PCD (polycrystalline diamond) fishtail cutter

A fishtail milling cutter and right cutter technology, which is applied to milling cutters, milling machine equipment, manufacturing tools, etc., can solve problems such as low roughness, low speed, and poor precision, so as to avoid burrs, reduce cutting force, and improve Effects on processing quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

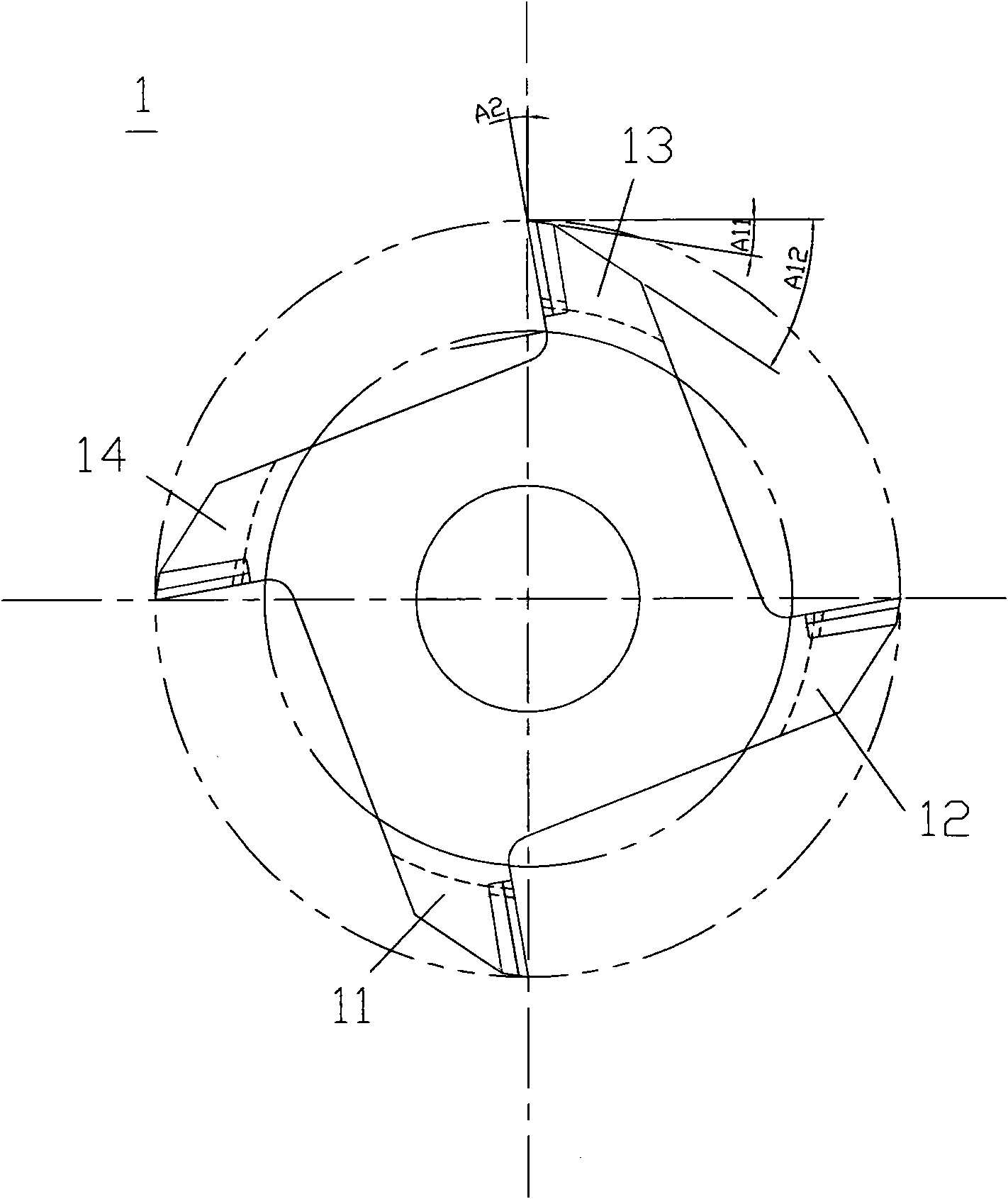

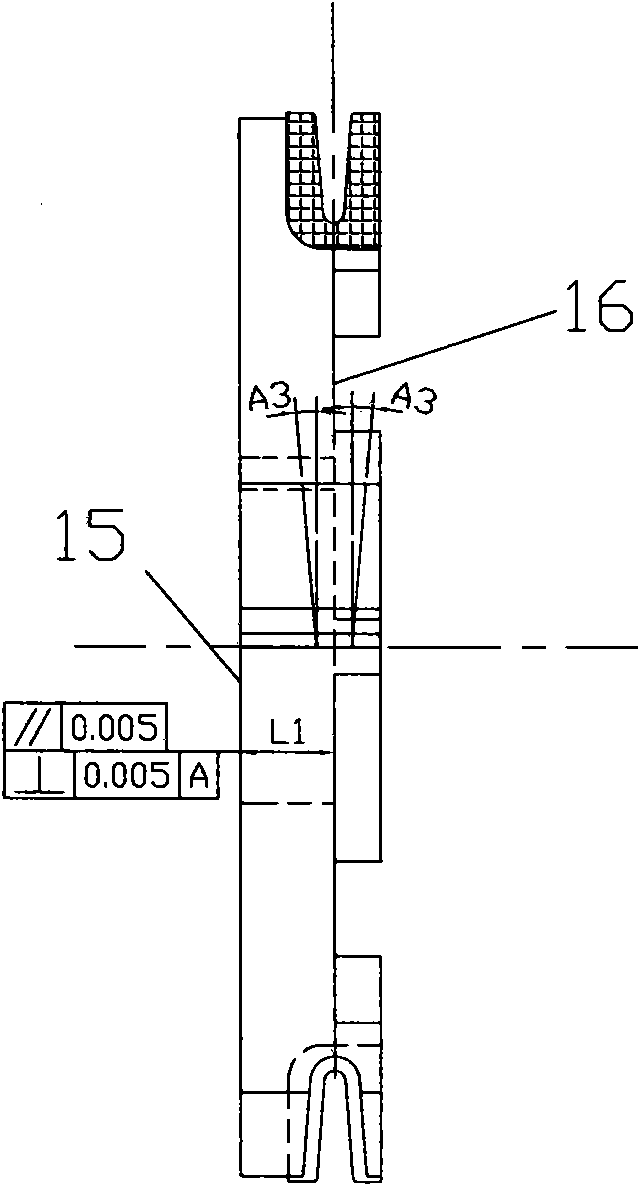

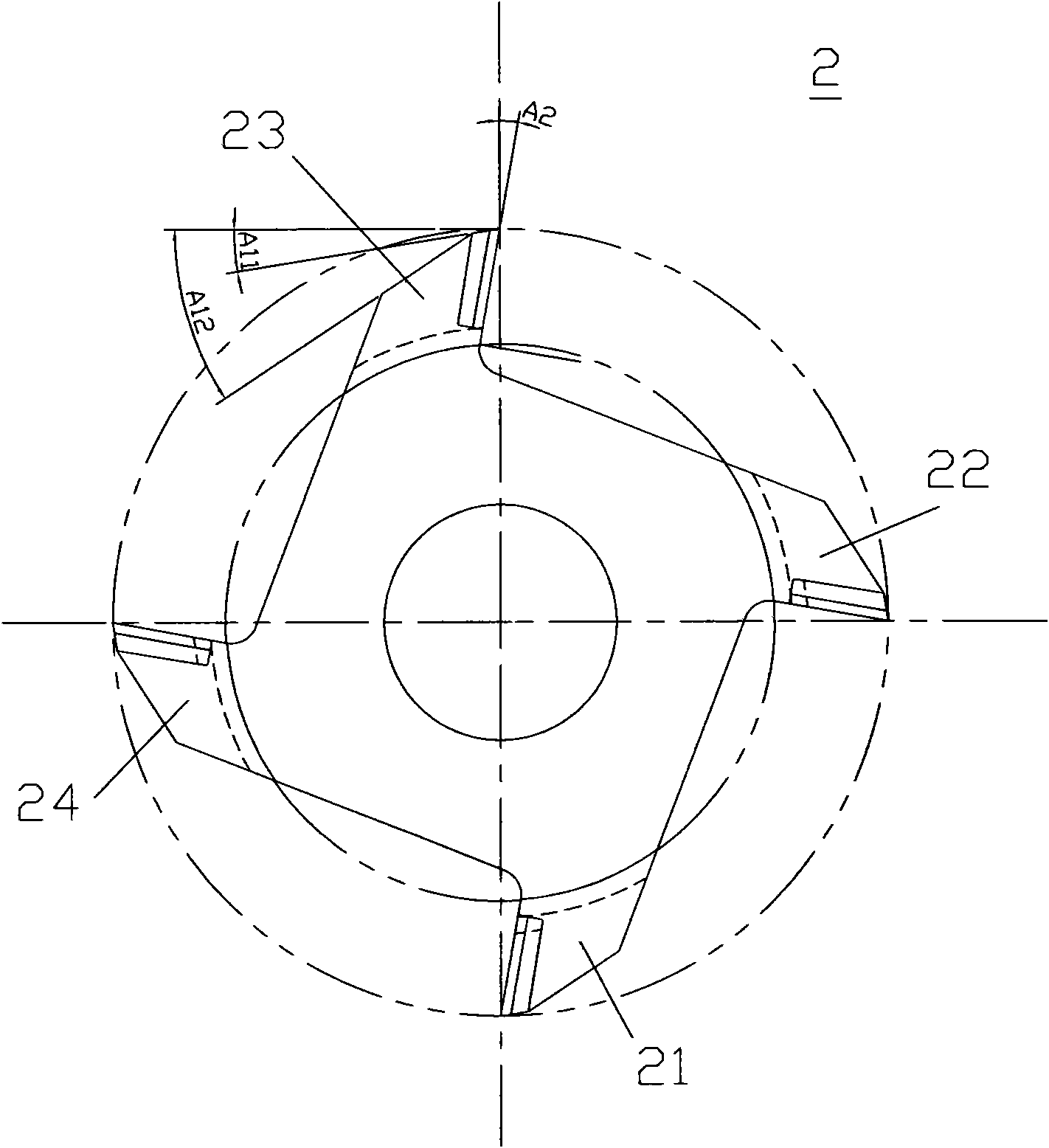

[0021] Such as Figure 1 to Figure 4 As shown, in order to achieve the stated purpose, the PCD fishtail milling cutter of the present invention is formed by the relative combination of the mirror surface of the left knife 1 and the right knife 2, and the left knife 1 and the right knife 2 can be relatively rotatably arranged (for example, the co-rotating axis setting) to adjust the distribution angle of the PCD teeth 11 to 14, 21 to 24 on the circumference. The left knife 1 and the right knife 2 are made separately.

[0022] exist Figure 1 to Figure 4 In the shown embodiment, each specific dimension of the tool is marked in detail according to national standards, and the unit of each length dimension in the figure is mm.

[0023] The left knife 1 and the right knife 2 are generally composed of mirror images, but if there is system resonance, the left knife 1 and the right knife 2 rotate about 5° relative to each other; if it is necessary to strengthen chip breaking, the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com