Connecting tube used for large-section conducting wire

A splicing tube and large cross-section technology, which is applied in the direction of connection where permanent deformation plays a role, connecting contact material, multi-core cable end parts, etc., can solve the problem that the splicing tube can no longer meet the requirements, and achieve crimping quality easily, The effect of the mature crimping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

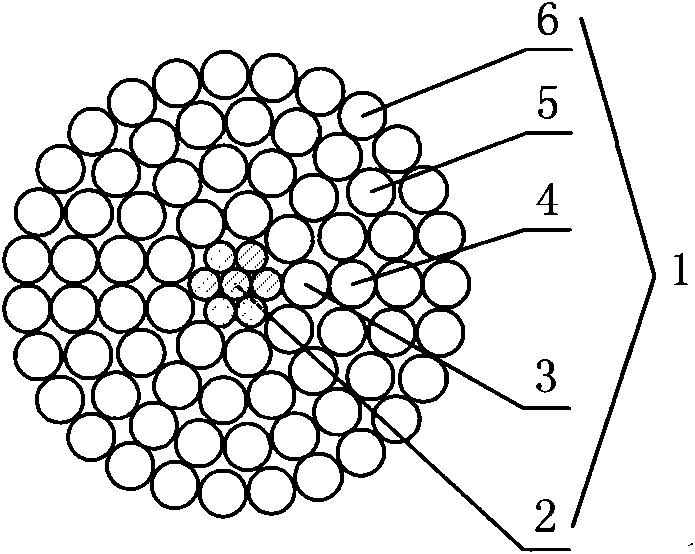

[0030] Such as figure 1 As shown, the four-layer aluminum wire steel-cored aluminum stranded wire is a kind of large-section wire. This large-section wire 1 includes a steel core 2. The steel core 2 is covered with an inner layer of aluminum wire 3 from the inside to the outside. Layer aluminum wire 4, adjacent outer layer aluminum wire 5 and outer layer aluminum wire 6.

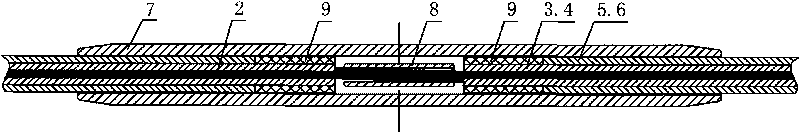

[0031] Such as image 3 As shown, the connecting pipe for large cross-section conductors described in this example is used to join two large cross-section conductors 1 to transmit mechanical and electrical loads. The connecting pipe includes an aluminum pipe 7, a steel pipe 8, and two aluminum lined pipes 9. , The steel cores 2 of the two large cross-section conductors 1 extend into the steel tube 8 from both ends of the steel tube 8. The steel tube 8 presses the two steel cores 2 placed in the overlapped shape, and the two aluminum lined tubes 9 are respectively sleeved on the adjacent inner aluminum wires 4 o...

Embodiment 2

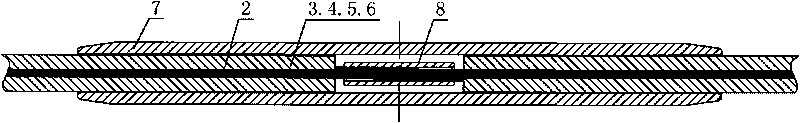

[0040] The structure and connection method of the connecting pipe described in this example are basically the same as those in Example 1, except that:

[0041] The connecting tube includes an aluminum tube 7, a steel tube 8 and an aluminum liner tube 9. The aluminum liner tube 9 is simultaneously sleeved on the adjacent outer aluminum wires 4 of the two wires and the steel tube 8 used for crimping the steel core of the two wires. Above, the length of the aluminum liner 9 is the sum of 3-4 times the outer diameter of the wire and the length of the steel pipe 8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com