Inside and outside ring-shaped steel structure three-dimensional divergent construction method

A construction method and steel structure technology, applied in the direction of building structure, geometric CAD, construction, etc., can solve the problems of inability to form flow construction, slow construction progress, waste of resources, etc., to improve processing quality and efficiency, avoid air pollution, The effect of speeding up the hoisting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

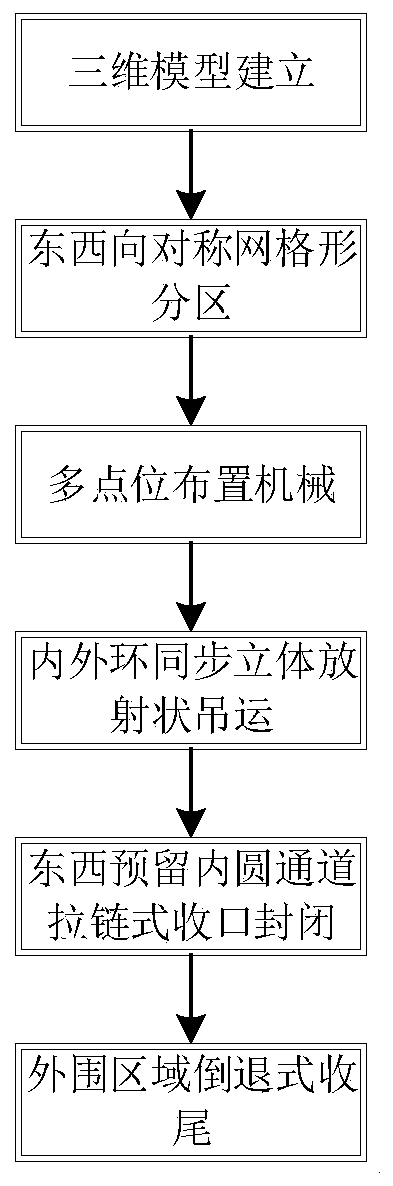

[0025] see figure 1 , the present invention provides a technical solution: a three-dimensional divergent construction method of inner and outer ring-shaped steel structures, including BIM modeling, determination of construction ideas, horizontal plane projection partitioning of the structure, mechanical equipment layout, radial three-dimensional hoisting, and zipper closing Enclosed, peripheral area setback finishing.

[0026] This method processes and prefab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com