Strain clamp for large-section lead

A technology of tension-resistant clamp and large cross-section, which is applied in the direction of adjusting/maintaining mechanical tension, which can solve the problems of wires not getting grip force, etc., and achieve the effects of mature crimping process, easy crimping quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

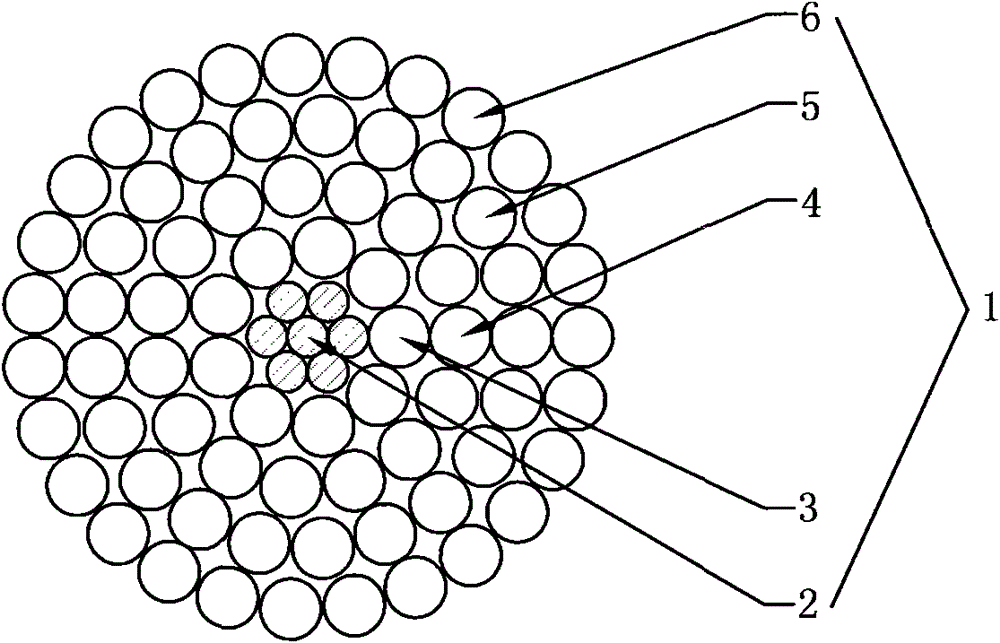

[0030] Such as figure 1 As shown, the four-layer aluminum wire steel-cored aluminum stranded wire is a kind of large-section wire, and the wire 1 of the present invention is this kind of large-section wire 1: including a steel core 2, and the outside of the steel core 2 is covered in order from the inside to the outside. There are inner layer aluminum wires 3, adjacent inner layer aluminum wires 4, adjacent outer layer aluminum wires 5, and outer layer aluminum wires 6.

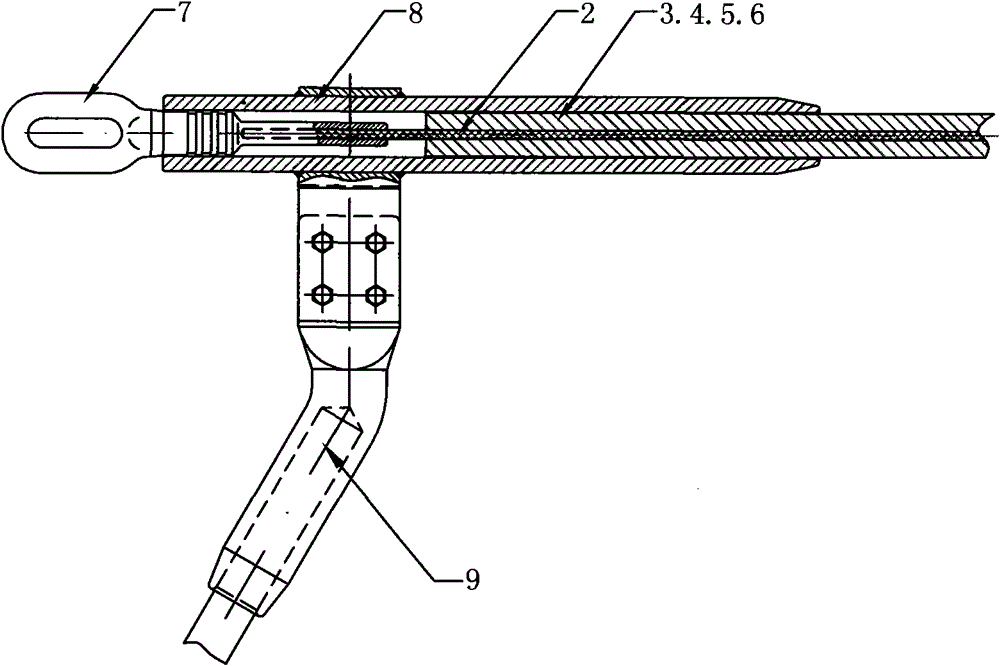

[0031] Such as image 3 As shown, the tensile clamp for large cross-section conductors in this example mainly includes a tensile steel anchor 7, a tensile aluminum tube 8, a drain clamp 9 and an aluminum liner 11. The upper part of the drain clamp 9 uses a connecting bolt It is connected with the deflector 12 on the tensile aluminum tube 8, and a tensile jumper 10 is crimped at the bottom of the tensile aluminum tube 8 to transmit current. The tensile steel anchor 7 is connected to the rear end of the tensile alu...

Embodiment 2

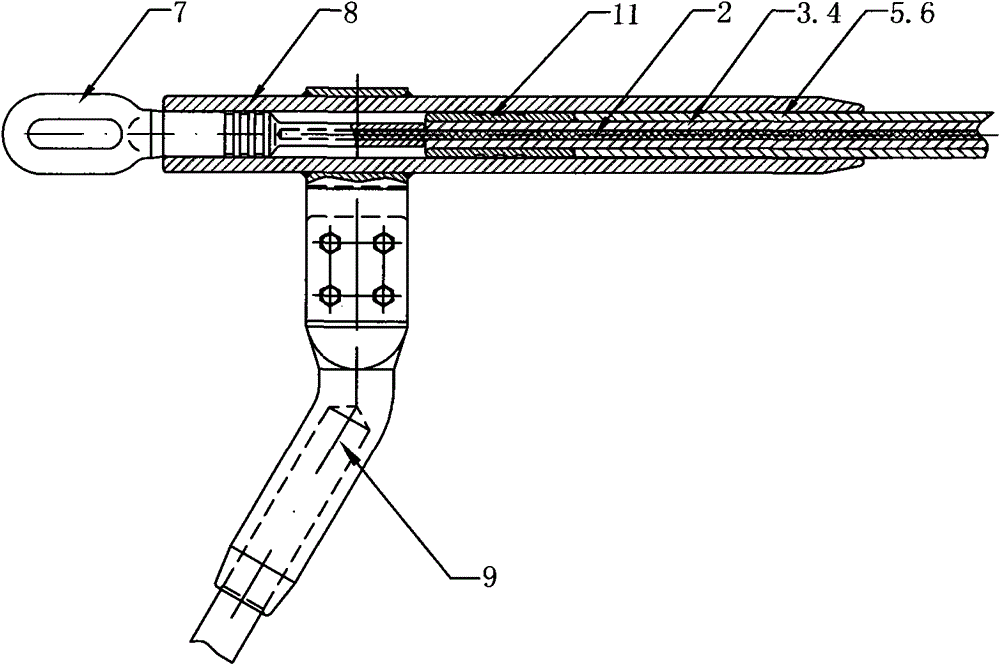

[0042] The structure and connection mode of the strain clamp described in this example are basically the same as that of Example 1, except that:

[0043] Such as Figure 4 As shown, a section of aluminum liner 11 is also provided in the tensile aluminum tube 8. The aluminum liner is simultaneously sleeved on the steel tube 73 of the tensile steel anchor 7 and the adjacent outer aluminum wire 5 and the outer aluminum wire 5 and The part of the outer aluminum wire 6 is adjacent to the inner aluminum wire 4 (that is, the aluminum liner simultaneously holds the large cross-section wire adjacent to the inner aluminum wire 4 and the steel pipe of the tensile steel anchor 7).

[0044] Such as Figure 8 As shown, the structure of the aluminum liner can be as Figure 8 The integrally formed round tube shown in a, 8b can also be like Figure 8 c. 8d shows a round tube formed by splicing two semicircular tubes. The length of the aluminum liner 11 is the length of the steel pipe 73 plus 3-4 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com