Pre-cast binding veneer integrally-formed fabricated wallboard for green building and production method thereof

A technology of green building and production method, which is applied in the direction of construction, building materials, building components, etc., and can solve problems such as impermanence, easy to fall off, and not durable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

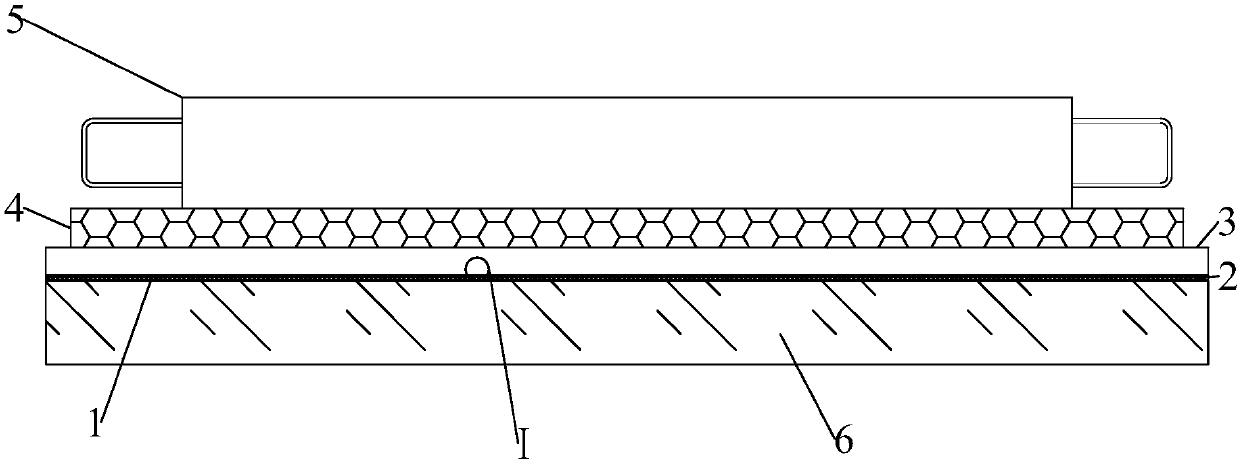

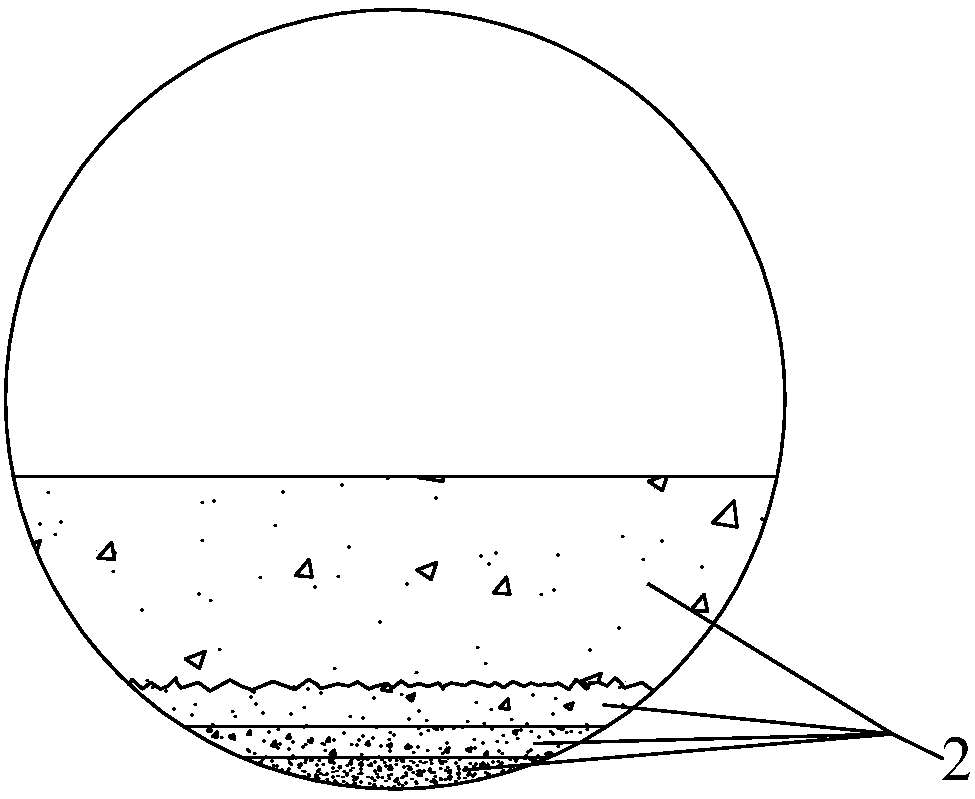

[0009] Embodiment 1, as figure 1 As shown, the green building of the present invention first pours the cementitious decorative surface into an integrally formed assembled wallboard and the production method, there are firstly poured the decorative surface 1 of the cementitious material of the decorative cement and the outer leaf wallboard 3 made by pouring and forming and assembling In the wallboard structure, there is a structure 2 of gelling materials blending between the decorative surface 1 and the outer leaf wallboard 3 . The cementitious material of the decorative surface 1 and the concrete cementitious material of the outer leaf wall panel 3 coagulate and change together to form a stable and highly integrated, integrated structure to achieve stronger and more durable. The cementitious material forms an impermeable finish and is integrated into the concrete of the wall panels. The formed prefabricated wall panel with a decorative surface has a more firm and reliable dec...

Embodiment 2

[0013] Embodiment 2, the green building of the present invention first casts the cementitious decorative surface integrally formed assembled wallboard and the production method, is to pour the slurry of the cementitious material of white cement on the bottom mold first to form the decorative surface, and the decorative surface material is initially set First, sprinkle white crushed stone fine aggregate on the slurry of white cement cementitious material, and then pour the concrete of the outer leaf wall panel structure on the decorative surface material to make the assembled wall panel structure. The concrete of the outer leaf wall panel structure is poured to form the outer leaf wall panel, and then covered with foam plastic, and the concrete of the inner leaf wall panel structure is poured on the foam plastic, and cured together to form. The cementitious material of white cement, the outer leaf wall board and other wall structure concrete, coagulate and solidify together to f...

Embodiment 3

[0015] Embodiment 3, a kind of prefabricated decorative surface of a green building is poured into an integrally formed assembled wallboard and its production method:

[0016] A. Spread the release agent evenly on the bottom mold;

[0017] B. The upper surface of the bottom form is poured with cementitious material decorative surface slurry fused with gray and white cement, and flattened to form a decorative surface;

[0018] C. Apply and roll the decorative layer evenly on the decorative surface in the stage of initial setting to intermediate setting, and form a slurry on the decorative surface;

[0019] D. On the slurry on the decorative surface, pour the outer leaf layer of concrete and lay steel bars to form the outer leaf layer;

[0020] E. Cover the foamed plastic on the outer leaf plate layer after the pouring, and the steel bars connecting the outer leaf plate and the inner leaf plate pass through the foam plastic and connect with the inner leaf plate steel bars;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com