Electromechanical and steel structure integrated construction method

A construction method and technology for steel structures, applied in design optimization/simulation, image data processing, special data processing applications, etc., can solve problems such as steel structure damage, reduce secondary rework, improve primary survival rate, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

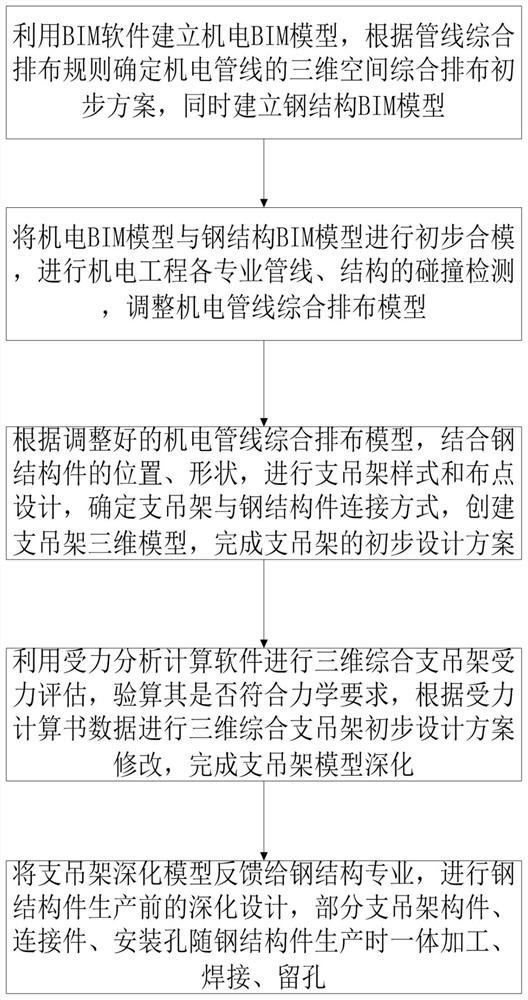

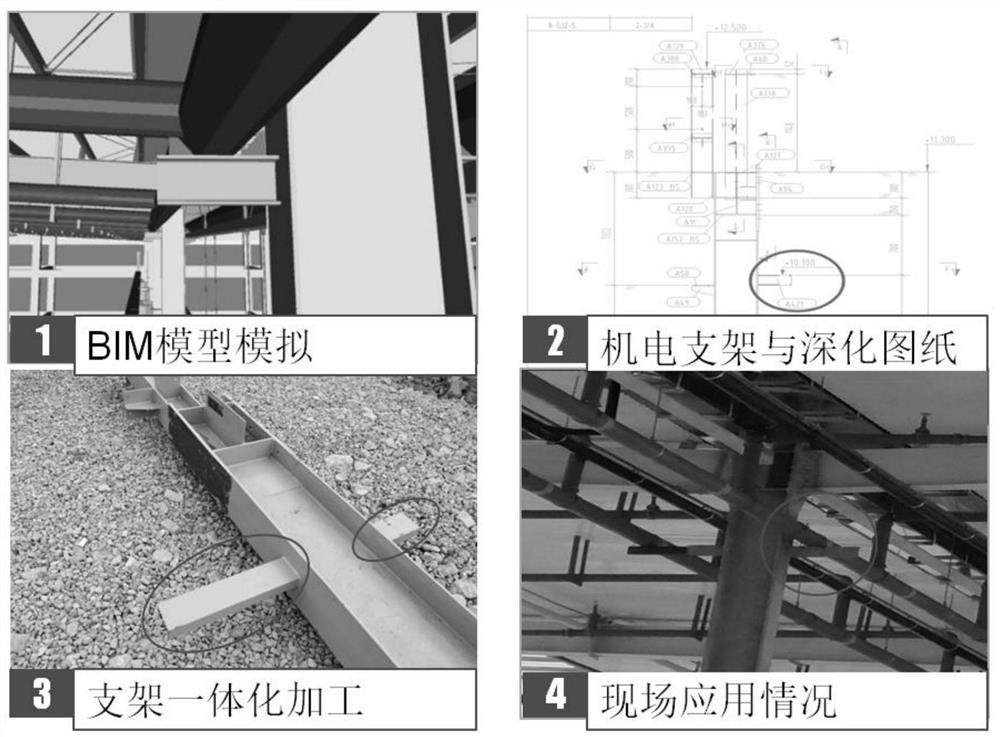

[0038] This embodiment provides an integrated construction method of electromechanical and steel structures, such as figure 2 , including the following steps:

[0039] 1. Preliminary in-depth design of each major

[0040] Use BIM software to establish three-dimensional models of pipelines in various disciplines of electromechanical engineering (water supply and drainage, HVAC, electrical, power), and determine the preliminary plan for comprehensive layout of electromechanical pipelines in three-dimensional space according to the comprehensive layout rules of pipelines.

[0041] Among them, the main steel structure adopts Tekla software to create a three-dimensional deepening model, completes the creation of structural nodes according to the design requirements of the main structure, and exports the IFC format file after the deepening is completed.

[0042] Revit and MagiCAD software are used in mechanical and electrical engineering to establish refined 3D information models,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com