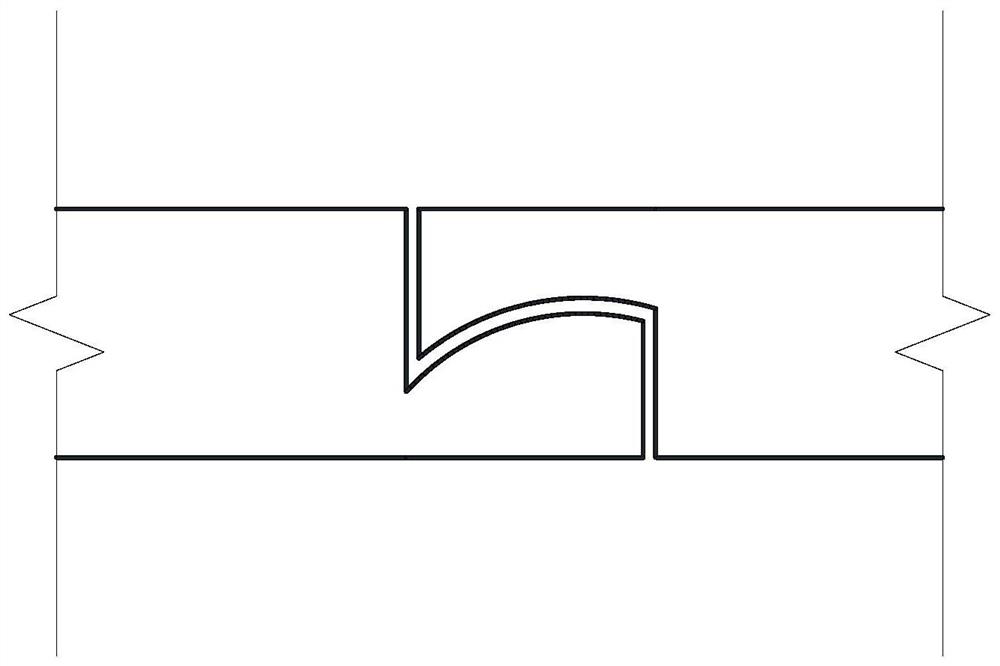

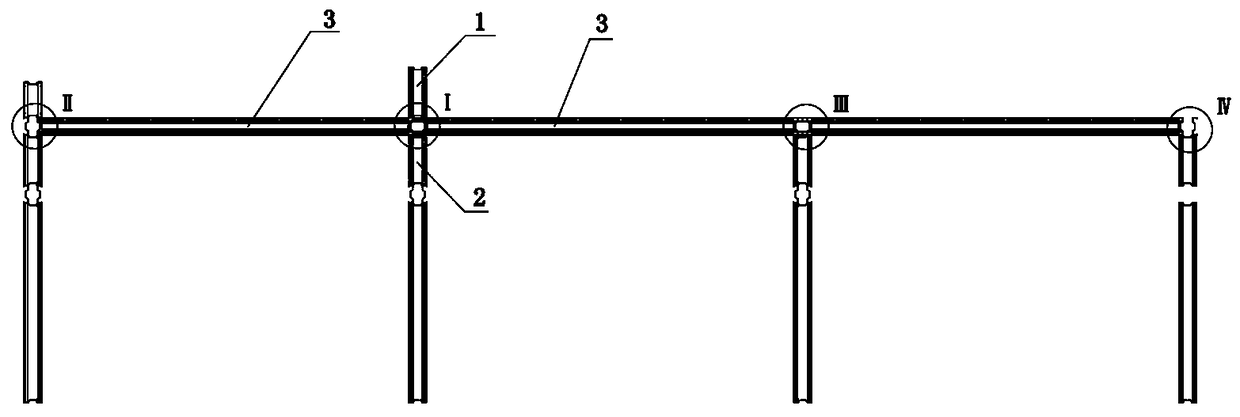

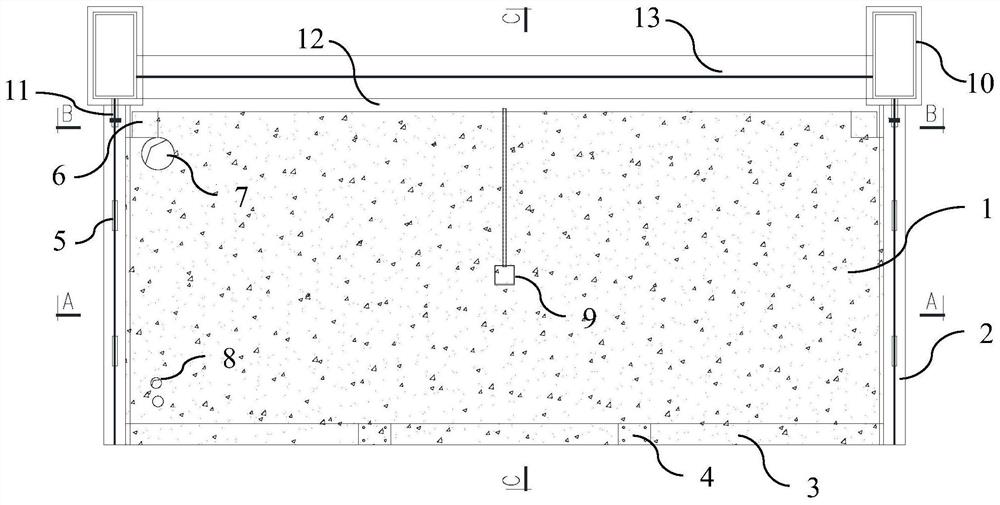

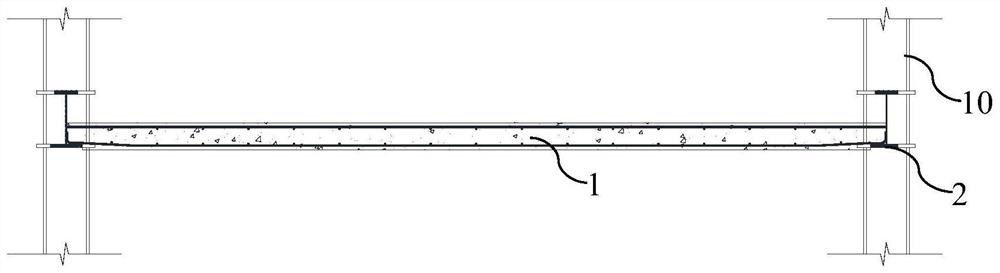

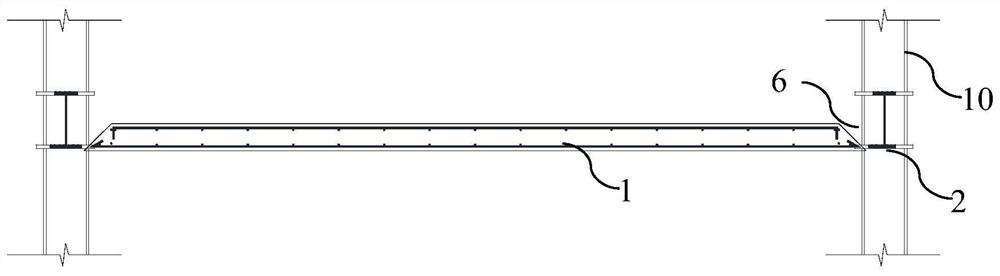

High-performance concrete cylindrical permanent formwork capable of being assembled and construction method thereof

PendingCN113106851AGuaranteed validityGuaranteed durabilityBridge structural detailsBridge erection/assemblyMortise and tenonArchitectural engineering

The invention belongs to the technical field of bridge lower structure construction formworks, and relates to an ultra-high performance concrete splicable cylindrical permanent formwork and a construction method thereof, the formwork is made of ultra-high performance concrete, construction load generated when concrete is poured in the pouring formwork can be borne without arranging steel bars in the formwork. All the connecting structures and the standard plates are prefabricated together to guarantee effectiveness and durability of the connecting structures, self-locking cambered surface mortise and tenon structures are used, the stress requirement of the formwork is met, meanwhile, using of bolts is reduced, the construction speed is increased, the construction method that the prefabricated standard plates are adopted for assembling formwork segments is adopted, and the characteristic that ultra-high-performance concrete needs to be subjected to steam curing is met. The manufacturing quality of the standard plate is guaranteed through factory prefabrication, the standard plate is convenient to store and transport, site construction in the construction process is effectively reduced, the construction efficiency and the construction quality are guaranteed, and the formwork is suitable for post-disaster rapid reconstruction and repair engineering of the bridge substructure and has great application value and good economic benefits.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

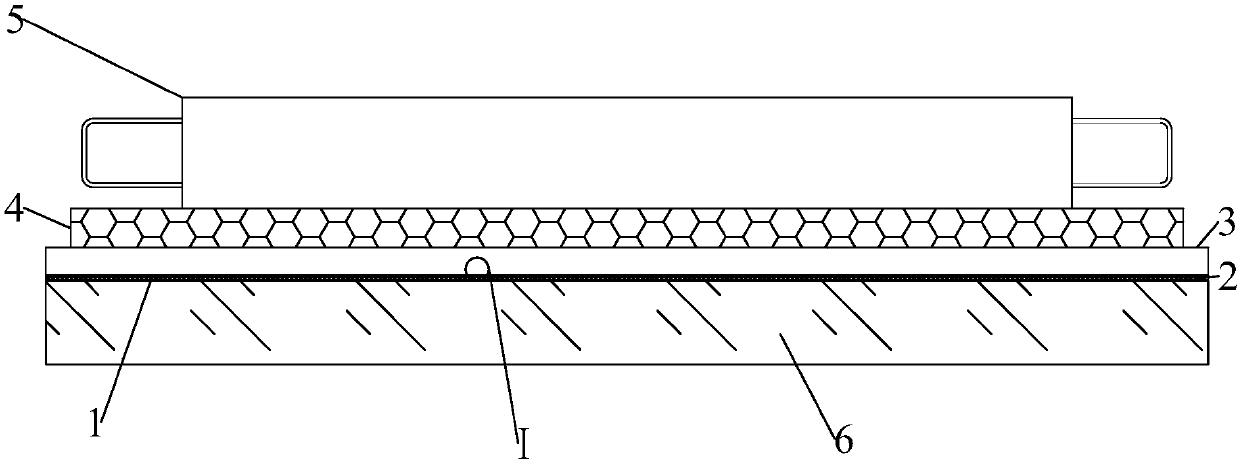

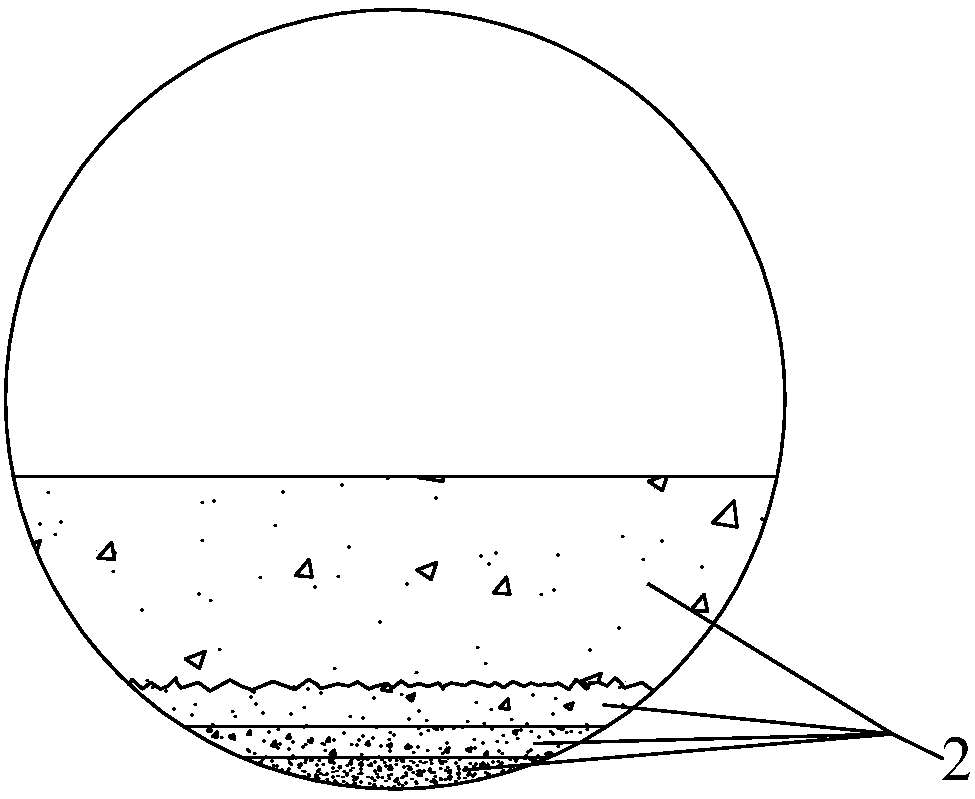

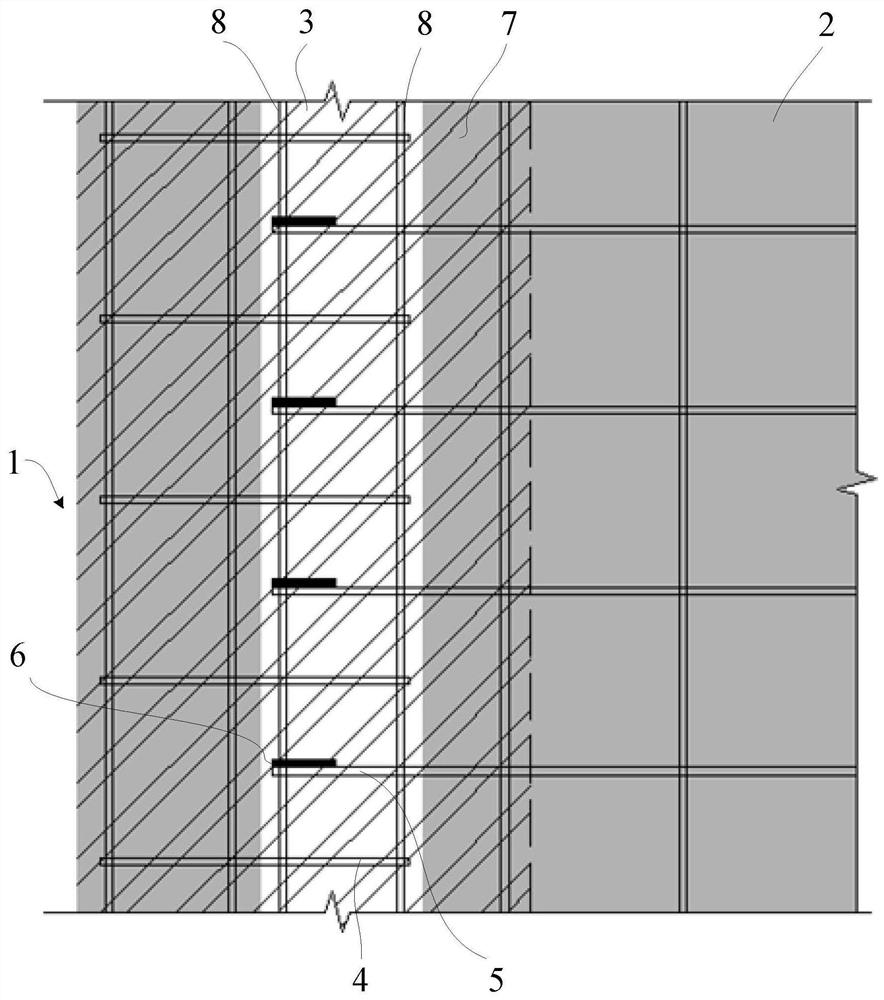

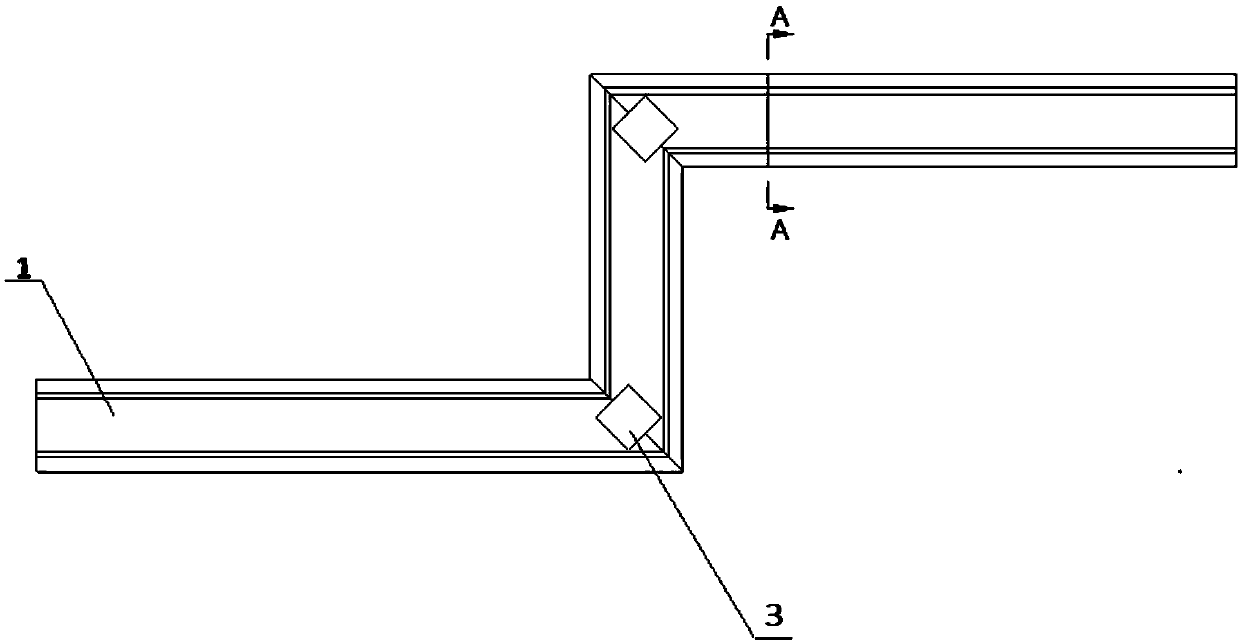

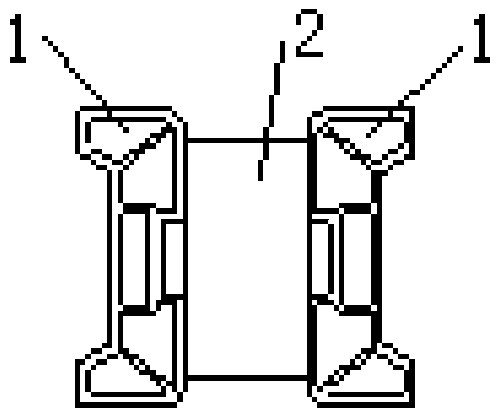

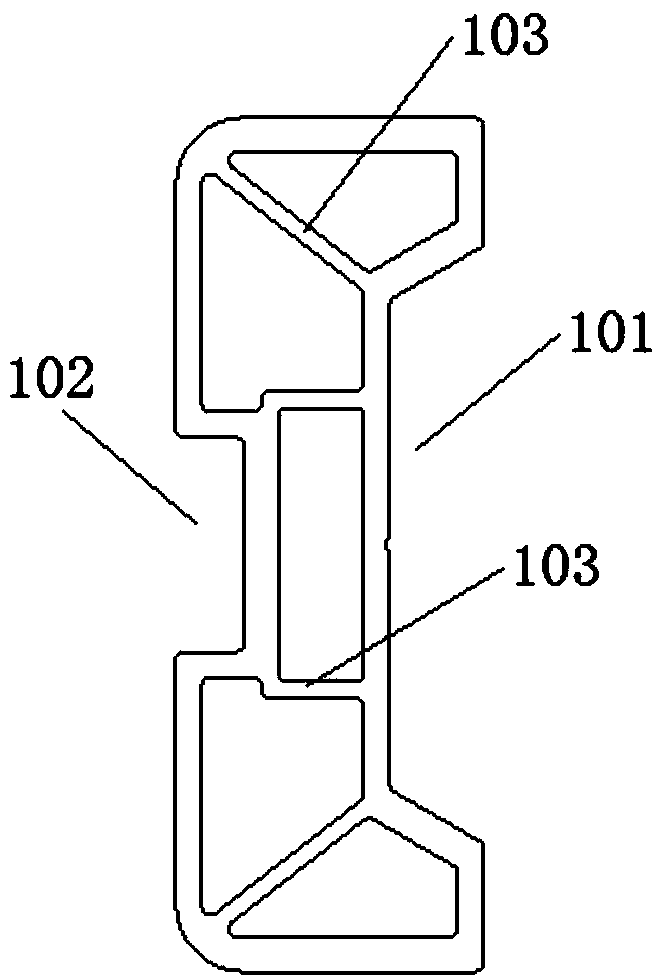

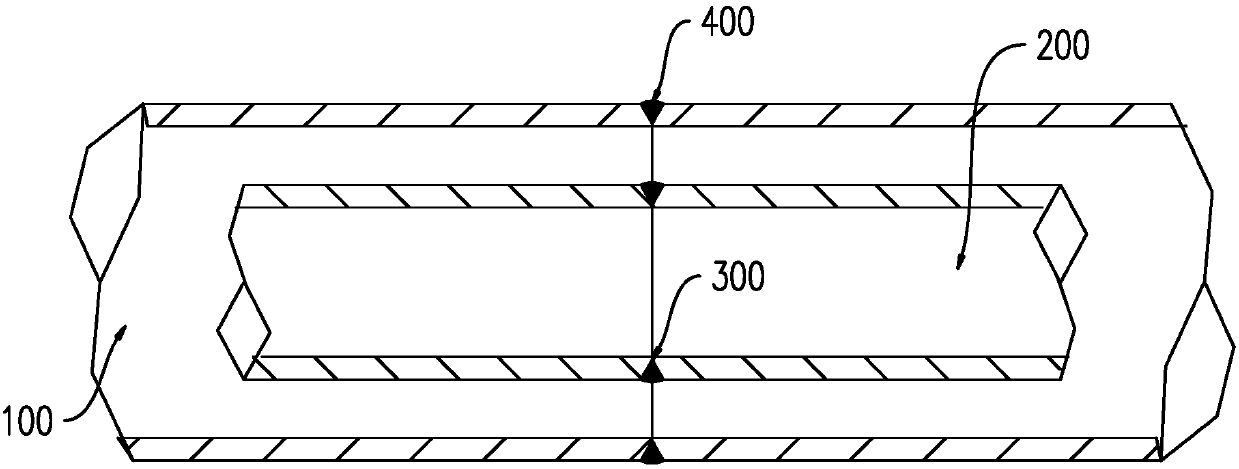

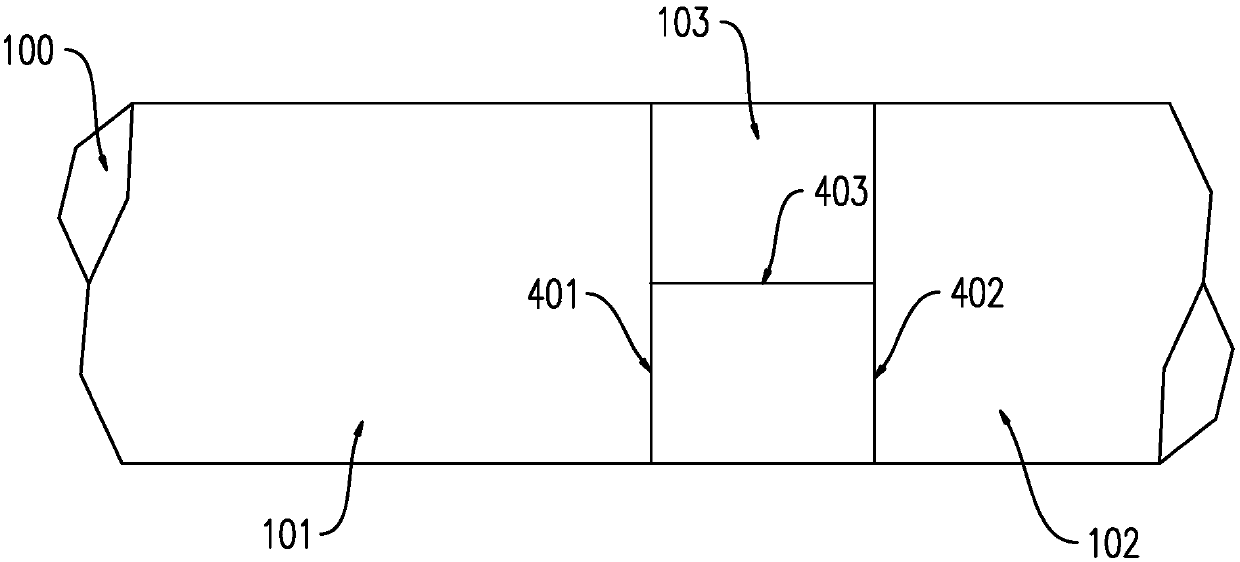

Pre-cast binding veneer integrally-formed fabricated wallboard for green building and production method thereof

InactiveCN107932717AHigh durabilityReduce on-site constructionConstruction materialSurface layering apparatusMolecular bindingMaterials science

The invention discloses a pre-cast binding veneer integrally-formed fabricated wallboard for a green building. The pre-cast binding veneer integrally-formed fabricated wallboard for the green buildingcomprises an overall structure of the fabricated wallboard and a concrete wall (3) on the outer side; a veneer (1) made of a binding material is arranged on the outer side of the concrete wall (3); and the material of the veneer (1) made of the binding material is fused with the material of the concrete wall (3) mutually. As for the mutual fusion of the material of the veneer (1) made of the binding material and the material of the concrete wall (3), a fusion structure (2) for material molecular reaction binding is formed between the veneer (1) and the fabricated concrete wallboard. Particularly, the binding material of the veneer and the binding material of the concrete wall are condensed and hardened together after being fused, thus the material of the veneer and the concrete material of the wallboard form an integrated molecular binding reaction structure, field operation of a construction site is reduced, an environment-friendly production mode is realized, and breakthrough of theproduction and construction technologies for establishment of the green building is achieved.

Owner:德睿盛兴(大连)装配式建筑科技有限公司

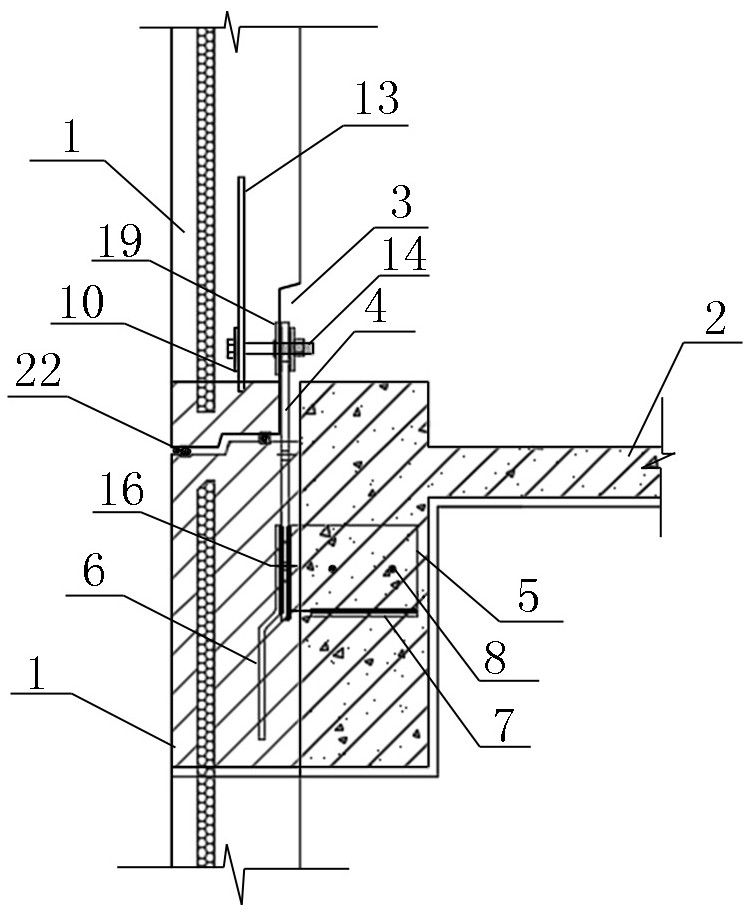

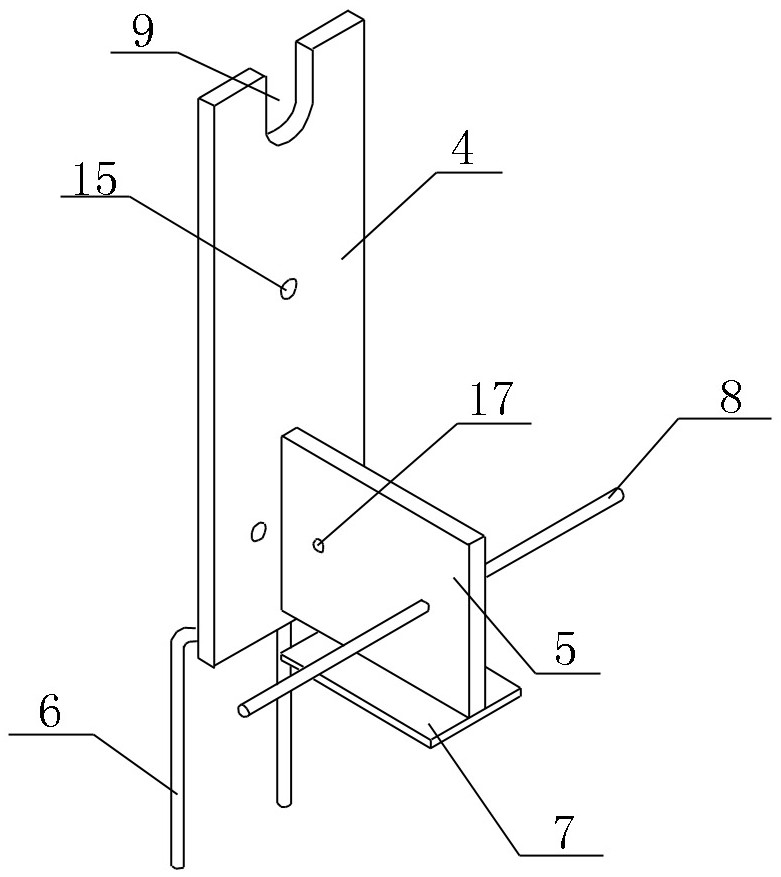

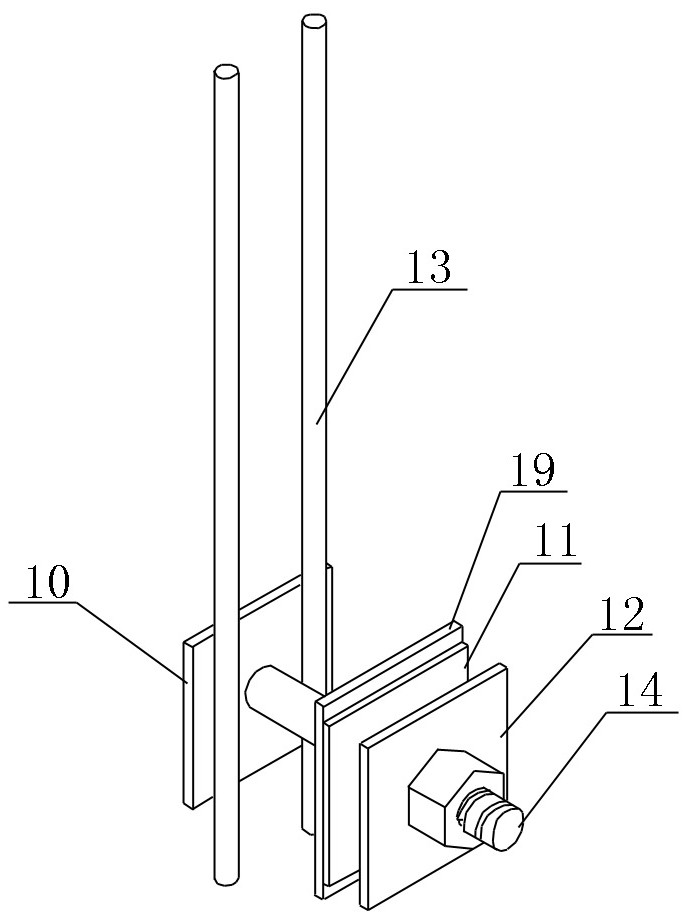

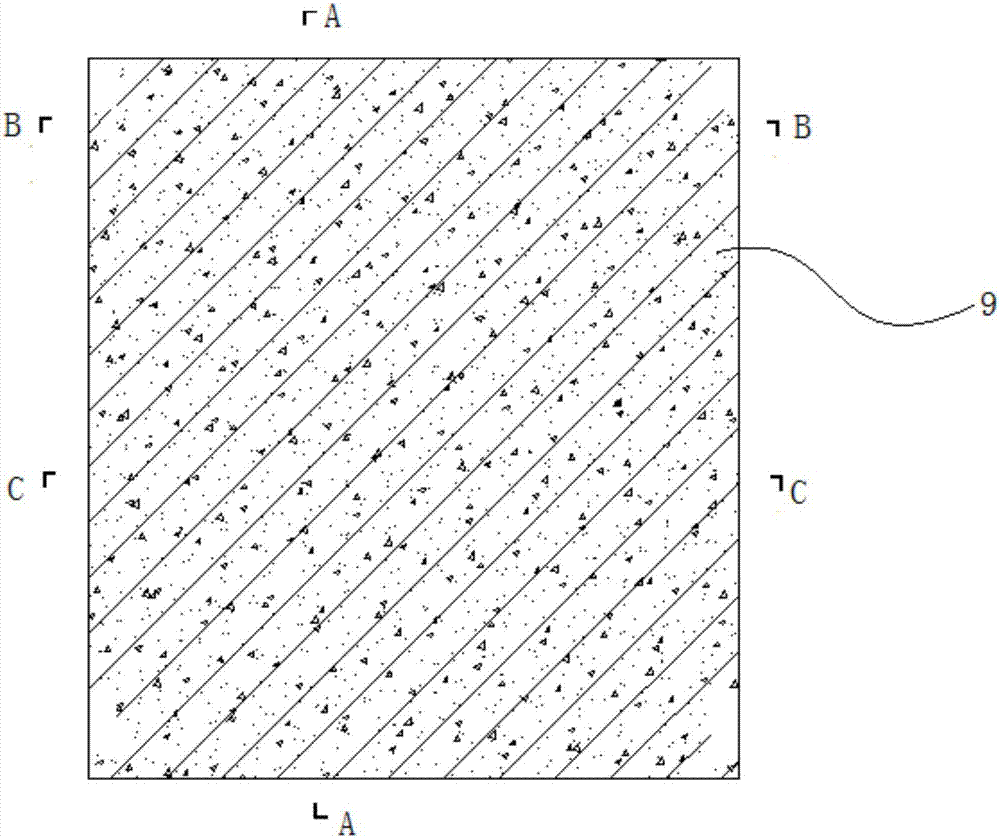

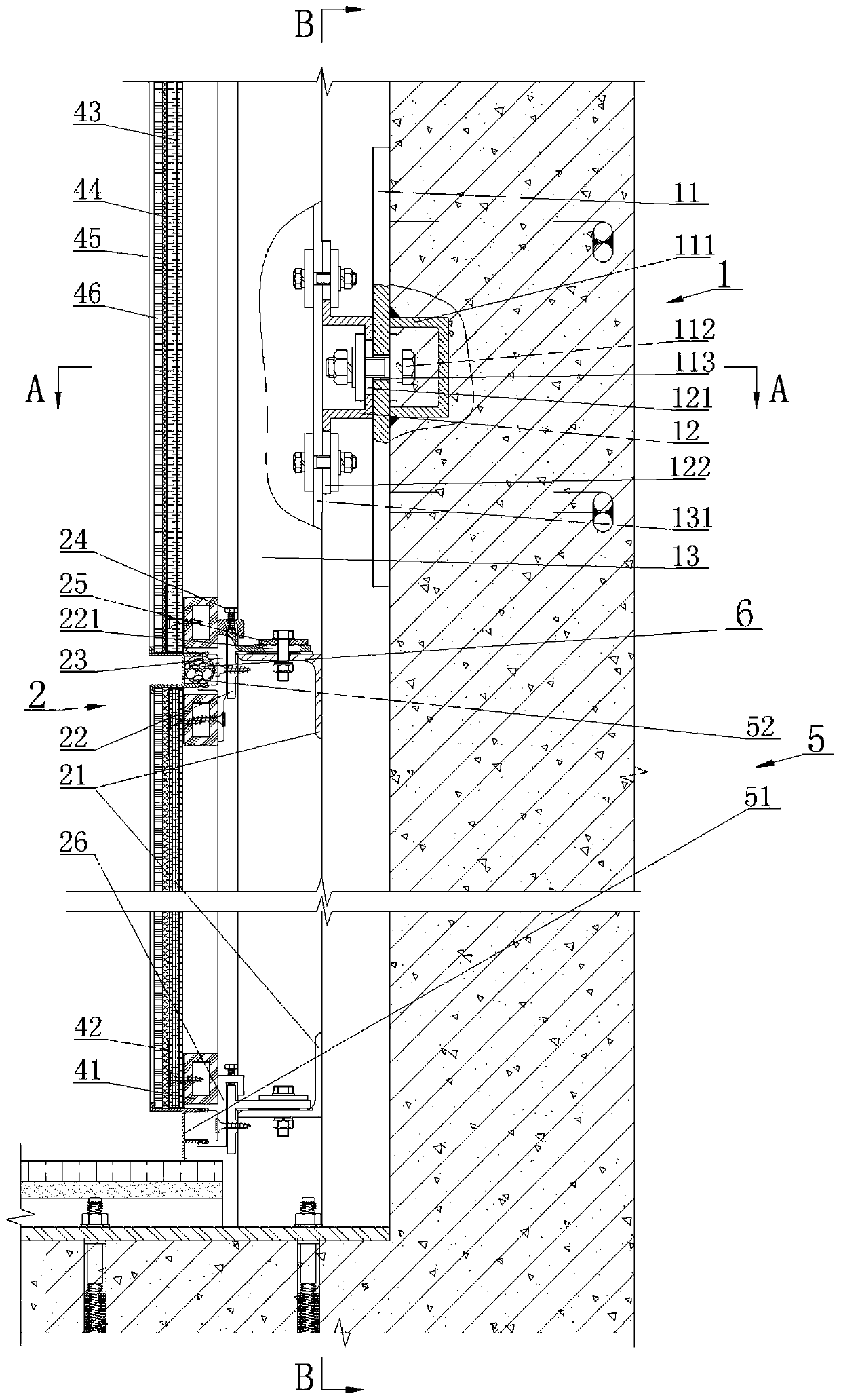

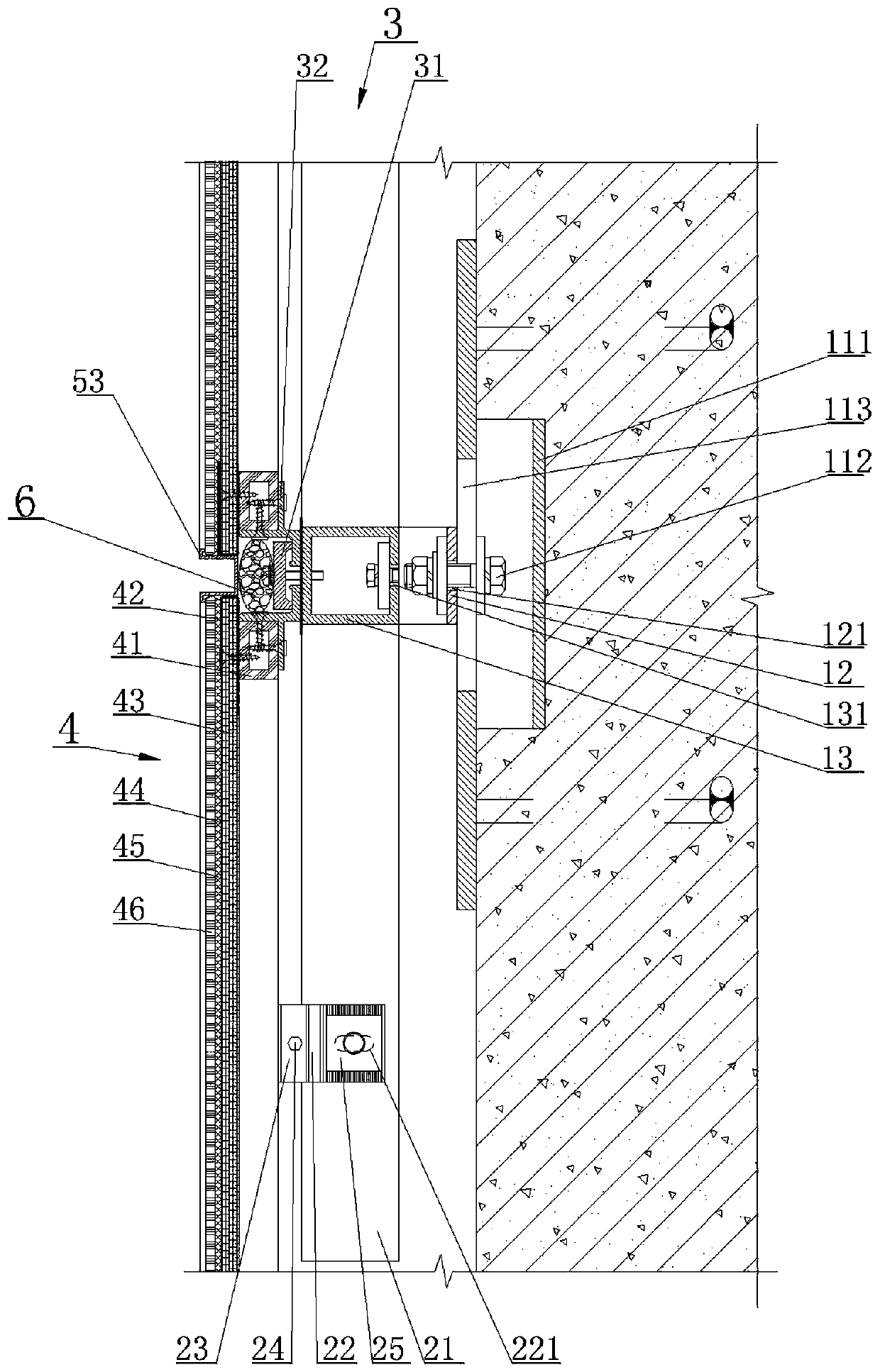

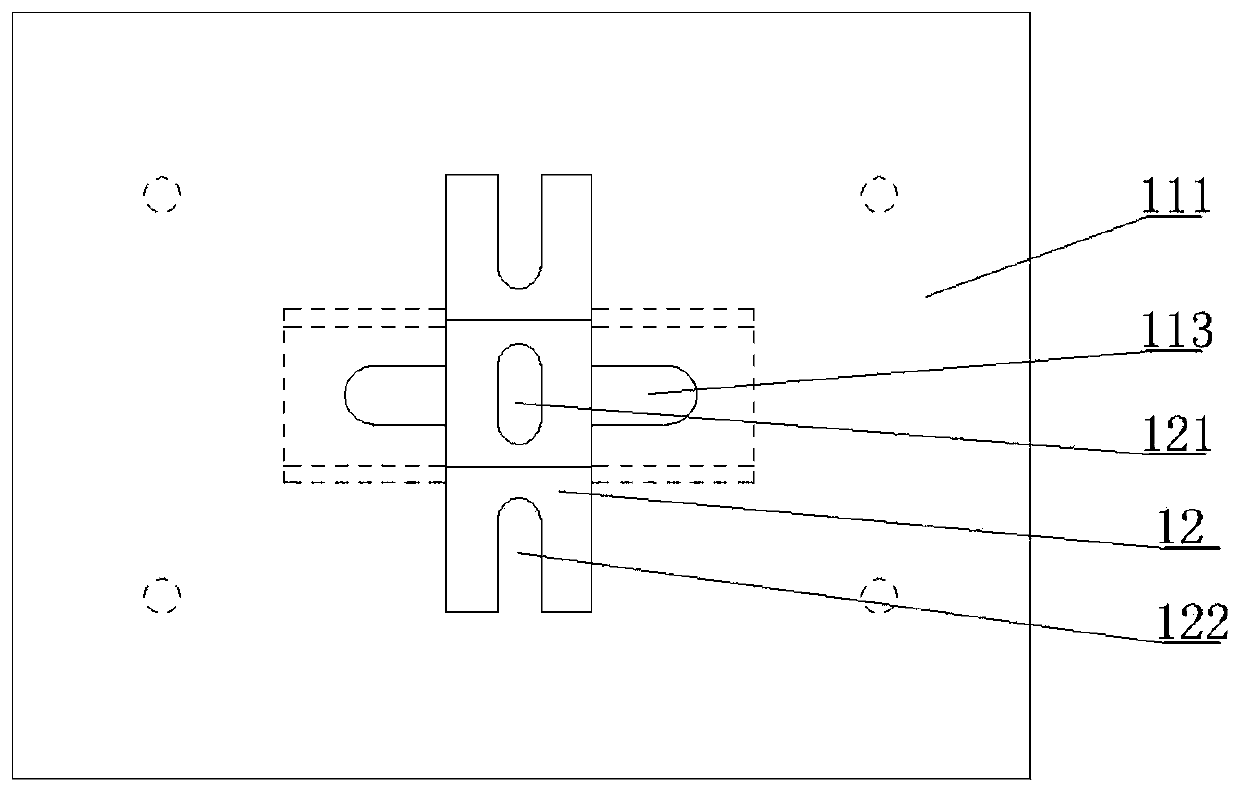

Prefabricated concrete externally-hung wallboard system and construction method thereof

InactiveCN113404193ACombined with accurate positioningEasy to operateWallsArchitectural engineeringShock resistance

The invention discloses a prefabricated concrete externally-hung wallboard system and a construction method thereof. The prefabricated concrete externally-hung wallboard system comprises a concrete externally-hung wallboard, upper hanging assemblies and lower hanging assemblies, the upper hanging components are connected between the upper part of the concrete externally-hung wallboard and a main body structure at intervals, and comprise first hanging plates, vertical buried plates, first vertical reinforcing steel bars, horizontal buried plates and horizontal reinforcing steel bars, the first hanging plates are buried in the upper portion of the concrete externally-hung wallboard, the upper ends of the first hanging plates exceed the top face of the concrete externally-hung wallboard, U-shaped grooves are formed in the middles of the tops of the first hanging plates, the lower hanging components are buried at the lower part of the concrete externally-hung wallboard at intervals and comprise second hanging plates, first clamping plates, second clamping plates, second vertical reinforcing steel bars and connecting bolts, the first clamping plate and the second clamping plate o the upper layer are clamped on two sides of the first hanging plate on the lower layer, and the connecting bolt on the upper layer is clamped in the U-shaped groove on the lower layer. According to the prefabricated concrete externally-hung wallboard system and the construction method, the technical problems that a connecting piece of a traditional externally-hung wallboard is difficult to position and prone to displacement, the thickness of a protection layer is difficult to control, a heat preservation layer is prone to floating, and shock resistance is poor are solved.

Owner:新城控股集团实业发展有限公司

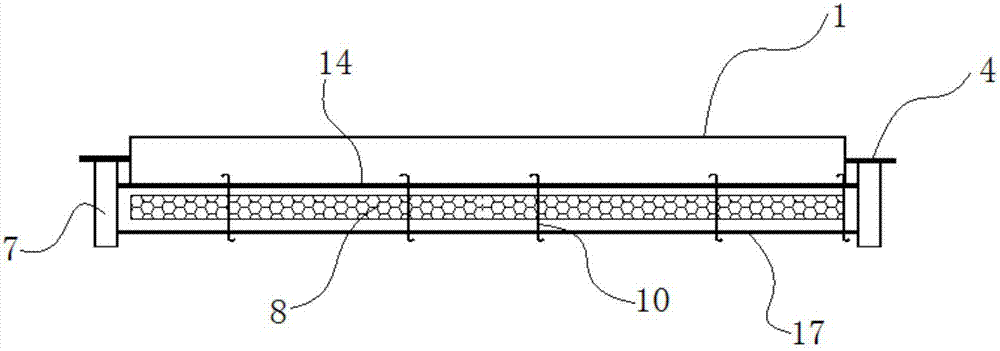

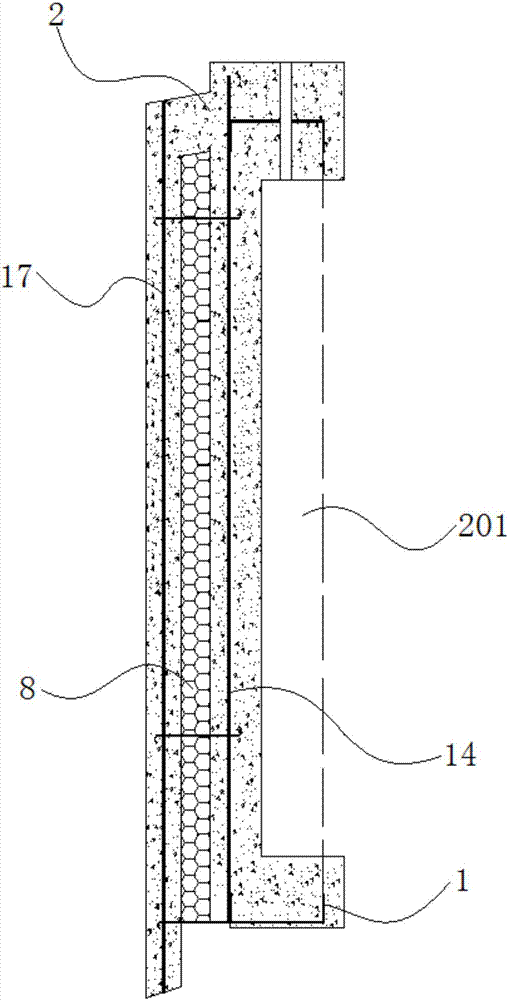

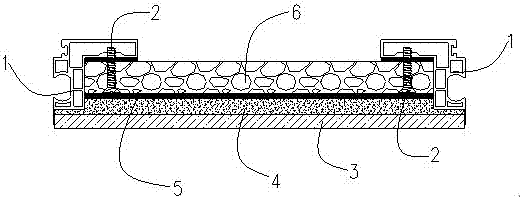

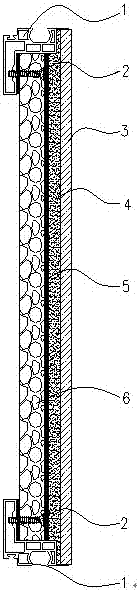

Prefabricated composite structure wallboard with free thermal-insulation form and manufacturing method thereof

PendingCN107989253ASave templateLow costCeramic shaping apparatusBuilding componentsThermal insulationMaterials science

The invention provides a prefabricated composite structure wallboard with free thermal-insulation form and a manufacturing method thereof. The prefabricated composite structure wallboard comprises a steel skeleton, concrete and a steel mesh. The steel skeleton includes a plurality of longitudinal and horizontal steels. The steels are joined to form a designed shape in a welded or bolted mode. Themanufacturing method of the external wallboard comprises the steps of processing the steel skeleton, laying the steel mesh, pouring concrete, arranging a thermal-insulation board layer and outer wallmaterial and the like. The external wall is constructed only through the installation of the unit external wall panel in the main body of the structure, and the installation is convenient and reliable, so that the site construction is reduced and the construction period is shortened. The external wallboard is pre-produced in the workshop, the environment is protected, the energy is saved, and thetemplate is saved, so that the cost is reduced, the quality of the building is improved, and the external wallboard is not affected by the freezing and other climates.

Owner:重庆欧冠钢结构有限公司

Staggered mutual anchoring connecting structure for prefabricated shear walls and vertical joints at edge members

InactiveCN113026985AReduce the use effectReduce on-site constructionWallsClimate change adaptationRebarMechanical engineering

The invention discloses a staggered mutual anchoring connecting structure for prefabricated shear walls and vertical joints at edge members. The staggered mutual anchoring connecting structure comprises two prefabricated shear walls and the vertical joints at the edge members, wherein steel bars are reserved in the prefabricated shear walls and are anchored into the vertical joints at the edge members in a staggered mode, U-shaped stirrups are bound on site, the stirrups are closed, longitudinal steel bars are placed, and finally, the vertical joints are poured through composite materials such as ultrahigh-performance concrete, high-performance concrete, steel fiber reinforced concrete, reactive powder concrete and ECC, so that the connection of the prefabricated shear walls and the edge members is completed. According to the staggered mutual anchoring connecting structure of the scheme, the steel bars at the prefabricated shear wall and the edge members are directly anchored into a post-pouring area, so that additional connecting steel bars at the inner edge members of wallboards of the prefabricated shear walls are omitted, and the required length of the vertical joints is small; the prefabricated shear walls are flexible to disassemble, and standardized production of a prefabricated building is facilitated; and the technical problems of complexity in connection of an existing assembly type shear wall and the vertical joints at the edge members and more on-site wet operation are solved.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Composite wall body material

The invention provides a novel composite wall body composition and relates to the field of building construction mounting. An interlayer structure is adopted, rapid splicing of a composite wall body is achieved, a composite wall body material comprises an aluminum alloy sectional material, cement fiber plates, countersunk head flat machine screws, waterproof glue, ceramic tile glue, ceramic tiles, aluminum alloy thin plates, aluminum honeycomb cores, self-tapping screws and epoxy resin glue. According to the composite wall body composition, screw holes are punched in one material firstly and twisted together, then the glue meeting the requirement is smeared, then another material is placed to enable the upper material and the lower material to be seamlessly attached, and thus sealing performance of wall body splicing is ensured. The selected materials of the composite wall body material all have the waterproof, fireproof, small-weight, high-rigidity and long-service-life characteristics, meanwhile are convenient to transport and can be completed in a factory completely according to the measured sizes in a construction site, work division production is achieved, the rapid effect is achieved, the materials can be spliced and mounted when being transported to the site, time is saved, noise is reduced, the site is protected, and the environment-friendly and energy-saving effects are achieved.

Owner:ZHUHAI SINGYES GREEN BUILDING TECH +2

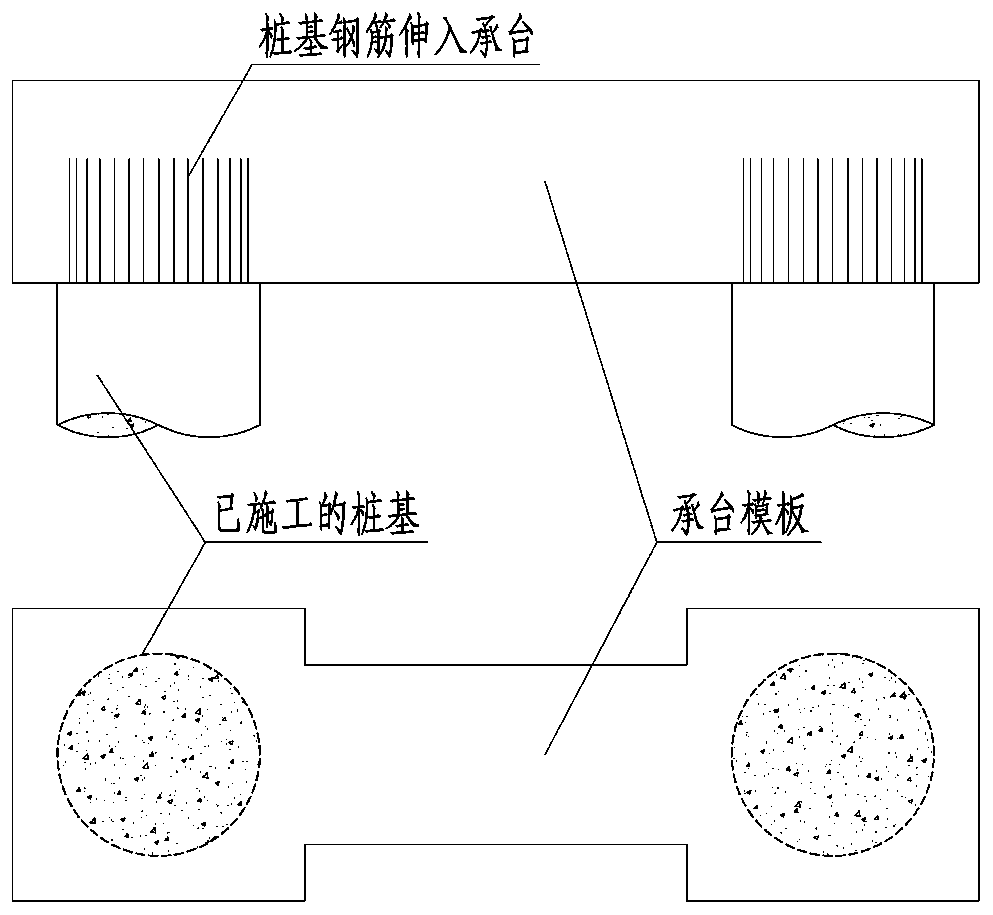

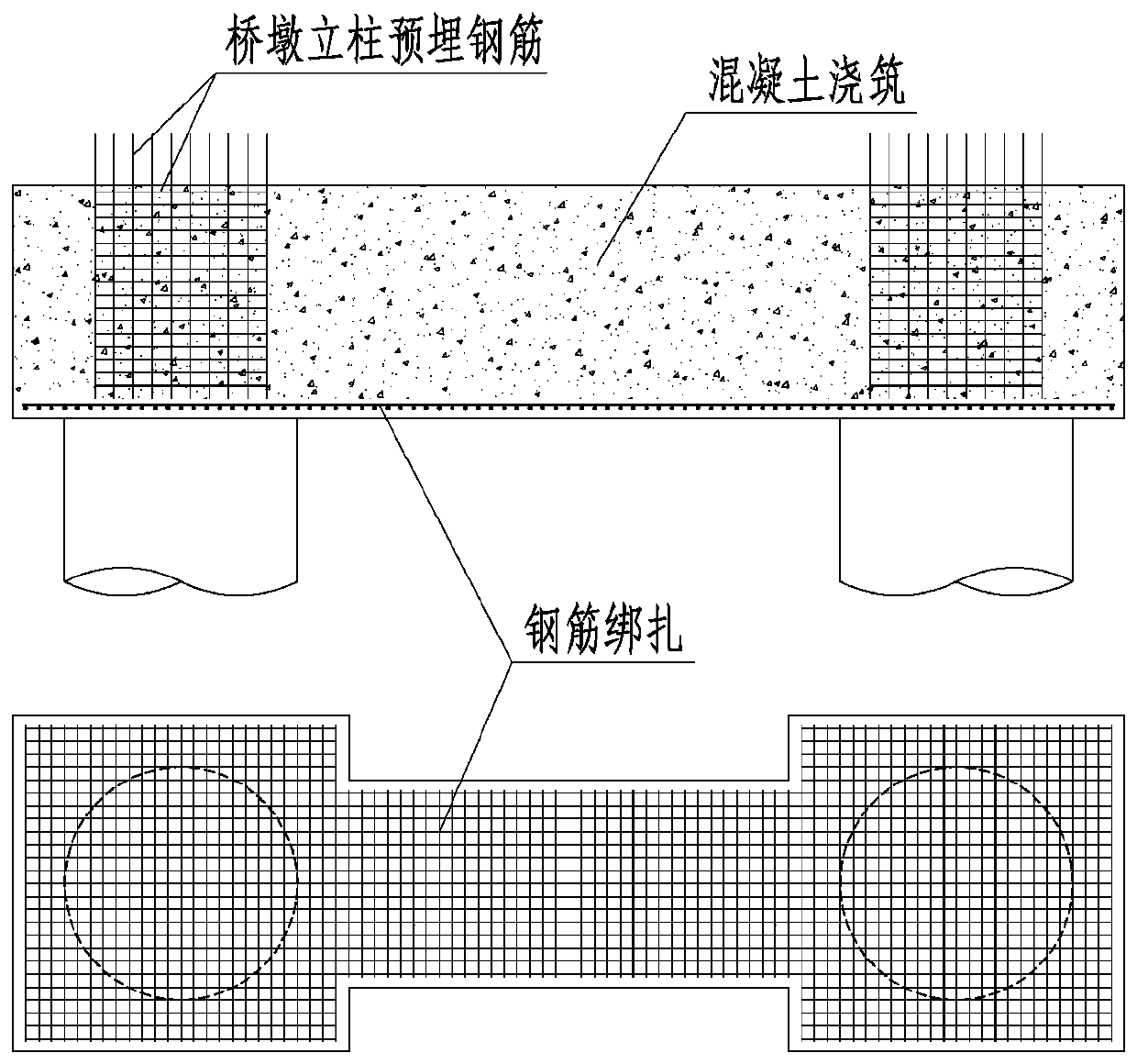

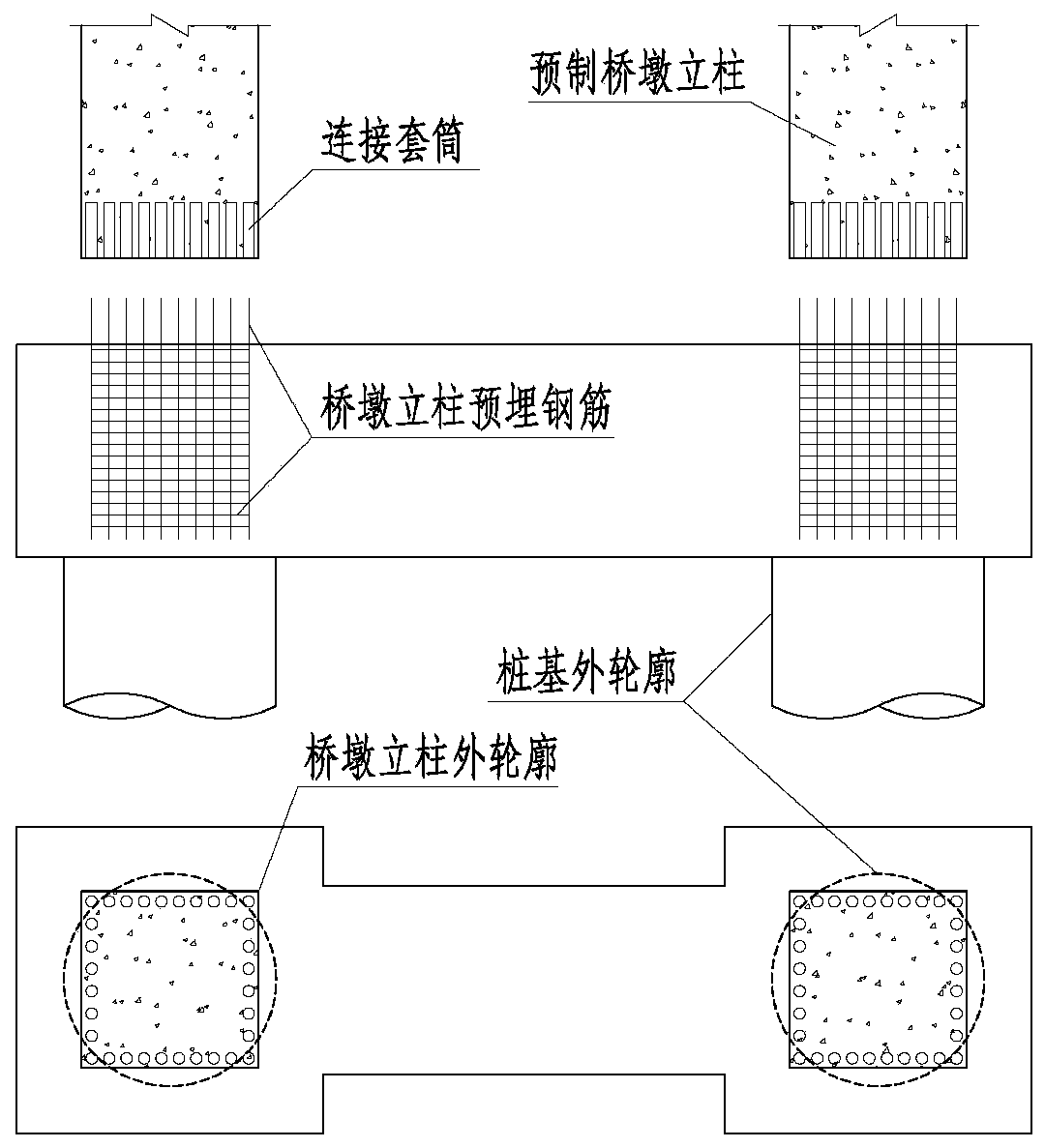

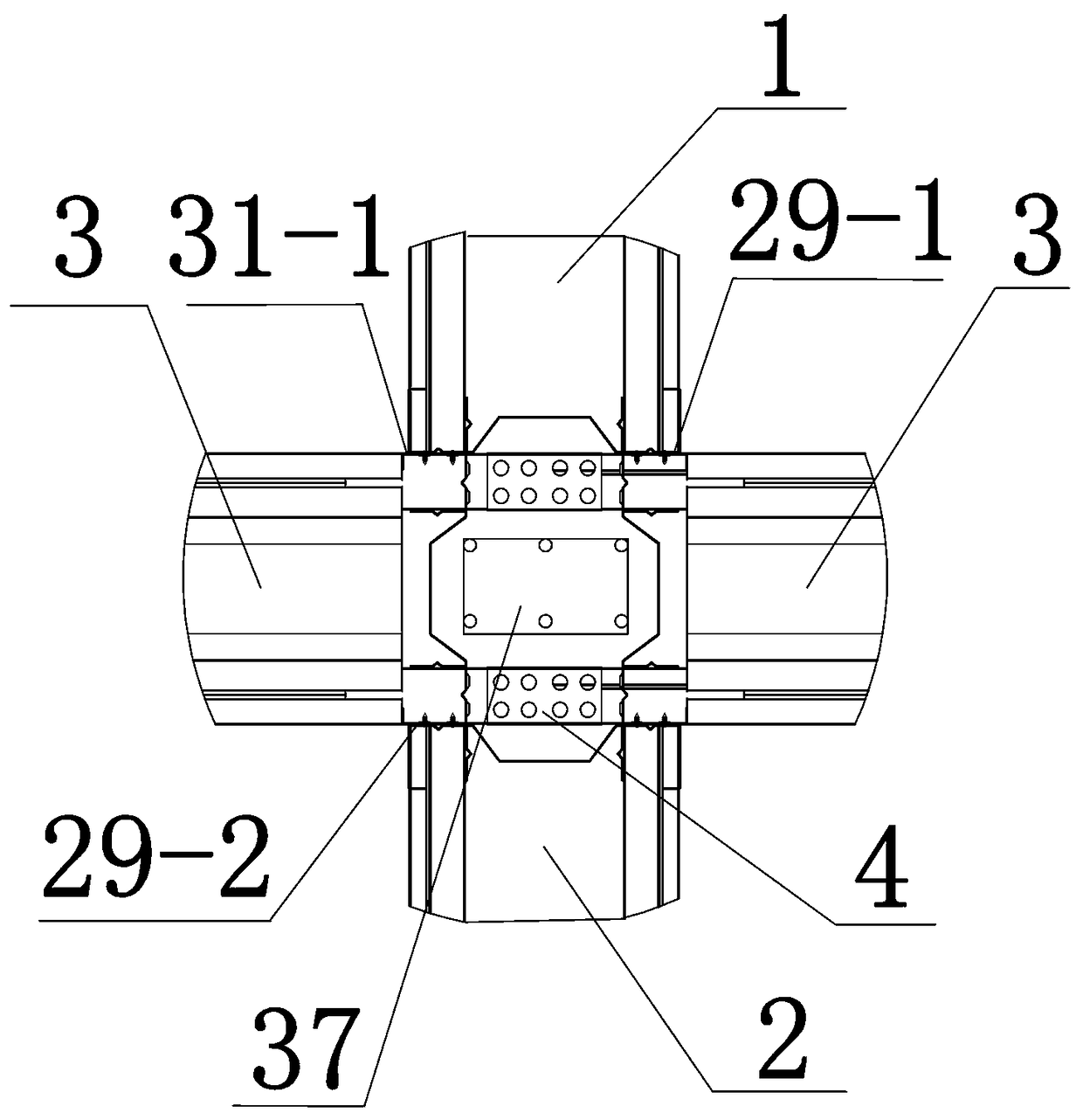

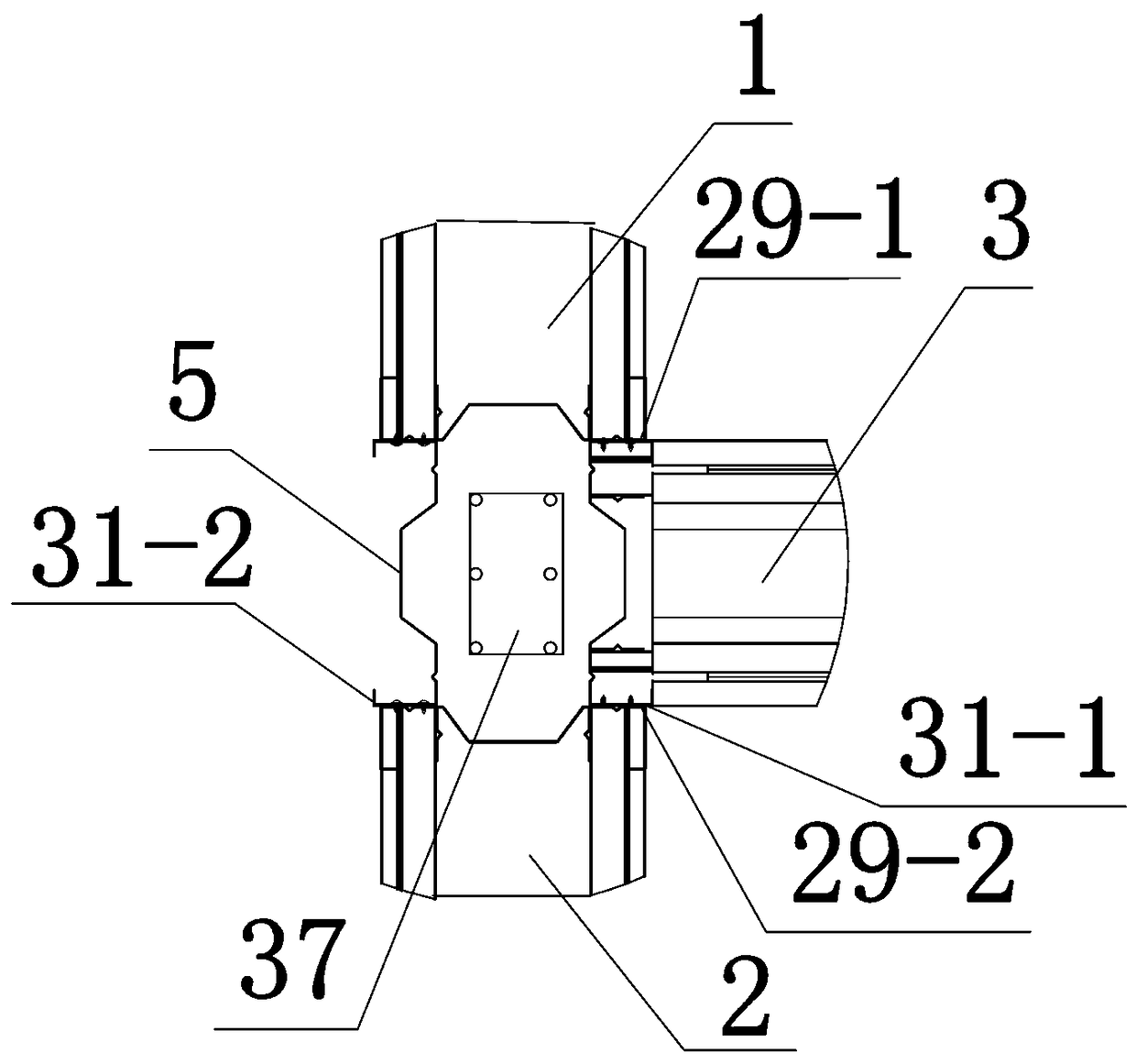

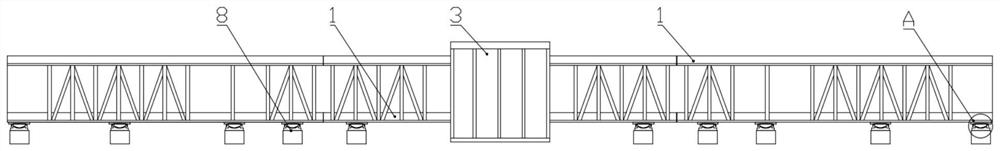

Double-column type pier prefabricated bearing platform structure and construction method thereof

PendingCN110202690AAchieve prefabricationImprove construction qualityCeramic shaping apparatusFoundation engineeringRebarPrefabrication

The invention discloses a double-column type pier prefabricated bearing platform structure and a construction method thereof, and can realize factory prefabrication of the double-column type pier bearing platform. The construction method comprises the steps that the formwork erecting of the bearing platform is carried out, steel bars binding and pouring are carried out and the positioning of the prefabricated pier body stand column pre-buried steel bar are carried out in a factory standardized process. According to the double-column type pier prefabricated bearing platform structure and the construction method thereof, the conventional cast-in-place double-column type bridge pier bearing platform is prefabricated, and meanwhile, the situation that a former double-column type bridge pier bearing platform needs on-site formwork erecting, steel bar binding, pouring vibrating and curing is changed into a prefabrication mode in a factory; the prefabricated bearing platform is provided withintegral transportation and hoisting conditions, the prefabricated bearing platform is matched with the integrated bridge girder erection machine and can be used for realizing the transportation and integrated erection of the prefabricated bearing platform girder.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

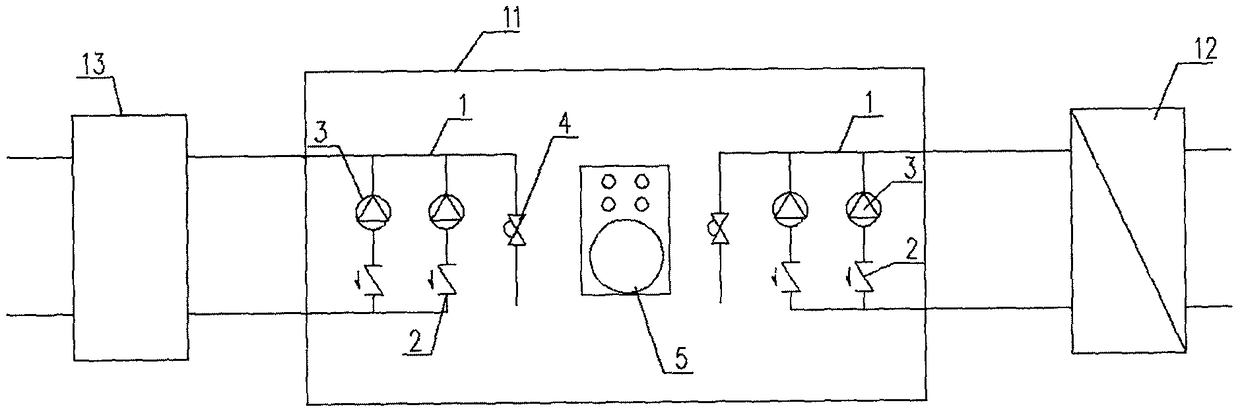

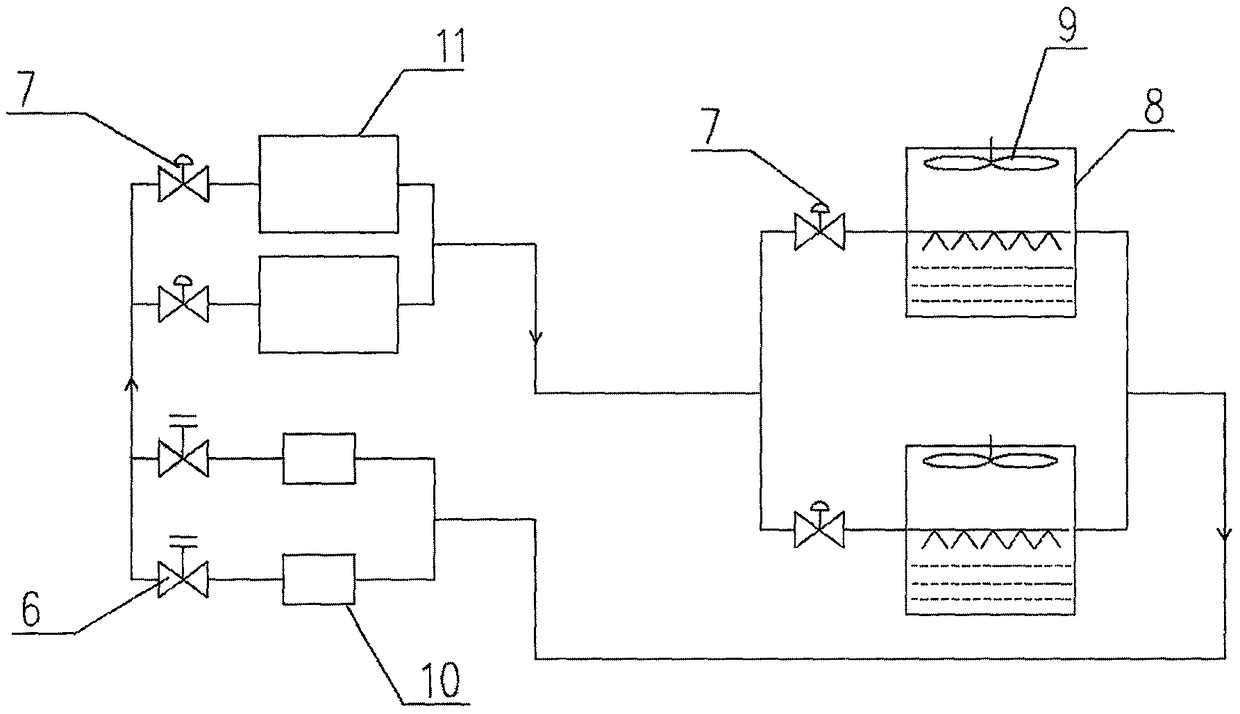

Integral air conditioner and terminal water system device

InactiveCN109373553AImprove cooling efficiencyReduce technology requirementsMechanical apparatusSpace heating and ventilation detailsCooling towerChilled water

The invention relates to an integral air conditioner and terminal water system device which comprises at least two groups of refrigeration mechanisms connected in parallel and a cooling mechanism; therefrigeration mechanisms comprise chilled water pipes, chilled water pumps, check valves and constant pressure water replenishing mechanisms; the cooling mechanism comprises at least two groups of cooling towers connected in parallel, control valves and fans; at least two groups of flow monitoring mechanisms and pressure regulating valves are connected in parallel between the refrigeration mechanisms and the cooling mechanisms; the cooling mechanism is connected with the flow monitoring devices and the cooling towers through return passages; and the integral air conditioner and terminal watersystem device further comprises an energy storing mechanism connected with the cooling mechanism and the terminals of air conditioners. Multiple groups of cooling towers are arranged to perform hydraulic regulation on a single or multiple refrigeration mechanisms, so that the application range of a system is enhanced; and the independent flow monitoring devices and the independent pressure regulation valves, which are connected with each refrigeration main body, are used to improve the refrigeration efficiency of the system. The refrigeration mechanisms form an integral structure, so that theconstruction fields can be reduced, and the cost is reduced.

Owner:BEIJING KCALIN NEW ENERGY TECH

Construction method for connecting floor slabs and wall surface joints of multilayer light steel structure building

The invention belongs to the technical field of building overall structures and particularly relates to a construction method for connecting floor slabs and wall surface joints of a multilayer light steel structure building. The construction method is characterized by comprising the following steps of (1) modular production of floor slab structures of the light steel structure fabricated building,(2) modular production of wall surface structures of the light steel structure fabricated building, and (3) connecting forms of the different floor slabs and different wall surface structure modules.The joints are simple in structure and convenient to mount, integrity is good after completion, and connecting is firm, also durable and stable; seam mounting parts are concealed inside seams, thus the attractiveness of surface decoration is not affected, and the seams can also be arranged in the junctions of the wall surfaces and the floor slabs; the joints do not affect passing and connecting of water and electricity pipelines pre-arranged in the floor slabs; and through the connecting method of the joints, the problem that when the area of the single floor slab is large, the length and thewidth exceed the limits, and consequently, the floor slabs cannot be transported is solved.

Owner:辽宁福瑞达建筑科技有限公司

Anti-corrosion aluminum formwork reinforcing back bar

PendingCN109555307ASpecial structureResistance to hydrostatic pressureAuxillary members of forms/shuttering/falseworksForming/stuttering elementsHydrostatic pressureEngineering

The invention discloses an anti-corrosion aluminum formwork reinforcing back bar, which comprises single pipes and a connecting piece. The single pipes are extruded aluminum profiles, and the sectionof each single pipe is a closed cavity; grooves I and grooves II are formed in the two side faces of the cavities correspondingly, and reinforcing ribs for dividing each cavity into five chambers arearranged in the cavity; the connecting piece is a hollow aluminum pipe with the rectangular section; and the grooves I in the two single pipes are provided with outward openings, formed in a back-to-back mode and connected into a back bar plate single body structure through the hollow aluminum pipe arranged between the back faces of the two single pipes. According to the anti-corrosion aluminum formwork reinforcing back bar, the problems that rigidity is insufficient, and transformation is prone to occurring are solved while lightweight is ensured, and the hydrostatic pressure of concrete is resisted better; and chromized layers and electrostatic sprayed layers are arranged on the surfaces of the aluminum profile single pipes, abrasion resistance and anti-aging capacity of the back bar areimproved, the surface anti-corrosion capacity of the back bar is further improved greatly, and thus the service life of the aluminum alloy profiles can be effectively prolonged.

Owner:忠旺(辽阳)铝模板制造有限公司

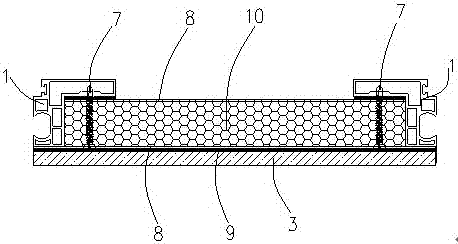

Large-specification energy-saving ceramic plate curtain wall structure and construction method thereof

PendingCN111456306AEnables detachable connectionsEliminate on-site welding processWallsHeat proofingCeramic compositeSteel frame

The invention discloses a large-specification energy-saving ceramic plate curtain wall structure and a construction method thereof. The curtain wall structure comprises a steel frame assembly, a transverse fixing assembly, a vertical fixing assembly, a ceramic composite plate assembly and an edge and opening closing assembly. According to the large-specification energy-saving ceramic plate curtainwall structure and the construction method thereof, the specific notch embedded parts and capital omega-shaped adapting parts are adopted, detachable connection among all the parts can be achieved, the on-site welding process is omitted, and the steel frame assembly can be conveniently detached at any time; and through position-adjustable connection among an aluminum alloy stand column, the capital omega-shaped adapters and the notch embedded parts, a function that errors can be adjusted at any time is achieved, a T-shaped aluminum alloy inner hanging piece is detachably and fixedly connectedwith a transverse angle steel, a ceramic composite plate assembly is hung on the T-shaped aluminum alloy inner hanging piece through an F-shaped aluminum alloy outer hanging piece, the position precision is adjustable, installing and uninstalling are conducted at any time, maintenance is convenient, steel is saved, and tedious temporary reinforcing measures during solidification of ceramic tile glue in the past are omitted.

Owner:中建五局装饰幕墙有限公司

Double pipe welding method

ActiveCN105710551BReduce the overall length of the weldReduce construction difficultyWelding apparatusDouble tubeButt welding

The invention discloses a welding method for a double-layered tube. The welding method comprises the following specific steps of preparing the double-layered tube, wherein the double-layered tube comprises an inner tube and an outer tube, the outer tube is sleeved with an outer tube sleeve, the inner tube comprises a left inner tube and a right inner tube, and the outer tube comprises a left outer tube and a right outer tube; attaching and aligning end faces of the left inner tube and the right inner tube, reserving a gap between the left outer tube and the right outer tube, moving the outer tube sleeve onto the left outer tube or the right outer tube, and exposing the gap between the left outer tube and the right outer tube; performing application for inspection before welding on the left inner tube and the right inner tube according to the butt welding requirement; welding a connected part of the left inner tube and the right inner tube; polishing and cleaning a weld joint of the welded inner tube; performing application for inspection before welding on the left outer tube and the right outer tube according to the overlap welding requirement; moving the outer tube sleeve to the outer side of the gap in the first step, and separately welding a connected part between the left outer tube and the outer tube sleeve as well as a connected part between the right outer tube and the outer tube sleeve; and separately polishing and cleaning a weld joint between the left outer tube and the outer tube sleeve as well as a weld joint between the right outer tube and the outer tube sleeve.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Integral prefabricated balcony applicable to fabricated type building, connecting joint and fabrication method

PendingCN111926912AQuality assuranceGuaranteed accuracyBalconiesBuilding material handlingJoint (building)Structural system

The invention discloses an integral prefabricated balcony applicable to a fabricated type building, a connecting joint and a fabrication method, and belongs to the field of fabricated type buildings.Two integral prefabricated balcony modules are provided and can be matched with regular fabricated type building structural systems. Floor drain ports, waterproof facilities, fireproof facilities, water and electricity facilities and interior decorative finishes can be prefabricated in a factory, and on a building site, only the steps of integrally hoisting, connecting steel structures, conductingbuilding surface layer transition at connecting positions, and installing handrails need to be conducted. Because the entirety of the balcony modules other than connecting positions with framework pillars can be processed and assembled in the factory, on the other hand, the overall quality and precision of the a balcony are guaranteed; and on the other hand, onsite construction can be reduced andconstruction efficiency can be improved.

Owner:龙元明筑科技有限责任公司

Joint connection method between floor slab and wall of multi-storey light steel structure building

ActiveCN109322411BExtended service lifeRealize modular productionWallsFloorsFloor slabJoint (building)

The invention belongs to the technical field of building overall structures and particularly relates to a construction method for connecting floor slabs and wall surface joints of a multilayer light steel structure building. The construction method is characterized by comprising the following steps of (1) modular production of floor slab structures of the light steel structure fabricated building,(2) modular production of wall surface structures of the light steel structure fabricated building, and (3) connecting forms of the different floor slabs and different wall surface structure modules.The joints are simple in structure and convenient to mount, integrity is good after completion, and connecting is firm, also durable and stable; seam mounting parts are concealed inside seams, thus the attractiveness of surface decoration is not affected, and the seams can also be arranged in the junctions of the wall surfaces and the floor slabs; the joints do not affect passing and connecting of water and electricity pipelines pre-arranged in the floor slabs; and through the connecting method of the joints, the problem that when the area of the single floor slab is large, the length and thewidth exceed the limits, and consequently, the floor slabs cannot be transported is solved.

Owner:辽宁福瑞达建筑科技有限公司

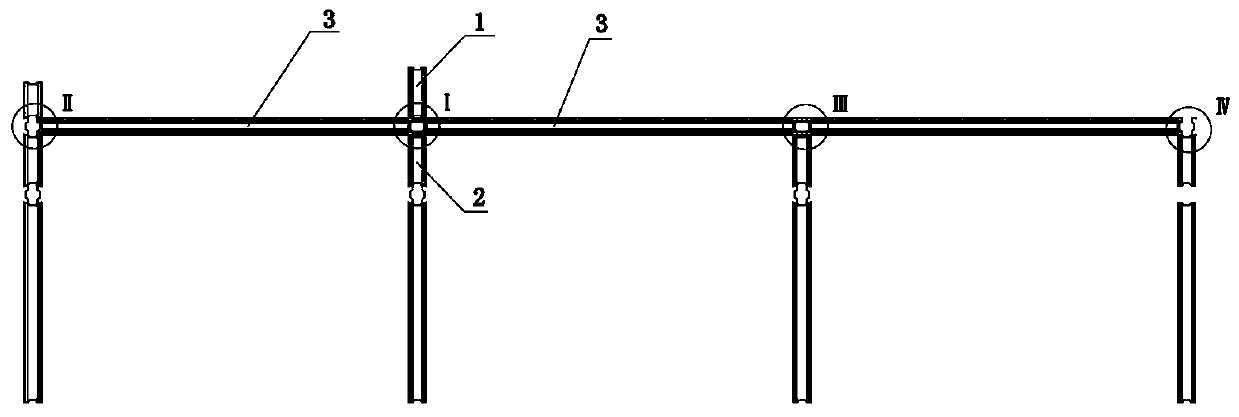

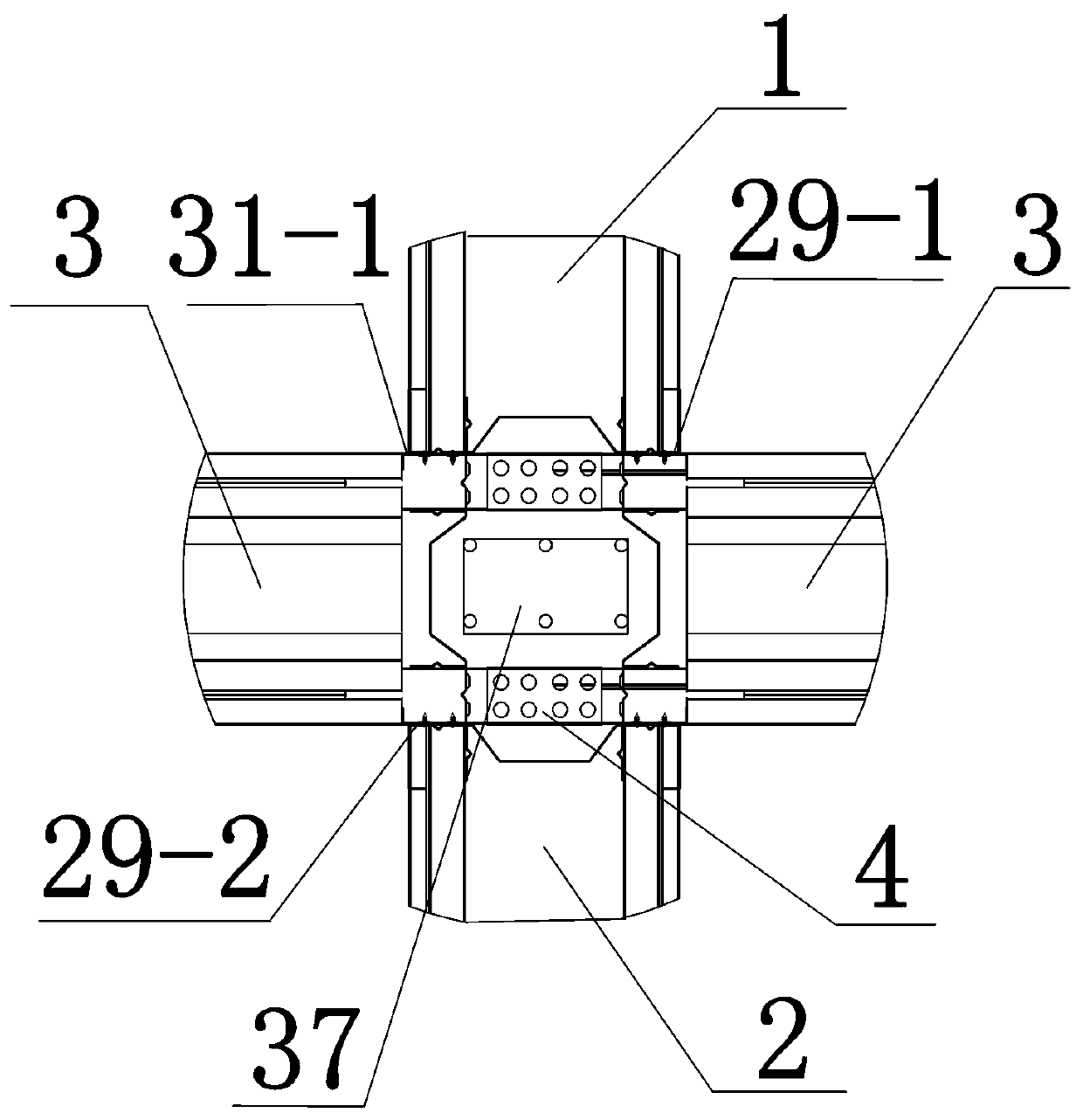

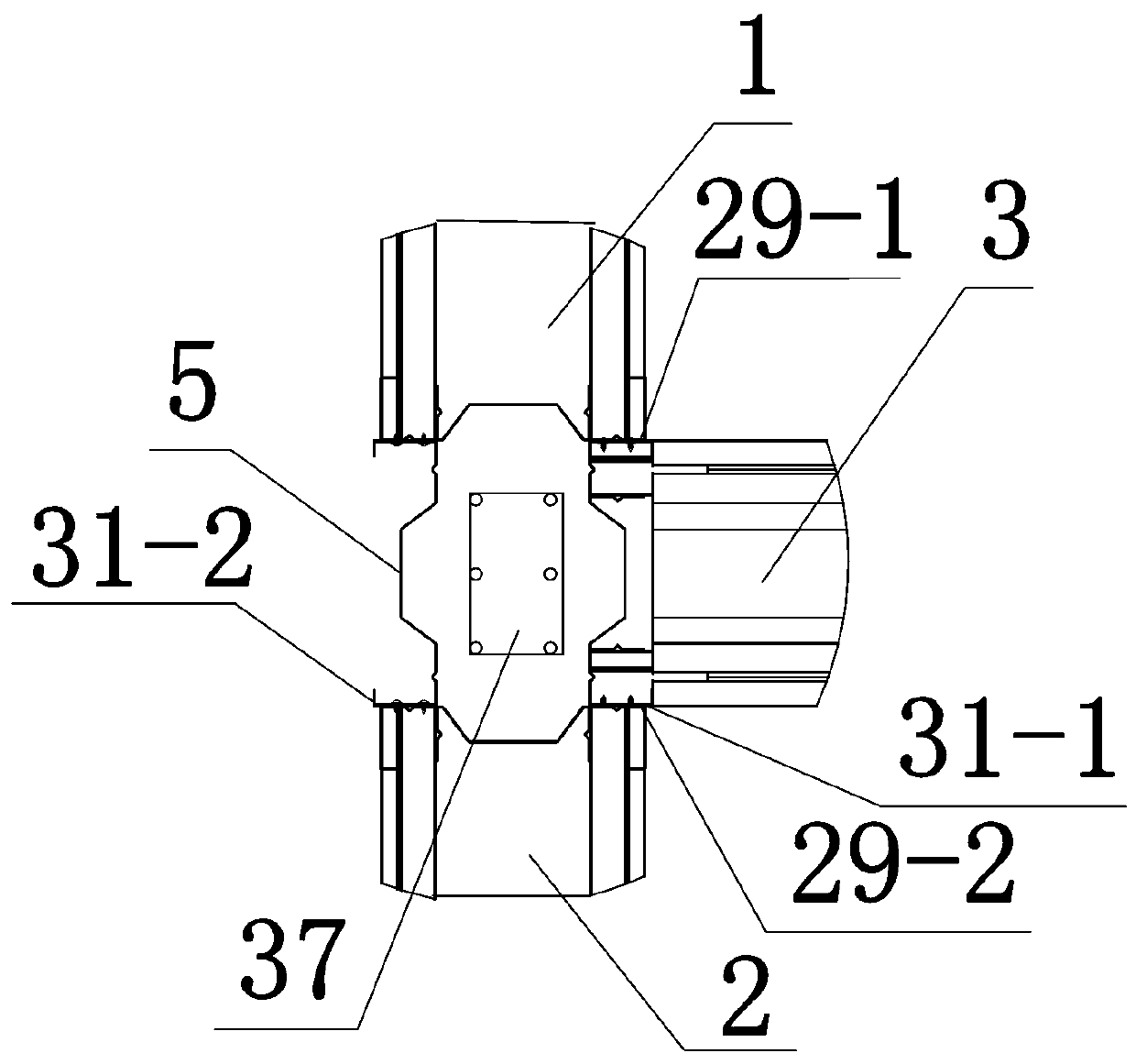

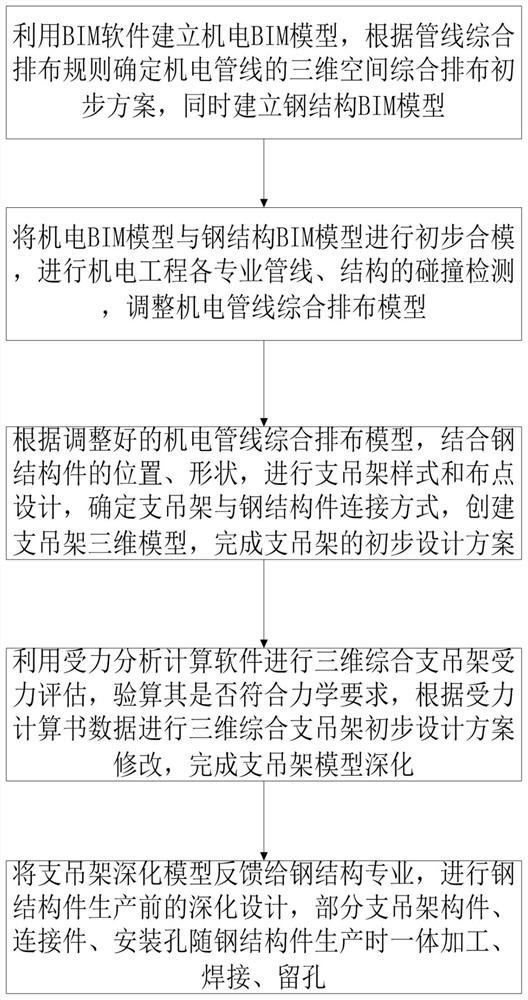

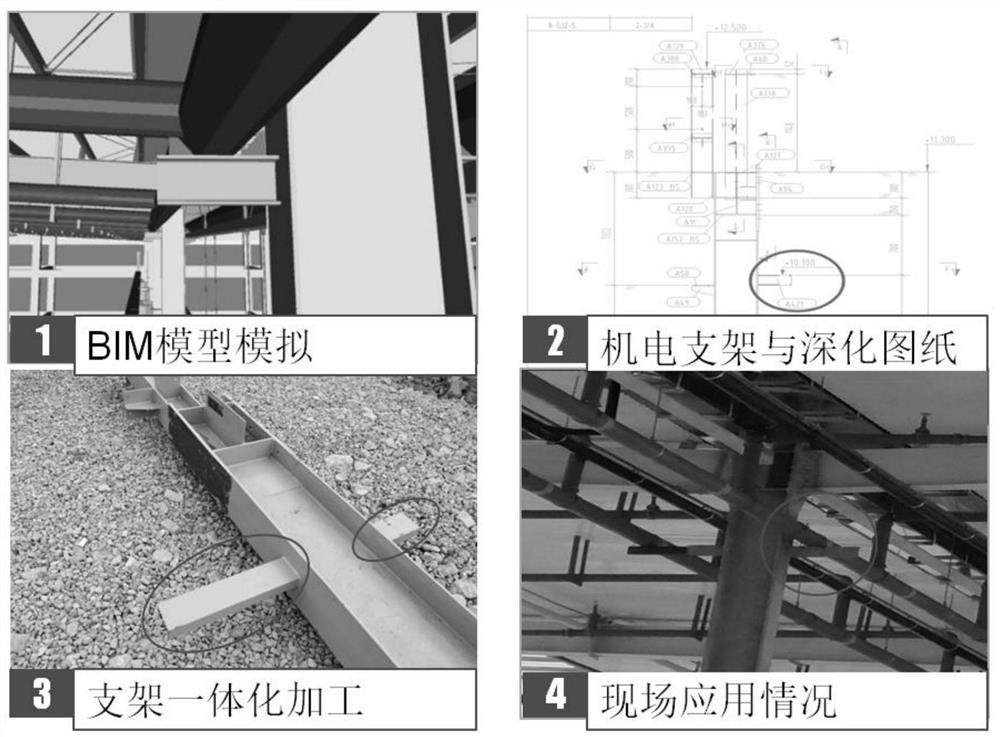

Electromechanical and steel structure integrated construction method

ActiveCN112926114AReduce on-site welding workReduce secondary reworkGeometric CADDesign optimisation/simulationLine tubingIndustrial engineering

The invention discloses an electromechanical and steel structure integrated construction method which comprises the following steps: simultaneously establishing a steel structure BIM model and an electromechanical BIM model by utilizing BIM software, carrying out integration, analysis and collision detection on the steel structure BIM model and the electromechanical BIM model, and adjusting an electromechanical pipeline comprehensive arrangement model; according to the electromechanical pipeline comprehensive arrangement model, completing preliminary design of a support hanger by combining the position and the shape of a steel structural part, conducting stress analysis on the support hanger subjected to preliminary design, conducting scheme modification, and completing support hanger model deepening; combining the support hanger deepening model to carry out steel structural member deepening design, dividing parts which can be machined together during machining into the steel structural members, and integrally machining along with production of the steel structural members. According to the method, steel structure deepening design and electromechanical deepening design are fused, the parts capable of being machined and produced together with the steel structural members are integrally machined, welded and holed along with the steel structural members, on-site welding construction and secondary rework are effectively reduced, and the one-time survival rate is increased.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

A wheel-track robot for substation inspection

ActiveCN105292281BGuaranteed normal walking speedAppropriate travel speedEndless track vehiclesDrive shaftEngineering

The invention relates to a substation inspection wheel-track obstacle-crossing robot. It mainly includes: a chassis; a power mechanism installed on the chassis, the power mechanism has a walking power source and a swing arm power source, and the walking power source outputs power to the walking wheels installed on both sides of the chassis through the transmission shaft; The swing arm driven by the power source of the swing arm is equipped with a main driving pulley, a swing arm pulley and an engaged walking track, and the main driving pulley and the driving pulley are assembled with the drive shaft; wherein , the swing arm power source realizes crawler walking and / or road wheel walking of the robot by driving the swing arm to swing. The robot provided by the invention can present different walking states according to different road conditions, and can obtain extremely high obstacle-surmounting ability by swinging the arm.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

Construction method for connecting floor slabs and wall surface joints of low-layer light steel structure building

The invention belongs to the technical field of building overall structures and particularly relates to a construction method for connecting floor slabs and wall surface joints of a low-layer light steel structure building. The construction method is characterized by comprising the following steps of (1) modular production of floor slab structures of the light steel structure fabricated building,(2) modular production of wall surface structures of the light steel structure fabricated building, and (3) connecting forms of the different floor slabs and different wall surface structure modules.The joints are simple in structure and convenient to mount, integrity is good after completion, and connecting is firm, also durable and stable; seam mounting parts are concealed inside seams, thus the attractiveness of surface decoration is not affected, and the seams can also be arranged in the junctions of the wall surfaces and the floor slabs; the joints do not affect passing and connecting ofwater and electricity pipelines pre-arranged in the floor slabs; and through the connecting method of the joints, the problem that when the area of the single floor slab is large, the length and thewidth exceed the limits, and consequently, the floor slabs cannot be transported is solved.

Owner:辽宁福瑞达建筑科技有限公司

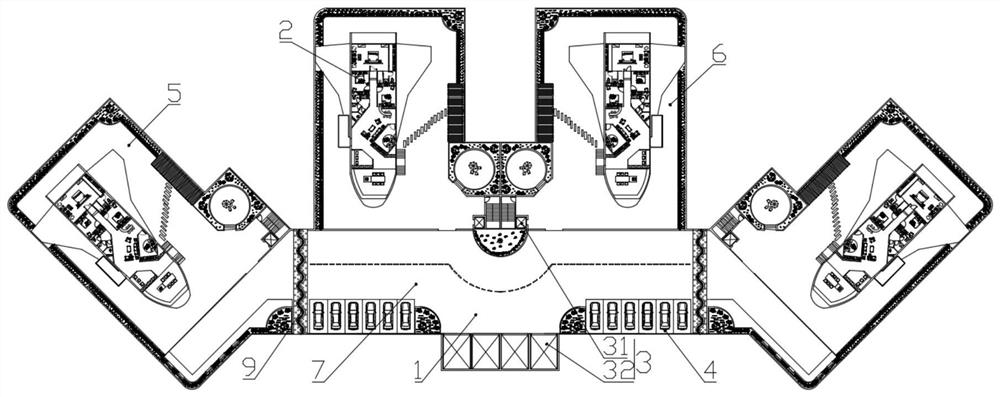

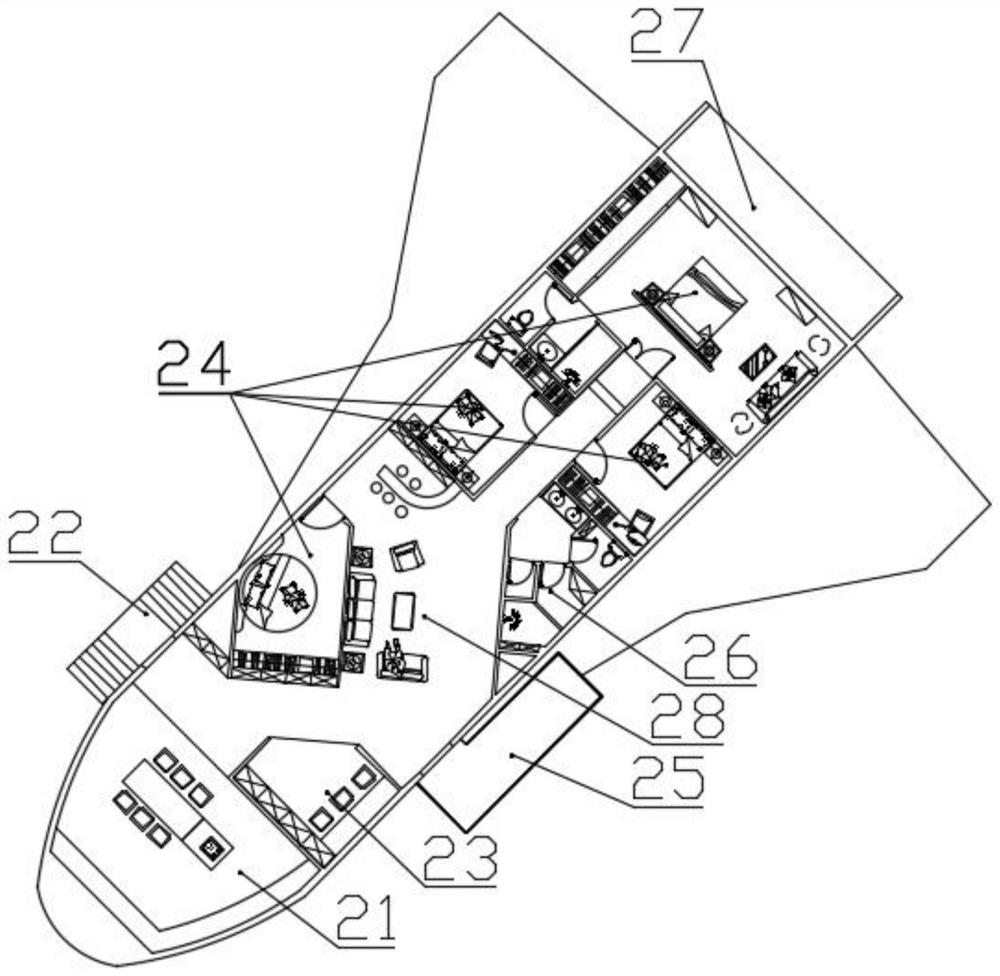

Full-prefabricated assembly type building

PendingCN114411942AReduce on-site constructionReduce labor intensityPublic buildingsProtective buildings/sheltersPierRaw material

The invention discloses a full-prefabricated assembly type building which comprises a supporting platform and a plurality of house bodies arranged on the upper surface of the supporting platform, and the house bodies are detachably connected to the supporting platform. The supporting platform can be single-layer or multi-layer; the supporting platform is connected to the pier column through the shock absorption and isolation supporting device. An existing building is divided into a supporting platform fixed to the ground and a house body installed on the upper surface of the supporting platform. The house body can be produced in a factory in a unified and standardized mode and then directly transported to the supporting platform to be installed. According to the building combination, site construction is greatly reduced, the labor intensity of workers is reduced, the construction quality is easy to control, dry construction can be achieved, water is saved, construction noise is low, dust is little, steel can be recycled, waste of raw materials is reduced, and garbage and environmental pollution are reduced. The method is less in field wet operation, high in construction efficiency and small in environmental pollution.

Owner:江苏领跑梦毛勒智造科技集团有限公司

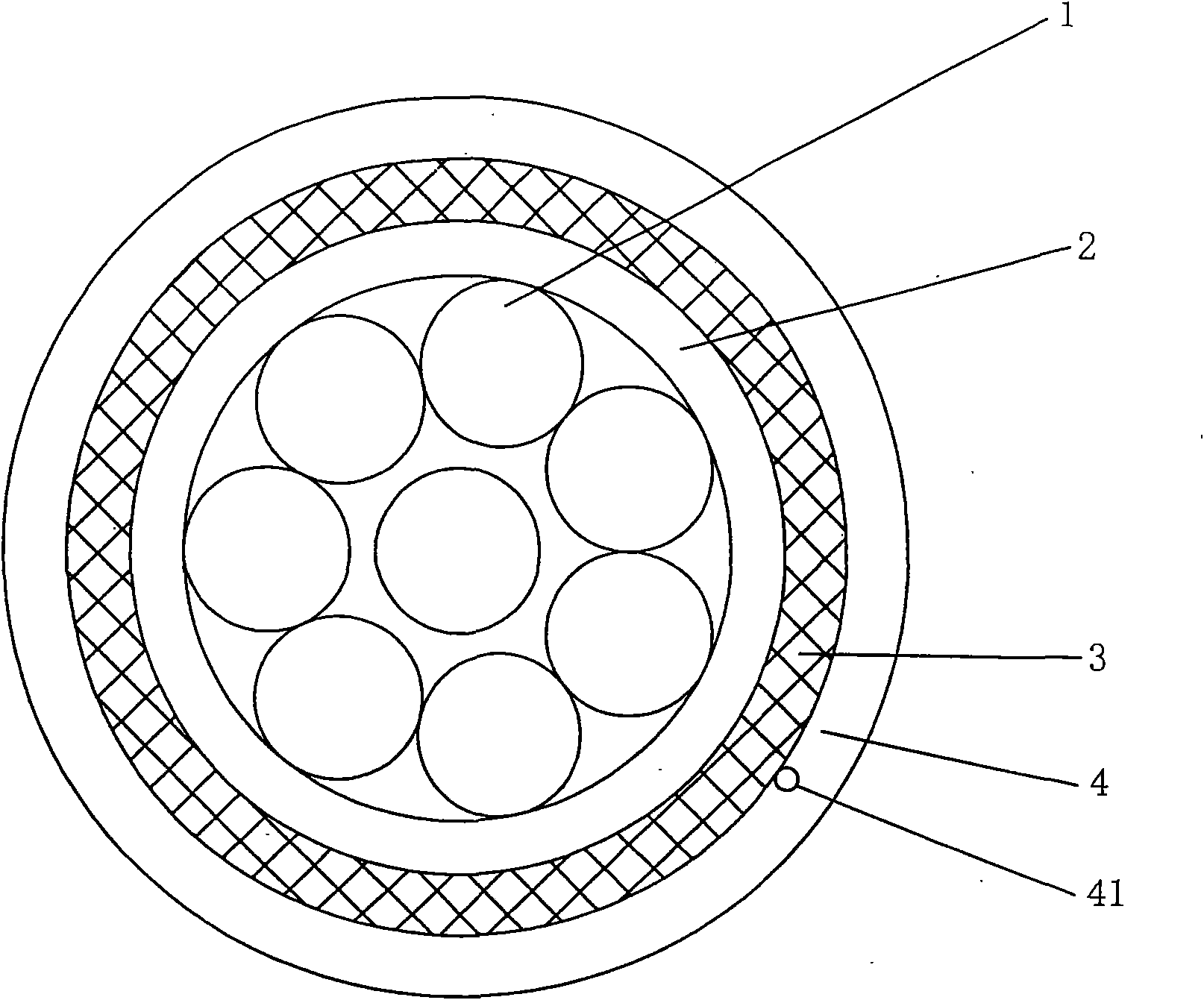

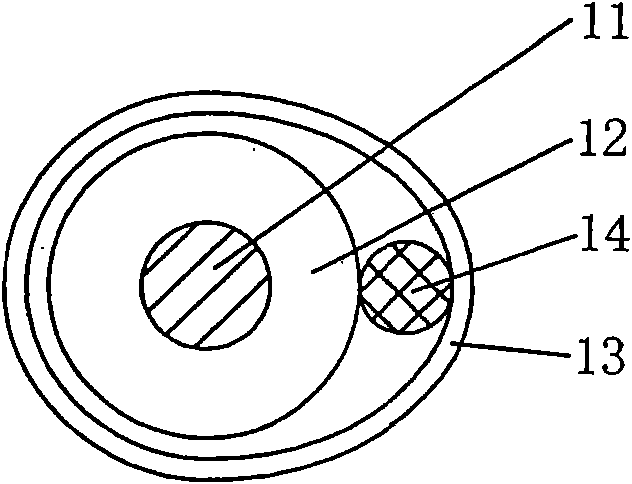

Coaxial cable for low frequency

InactiveCN101866718ASimple structureReduce the overall diameterCoaxial cables/analogue cablesMaterial consumptionAluminum composites

The invention relates to a coaxial cable for low frequency, belonging to the technical field of communication cables. The coaxial cable comprises a group of cable cores, a total shielding layer of an aluminum composite strip, a total weaving shielding layer and a sheath layer, wherein the total shielding layer of the aluminum composite strip is located outside the group of cable cores, the total weaving shielding layer is located outside the total shielding layer of the aluminum composite strip, and the sheath layer is located outside the total weaving shielding layer. The coaxial cable is characterized in that each of the cable cores comprises a conductor, an insulating layer, a composite strip and a ground wire, wherein the insulating layer is located outside the conductor, the composite strip is located outside the insulating layer, the ground wire is located between the insulating layer and the composite strip, and the composite strip is formed by a polyester strip and a metallic layer combined at the surface of one side of the polyester strip. The invention has the advantage of simplified structure, which ensures that the whole diameter of the formed coaxial cable is reduced, thereby facilitating site construction and being beneficial to reducing material consumption so as to save resources.

Owner:CHANGSHU HONGLIN WIRE & CABLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com