Substation wheeled obstacle surmounting mechanism, robot and method thereof

A substation and robot technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of poor environmental adaptability, low efficiency, complex control system and mechanical structure, etc., achieve high automation, reduce input costs, and overcome obstacles simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

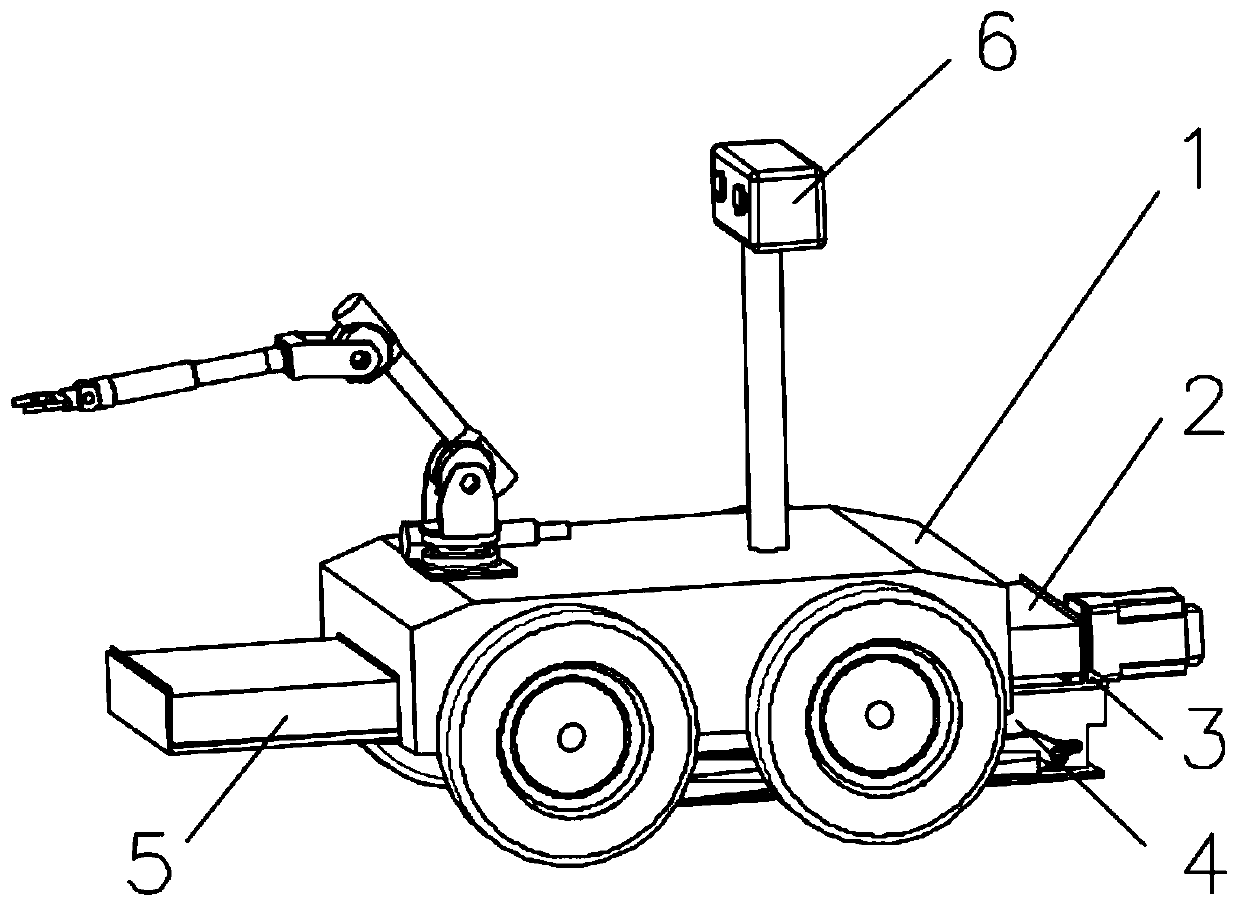

[0037] The invention proposes a novel wheeled obstacle-surmounting robot for a substation. The wheeled robot uses wheels to walk normally on ordinary flat roads; when encountering a curb (the height of the curb is 100-200mm), the wheeled robot uses a lifting platform and a screw guide mechanism to assist it to cross obstacles.

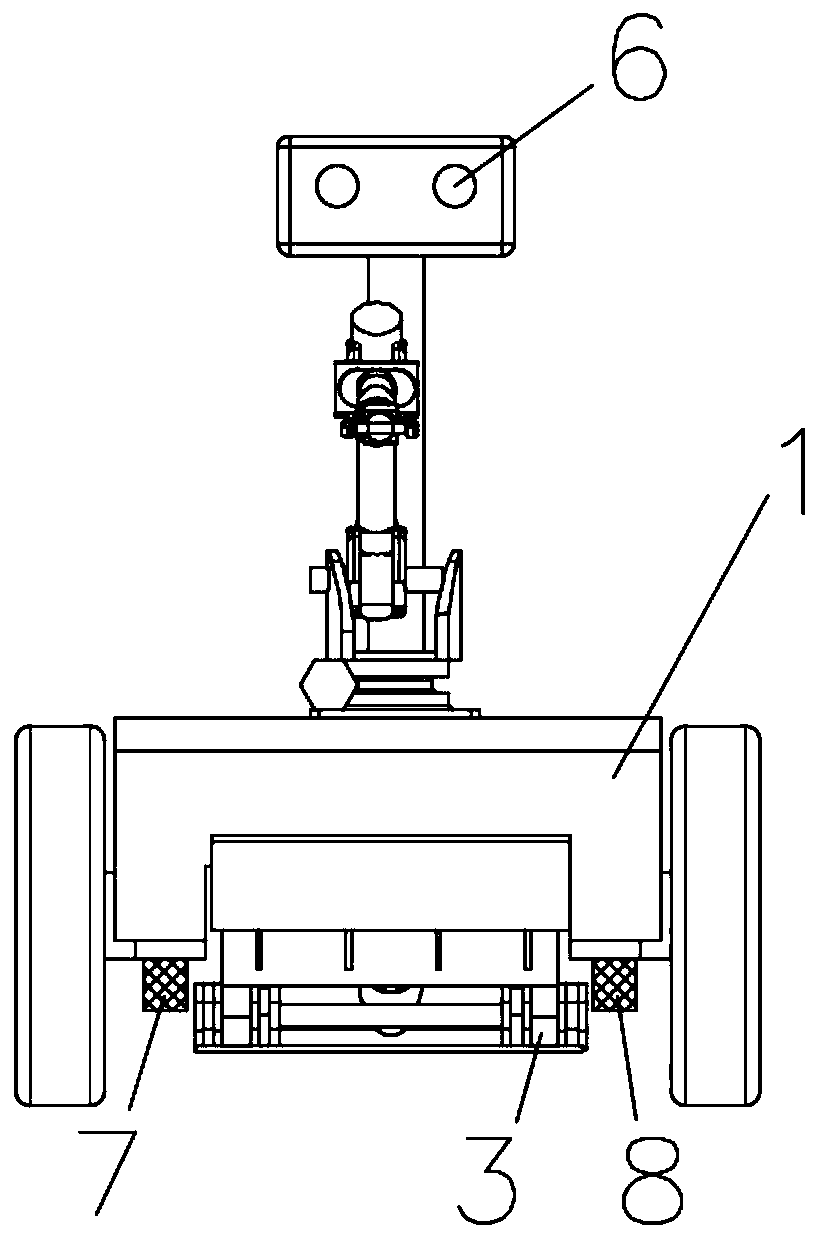

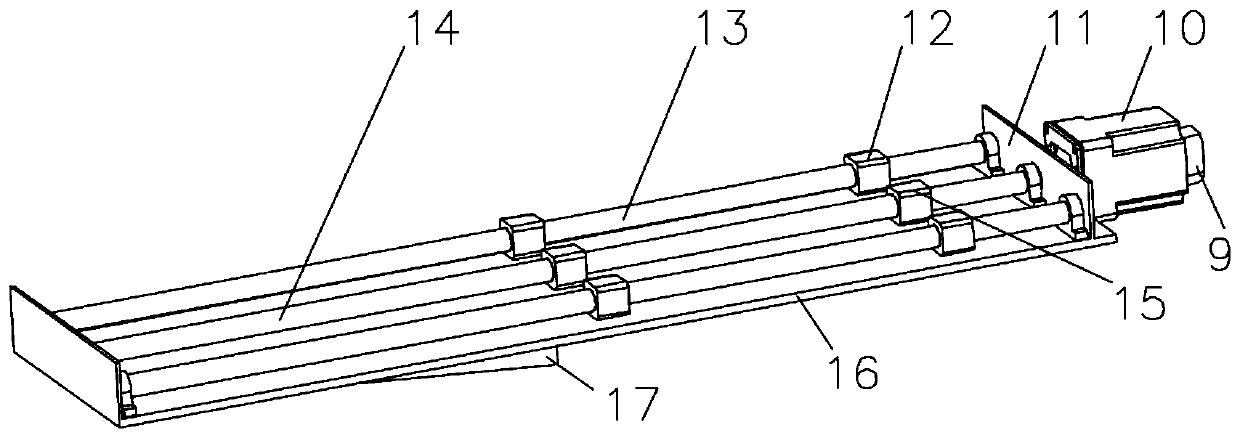

[0038] The wheeled robot chassis 1 is an ordinary substation inspection robot, and its internal drive mode is dual-motor front-wheel drive. The wheeled robot chassis 1 is connected with the lead screw guide rail mechanism 3 through four sliders 12, two screw nut sliders 15, the bottom of the wheeled robot chassis 1 and the four sliders 12, two screw nut sliders 15 It can be connected by screws, and the left distance sensor 7 and the right distance sensor 8 are installed under the wheeled robot chassis 1, which are symmetrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com