A wheel-track robot for substation inspection

A robot and wheel-track technology, which is applied in the field of robots, can solve the problems that the track does not touch the ground, cannot realize the climbing function, and limits the ability of the robot to overcome obstacles, so as to reduce on-site construction and improve the ability to overcome obstacles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

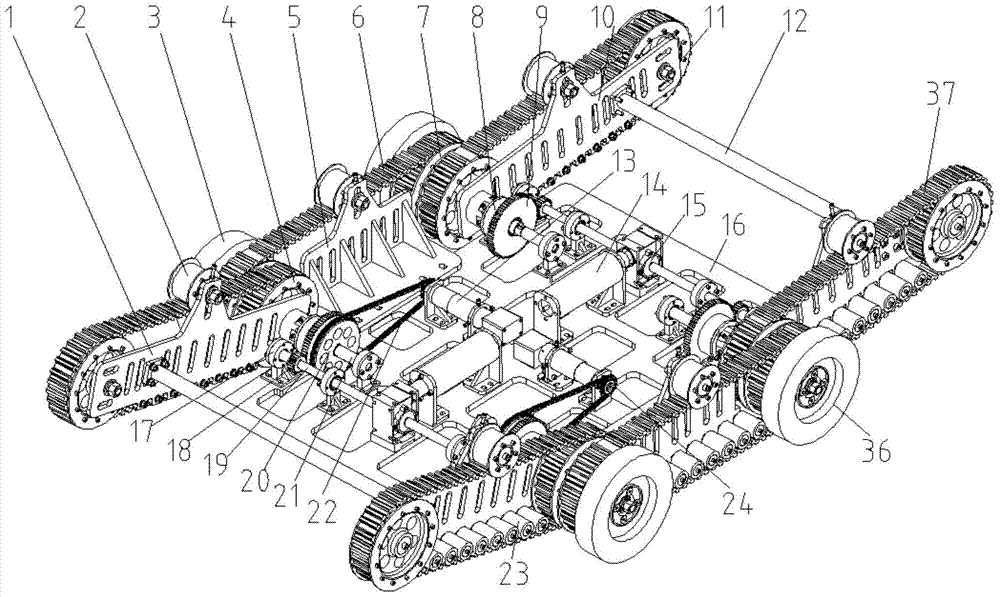

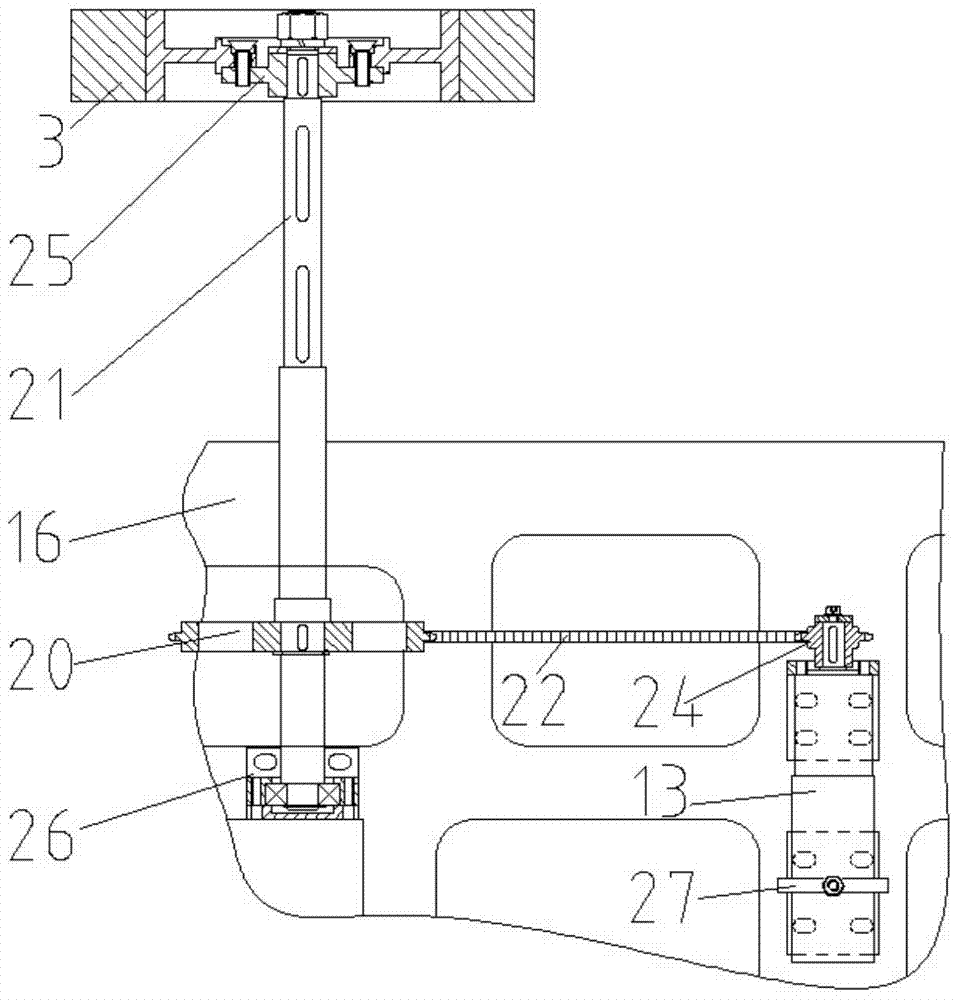

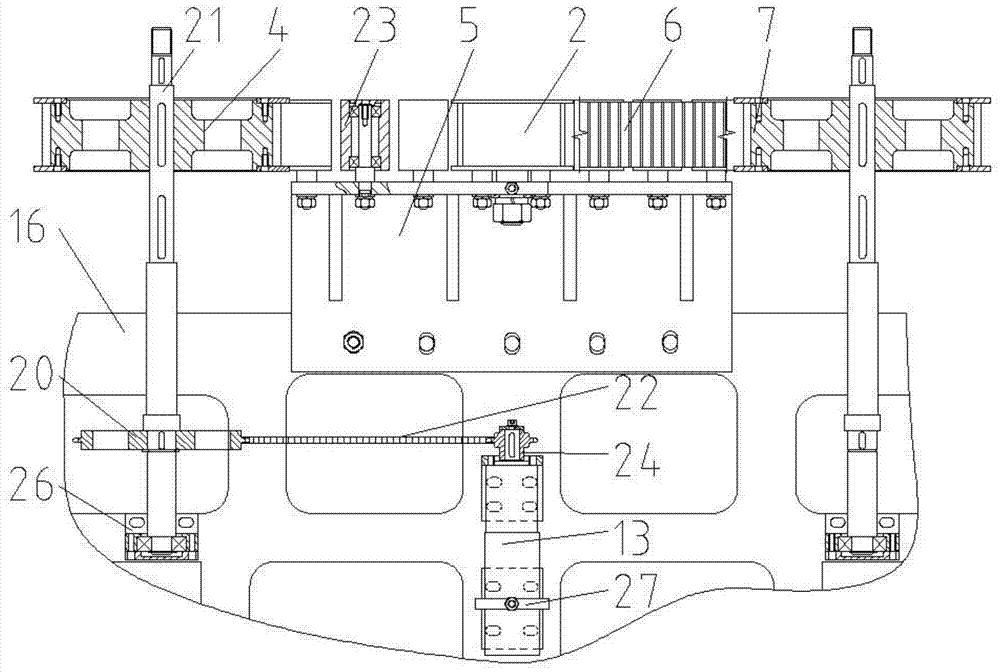

[0047] Embodiment: A substation inspection wheel-track obstacle-climbing robot, whose structure refers to figure 1 and figure 2As shown, including the chassis 16; the front part of the chassis 16 is fixed with two sprocket reduction motors 13 through the sprocket motor seat 27, and a small sprocket is installed on the output shafts of the two sprocket reduction motors 13 through the connecting key. 24. The small sprocket 24 is transmitted to the large sprocket 20 through the chain 22 to realize the step-by-step transmission of the torque output by the sprocket reduction motor 13. The large sprocket 20 is installed on the transmission shaft 21, and the power is then transmitted to the transmission shaft through the connecting key 21. One end of the transmission shaft 21 is fixed on the transmission shaft bearing seat 26, and the transmission shaft bearing seat 26 is installed on the chassis 16. The other end of the transmission shaft 21 drives the road wheel collar 25, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com