Assembled indoor glass balustrade structure

A technology for glass balustrades and inner glass, which is applied to ladder structures, railings, building structures, etc., can solve the problems of manpower and material resources, inconvenient construction, long construction period, etc., reducing on-site construction and convenient and quick installation. , the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

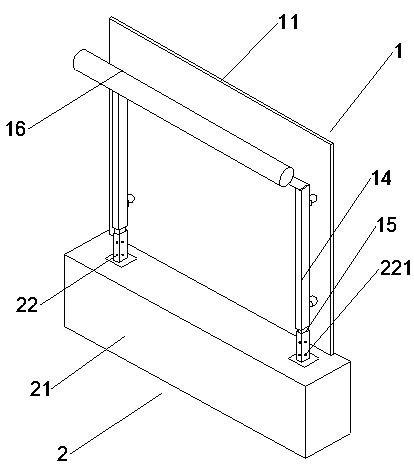

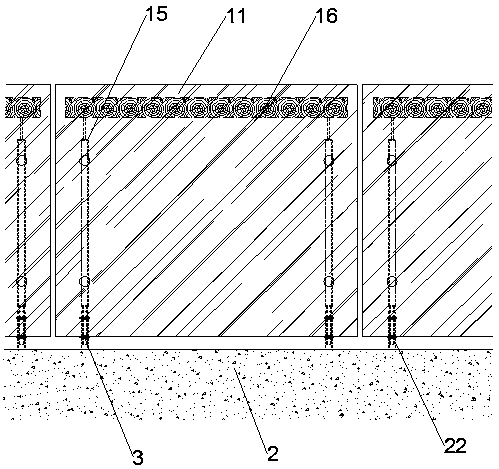

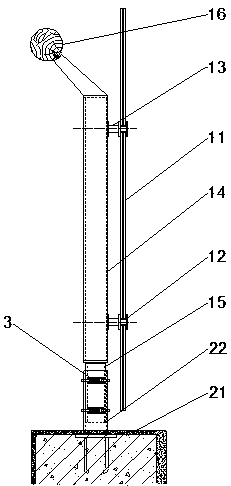

[0016] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0017] Such as figure 1 , figure 2 , image 3 with Figure 4 The shown assembled indoor glass balustrade structure includes a plurality of glass balustrade units 1, and the glass balustrade units 1 are installed on the fixed base unit 2 below them, and the glass balustrade units 1 include For tempered laminated glass 11, two vertically arranged square columns 14 are connected to one side of tempered laminated glass 11 through stainless steel barge joint 12 and stainless steel fixed claw 13, and the fixed base unit 2 includes a base 21 and is arranged on The square sleeve 22 on the base 21, the sleeve 22 is provided with two and corresponds to the two uprights 14, at the lower end of the uprights 14 and along the radial direction of the uprights 14 there is a square Connecting rod 15, the outer diameter of the column 14 is equal to the outer diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com