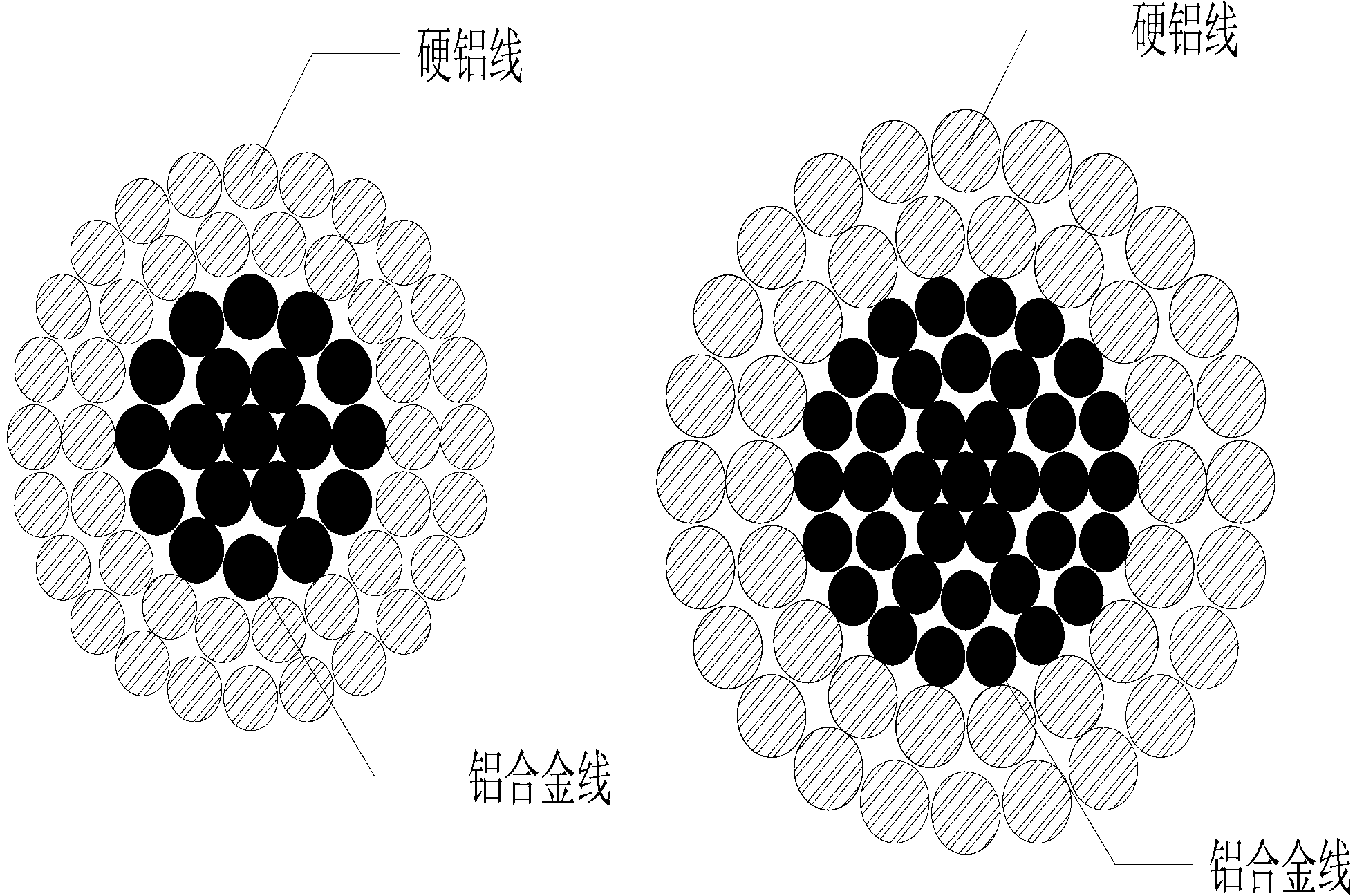

Strain clamp for aluminum alloy core aluminum stranded wire

A technology of core aluminum stranded wire and tension-resistant clamps, which is applied in the direction of adjusting/maintaining mechanical tension, can solve the problems of uneven crimping effect and low product strength, and achieve mature crimping process, good electrical performance and corrosion resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

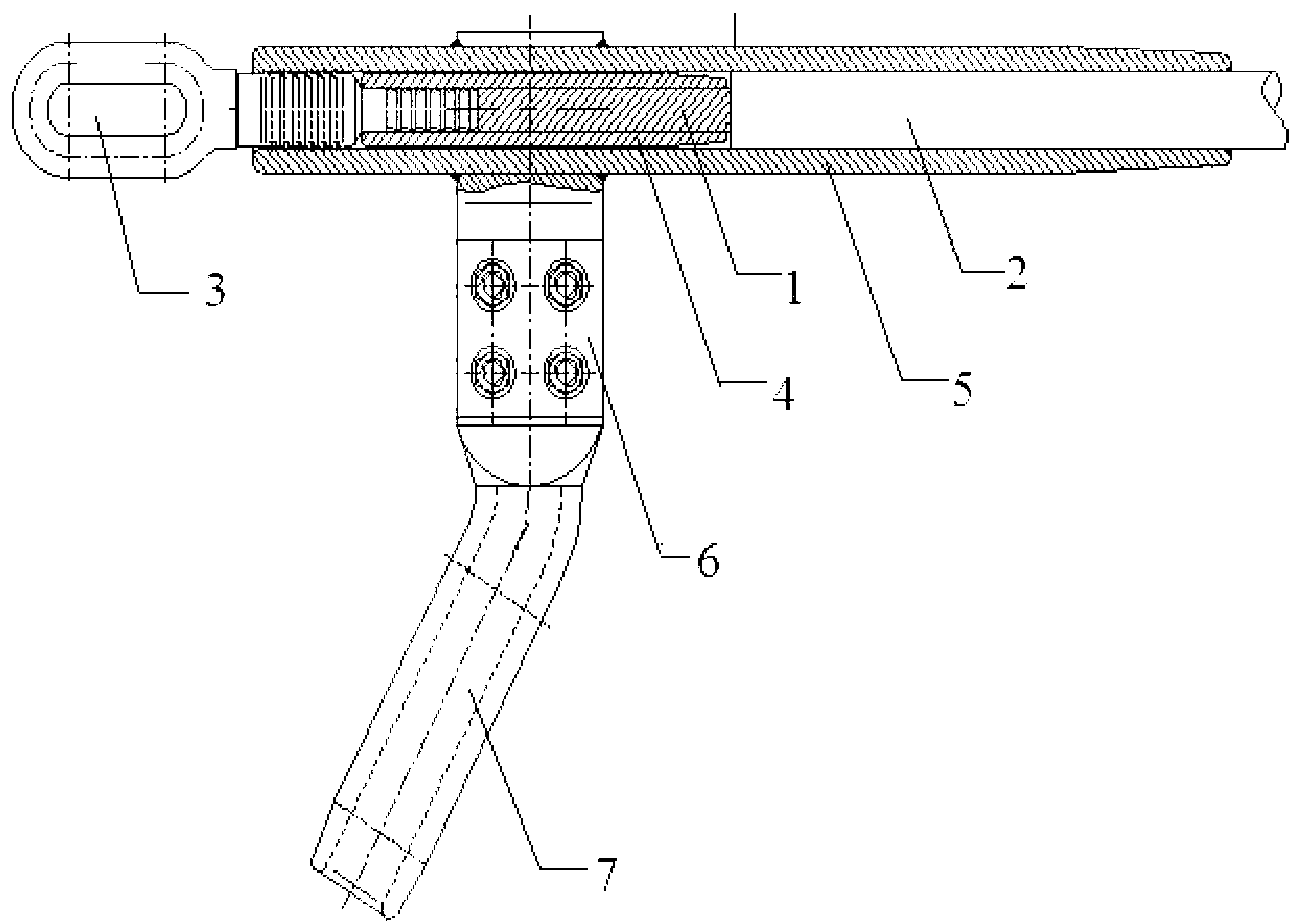

[0044] A strain clamp for an aluminum alloy cored aluminum stranded wire of the present invention will be further described in detail below in conjunction with the accompanying drawings.

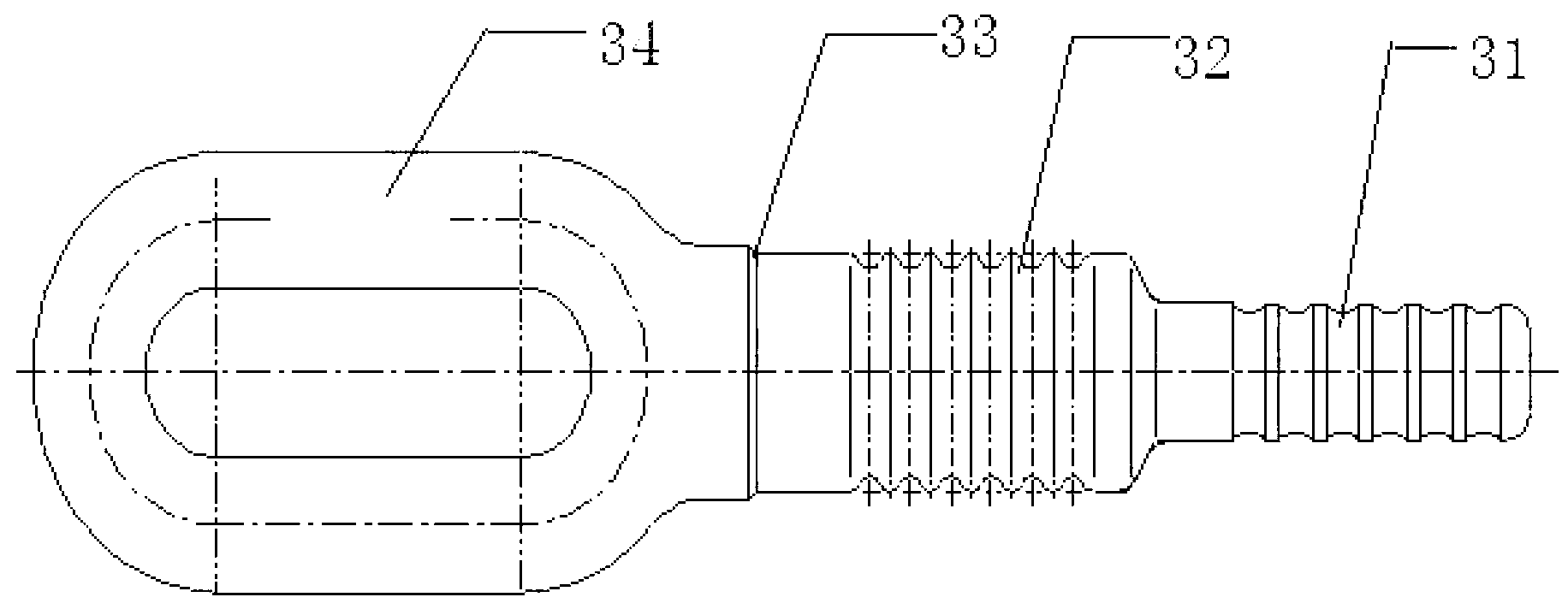

[0045] Such as figure 2 As shown, the strain clamp for aluminum alloy cored aluminum stranded wire of the present invention comprises a drain plate 6 and a drain clamp 7 connected thereto, a strain steel anchor 3, an aluminum alloy tube 4, a strain aluminum tube 5 and an aluminum alloy The core aluminum stranded wire 2, the anchor head 31 of the tensile steel anchor 3 is sleeved with an aluminum alloy tube 4 with a conical tubular structure at one end, the composition of the aluminum alloy tube 4 is 0.5%-0.65%, silicon 0.3%-0.5%, Iron 0.10%-0.17%, manganese ≤ 0.10%, chromium ≤ 0.10%, titanium ≤ 0.10%, aluminum as the balance, hardness 60HB; the middle connection part 32 of the tensile steel anchor 3 is sleeved with a tensile aluminum tube 5; The uncrimped ends of the aluminum alloy tube 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com