Staggered mutual anchoring connecting structure for prefabricated shear walls and vertical joints at edge members

A technology of prefabricated shear and edge components, applied in the direction of building components, walls, building structures, etc., can solve the problems of limiting the size of prefabricated shear walls, complex connection structure, long vertical joint length, etc., to achieve Achieve vertical hoisting operations, improve assembly efficiency, reduce use and on-site construction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

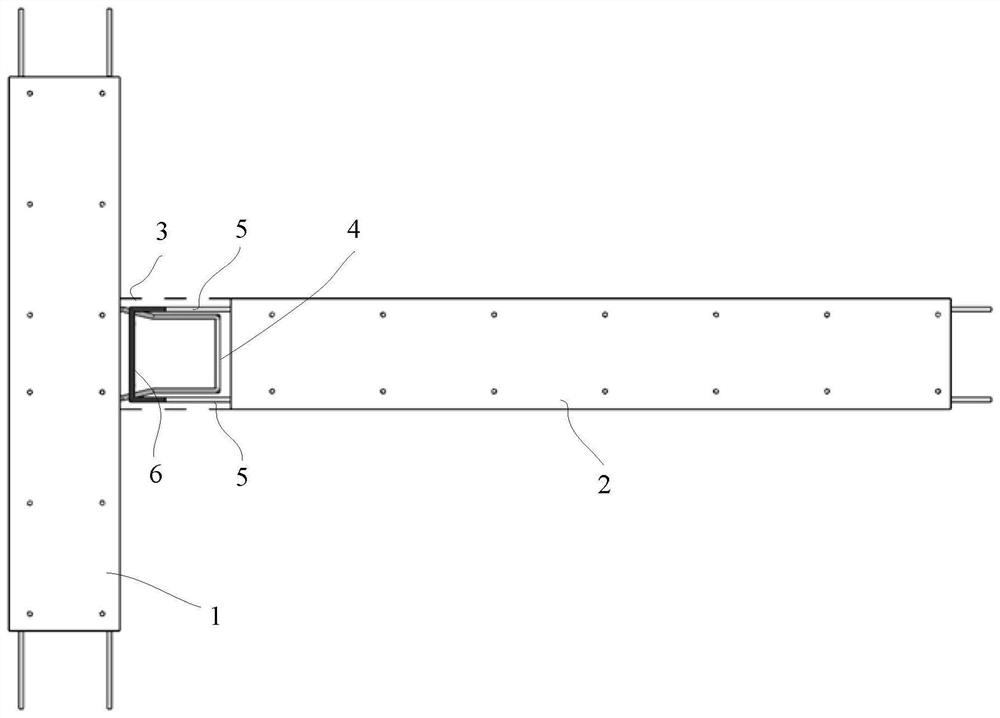

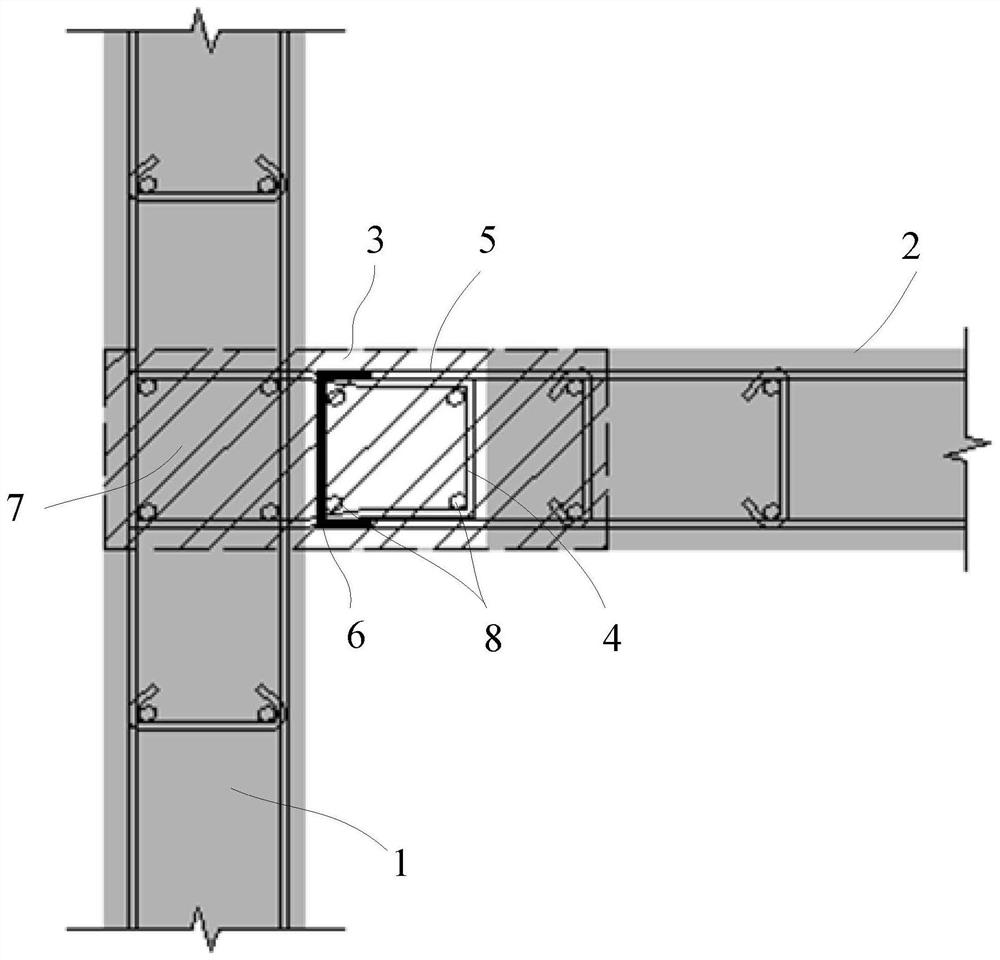

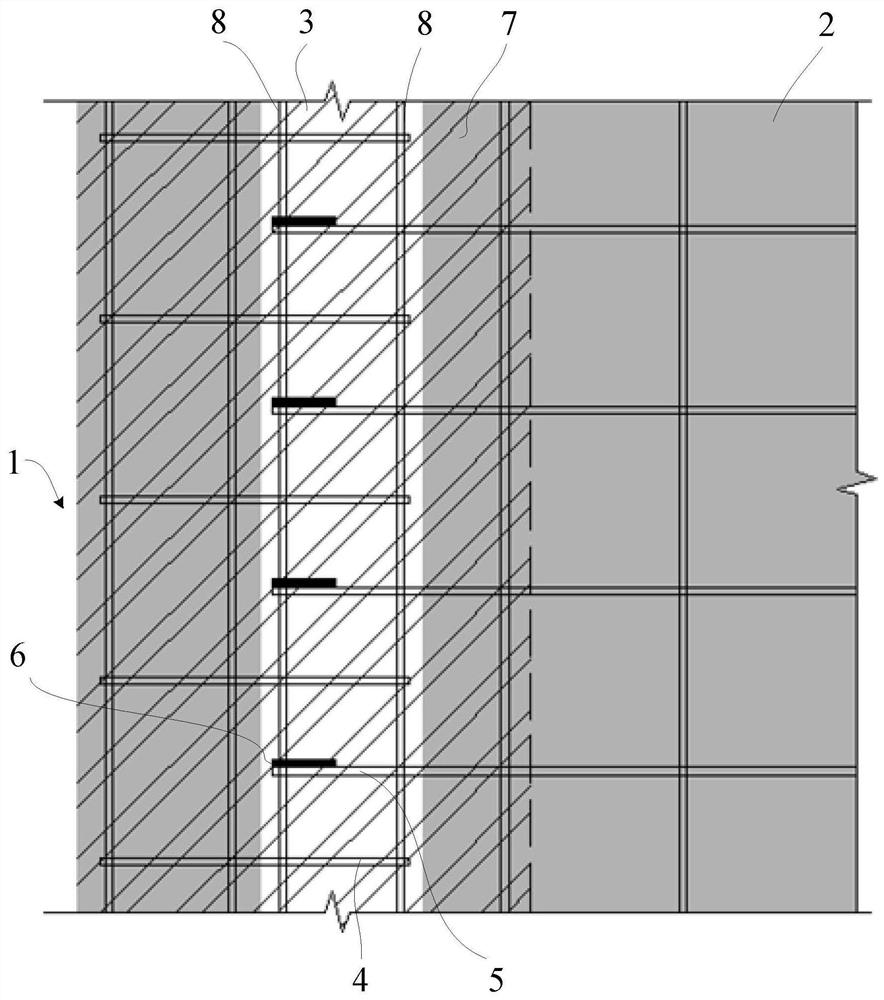

[0044] refer to Figure 1-3 , the embodiment of the present application discloses a prefabricated shear wall edge member vertical joint dislocation mutual anchor connection structure, including: the first prefabricated shear wall 1, the second prefabricated shear wall 2 and the edge member 7, the first prefabricated shear wall A vertical joint 3 is formed between the shear wall 1 and the second prefabricated shear wall 2; the edge member 7 includes a prefabricated part and a cast-in-place part; the prefabricated part at least includes a first part prefabricated in the first prefabricated The joint 3 is located in the edge member 7 and forms a cast-in-place part; the edge member 7 has a number of stirrups 4; the second prefabricated shear wall 2 has a number of horizontal reinforcement bars 5; the stirrups 4 and the horizontal reinforcement bars 5 are all extended into the vertical joint In the seam, and staggered and anchored to each other in the vertical direction.

[0045] ...

Embodiment 2

[0056] see Figure 7 The difference between this embodiment and Embodiment 1 is that the first part of the edge member 7 located in the middle of the first prefabricated shear wall 1 is anchored with stirrups, and the stirrups are in a semi-enclosed structure, such as U-shaped, wherein the stirrups The closed end is anchored into the first part of the first prefabricated shear wall 1 (that is, the prefabricated part of the edge member), and the open end includes two parallel steel bars to form a horizontal steel bar 5. The horizontal steel bar 5 is opposite to the first prefabricated shear wall 1. The wall surface extends outwards and extends into the vertical joint 3; the part of the horizontal steel bar 5 located in the first prefabricated shear wall 1 is bound and fixed with the longitudinal steel bar of the edge member (welding or other methods are included in other solutions). The second prefabricated shear wall 2 is a prefabricated concrete shear wall panel with a double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com