Connecting tube for support type expanding wire

A technology of expanded wire and support type, which is applied in the direction of connection, cable joint, and connection contact material where permanent deformation plays a role. It can solve the problems of increasing the number of split wires, increasing the number of wires, and increasing project investment. The effect of easy crimping quality and mature crimping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

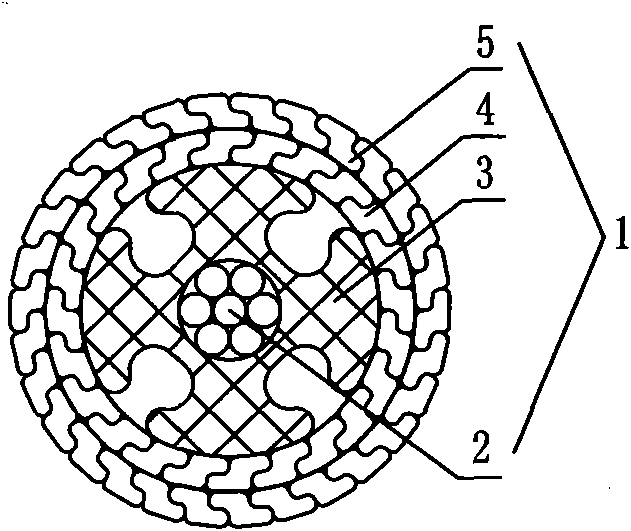

[0024] The invention provides a splicing tube for supporting type expanding wires, its function is to join two supporting type expanding wires to transmit mechanical and electrical loads, such as figure 1 As shown, the supporting expanded-diameter conductor 1 includes a steel core 1 , and the steel core is covered with a support layer 3 , an inner layer aluminum wire 4 and an outer layer aluminum wire 5 sequentially from the inside to the outside.

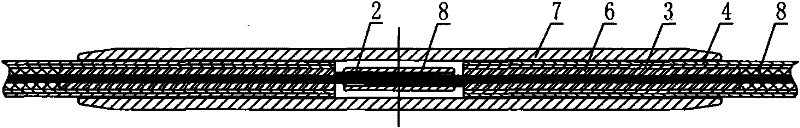

[0025] Such as figure 2 As shown, the connecting pipe described in this example includes aluminum pipe 7, steel pipe 8 and aluminum lining pipe 6, and the wires 1 extend into the aluminum pipe 7 from both ends of the aluminum pipe 7 respectively, and the heads of the two wires 1 are overlapped. Together, the heads of the two overlapped wires are crimped through the steel pipe 8 arranged in the aluminum tube 7. The aluminum tube 7 is provided with two aluminum liners 6, and the two aluminum liners are respectively socketed On the ...

Embodiment 2

[0033] The structure and connection method of the connecting pipe described in this example are basically the same as those in Example 1, except that:

[0034] An aluminum liner 6 is arranged inside the aluminum tube 7, and the aluminum liner is sleeved on the steel core 2 of the two wires and the steel pipe 8 for crimping the heads of the two wires at the same time. The length of the aluminum liner 6 is the length of the wire The sum of 6.5-7 times of the outer diameter and the length of the steel pipe 8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com