Anti-corrosion aluminum formwork reinforcing back bar

A technology of aluminum formwork and back flute, which is applied in the direction of formwork/formwork components, formwork/formwork/work frame connectors, and construction components on-site preparation, which can solve the problem of weld stress concentration and easy corrosion , large amount of welding and other problems, to achieve the effect of reducing on-site construction, prolonging service life and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

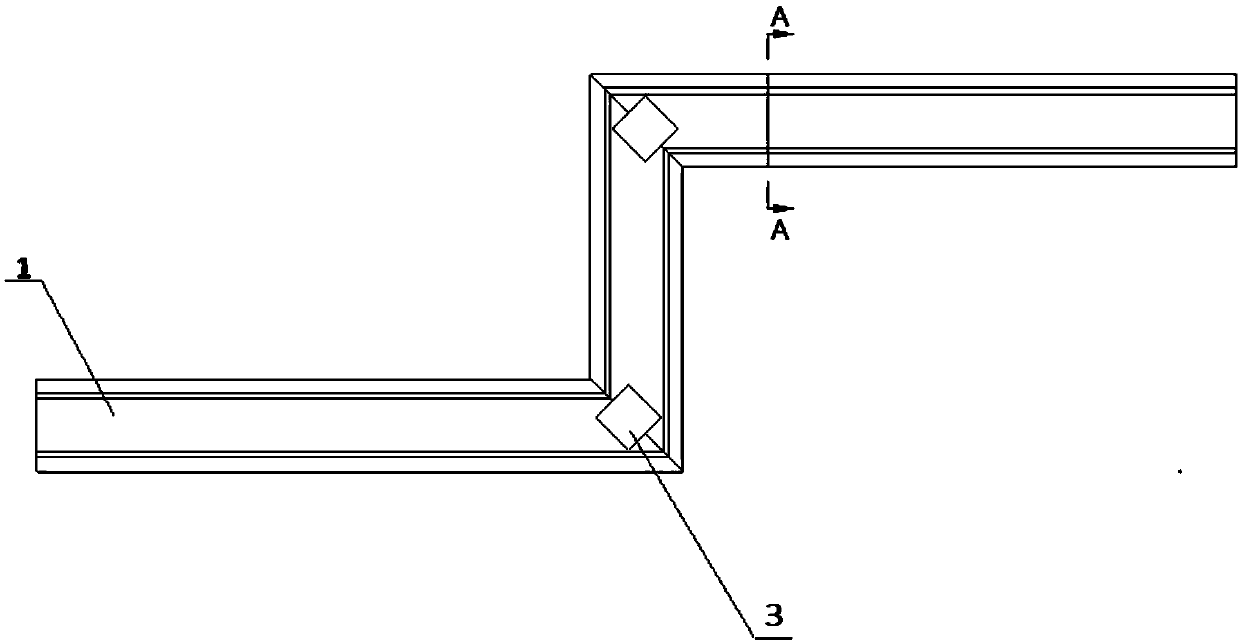

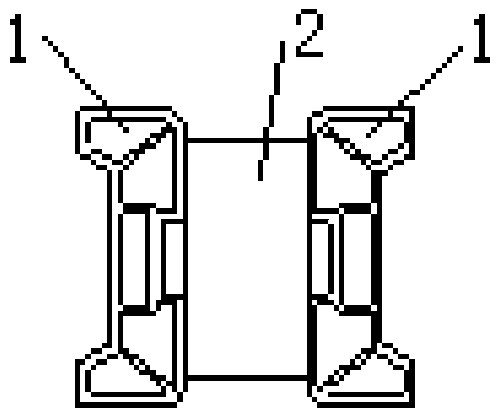

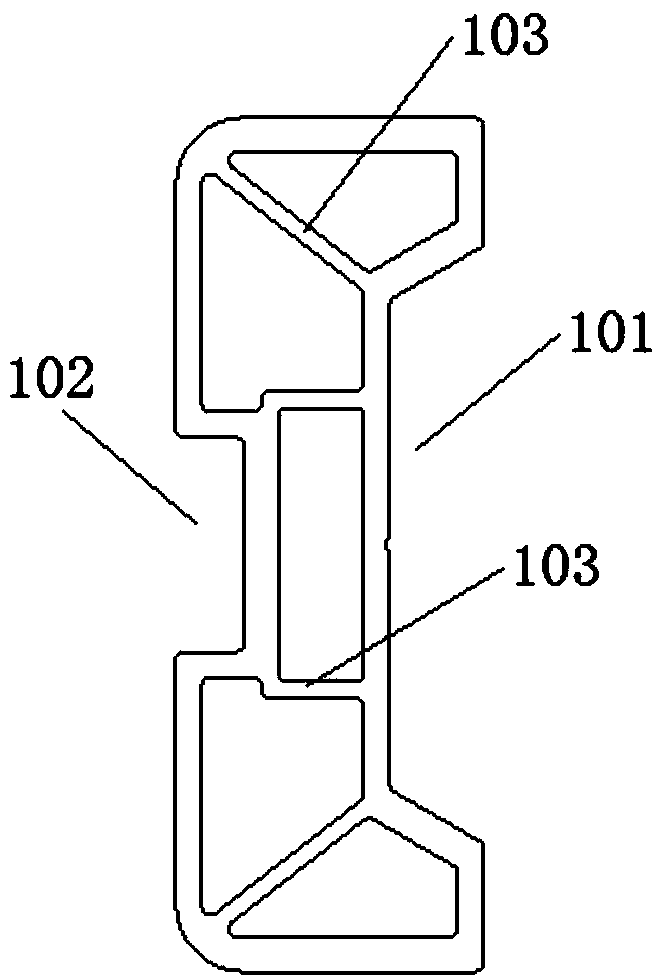

[0024] A corrosion-resistant aluminum formwork reinforcement back flute, including a single tube 1 and a connecting piece 2, the single tube 1 is an extruded aluminum profile, its cross section is a closed cavity, and the two sides of the cavity are respectively provided with grooves I101 The contour shape of the groove II102 and the groove I101 is isosceles trapezoidal, the contour shape of the groove II102 is rectangular, and the central axis of the groove I101 and the groove II102 coincides with the horizontal central axis of the cavity; The body is divided into five ribs 103 of chambers, the chamber in the middle is a zigzag shape, and the upper and lower ends of the zigzag chamber respectively have two chambers and the upper and lower chambers are symmetrical about the horizontal central axis of the cavity; The connecting piece 2 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com