Double-column type pier prefabricated bearing platform structure and construction method thereof

A technology of prefabricated caps and construction methods, applied in manufacturing tools, infrastructure engineering, ceramic molding machines, etc., can solve problems such as difficult control of maintenance quality, achieve the effects of ensuring connection and installation procedures, reducing on-site construction, and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

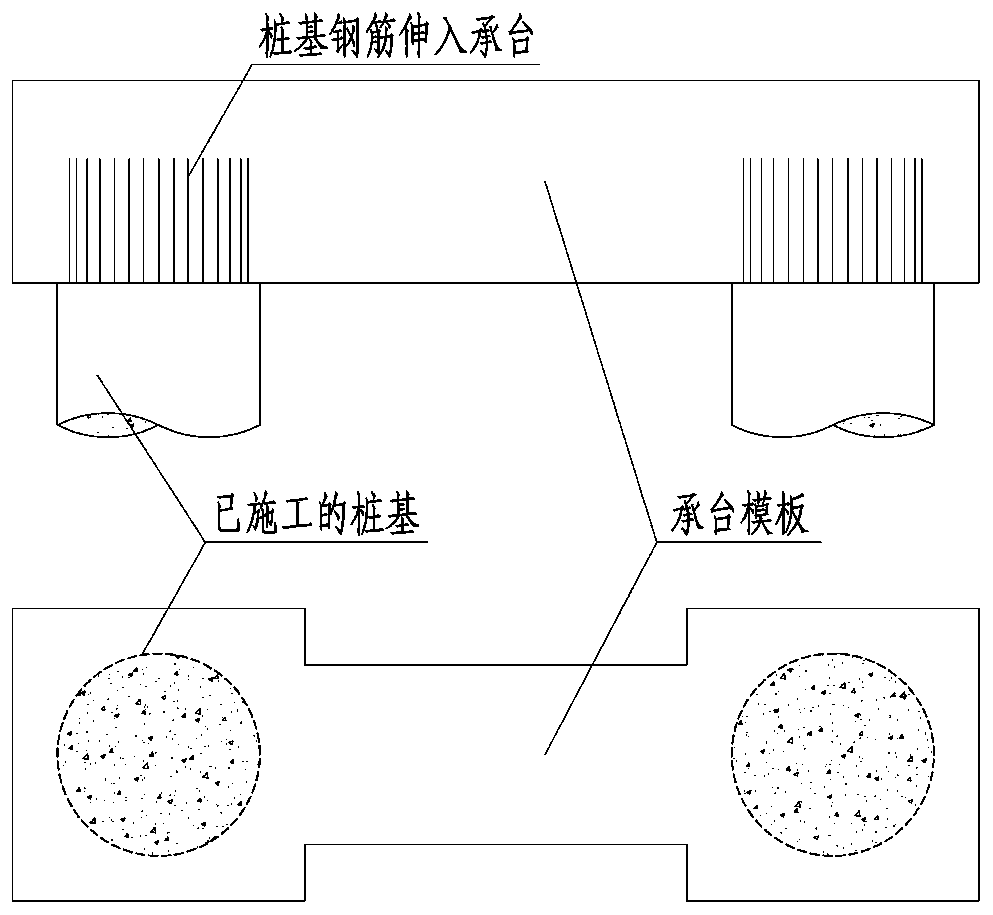

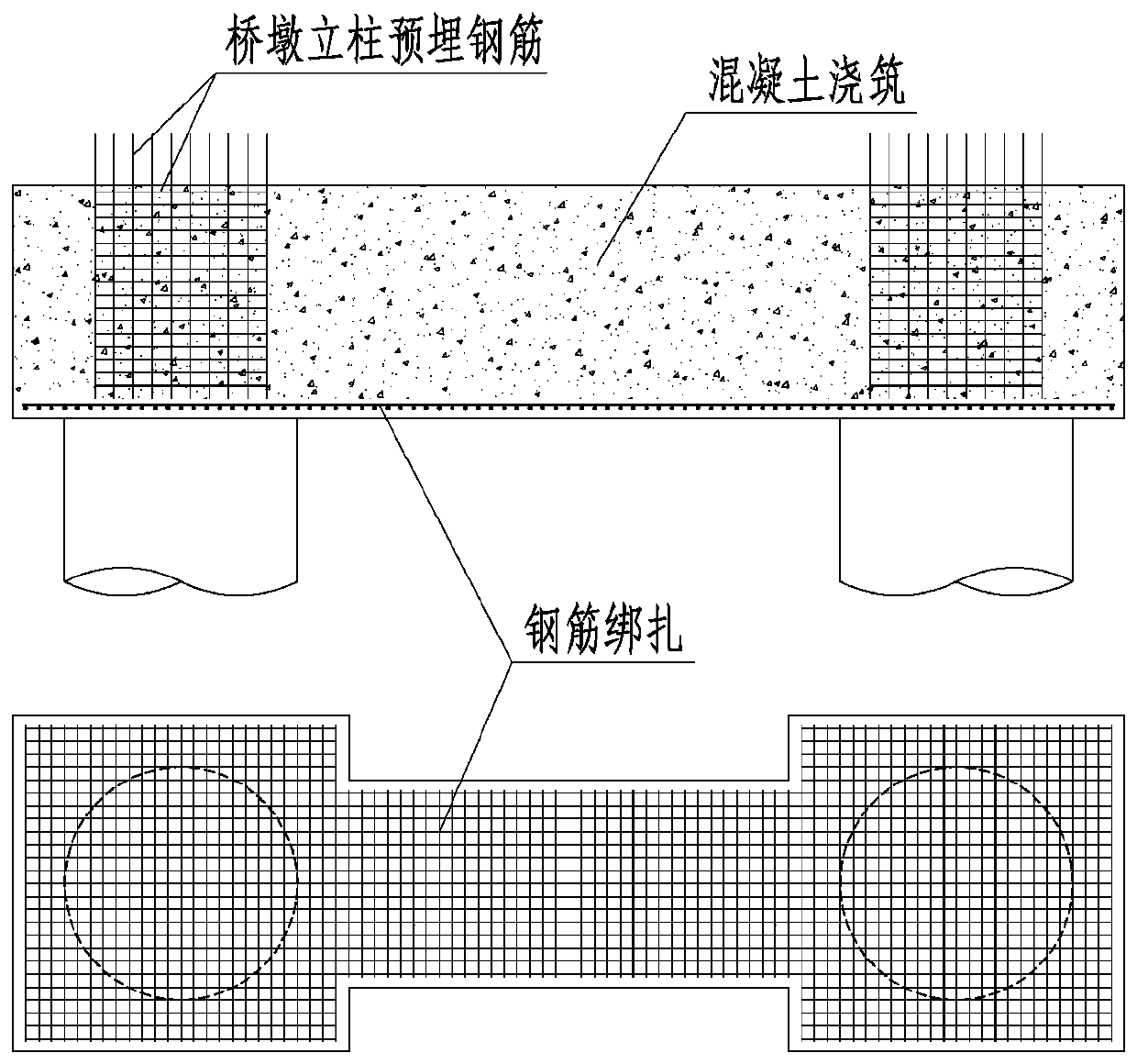

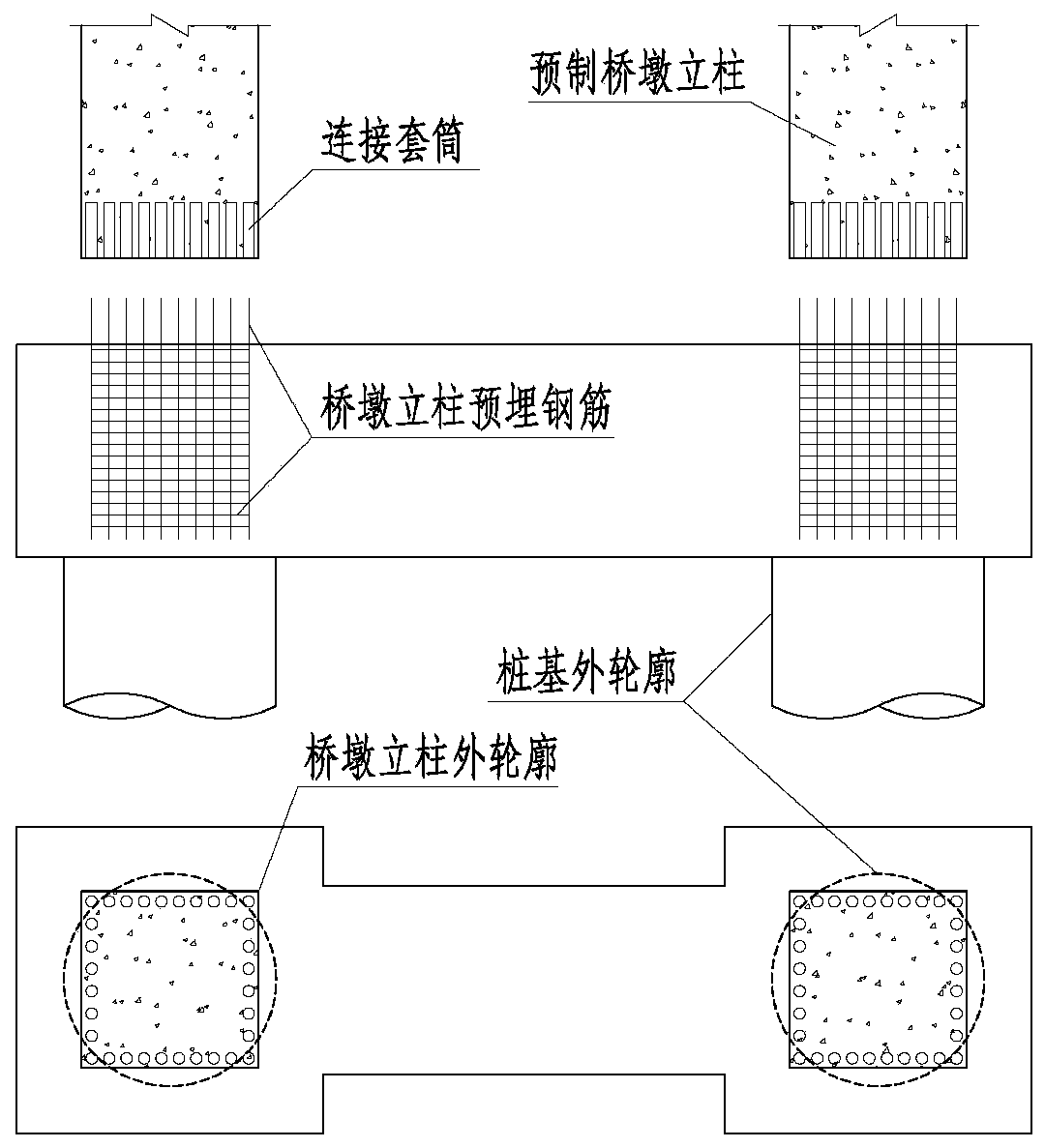

[0044] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0045] The basic structure of the double-column pier prefabricated cap of the present invention is as follows: Figure 4As shown, the plane shape of the prefabricated cap 1 of this double-column pier adopts a dumbbell shape, and openings are reserved at the corresponding positions of the pile foundation and the pier body column, and the size of the inner cavity 2 of the opening should be slightly larger than the diameter of the pile body, so The overall dimension of the bearing platform needs to be slightly larger than the size of the traditional bearing platform, but the overall weight can still be equal to or even lighter than the traditional bearing platform, so it is convenient to control the weight of the prefabricated bearing platform with openings b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com