Assembled fireproof combined building component and construction method thereof

A technology of building components and construction methods, applied in building components, building structures, fire protection, etc., can solve the problems that the fire resistance time of bare components cannot meet the requirements of fire resistance limit, etc., so as to save keel materials, avoid wet work, and shorten the construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

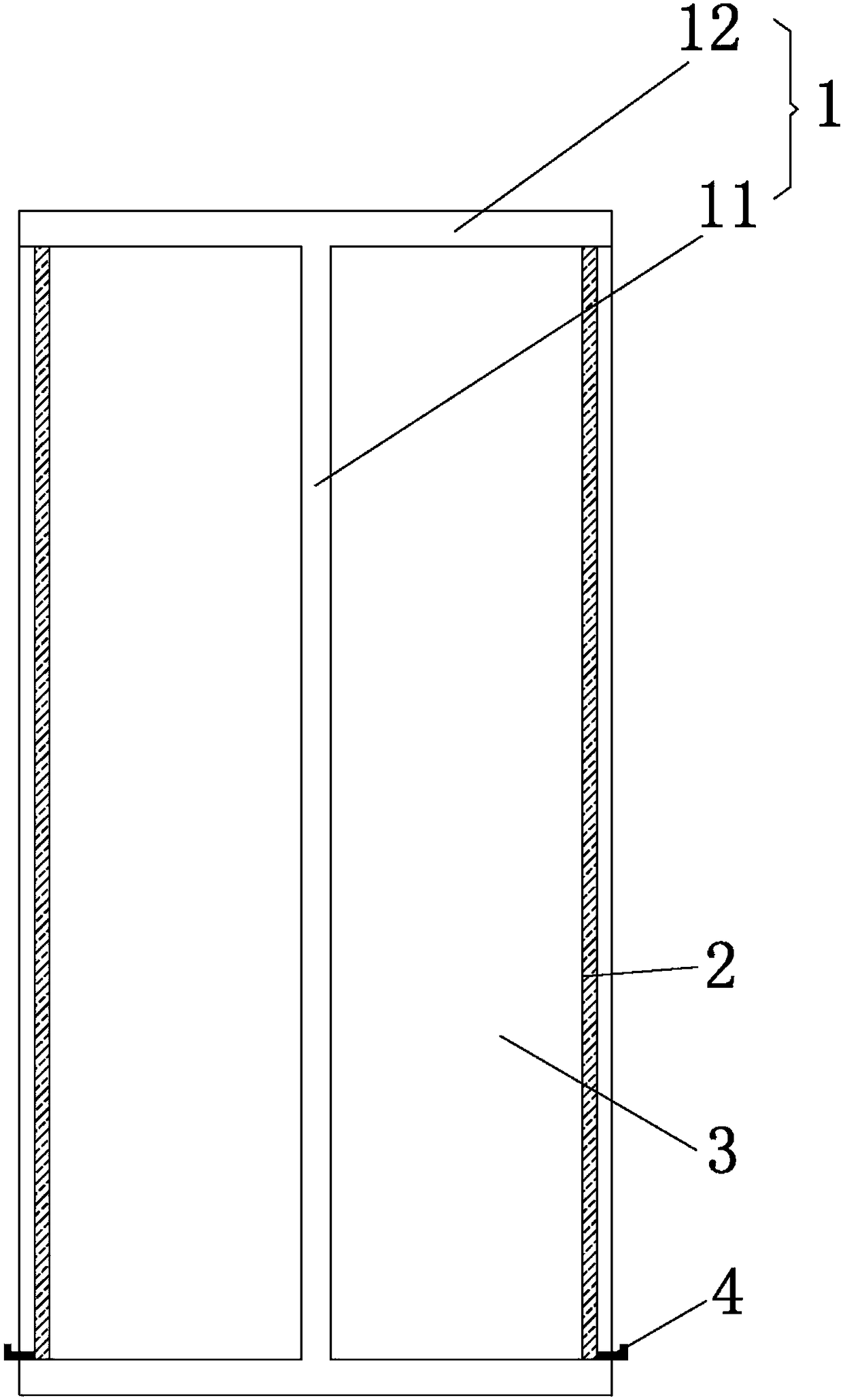

[0036] Please refer to the attached figure 2 to attach Figure 9 As shown, the present invention is a prefabricated fireproof composite building component, which includes H-shaped steel 1, said H-shaped steel 1 is welded by web 11 and flanges 12 arranged at both ends of web 11 and perpendicular to web 11 made. A tie steel bar 2 is welded between the flanges 12 .

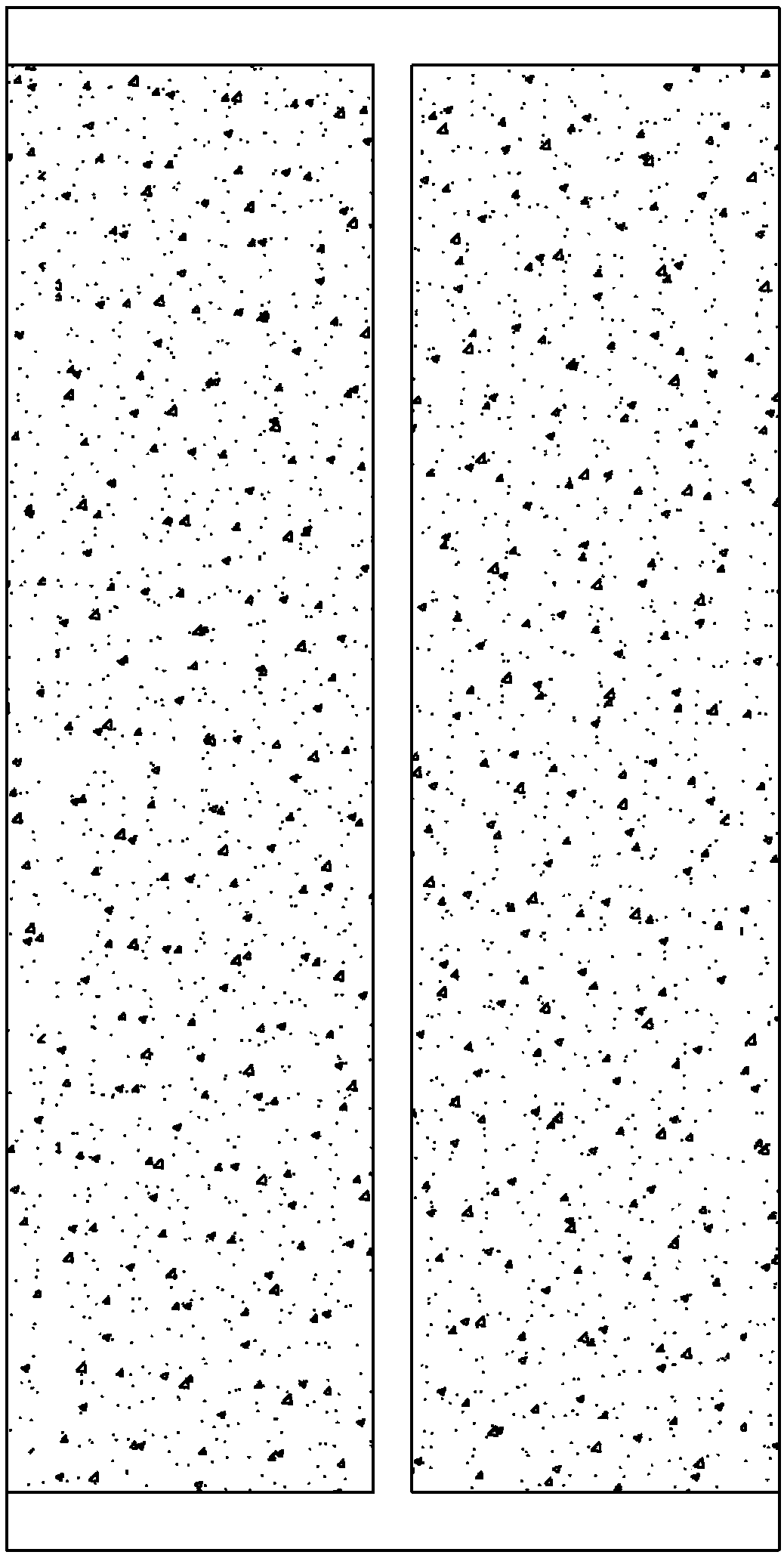

[0037] Concrete 3 is poured between the flanges 12 and on both sides of the web 11 , and the concrete 3 is poured to be flush with the sides of the flanges 12 .

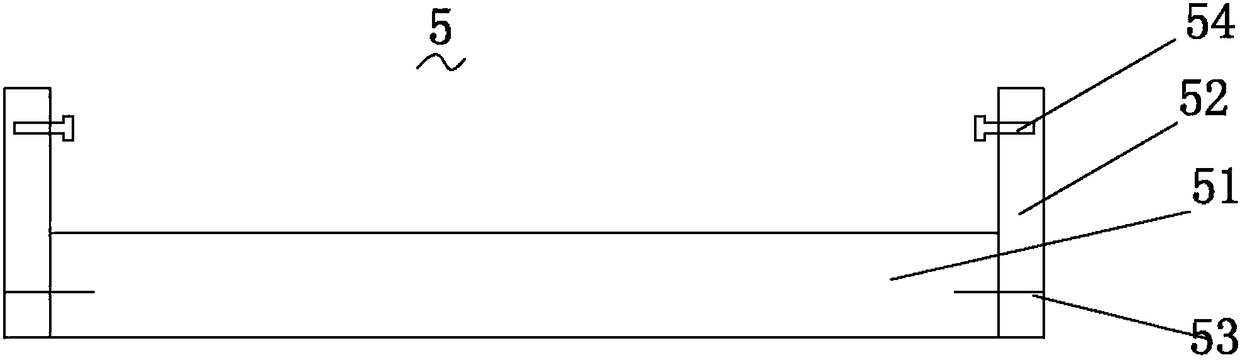

[0038] The embedded part 4 is welded on the flange 12 . A fireproof board 5 is hung on the embedded part 4 , and the fireproof board 5 and the flange 12 are bonded by polymer mortar 6 . Specifically, the fireproof board 5 includes a bottom plate 51 and side plates 52 arranged on both sides of the bottom plate 51; A hanging member 54 is disposed on the inner side of the side plate 52 .

[0039] The concrete 3 is provided with a plastering mortar layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com