Warehouse top bolt-sphere grid structure for clinker silo

A technology of grid structure and roof bolts is applied in large-capacity bulk material storage, roofs using flat/curved panels, building components, etc., which can solve the problems of difficulty in meeting design requirements and difficulty in applying large bolt pre-tightening force. , to achieve the effect of small welding work, improved force transmission and force performance, and improved storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

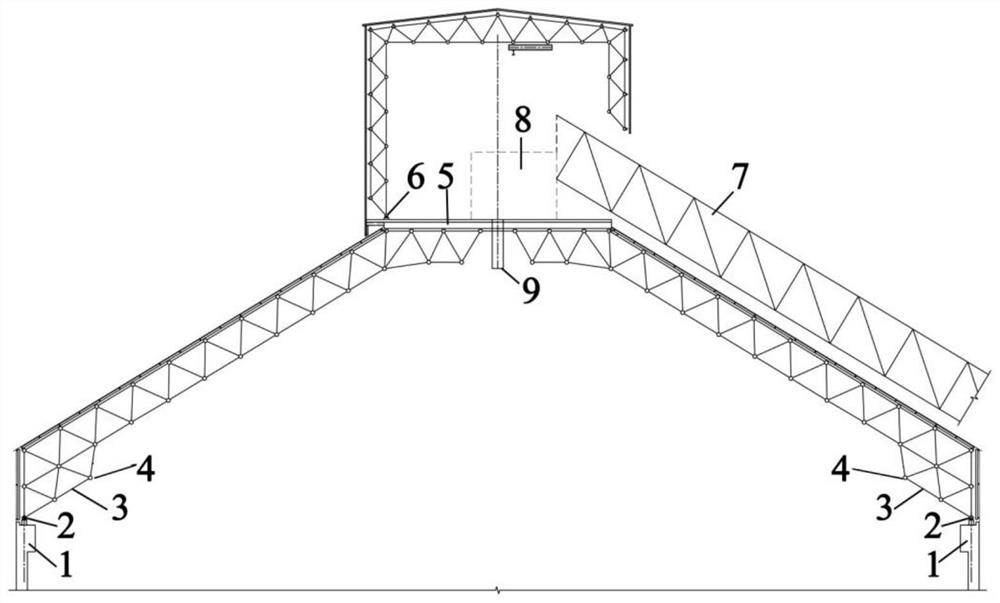

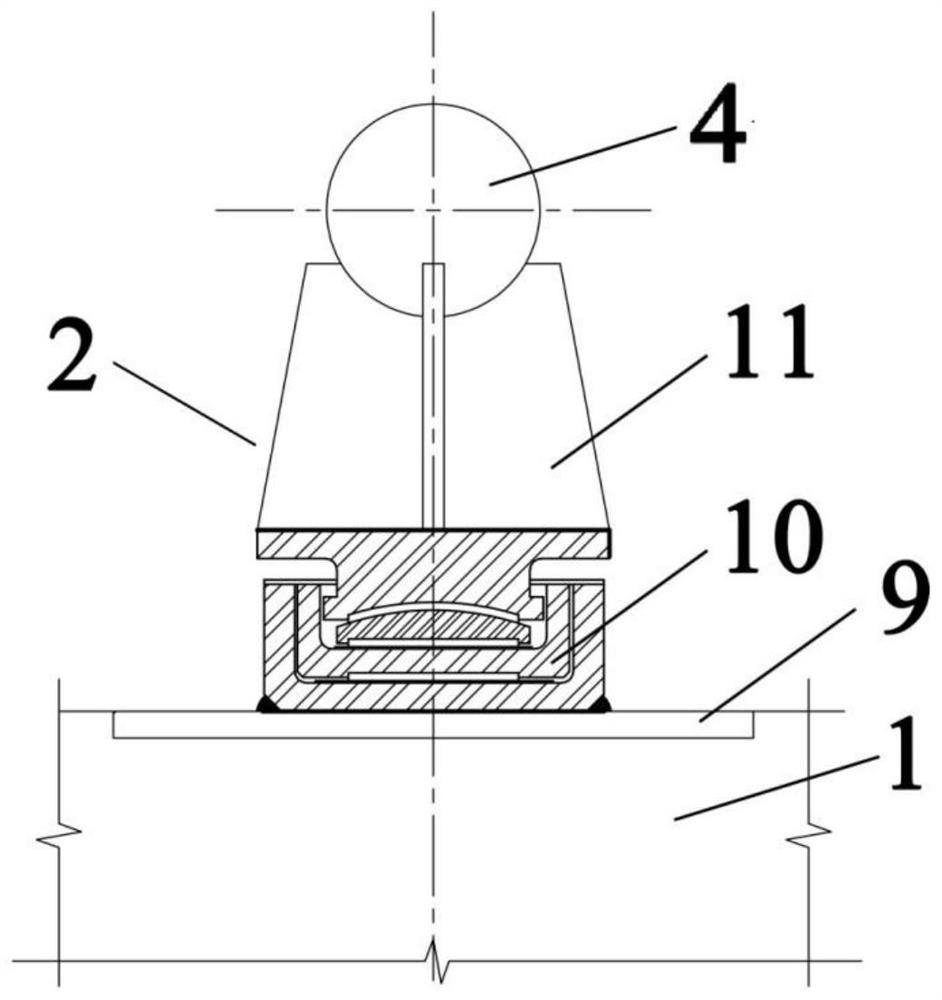

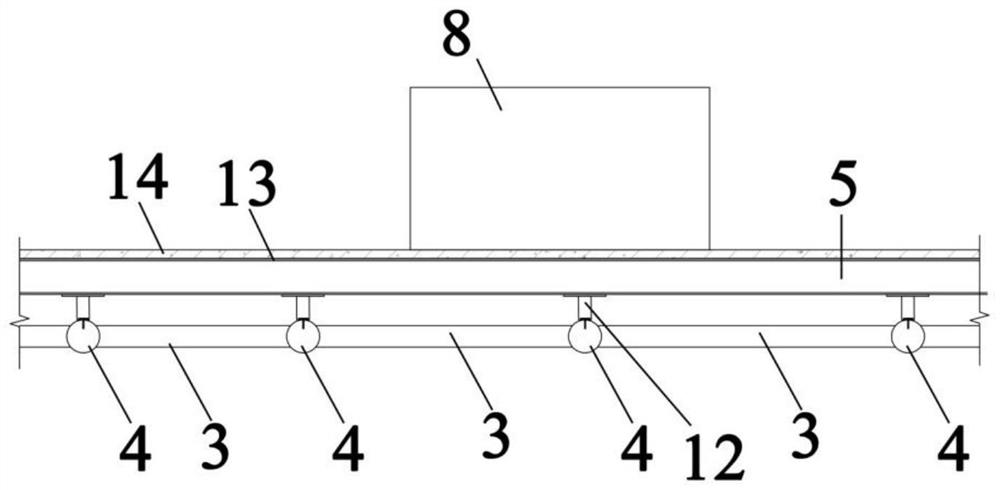

[0047] The silo roof bolt ball grid structure used for the clinker silo in this embodiment includes the clinker silo top round platform grid, the roof room platform and the warehouse roof grid, and the clinker silo top round platform grid includes the clinker silo net Frame support 2, round steel pipe 3, bolt ball joint 4, support 12, C-shaped purlin 15 and checkered steel plate 16, the bolt ball joint 4 and round steel pipe 3 of the round table grid on the top of the clinker storehouse are combined with each other, and the clinker storehouse The grid support 2 is connected to form a force-bearing unit. A three-layer grid is set at two grids near the clinker silo support to form a reinforcement ring near the grid support. The diameter of the net frame gradually decreases, and finally gathers at the platform of the roof of the warehouse, and the whole is in the shape of a circular platform;

[0048] The bolt ball joint 4 of the warehouse roof platform is combined with the round...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com